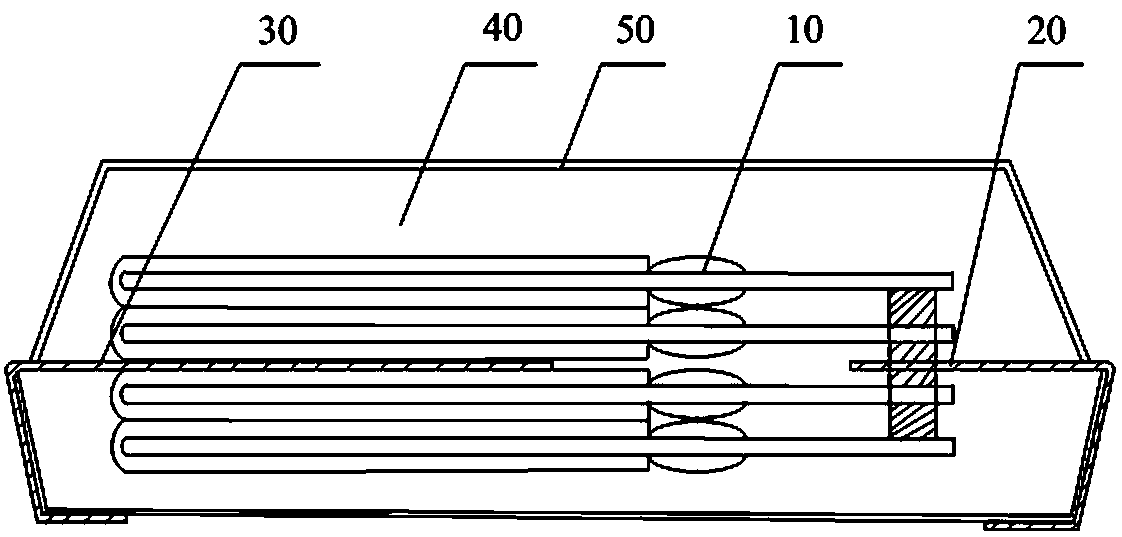

Humidity-resistant laminated solid-state aluminium electrolytic capacitor and manufacturing method thereof

An aluminum electrolytic capacitor, moisture resistance technology, applied in the field of capacitance, can solve the problems of capacitor leakage current rise, mutual detachment, expansion, etc., to reduce the equivalent series resistance and leakage current, improve high temperature and high humidity resistance, and improve product performance. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

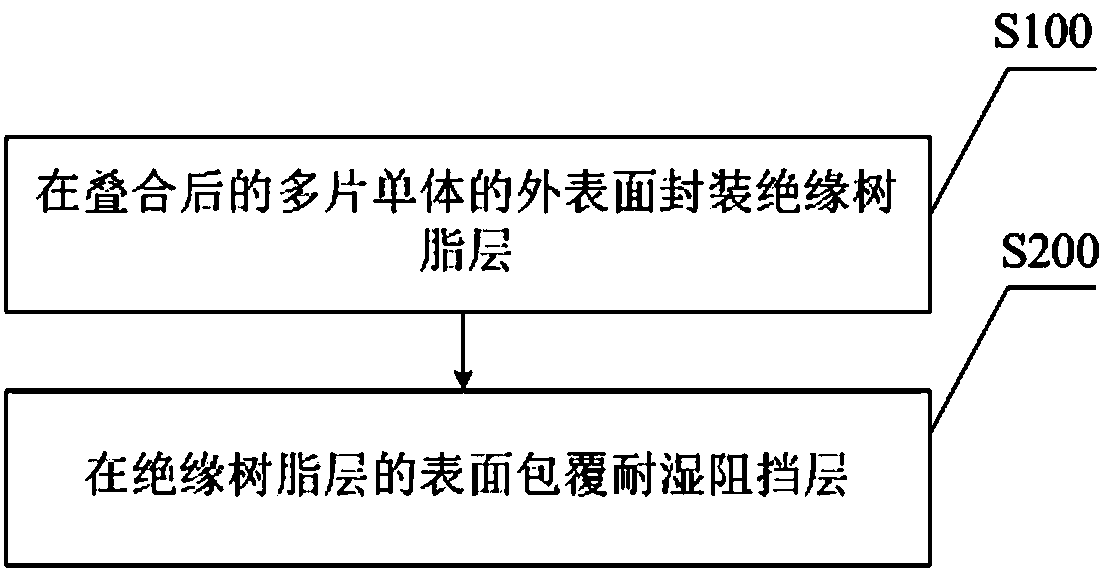

[0035] Embodiment 1, adopt paste method to make nano-Al 2 o 3 / Polyester composite material is pasted on the outer surface of the insulating resin layer. Specifically as follows:

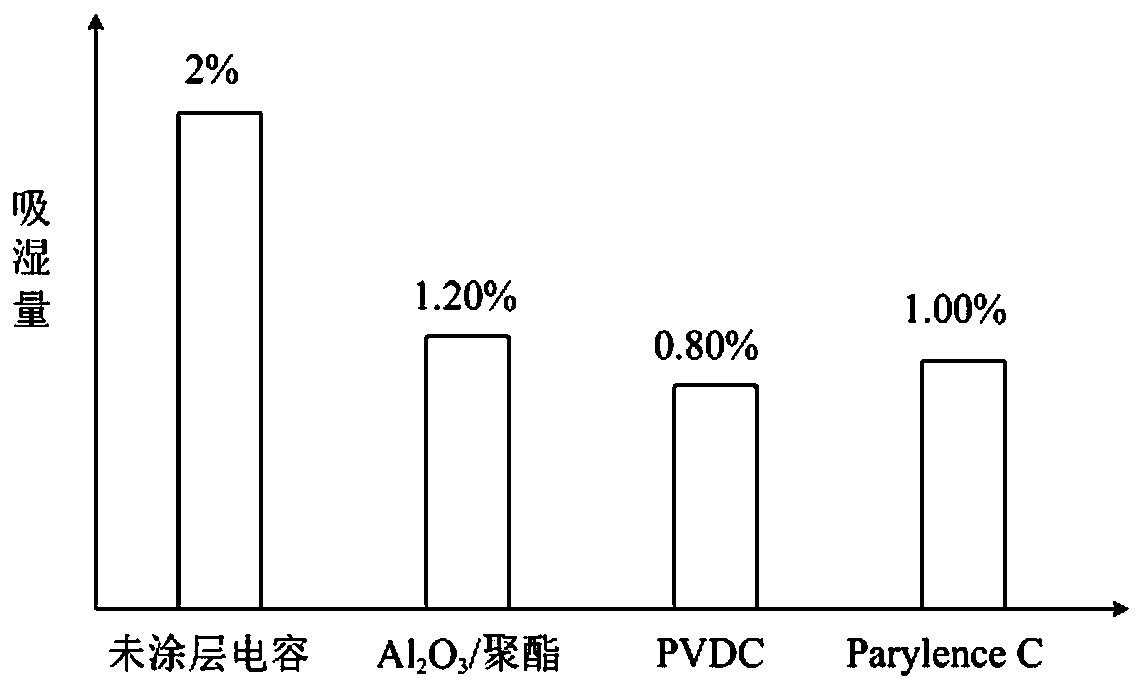

[0036] nano-Al by paste method 2 o 3 / Polyester composite material is pasted on the outer surface of the laminated solid aluminum electrolytic capacitor packaging material. The thickness of the composite material is 20-30 microns. The packaging material of the laminated solid capacitor is heat-cured epoxy resin. In order to enhance the adhesion, it is necessary to Corona treatment was performed on the surface of the sample to increase the surface roughness. Such as image 3 shown, will be pasted with nano Al 2 o 3 The laminated solid aluminum electrolytic capacitor made of polyester composite material was tested for 100h at double 85 (85°C, 85%RH). 2 o 3 / Polyester composite laminated solid aluminum electrolytic capacitors have a 40% reduction in moisture absorption compared to capacitor...

Embodiment 2

[0037] Embodiment 2. Polyvinylidene chloride was coated on the outer surface of the insulating resin layer by scraping method. Specifically as follows:

[0038] The outer surface of the laminated solid aluminum electrolytic capacitor packaging material is coated with the barrier material polyvinylidene chloride PVDC by scraping method. The packaging material of the laminated solid capacitor is heat-cured epoxy resin, and the coating thickness of the barrier layer is about The specific process flow includes surface pretreatment, scraping coating and drying. For specific process parameters, please refer to the relevant literature and patents of polyvinylidene chloride coating technology. Such as image 3 As shown, the laminated solid aluminum electrolytic capacitor coated with PVDC was tested for 100 hours at double 85 (85°C, 85% RH). The moisture absorption capacity is reduced by 60%.

Embodiment 3

[0039] Embodiment 3. The p-xylene polymer is coated on the outer surface of the insulating resin layer by vapor deposition method. Specifically as follows:

[0040]The outer surface of the laminated solid aluminum electrolytic capacitor packaging material is coated with the barrier material p-xylene polymer Parylene C by a vapor deposition method. The packaging material of the laminated solid capacitor is heat-cured epoxy resin, and the moisture-resistant barrier layer 50 is coated. The coating thickness is about 20 microns. The specific process includes surface pretreatment, evaporation, cracking and polymerization. For specific process parameters, please refer to relevant literature and patents on the mechanism of vapor deposition Parylene. Such as image 3 As shown, the laminated solid aluminum electrolytic capacitor coated with Parylene C was subjected to a double 85 (85°C, 85% RH) test for 100 hours. Capacitors absorb 50% less moisture.

[0041] The method for manufact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com