Emulsion pressure-sensitive adhesive for polarizer protective film, and polarizer protective film thereof

A technology for protective films and polarizers, applied in pressure-sensitive films/sheets, optics, adhesives, etc., can solve problems such as environmental pollution and complex technical processes, achieve good hydrophobicity, increase the degree of crosslinking, and reduce the probability of residual glue Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

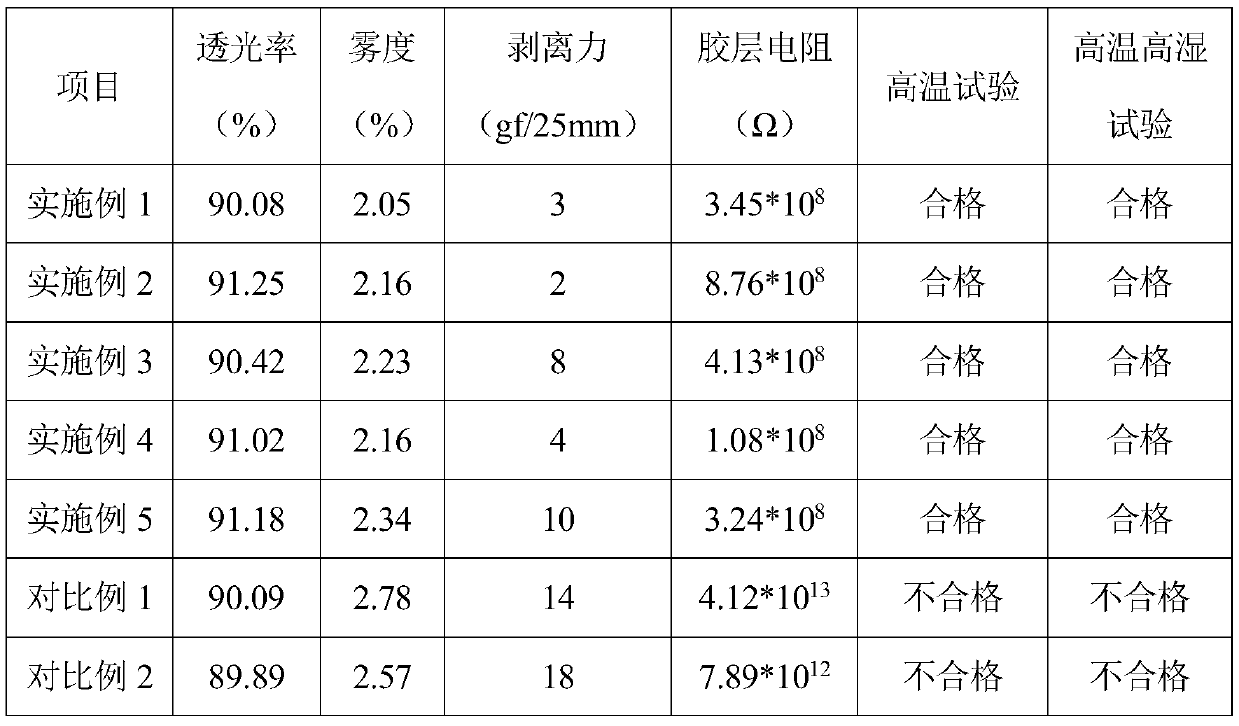

Examples

Embodiment 1

[0035] (1) Weigh 100 g of deionized water and 1 g of sodium acrylamido isopropyl sulfonate, stir and mix evenly to obtain a prefabricated solution;

[0036] (2) Weigh 33.7g of the prefabricated solution for dissolving 0.8g of ammonium persulfate to obtain an initiator solution; 2.5g of allyltrimethylammonium chloride, 25g of isooctyl methacrylate, 10g of vinyl acetate, 4g of , 1,1-trimethyl-N-2-propenylaminosilane, stirred quickly and mixed evenly to obtain an intermediate liquid;

[0037] (3) Add 0.8g sodium acetate and 5.9g intermediate solution to the remaining pre-preparation solution, pre-emulsify for 25 minutes to obtain a pre-emulsion, raise the temperature to 80°C, and add the initiator solution dropwise, until the pre-emulsion turns blue, add dropwise After the remaining initiator solution and the remaining intermediate solution are added, the emulsion is kept warm for 1 hour, then the temperature is lowered to 50°C, 2g of BI7982 (Bassington) and 1g of B1358 (Degussa)...

Embodiment 2

[0040] (1) Weigh 150g of deionized water and 2g of sodium methacrylate, stir and mix evenly to obtain a prefabricated solution;

[0041] (2) Take 76g prefabricated liquid and be used for dissolving 1g potassium persulfate to obtain initiator solution; 0.5g allyltrimethylammonium chloride, 0.5g diethyldiallylammonium chloride, 15g methyl Dodecyl acrylate, 8g methyl acrylate, and 3.5g of 1-hydroxyallyltrimethylsilane were stirred and mixed evenly to obtain an intermediate solution;

[0042] (3) Add 0.5g sodium pyrophosphate and 5.5g intermediate solution to the remaining pre-preparation solution, pre-emulsify for 20 minutes to obtain a pre-emulsion, raise the temperature to 82°C, and add the initiator solution dropwise, until the pre-emulsion turns blue, drop Add the remaining initiator solution and the remaining intermediate solution. After both additions are completed, the emulsion should be kept warm for 2.5 hours, and then cooled to 45°C. Add 0.4g BI7986 (Bassington), 0.4g B...

Embodiment 3

[0045] (1) Weigh 120 g of deionized water, 0.5 g of sodium acrylamide isopropyl sulfonate, and 1 g of sodium methacrylate sulfonate, stir and mix evenly to obtain a prefabricated solution;

[0046] (2) Take by weighing 36.5g prefabricated liquid and be used for dissolving 0.2g sodium persulfate, 0.3g potassium persulfate, obtain initiator solution; 2g diethyl diallyl ammonium chloride, 10g isooctyl methacrylate, 10g lauryl methacrylate, 2g methyl acrylate, 3g vinyl acetate, 1g 1-hydroxyallyltrimethylsilane, 1g 1,1,1-trimethyl-N-2-propenylaminosilane , quickly stir and mix evenly to obtain the intermediate liquid;

[0047] (3) Add 0.5g sodium acetate, 0.5g sodium pyrophosphate and 4.8g intermediate solution to the remaining pre-preparation solution, and pre-emulsify for 40 minutes to obtain a pre-emulsion, raise the temperature to 75°C, and add the initiator solution dropwise until the pre-emulsion becomes After blueing, add the remaining initiator solution and the remaining i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com