Weak-magnetic material recovering machine

A recycling machine, weak magnetic technology, applied in the direction of magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of high price, waste of resources, economic increase, etc., and achieve the effect of improving the recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

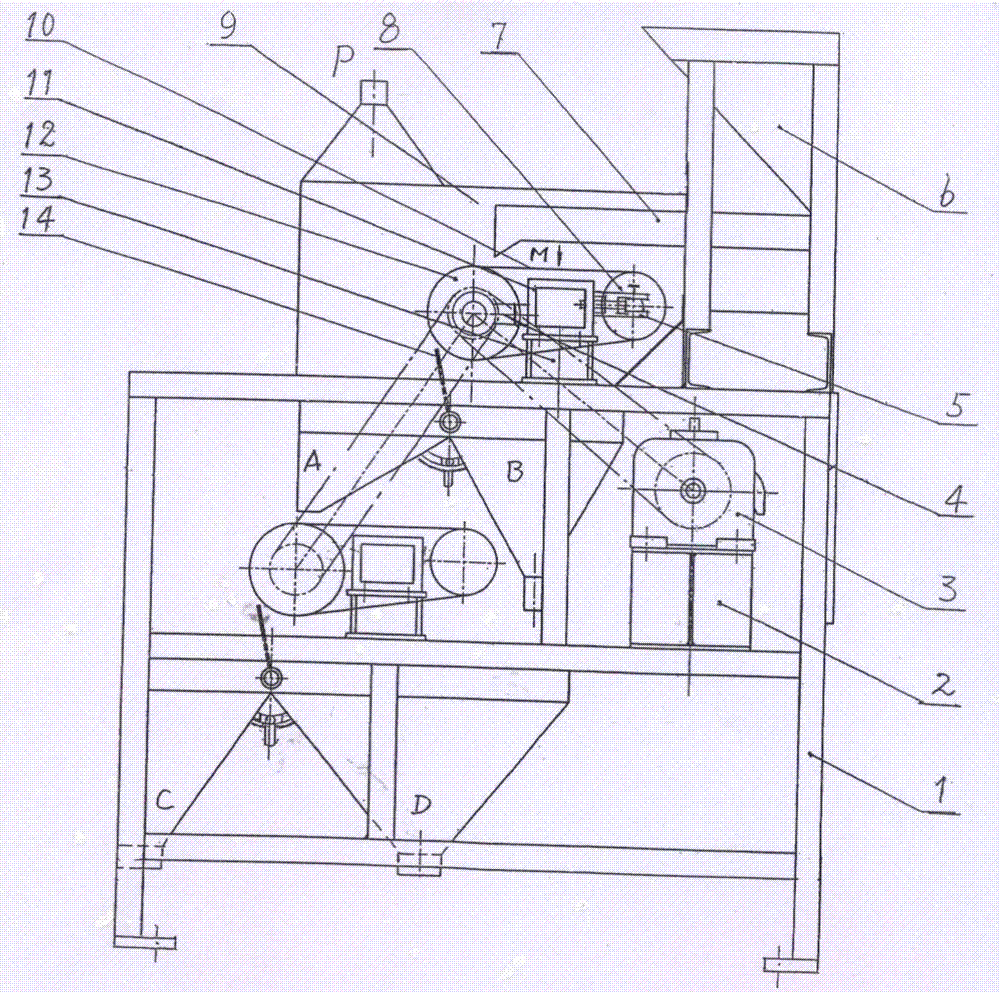

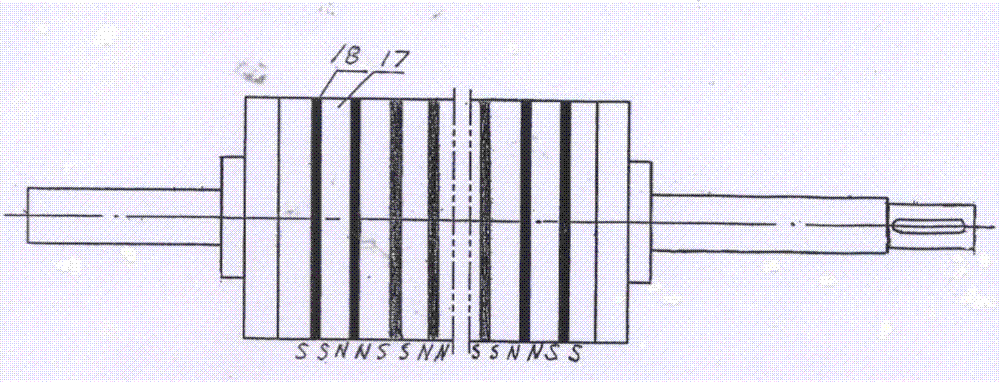

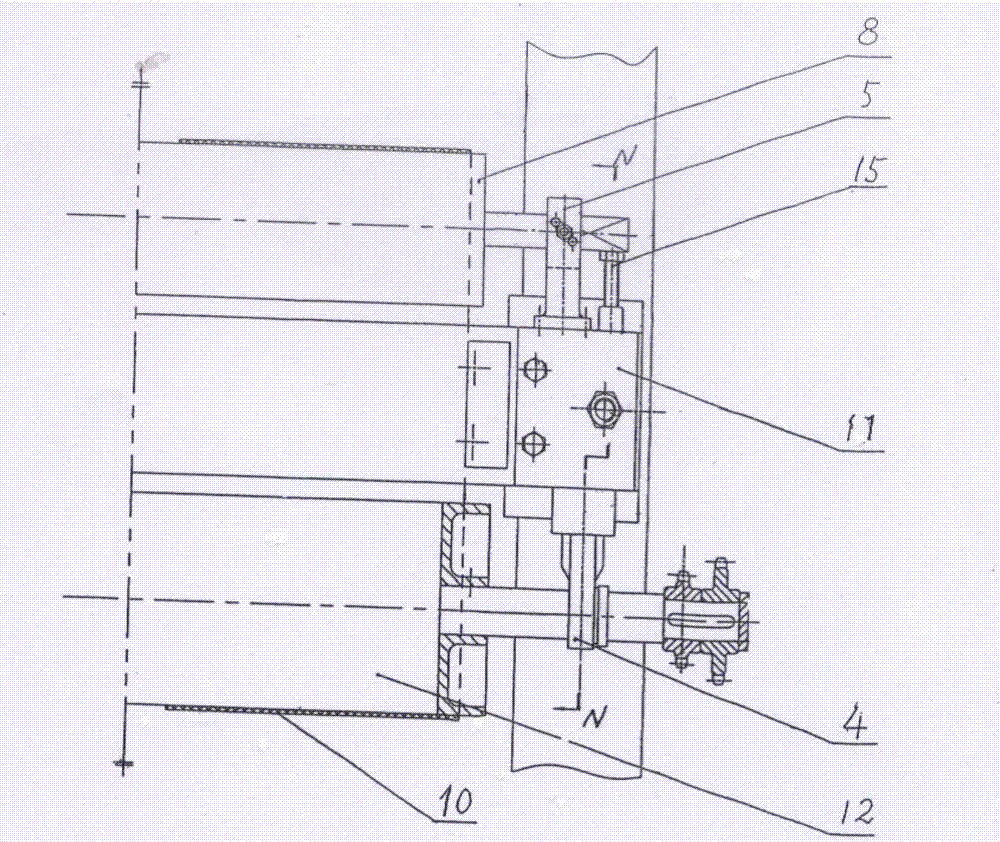

[0027] The present invention consists of a frame 1, a vibrating feeder 7, a magnetic roller 12, a reversing roller 8, a beam 11, a conveyor belt 10, a material distribution plate 14, a frequency conversion speed regulating motor 3 and a transmission mechanism and other components. In order to improve the recovery rate, a secondary sorting is used.

[0028] One side above the frame 1 is provided with a material storehouse 6, and the rear side of the material storehouse 6 is provided with an adjusting mechanism for controlling discharge, the middle part above the frame 1 is provided with a machine cover 9, and one side of the machine cover 9 is provided with a flip door, so that Turn up when replacing the conveyor belt 10, and the top of the machine cover 9 is provided with a dust outlet P connected to the dust removal system pipe; the middle and lower layers of the frame 1 are respectively provided with two discharge hoppers: the middle discharge hopper one, the middle discharge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com