Patents

Literature

57results about How to "Reliable attraction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

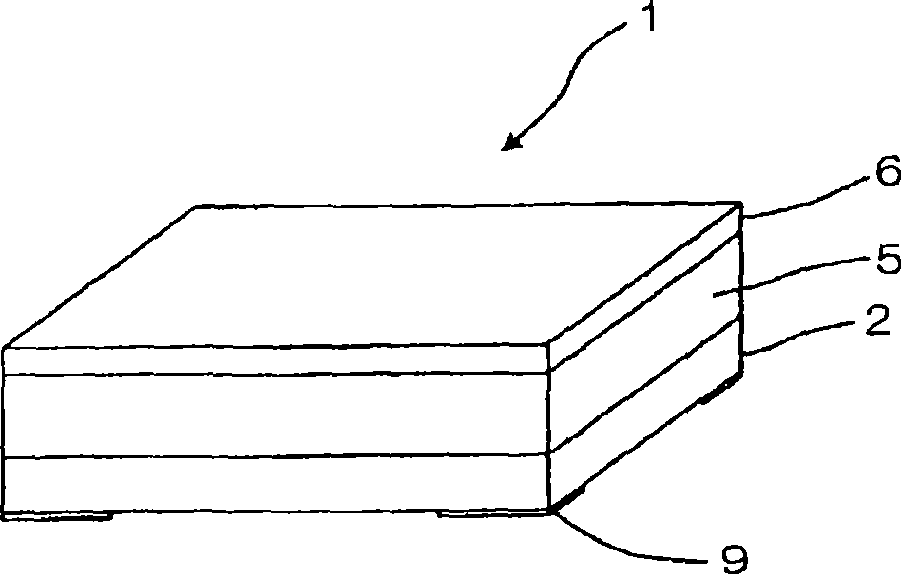

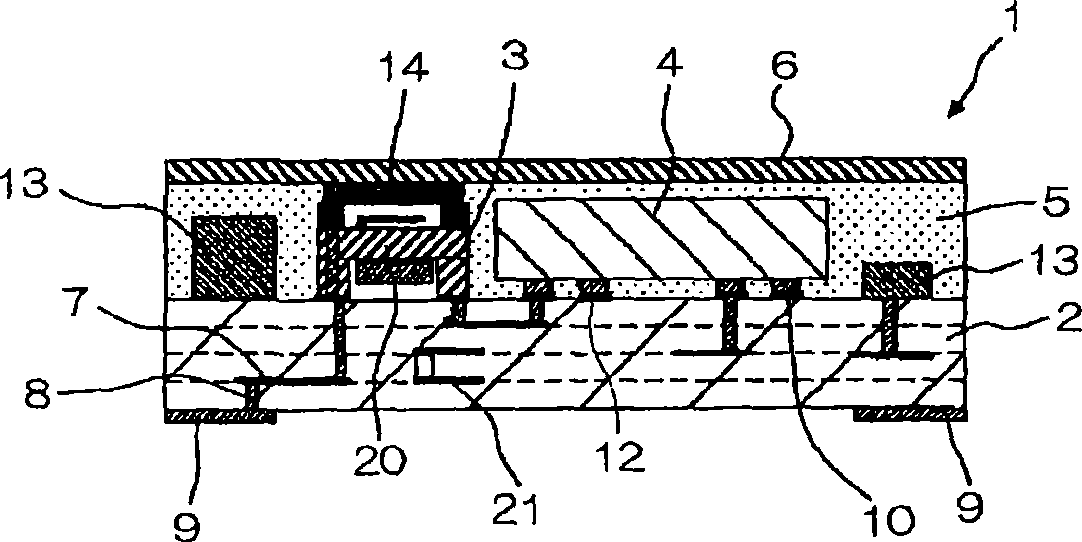

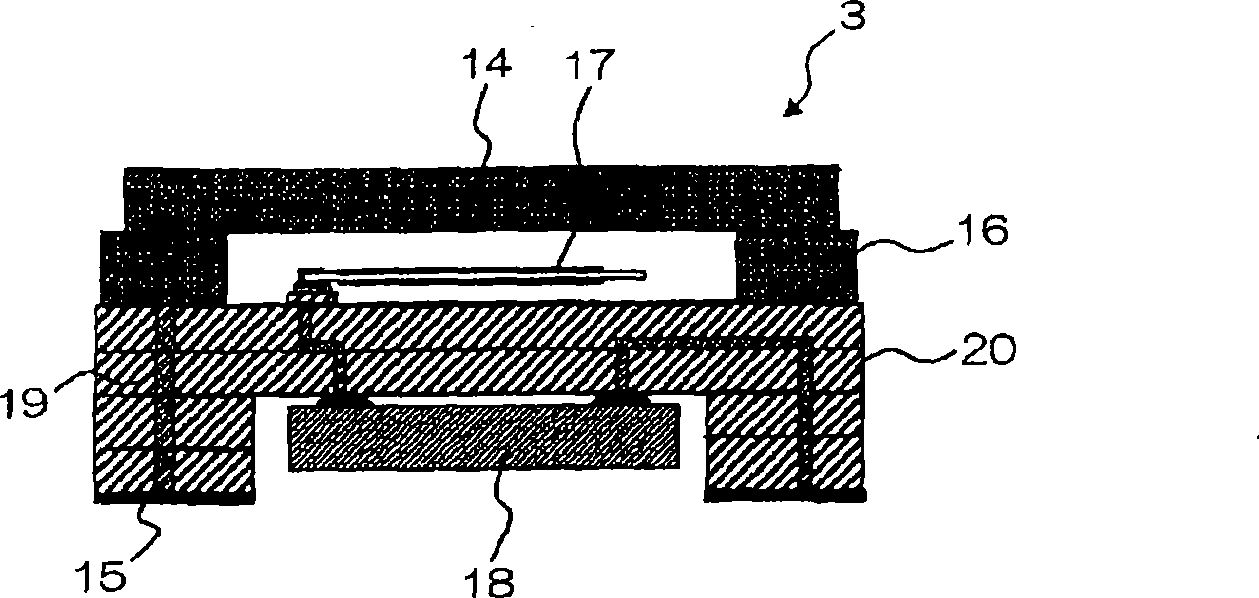

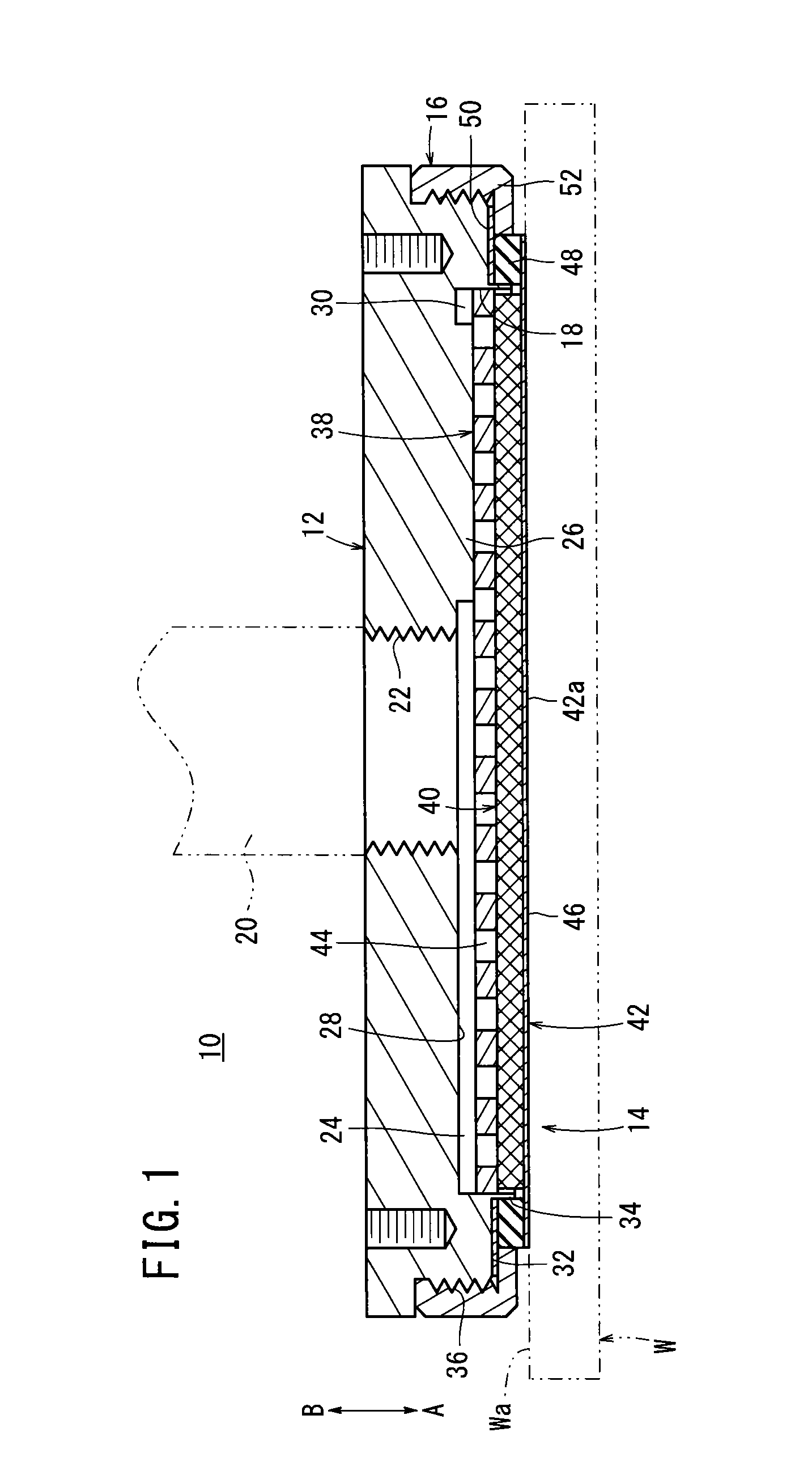

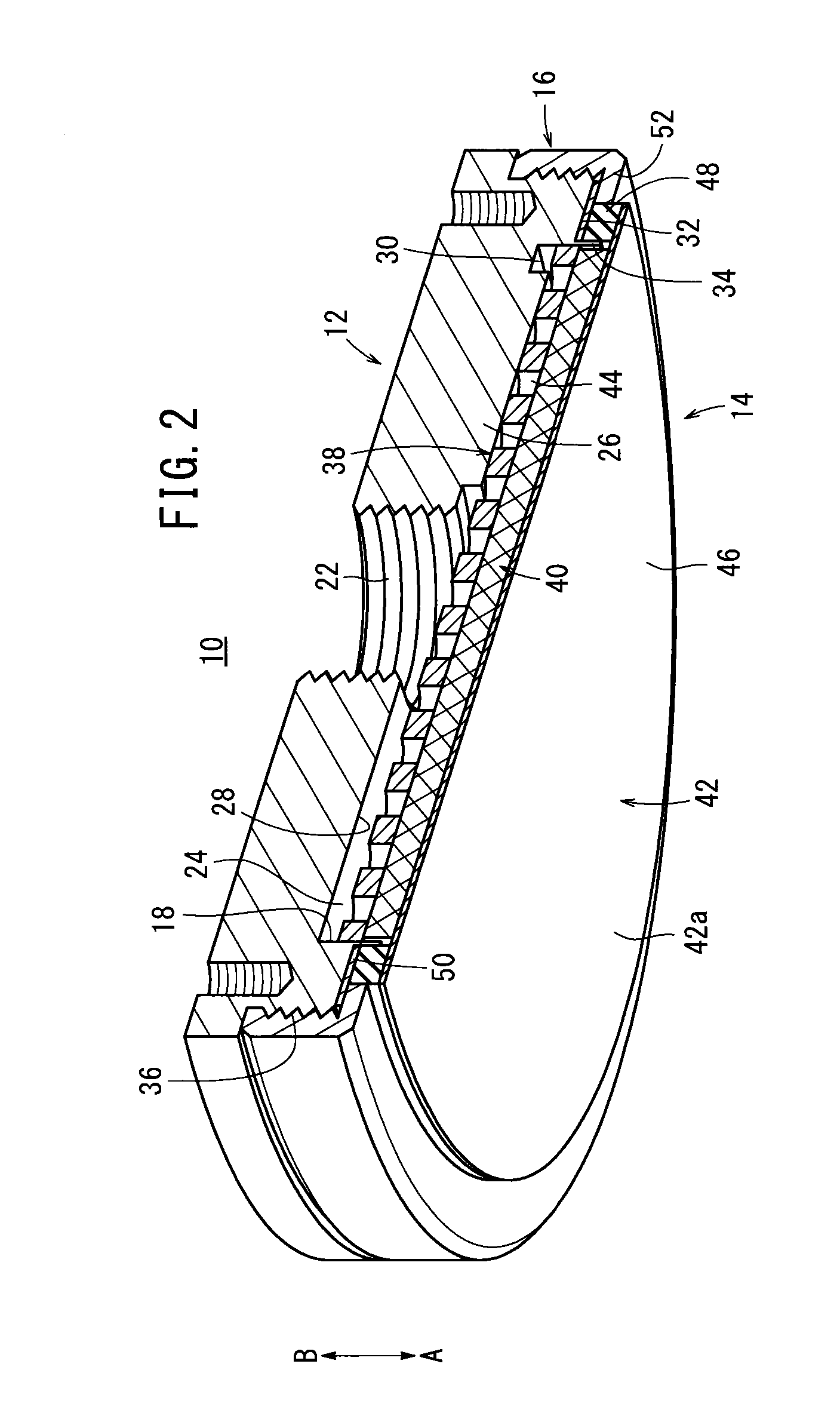

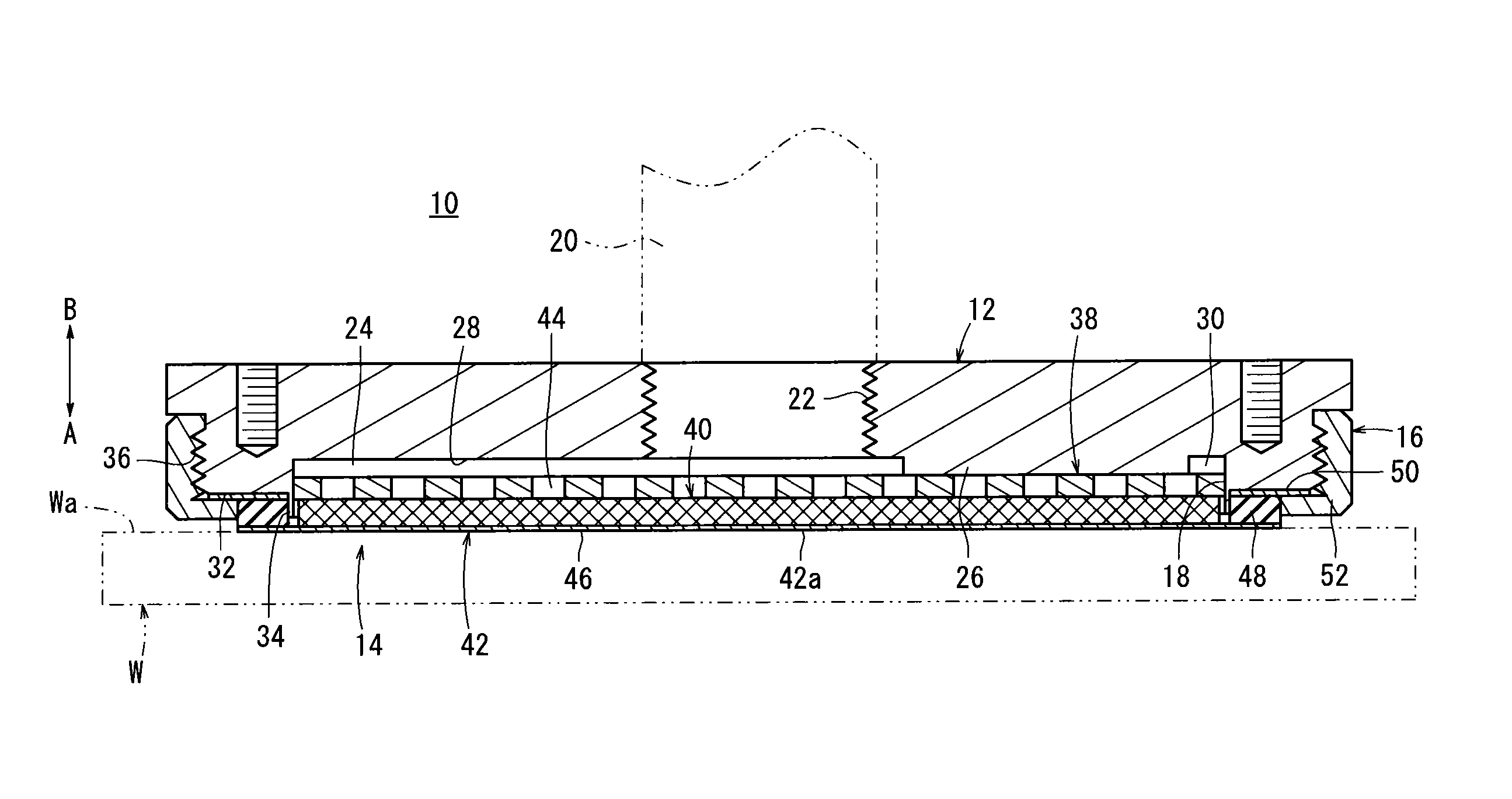

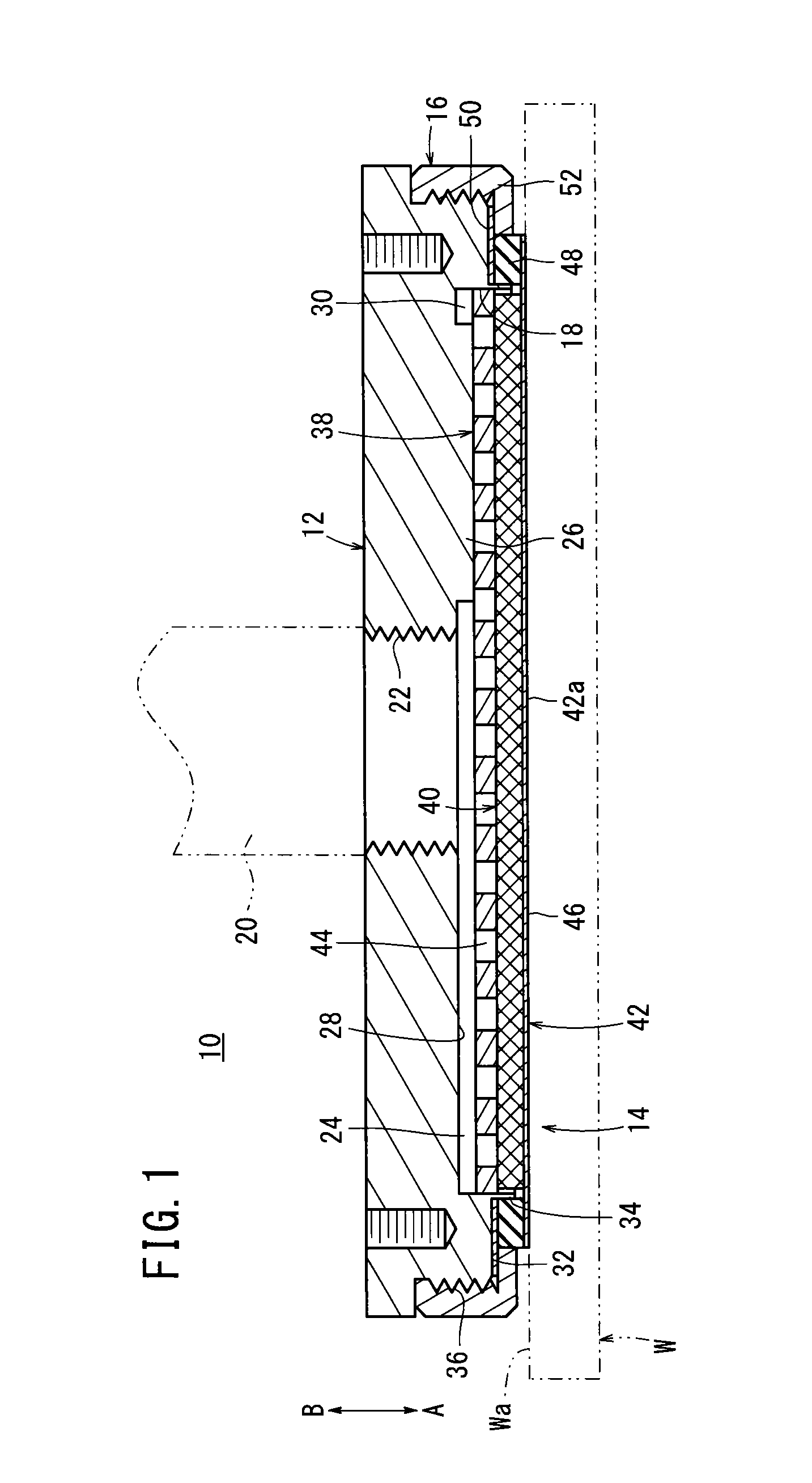

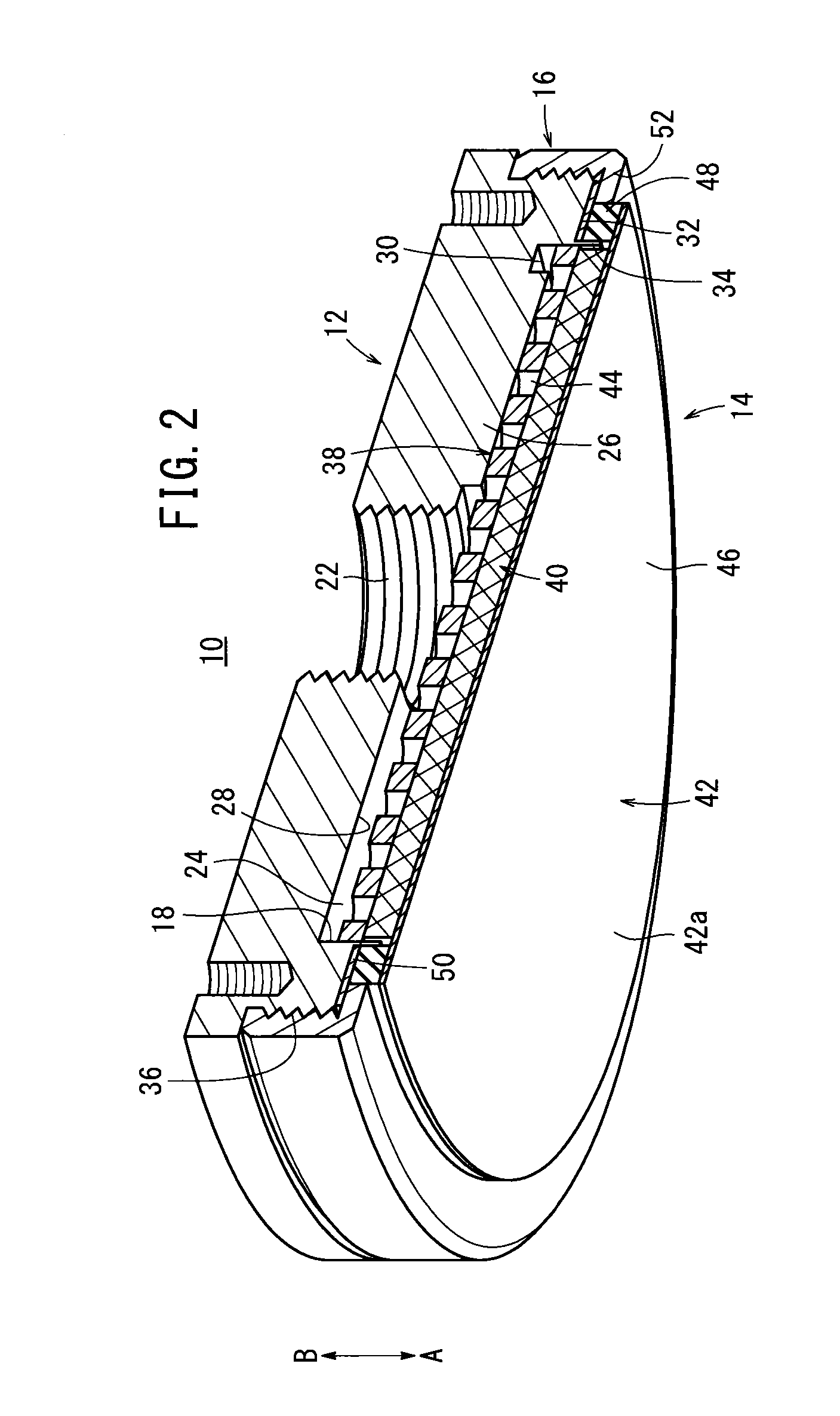

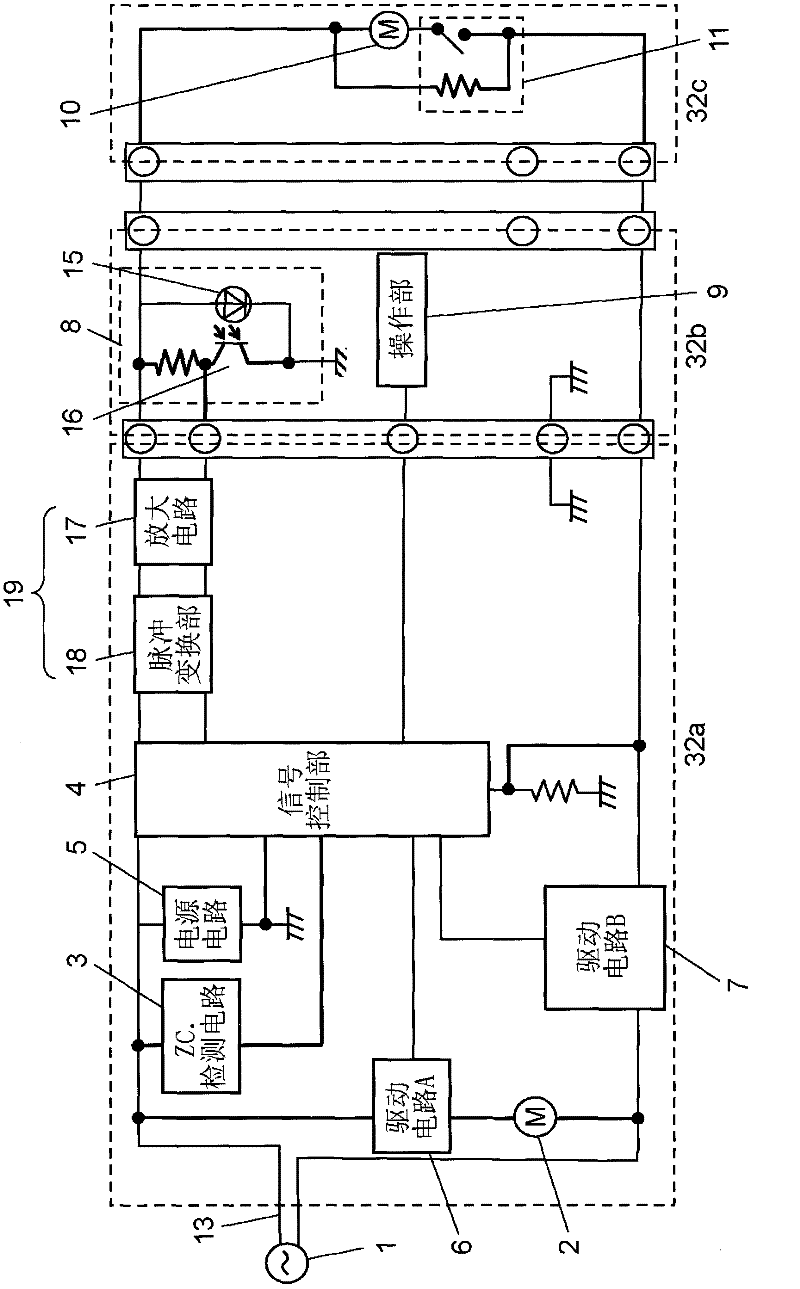

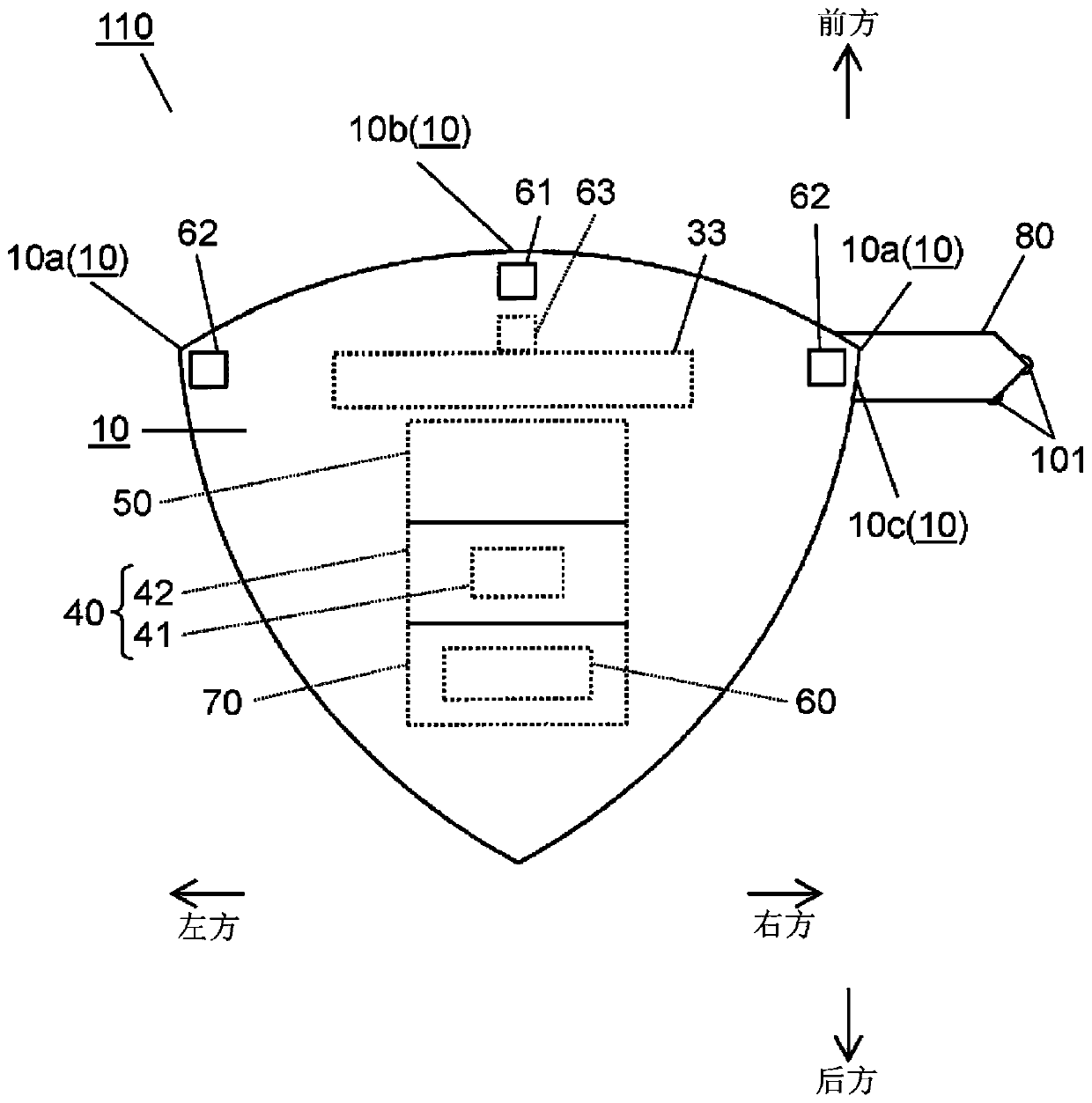

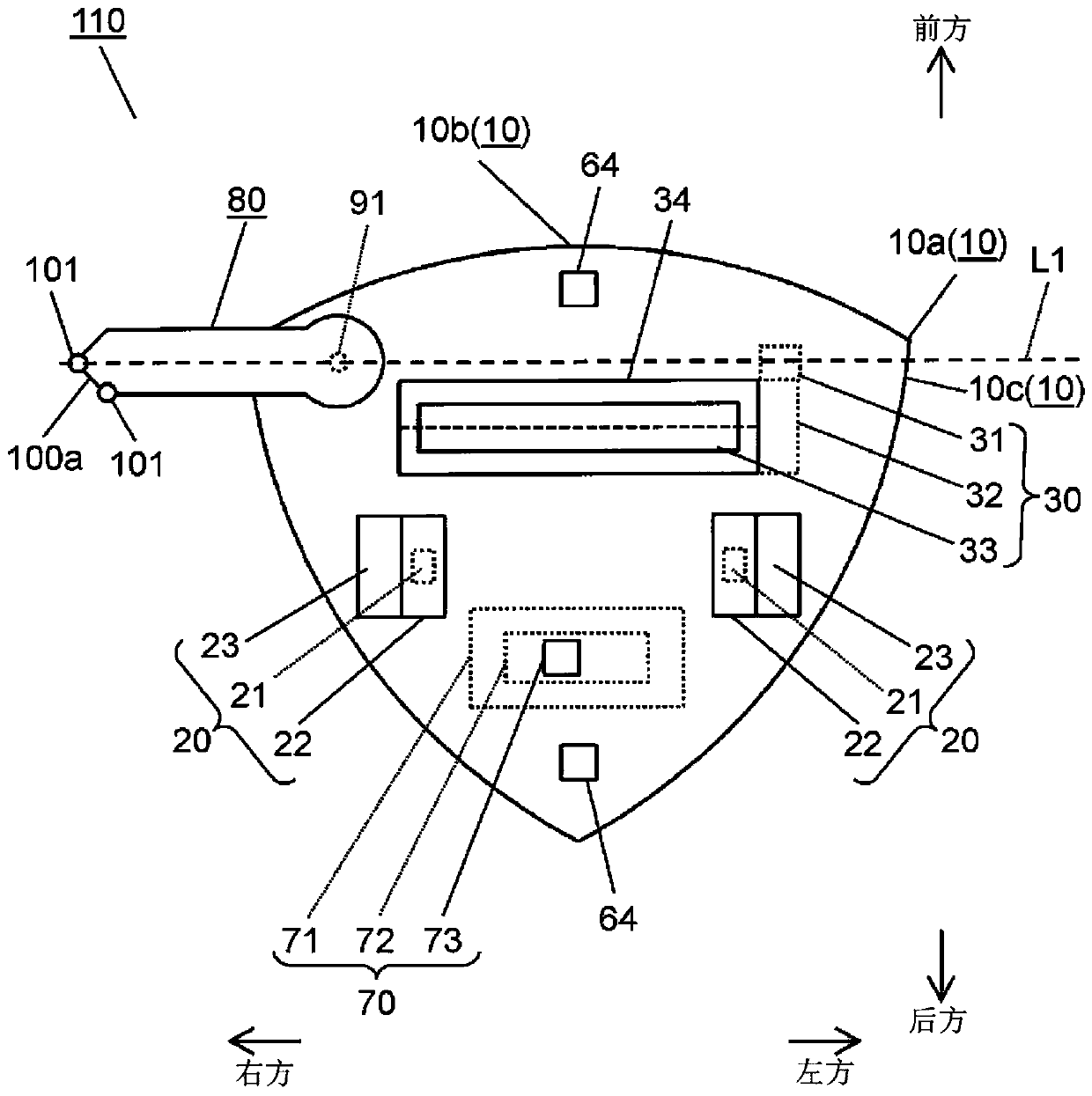

Circuit module, wireless communication apparatus and circuit module manufacturing method

InactiveCN101401206AReliable attractionIncrease surface areaImpedence networksCross-talk/noise/interference reductionElectromagnetic shieldingElectronic component

An electronic component (3) which has a shielding function and has the upper surface held at a reference potential, an electronic component (13) and a semiconductor component (4) are mounted on a wiring substrate (2). These components are covered with an insulating resin section (5), and a conductive layer (6) is formed on an upper surface of the insulating resin section (5). The conductive layer (6) is held at the reference potential by connecting the conductive layer (6) with a portion of the electronic component (3), which is held at the reference potential of the electronic component (3) and exposed from the insulating resin section (5). Thus, a small circuit module having excellent electromagnetic shielding function is provided.

Owner:KYOCERA CORP

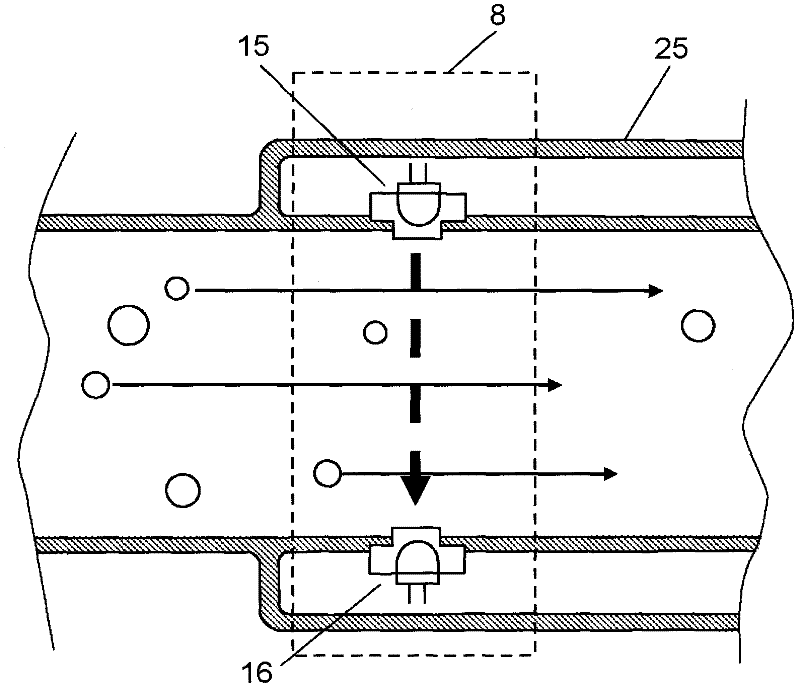

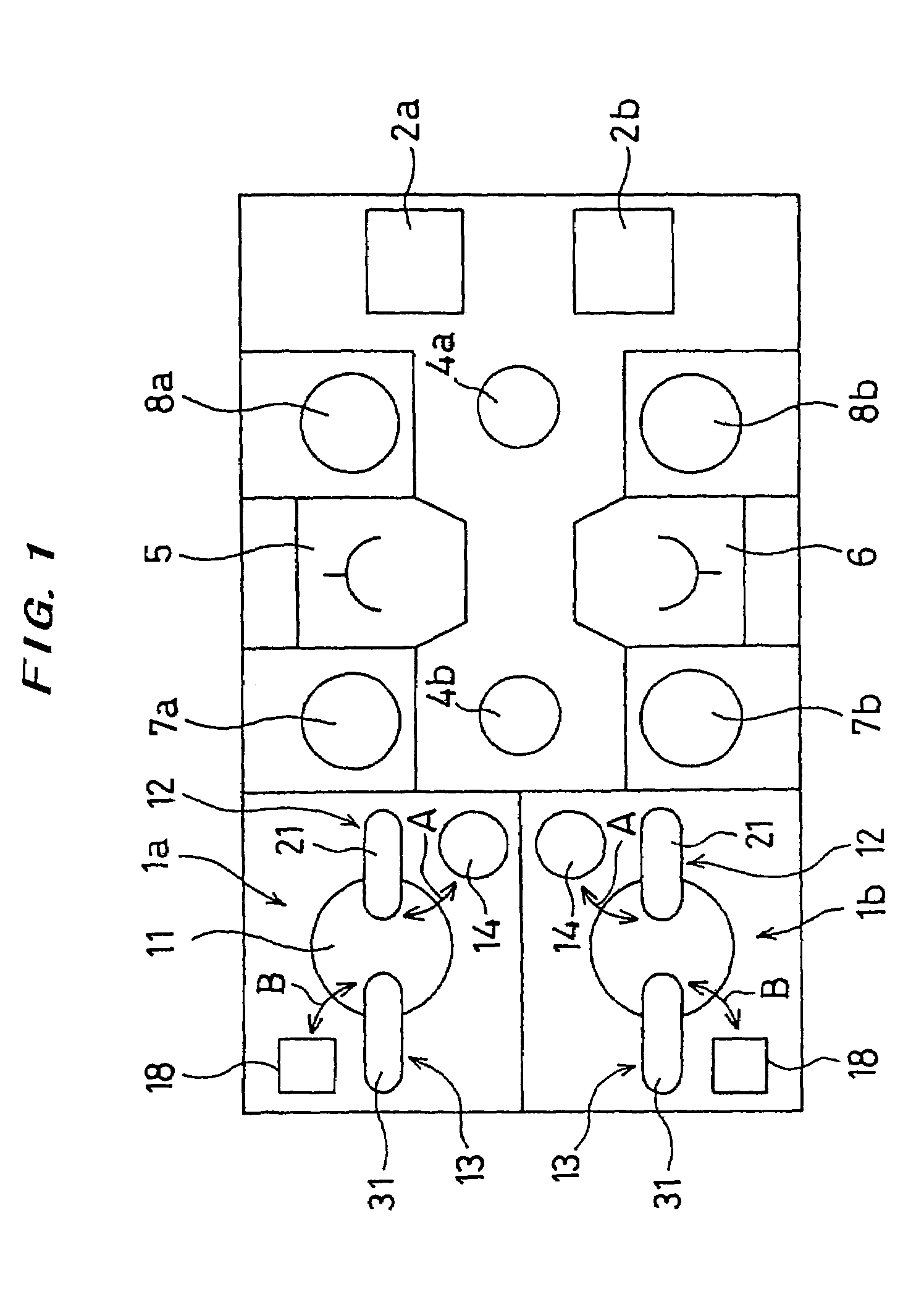

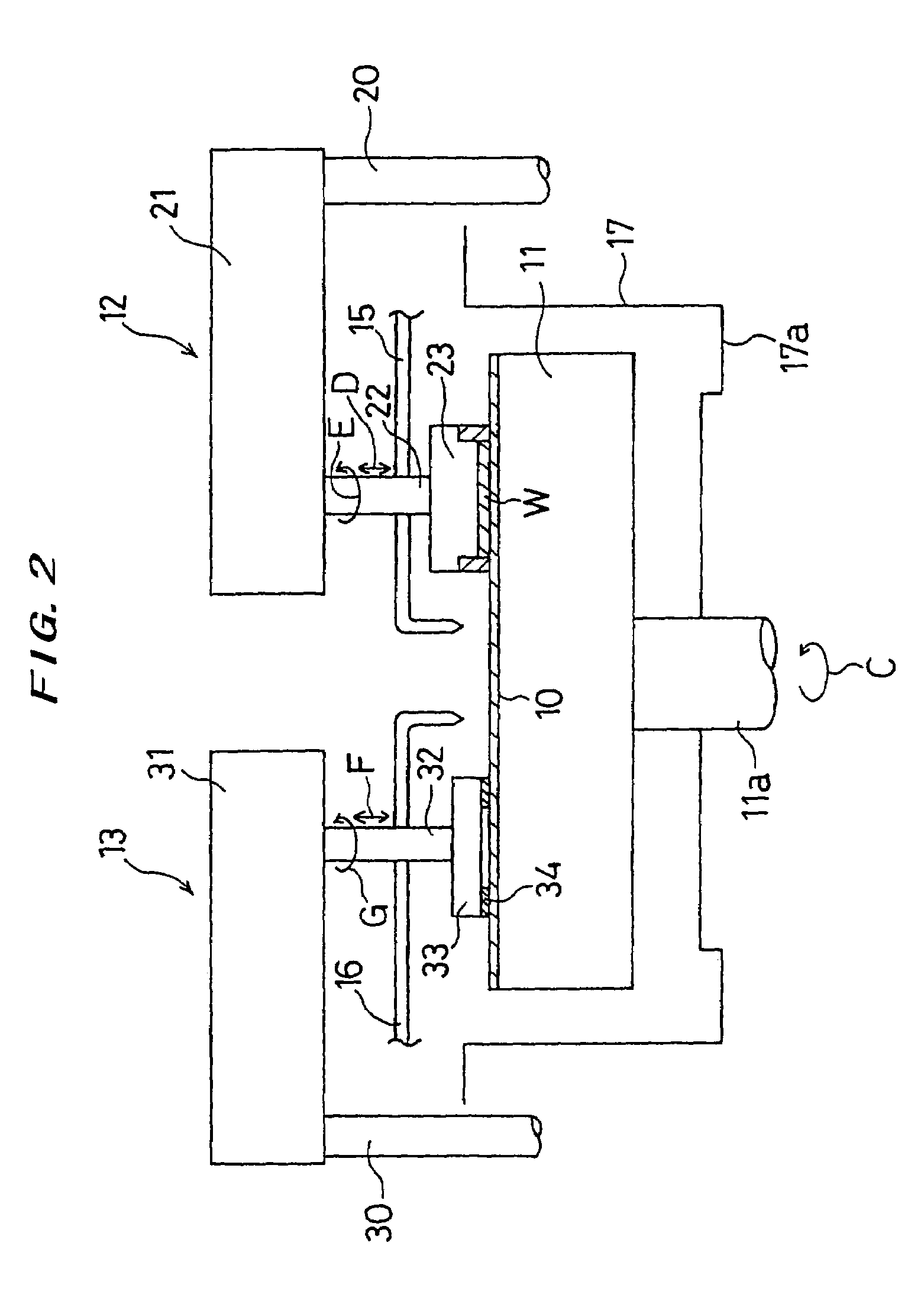

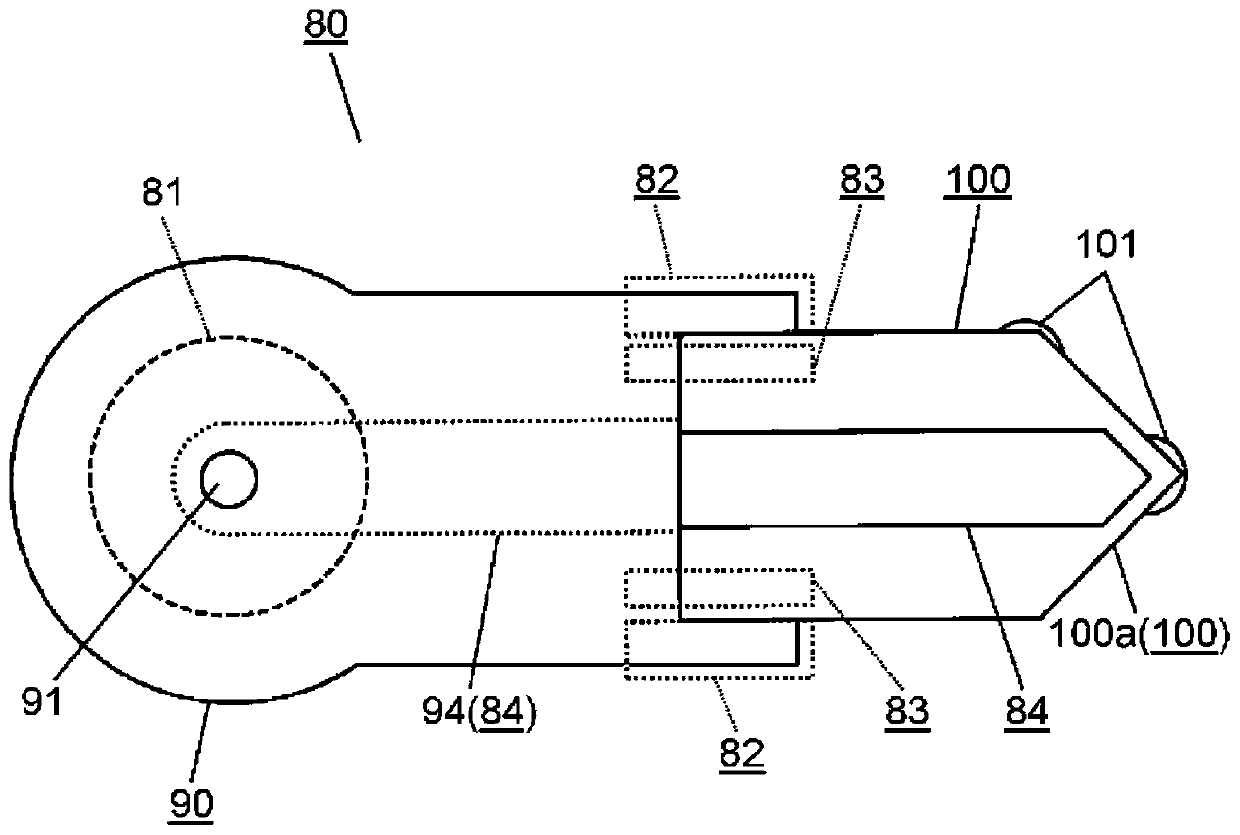

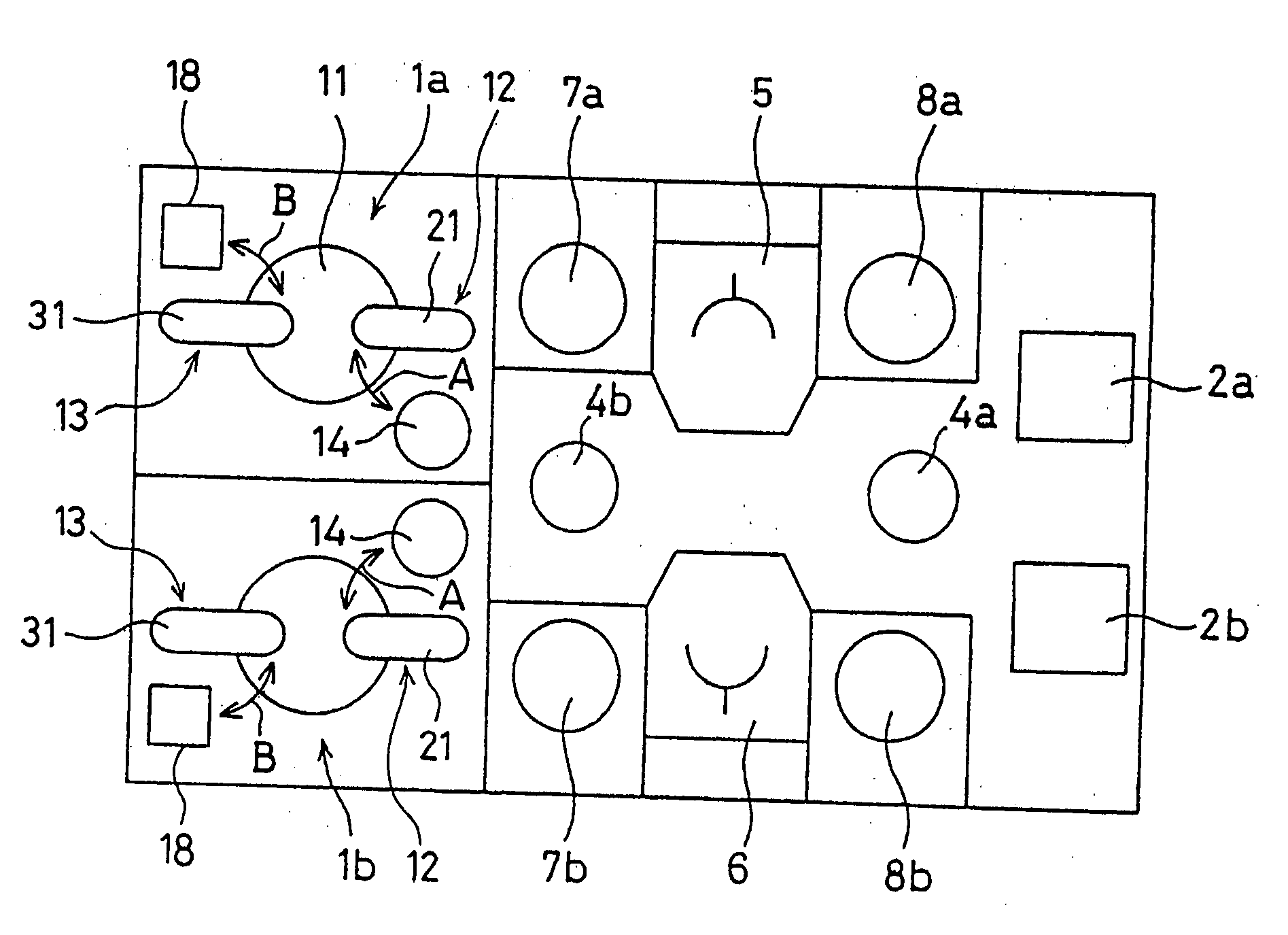

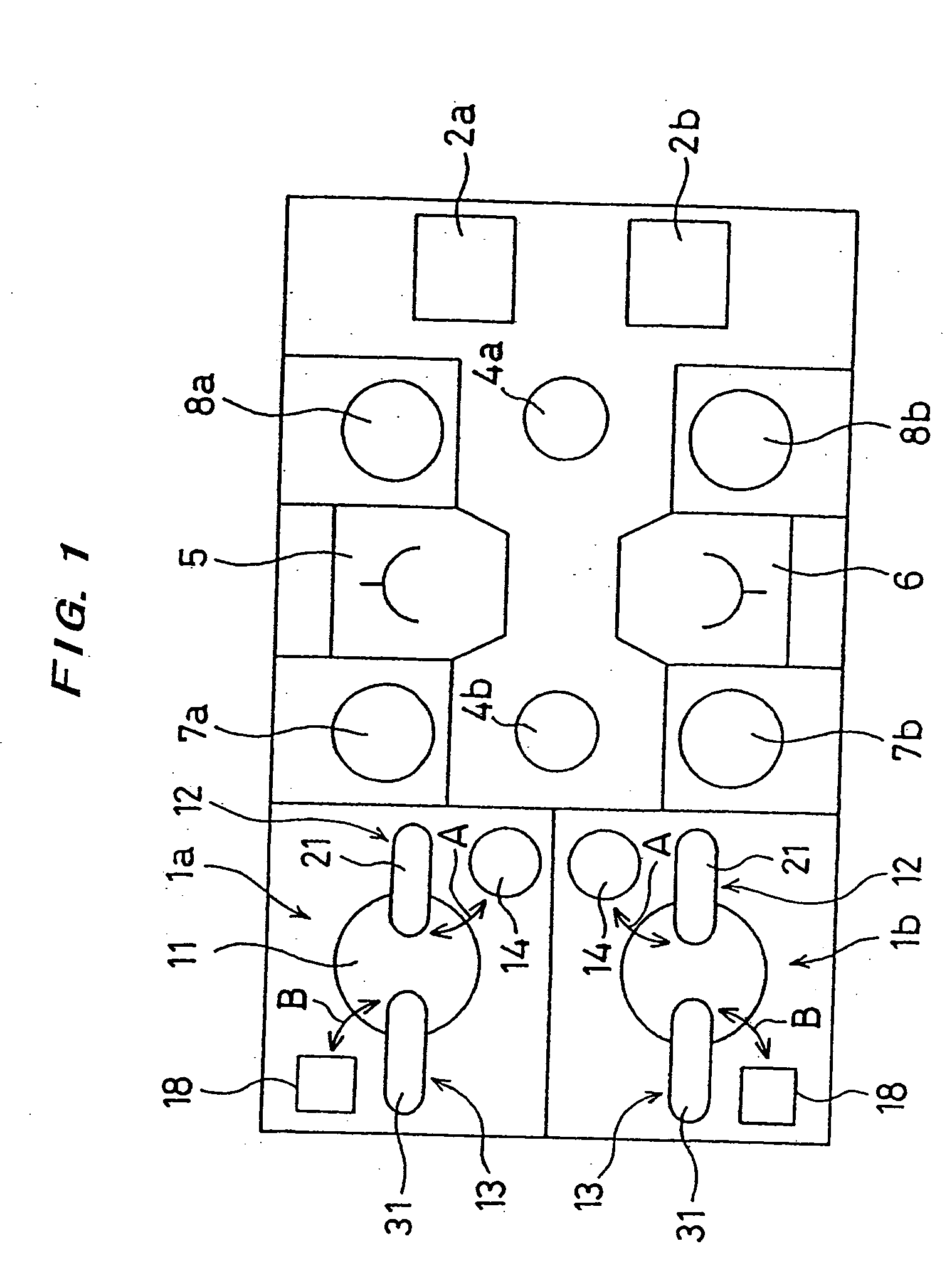

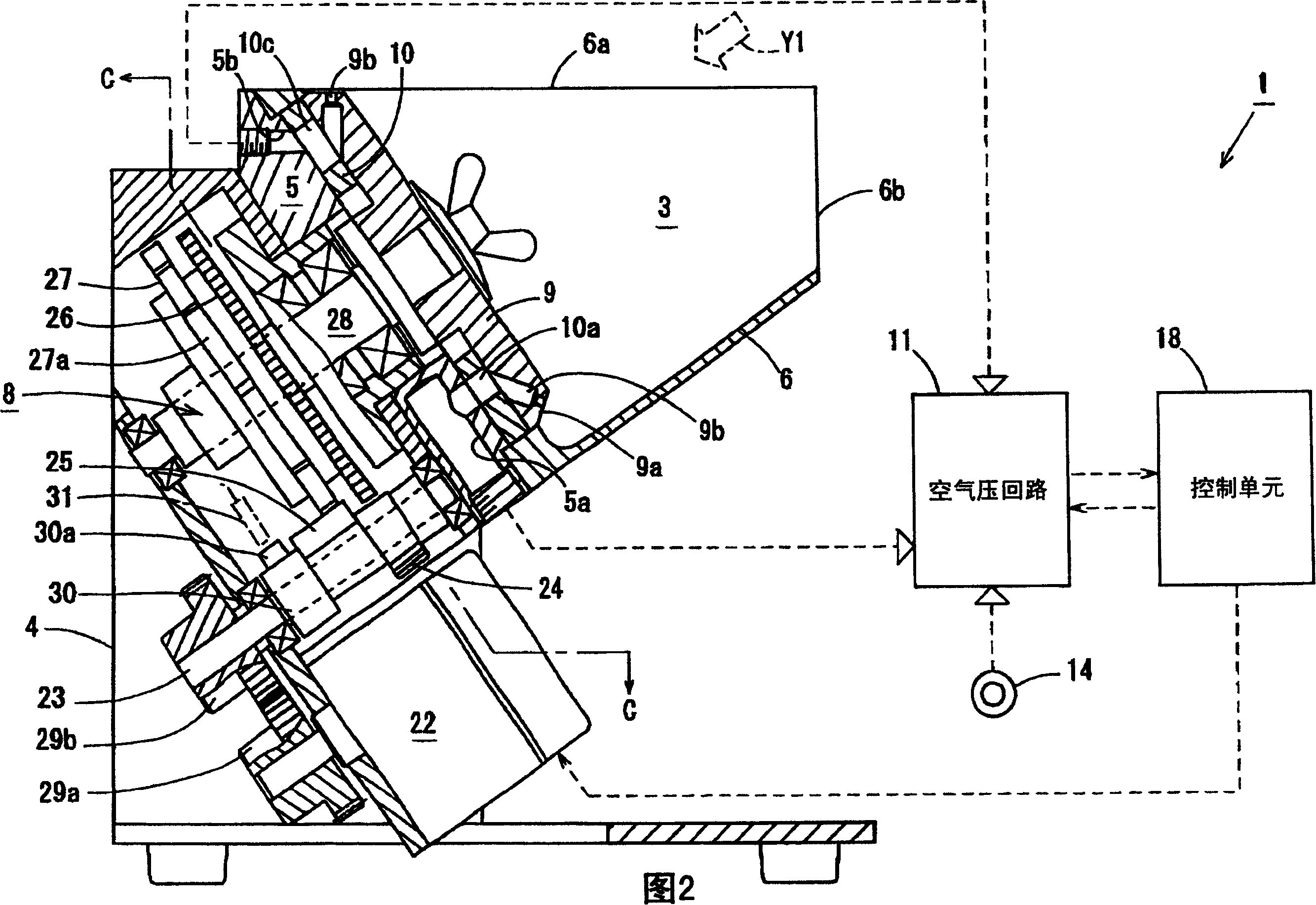

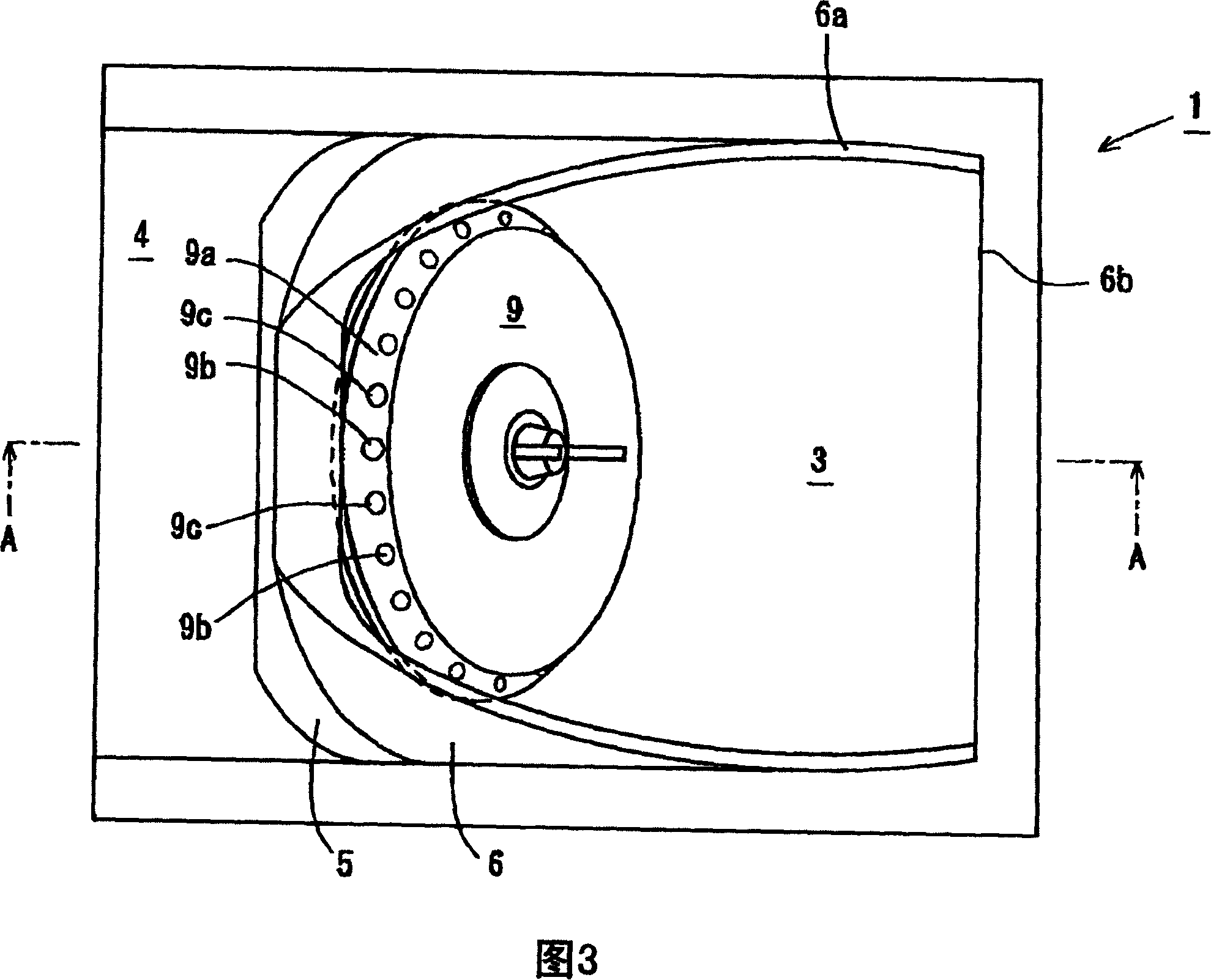

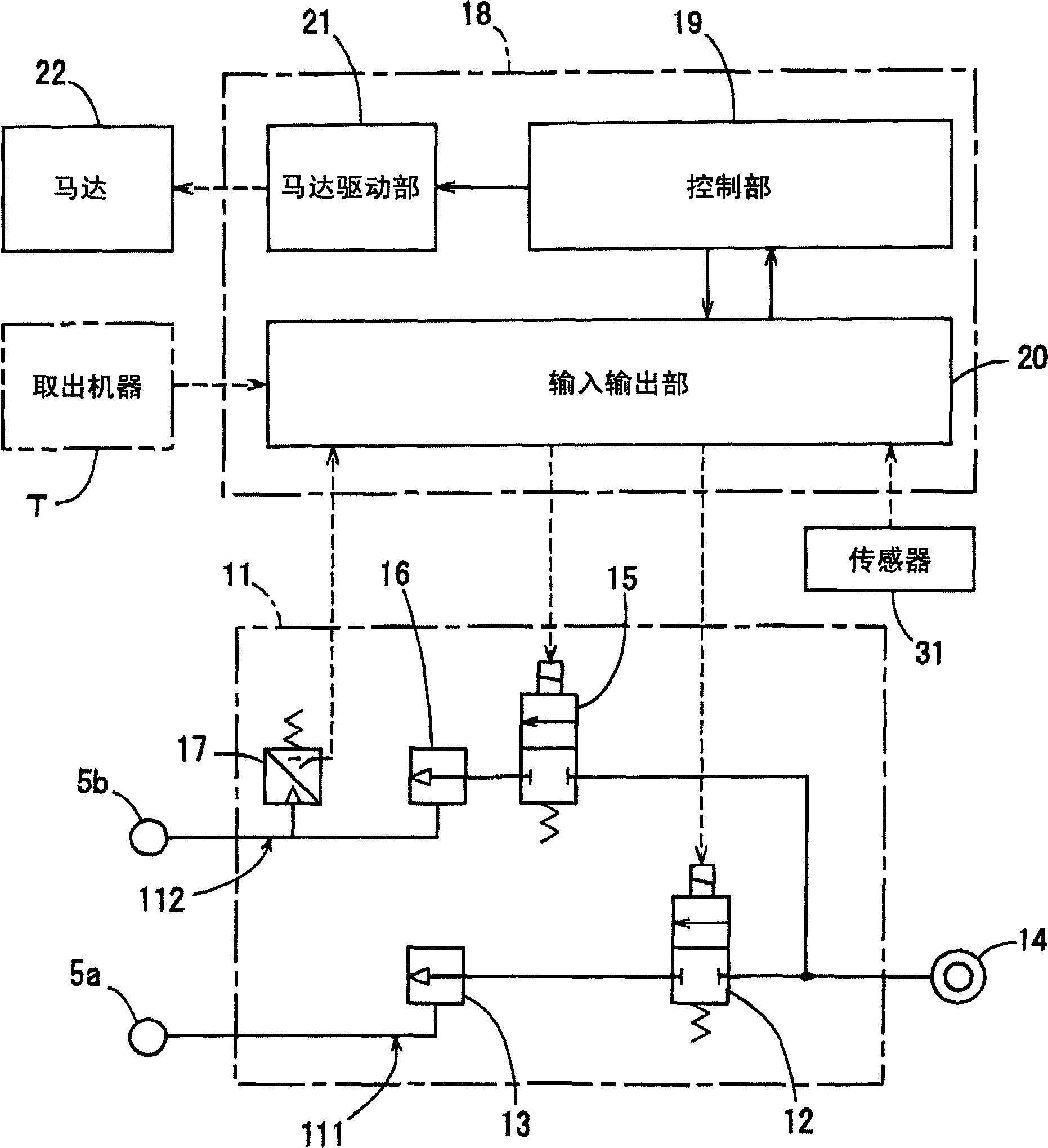

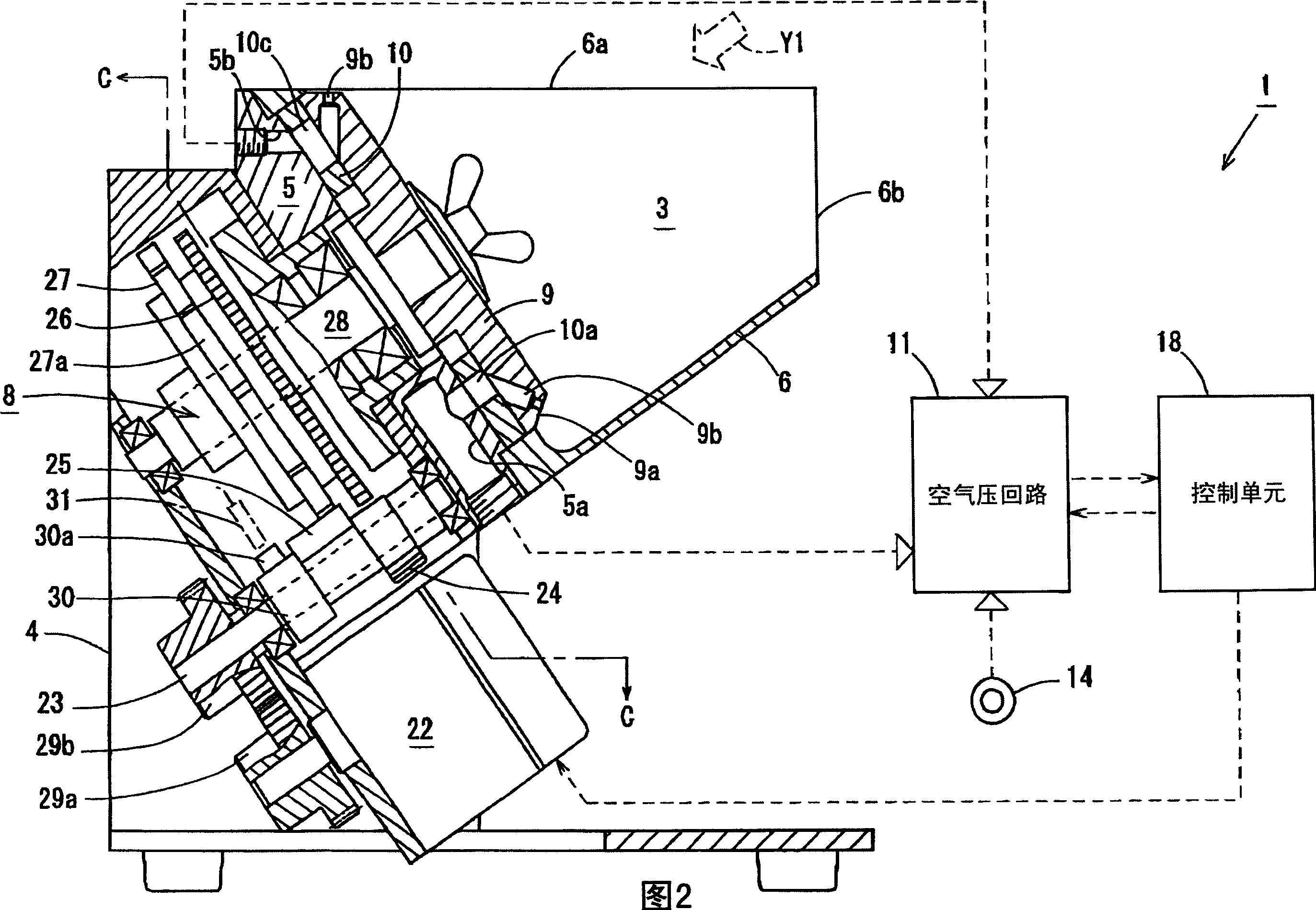

Vacuum suction apparatus

InactiveUS20130082475A1Avoid product qualityCurb consumptionGripping headsSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

Owner:SMC CORP

Vacuum suction apparatus

InactiveUS8960749B2Avoid product qualityCurb consumptionGripping headsSemiconductor/solid-state device manufacturingEngineeringBackplane

Owner:SMC CORP

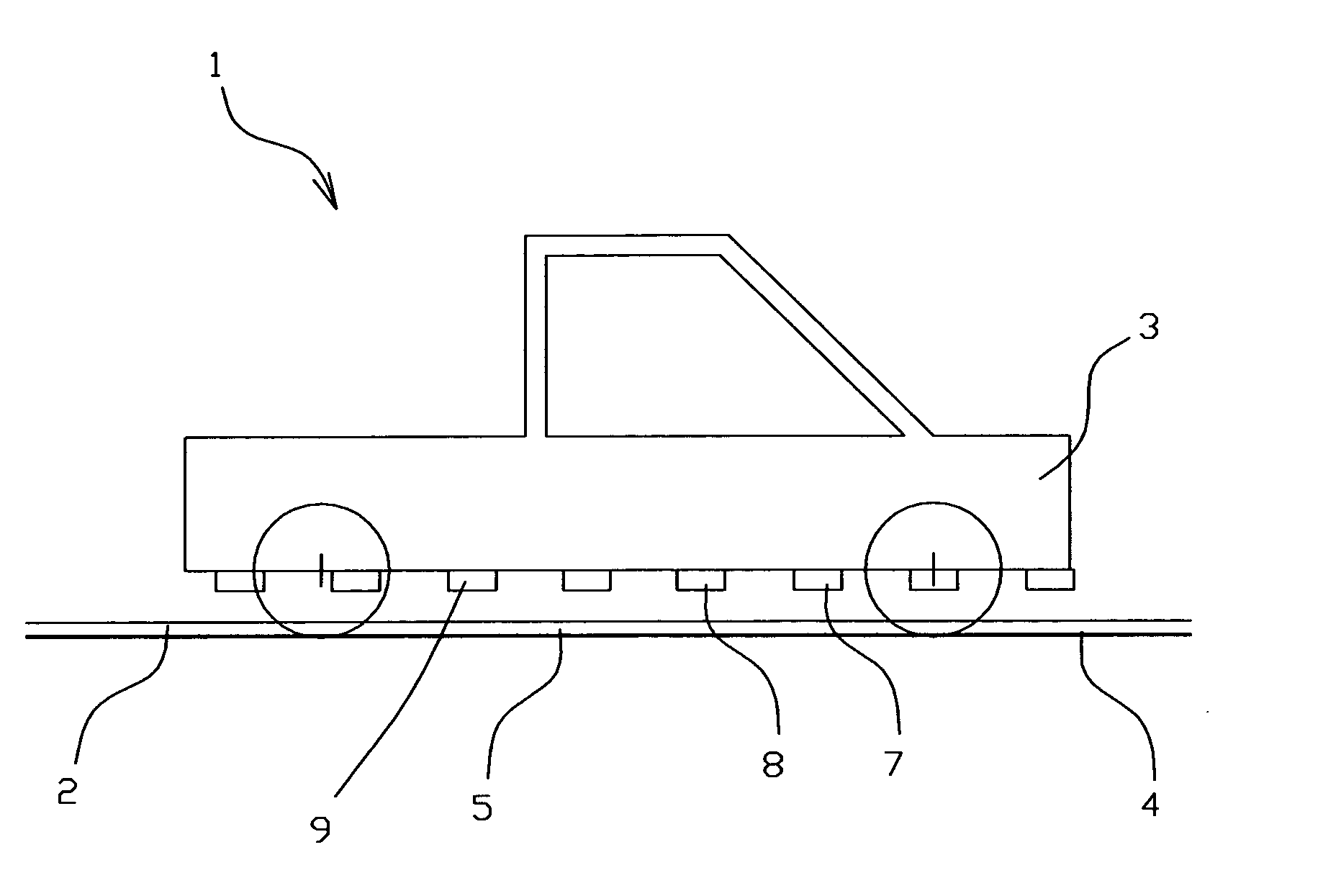

Electromagnetic moving toy system

InactiveUS20060005735A1Simple systemStable and reliableRolling drumsHelter-skeltersElectricityElectrical polarity

An electromagnetic moving toy system comprises a track and at least one vehicle located on the track. The track comprises electrically connected coils windings serving as a linear stator and located in a series way along the track. The coils windings are powered in such way that at least two adjacent coil windings operating in time. The linear stator further comprises a core made of magnet-conducting material with high eddy current resistance. The vehicle comprising magnetic means interacting with the coils windings so the magnetic means serving as a moving body providing a possibility for moving of the vehicle. The magnetic means are made as permanent magnets with alternative polarity. According to another embodiment, the track comprises magnetic means located in a series way along the track. The vehicle comprises electrically connected coils windings serving as a linear stator powered by at least one autonomous power source.

Owner:INDAL DESIGN LAB

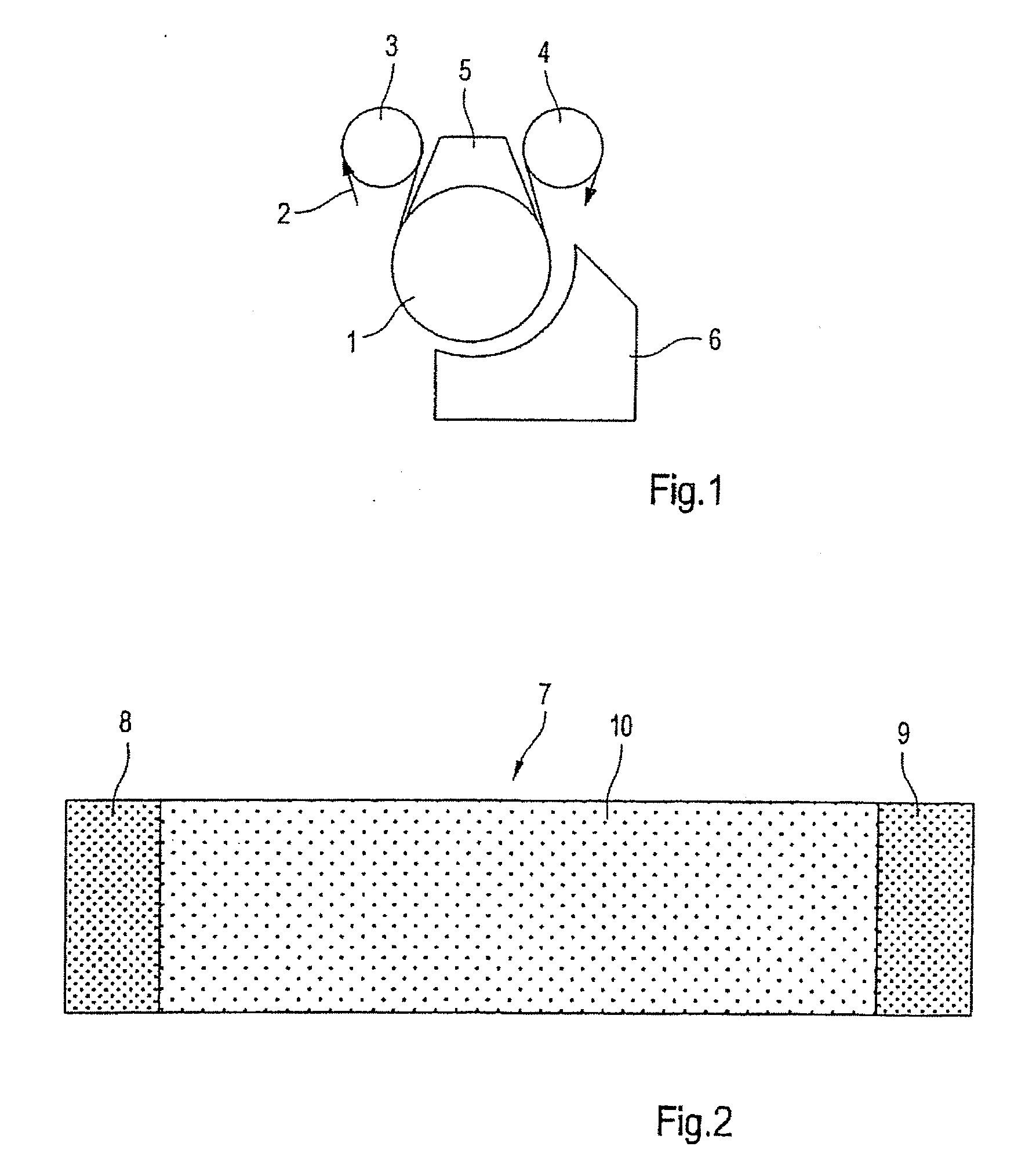

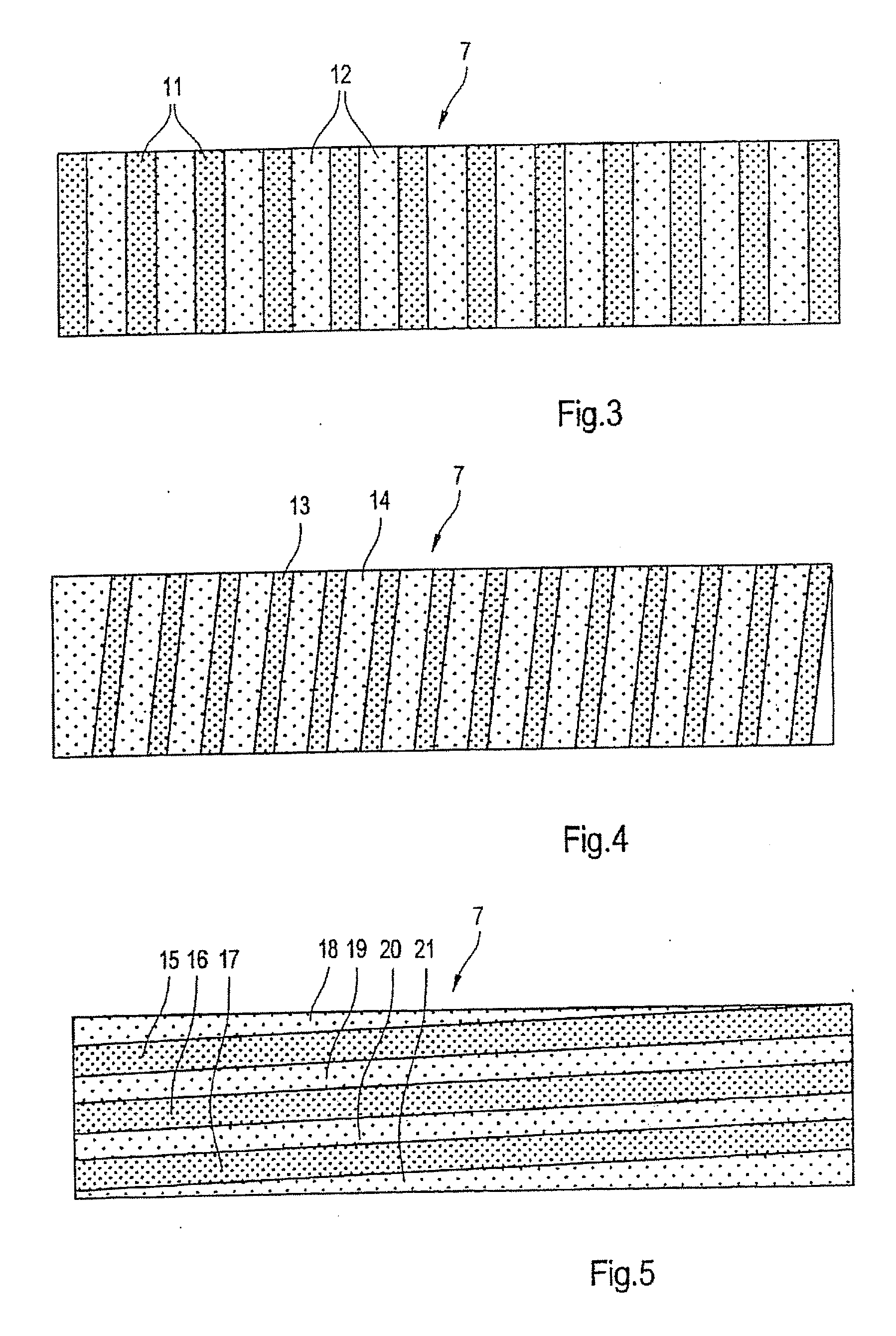

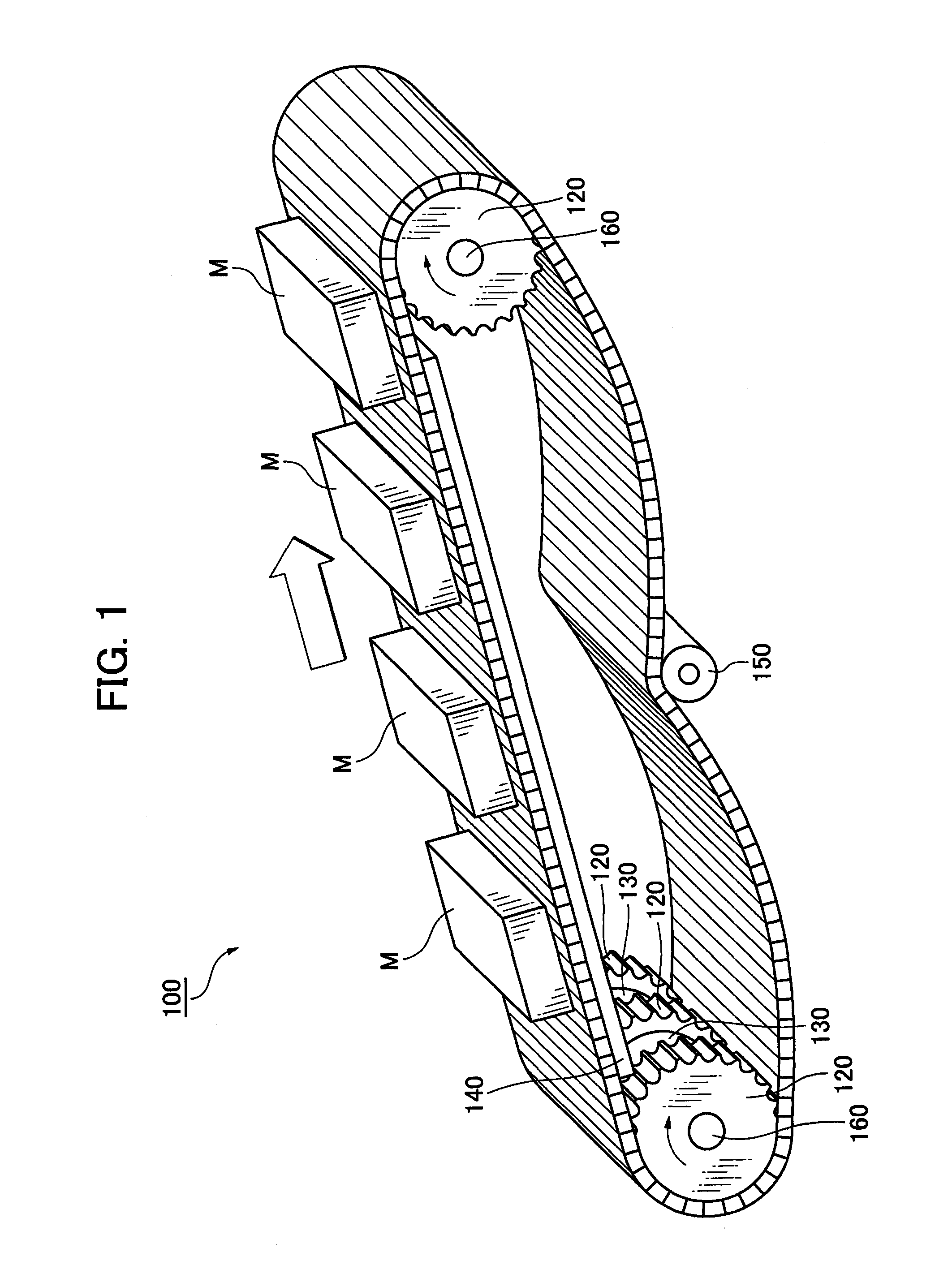

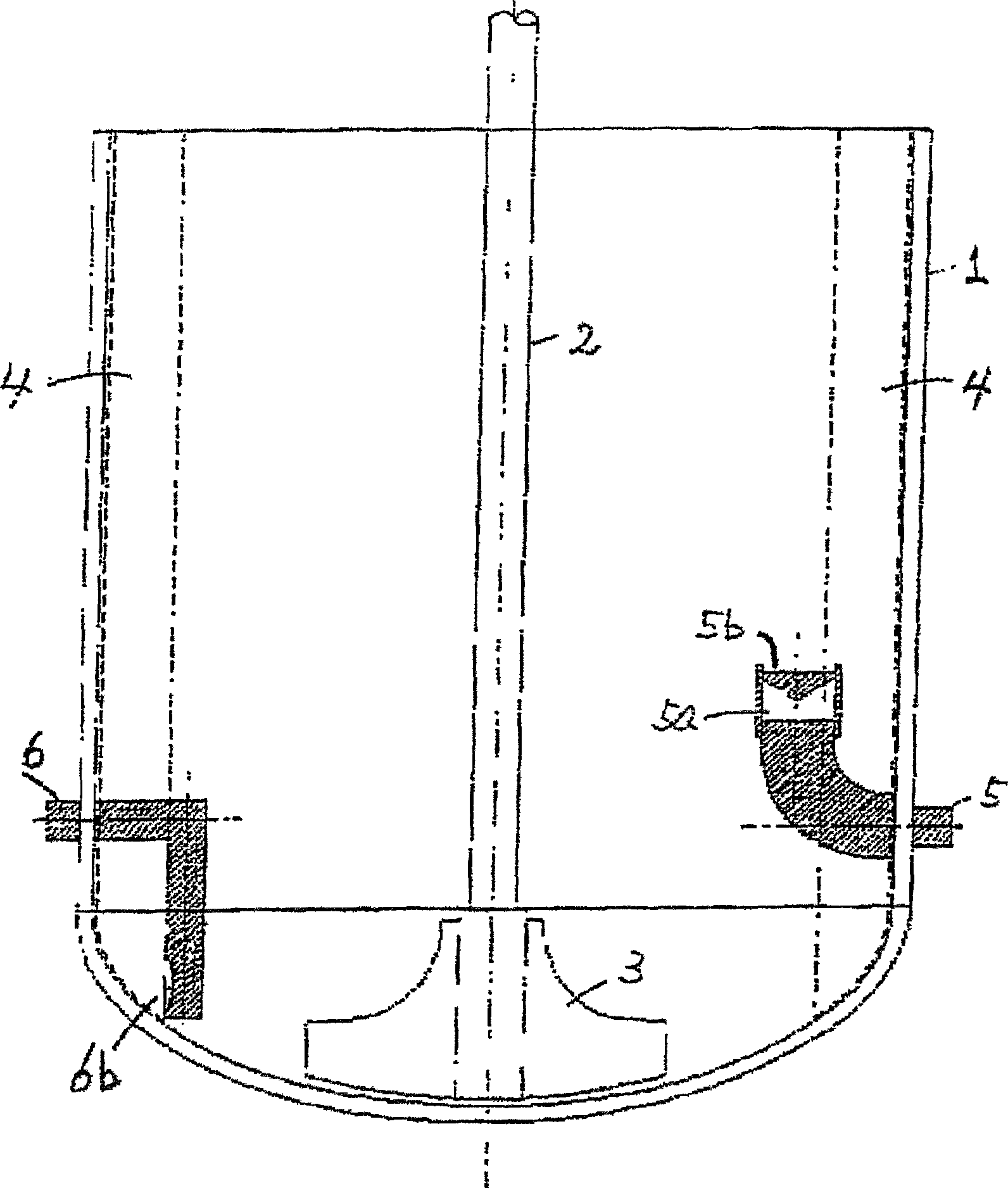

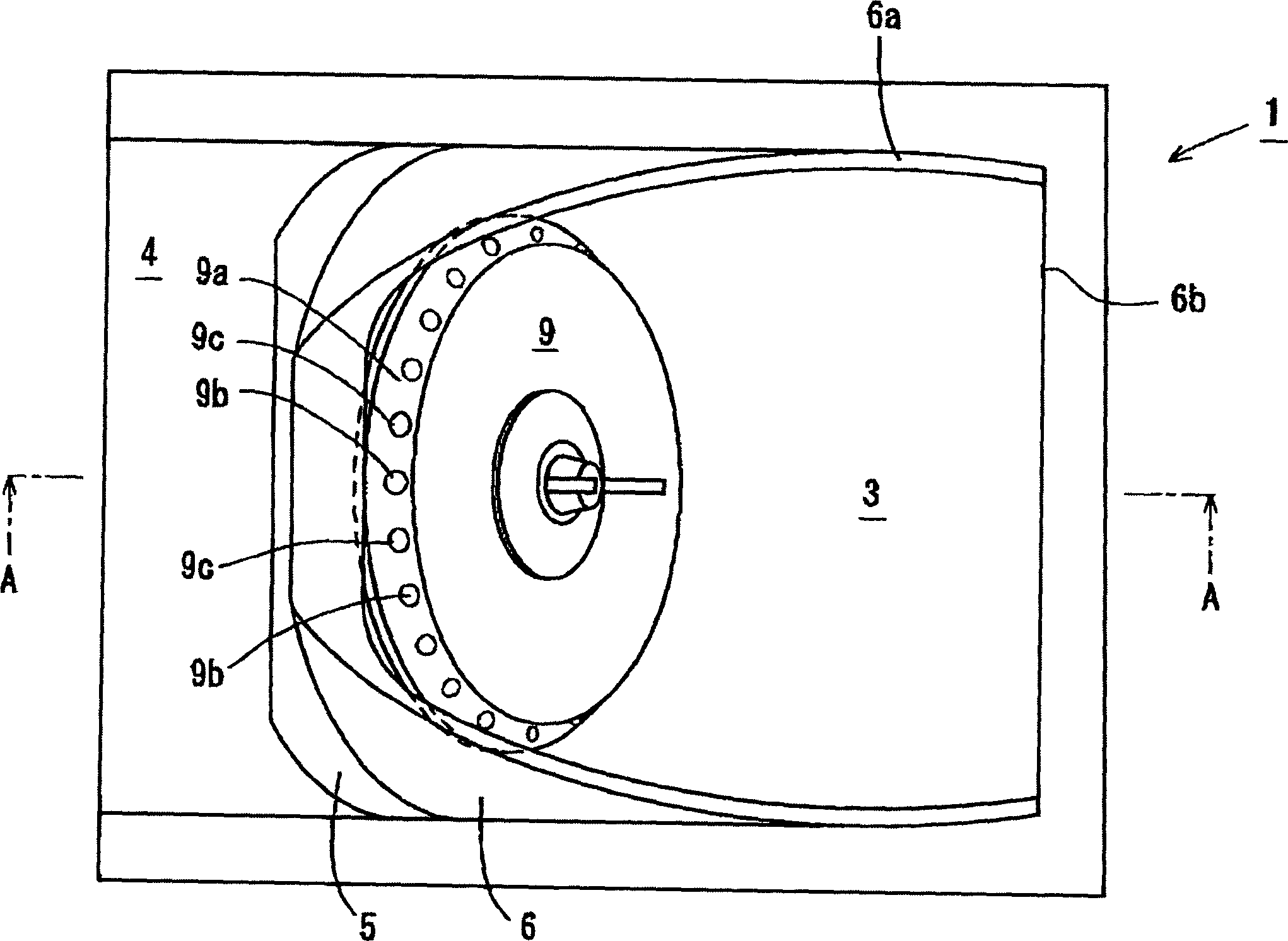

Suction roll in a machine for producing a fibrous web

InactiveUS20070084580A1Reliable transmissionEasy to removeMechanical working/deformationDryer sectionFiberDiagonal

The present invention provides a suction roll system in a drying section of a machine for manufacturing a fibrous web, the suction roll system including a suction roll having an outer circumferential surface. The circumferential surface defines holes configured for attracting the fibrous web by suction and includes regions, more than two of the regions including the holes, at least two of the regions relative to one another having different numbers of the holes per unit area or having the holes with different diameters per unit area. The circumferential surface has strips which extend in a circumferential direction, at least one strip which extends in a helical shape over the circumferential surface, or strips which extend either substantially in a direction of a longitudinal axis of the suction roll or diagonally relative to the longitudinal axis. The regions include the strips. The strips have an increased number of the holes per unit area in comparison with the remaining regions between the strips or have the holes with greater diameters in comparison with the remaining regions.

Owner:VOITH PATENT GMBH

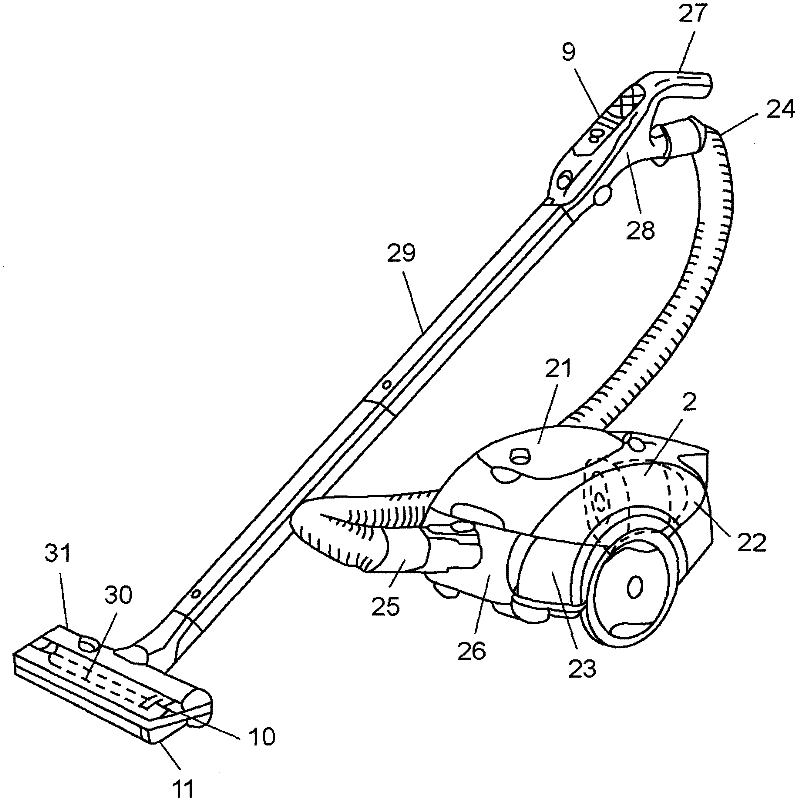

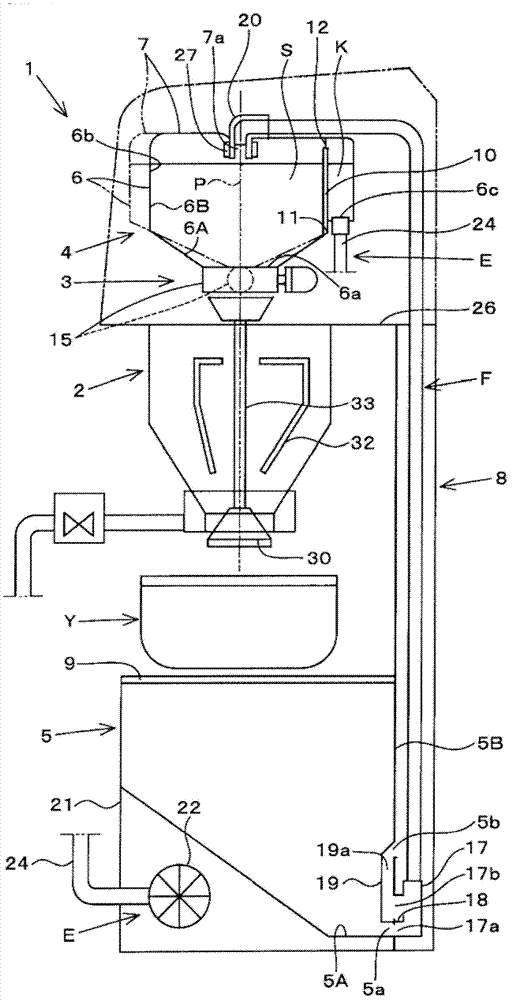

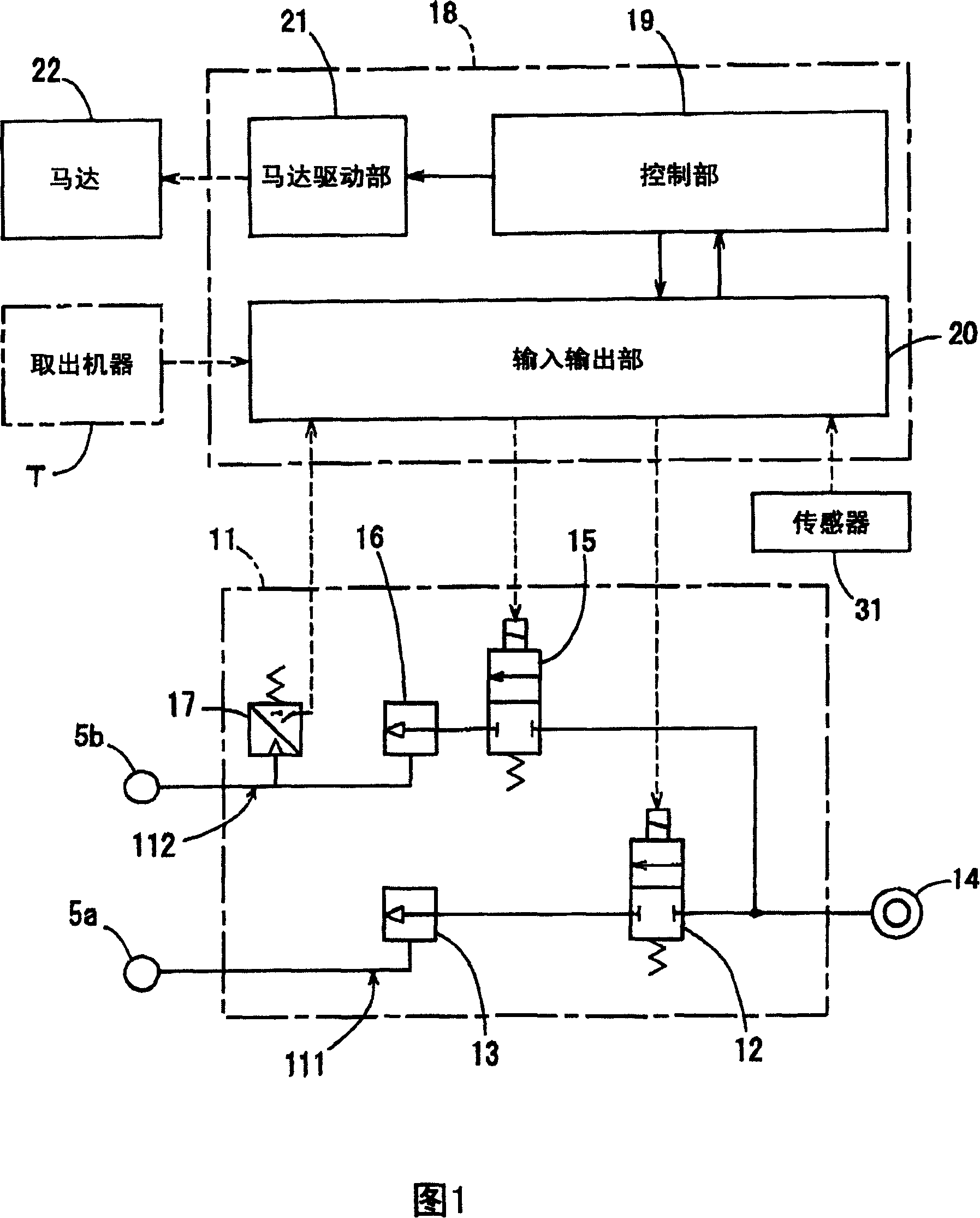

Electric vacuum cleaner

InactiveCN102334957AReliable attractionEasy to collect dustElectric equipment installationPower flowDust detection

The invention provides an electric vacuum cleaner, which is provided with: a vacuum cleaning head provided with an electromotor performing rotation and drive of a rotary brush; a movement speed detection part detecting movement speed of the vacuum cleaning head; a circuit detecting part detecting ground state; an electric air blower making the vacuum cleaning head generate attraction force; a collection dust detection part detecting the attracted dust; a signal control part controlling the revolution of the electromotor and the electric air blower according to the movement speed detection part, the circuit detecting part, and the collection dust detection part. Therefore, the ground state can be mastered, making the revolution of the electromotor and the electric air blower collect dust optimally.

Owner:PANASONIC CORP

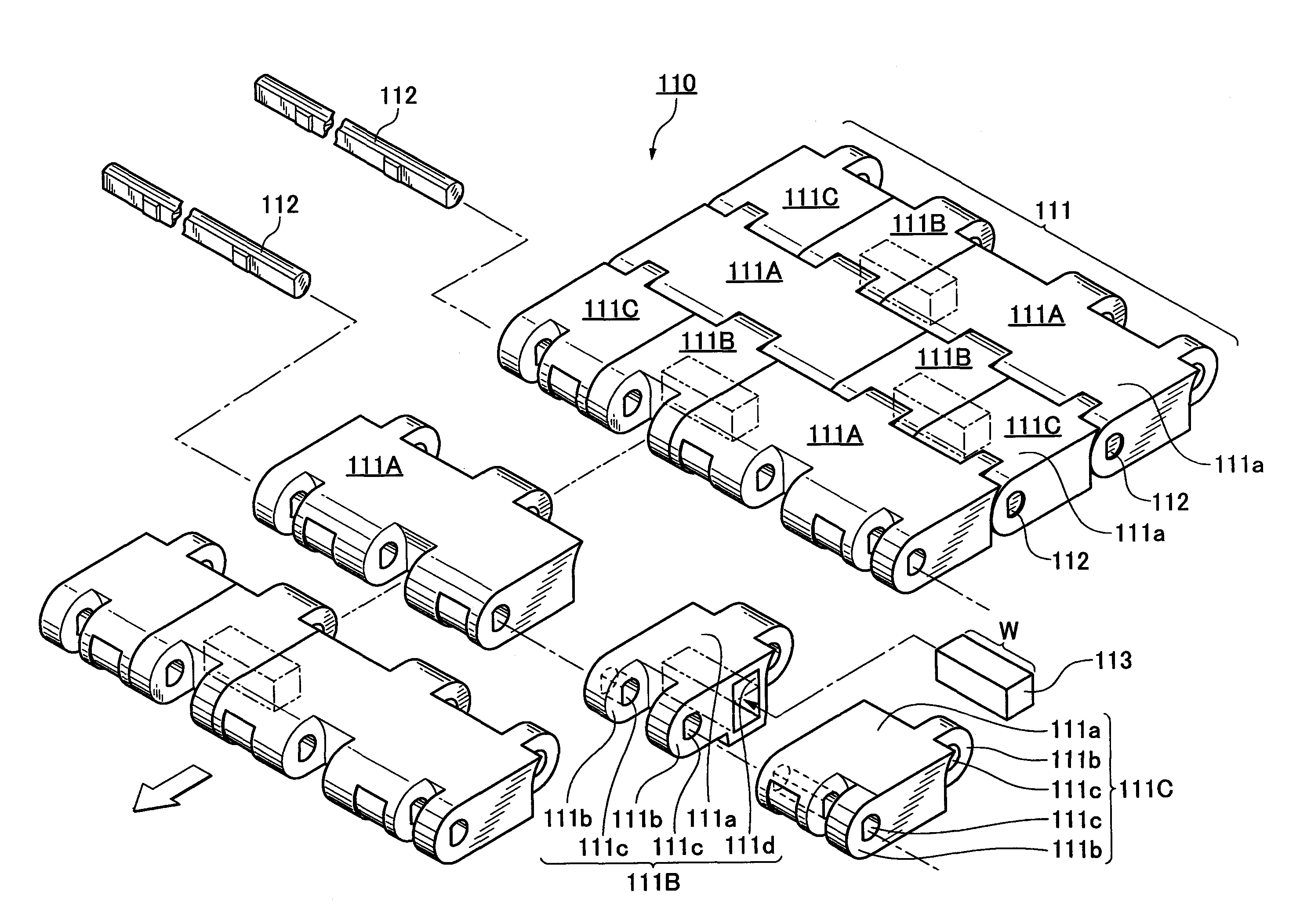

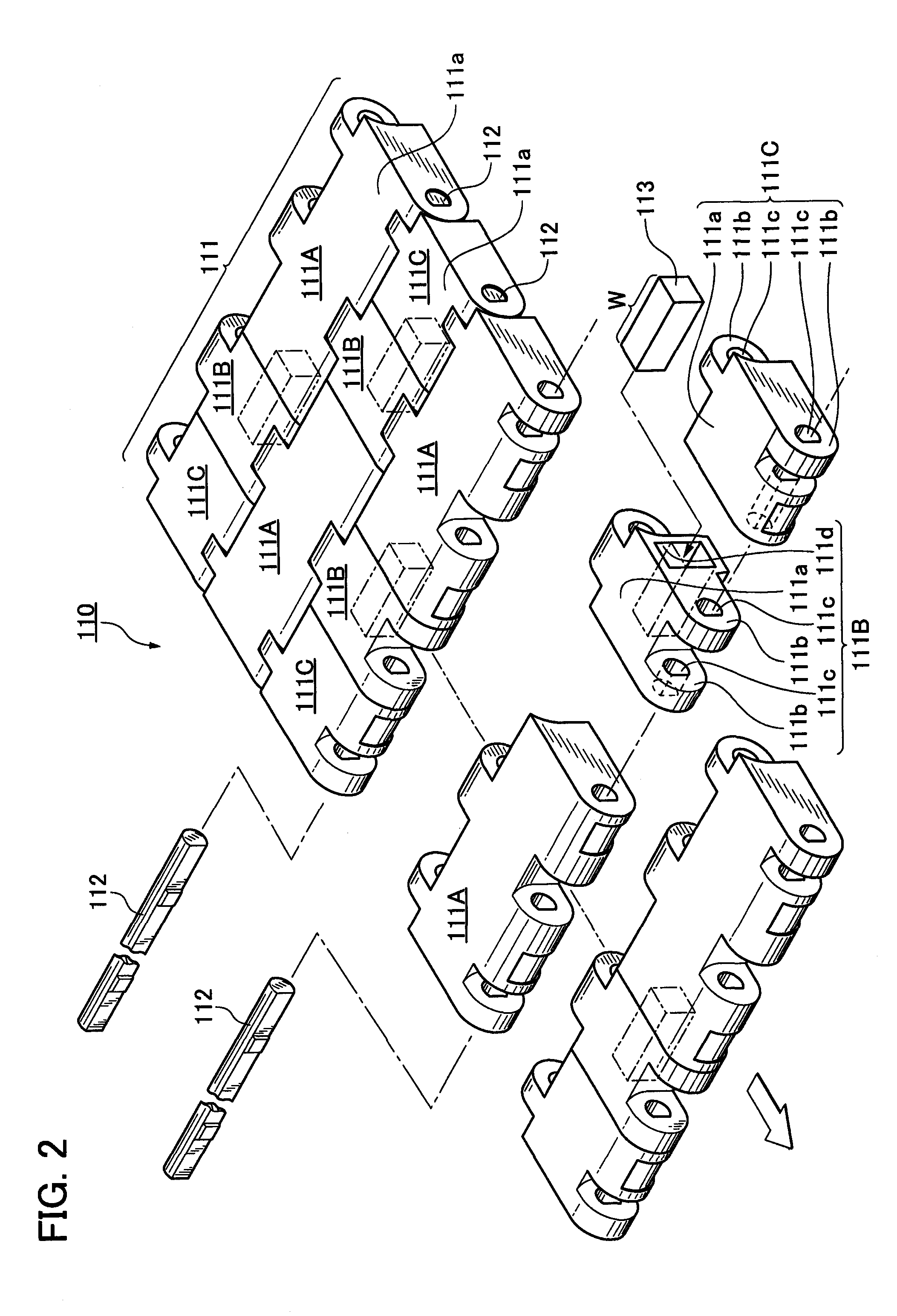

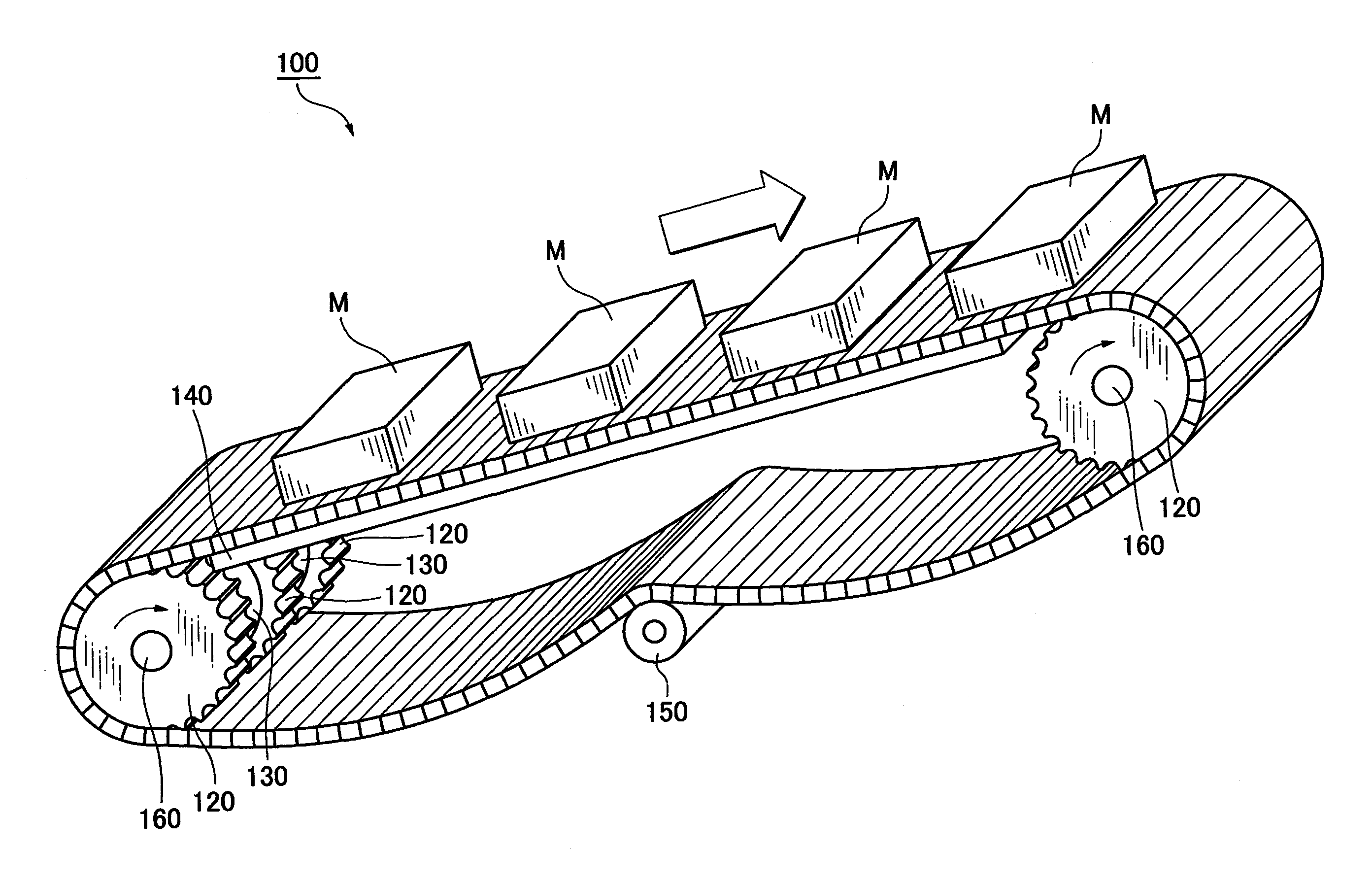

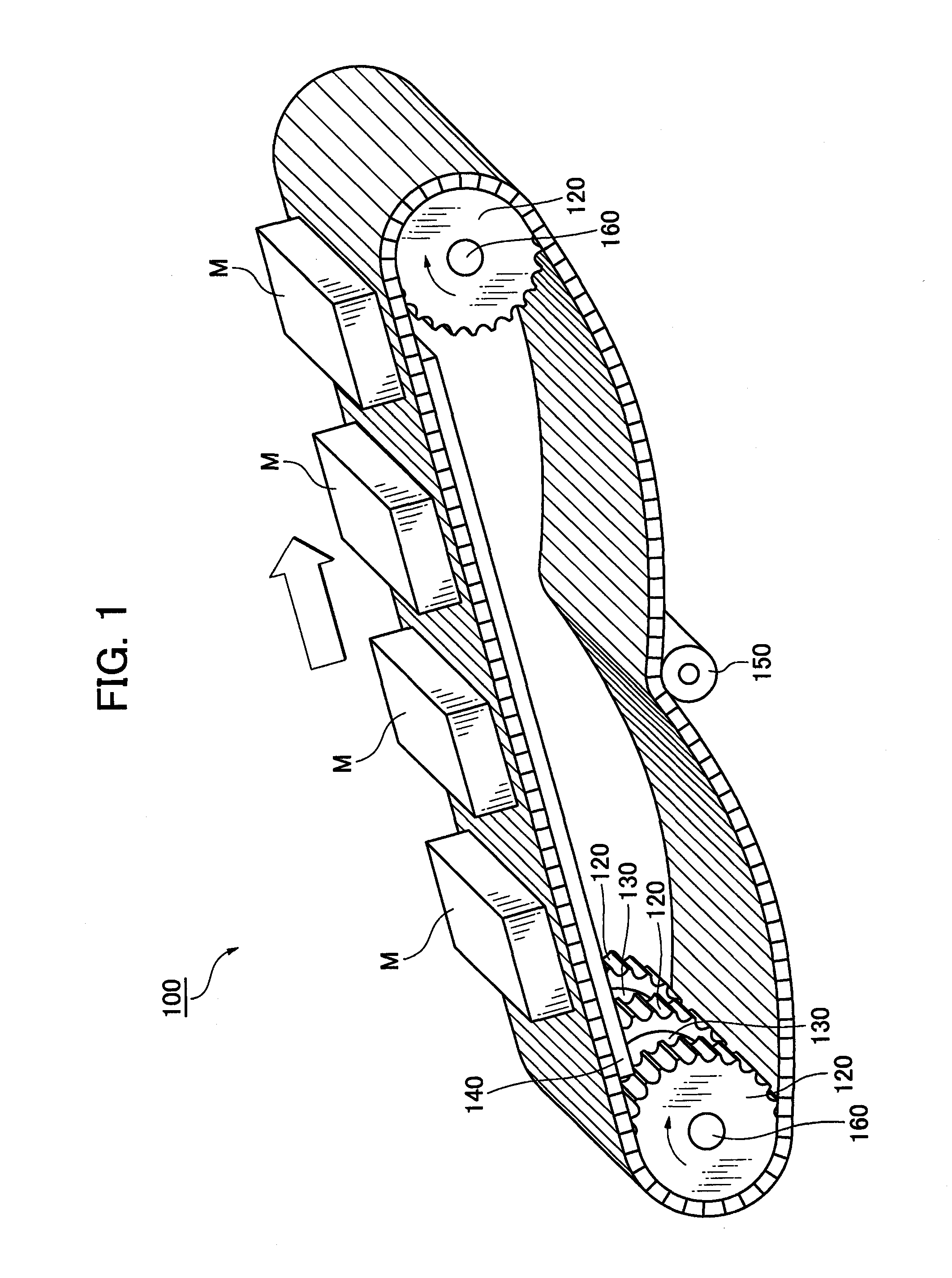

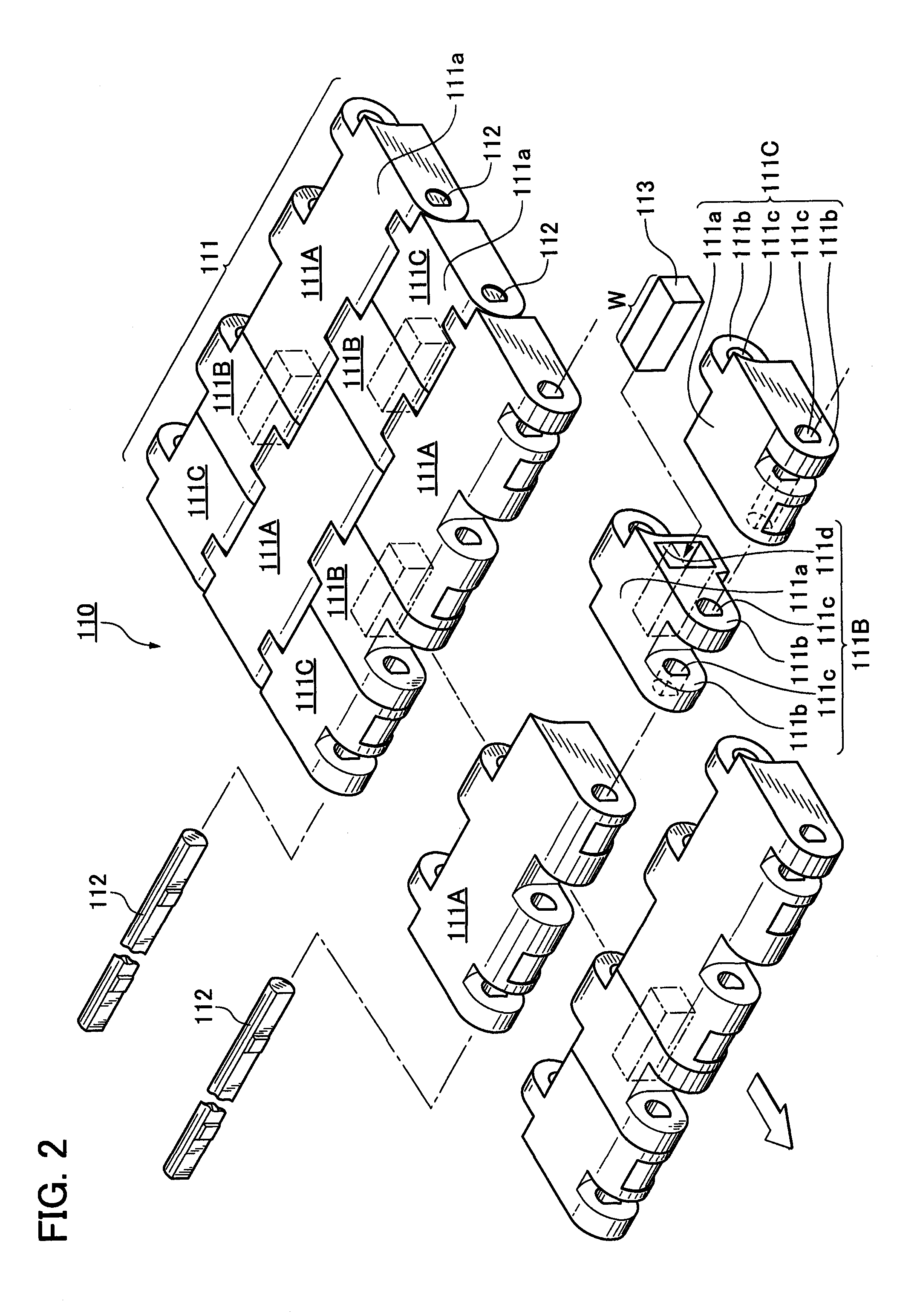

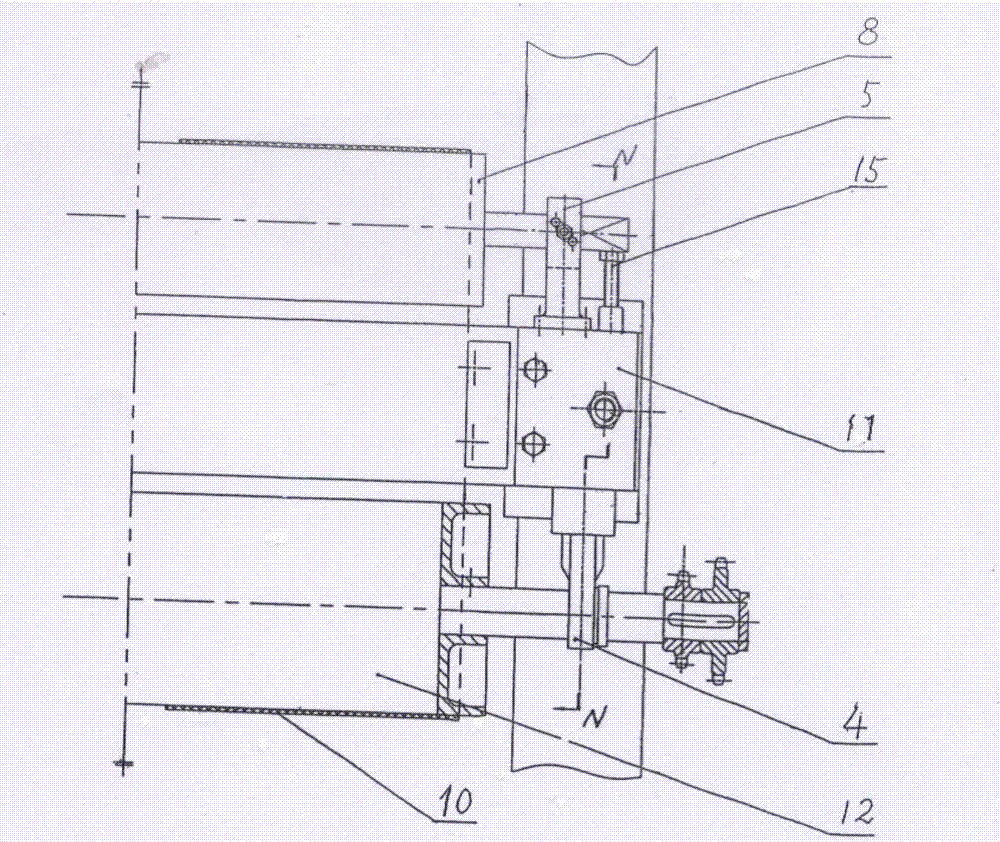

Chain conveyor system

The invention provides a chain conveyor system capable of avoiding damages and vibration noise by securely attracting and retaining metallic magnetic articles in inclined conveyor lines or slippery wet conveyor lines and of providing ready transfer or relay of the articles to other conveyors or equipment also in a conveyor terminal carry-out area. The chain conveyor system comprises a conveyor chain having article-attracting magnet pieces for attracting and retaining articles on loading surfaces thereof and an article-separating device that is disposed coaxially with a sprocket wrapped by and engaging with the conveyor chain and has article-separating magnet pieces that cut the attraction of the article-attracting magnet pieces with the articles on an outer circumferential parts of a free roller.

Owner:TSUBAKIMOTO CHAIN CO

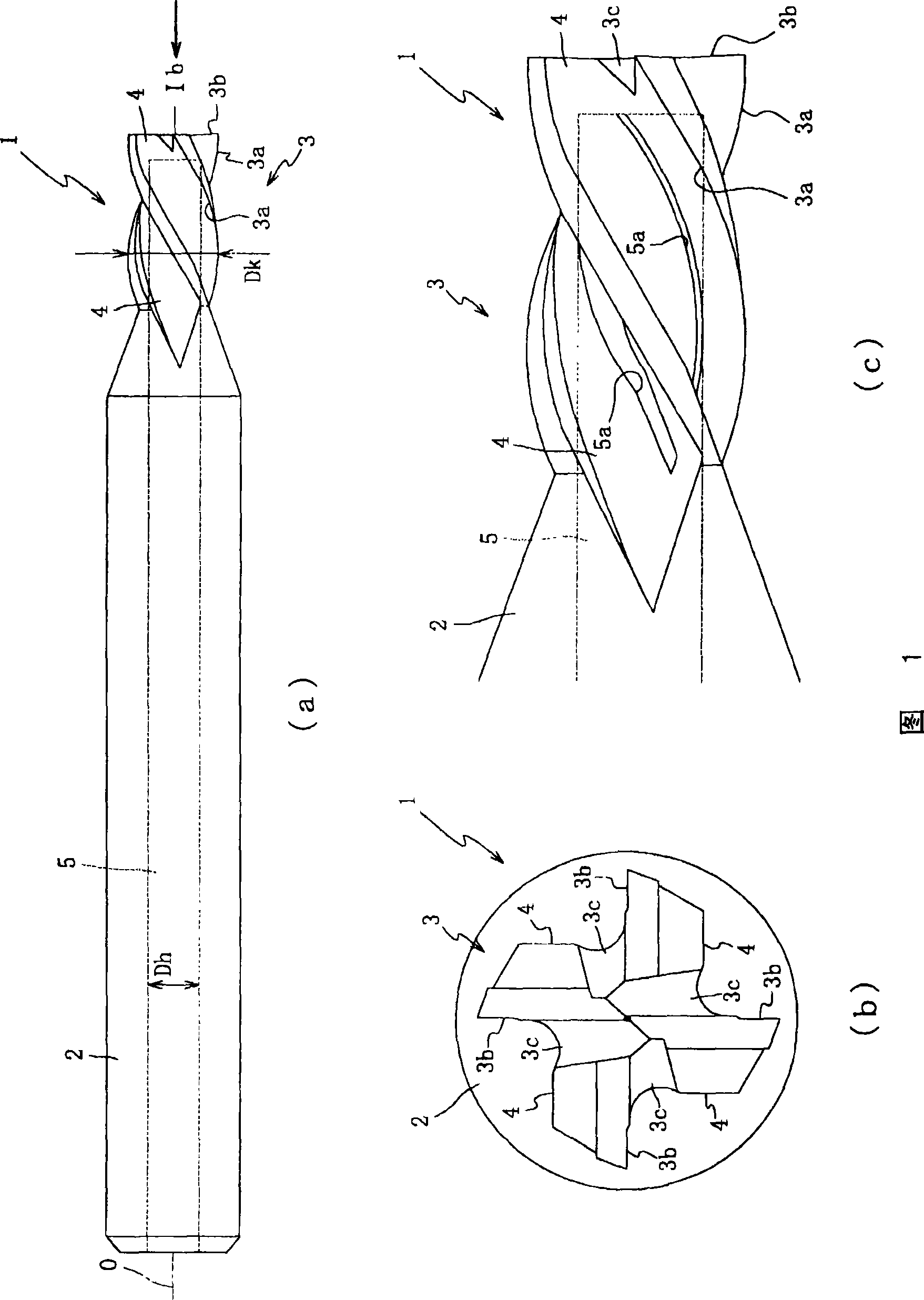

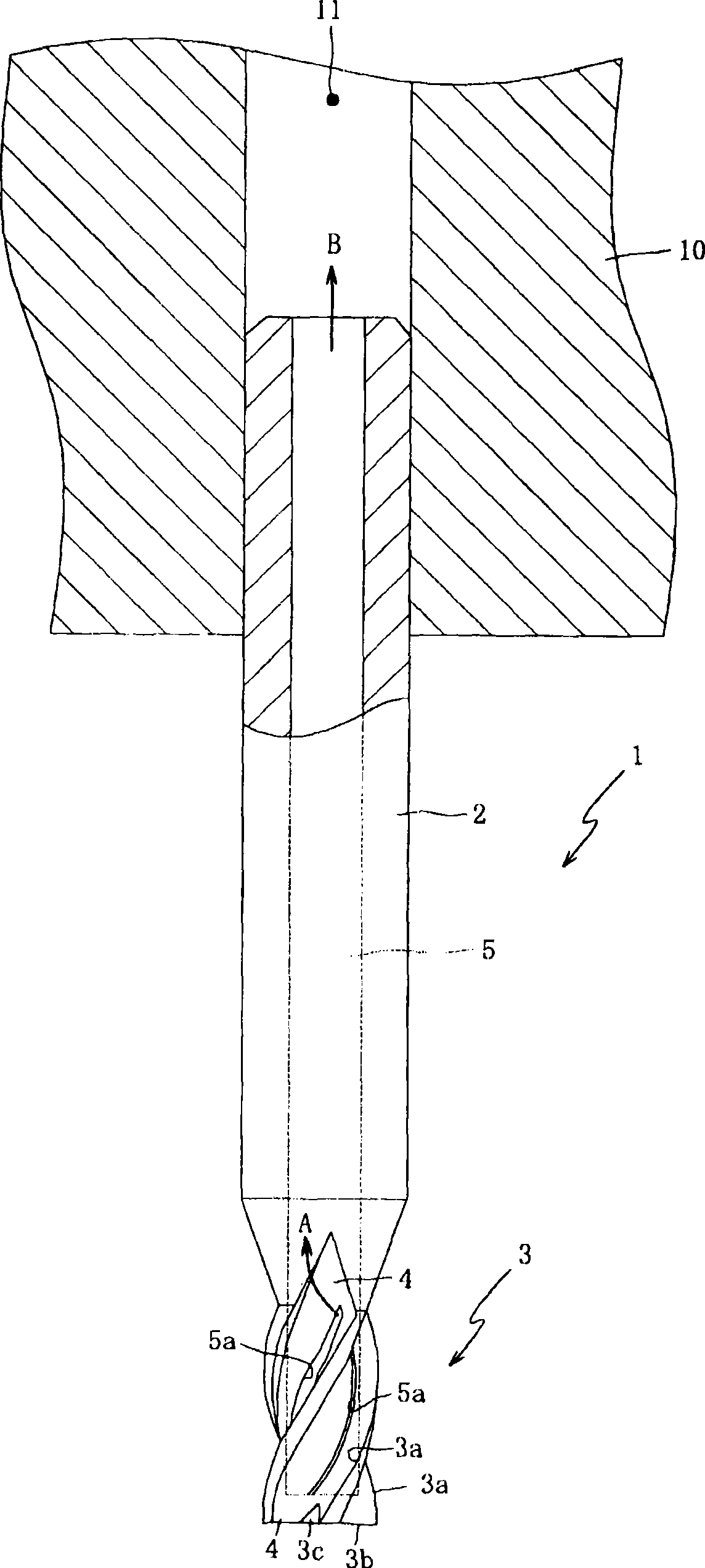

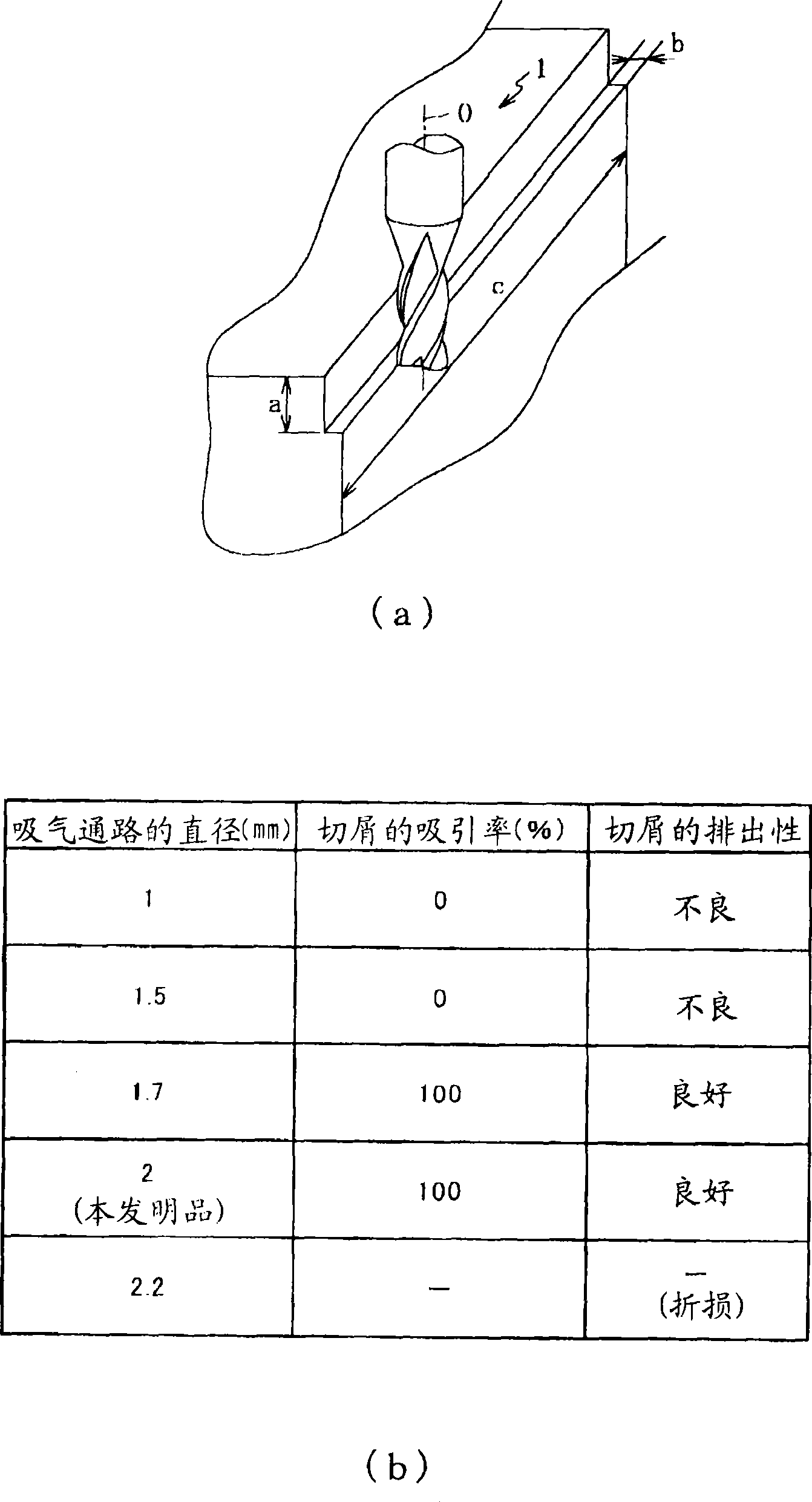

End milling tool

InactiveCN101394962AProhibition of useReduce recycling costsMilling cuttersShaping cuttersFluteMilling cutter

An end mill that realizes prevention of environmental pollution. End mill (1) has aperture (5a) resulting from opening forming along helical flute (4). The aperture (5a) is so structured as to communicate via air suction channel (5) with an opening of the rear end face of shank (2). Accordingly, by air suction through the air suction channel (5), chips generated at cutting processing can be forcibly suctioned from the aperture (5a), and the suctioned chips can be discharged outside from the opening of the rear end face of shank (2). As a result, as compared with conventional products, the use of cutting liquid for eliminating of chips can be suppressed (or rendered unnecessary) to thereby attain prevention of environmental pollution.

Owner:OSG

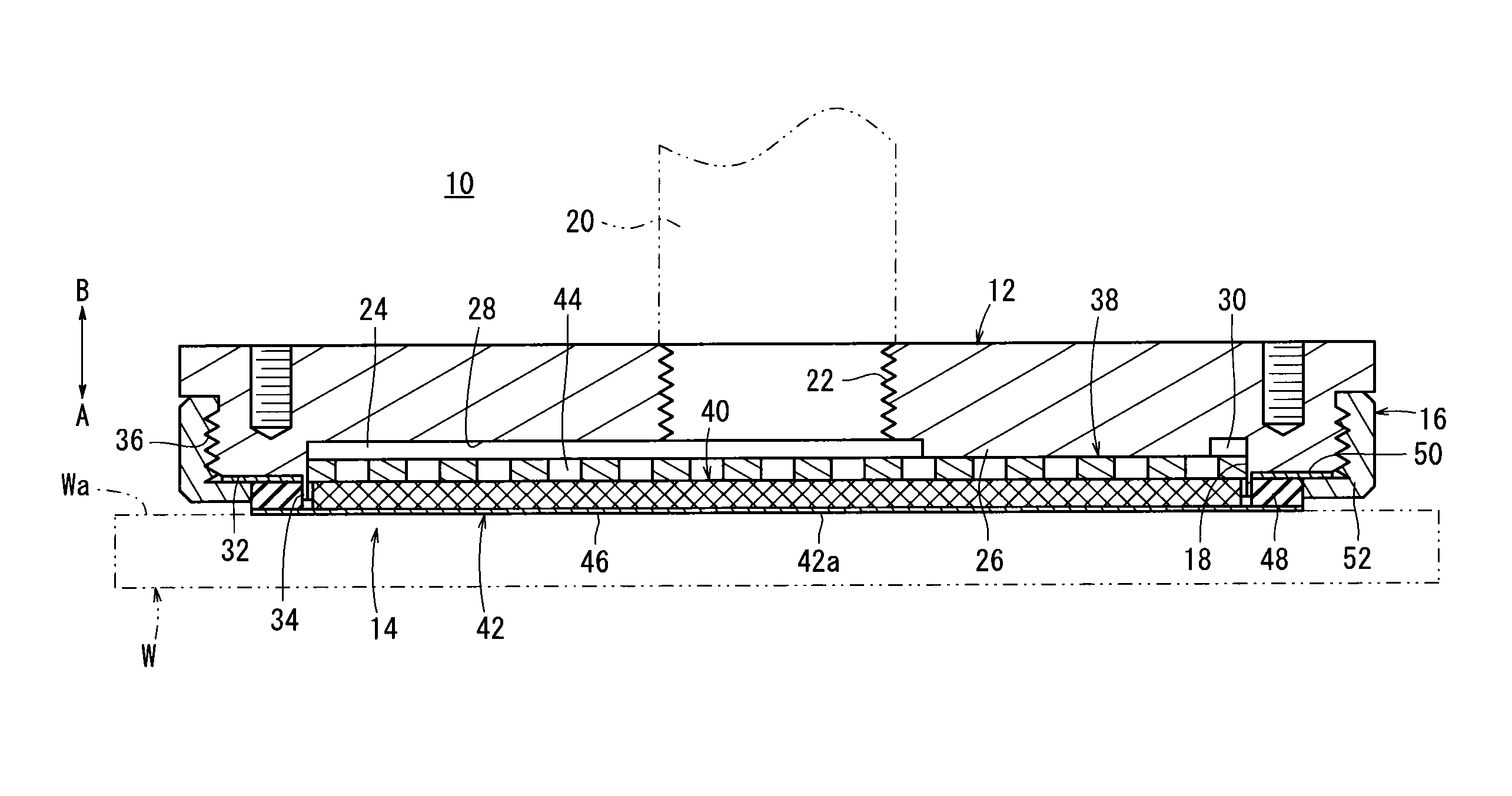

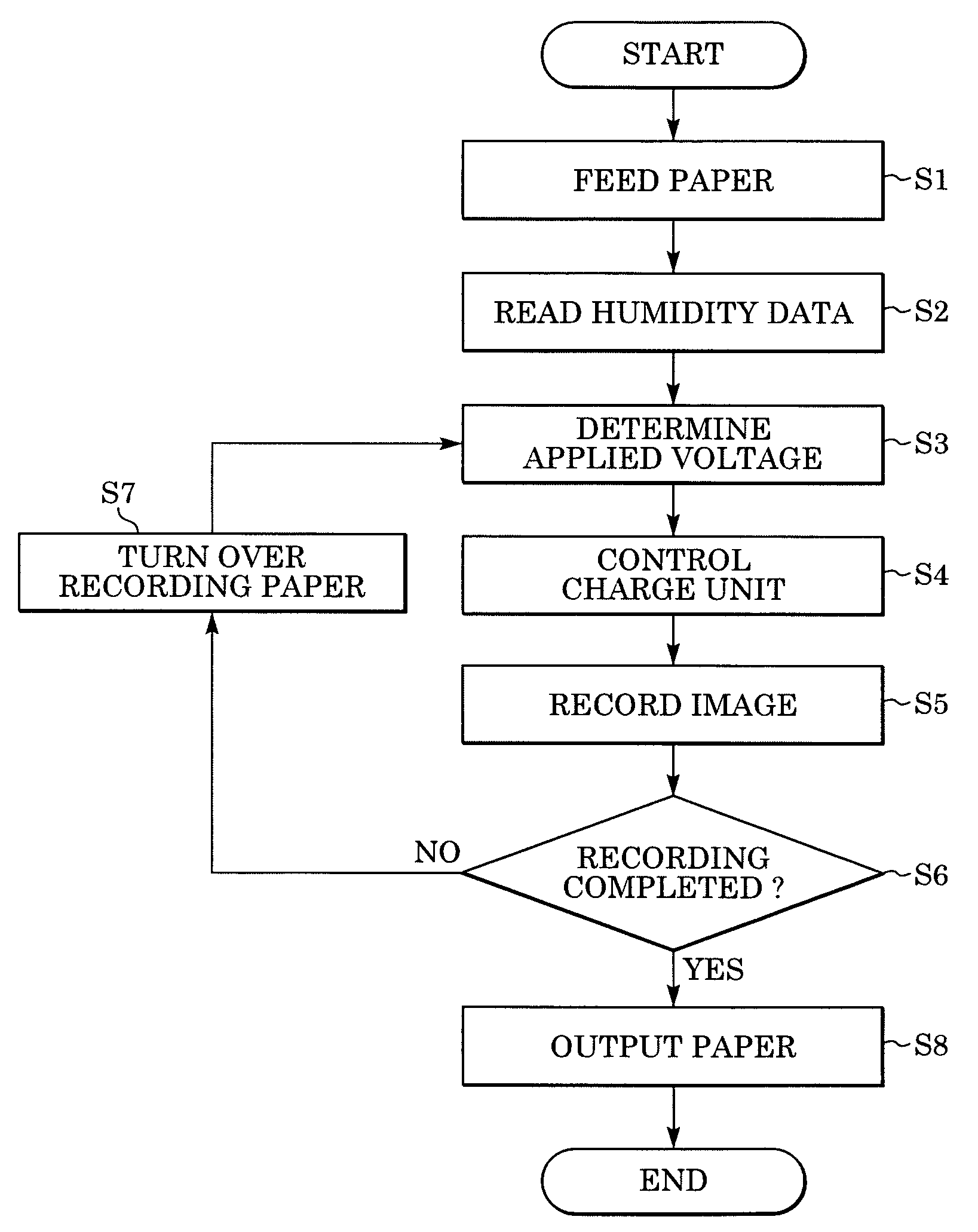

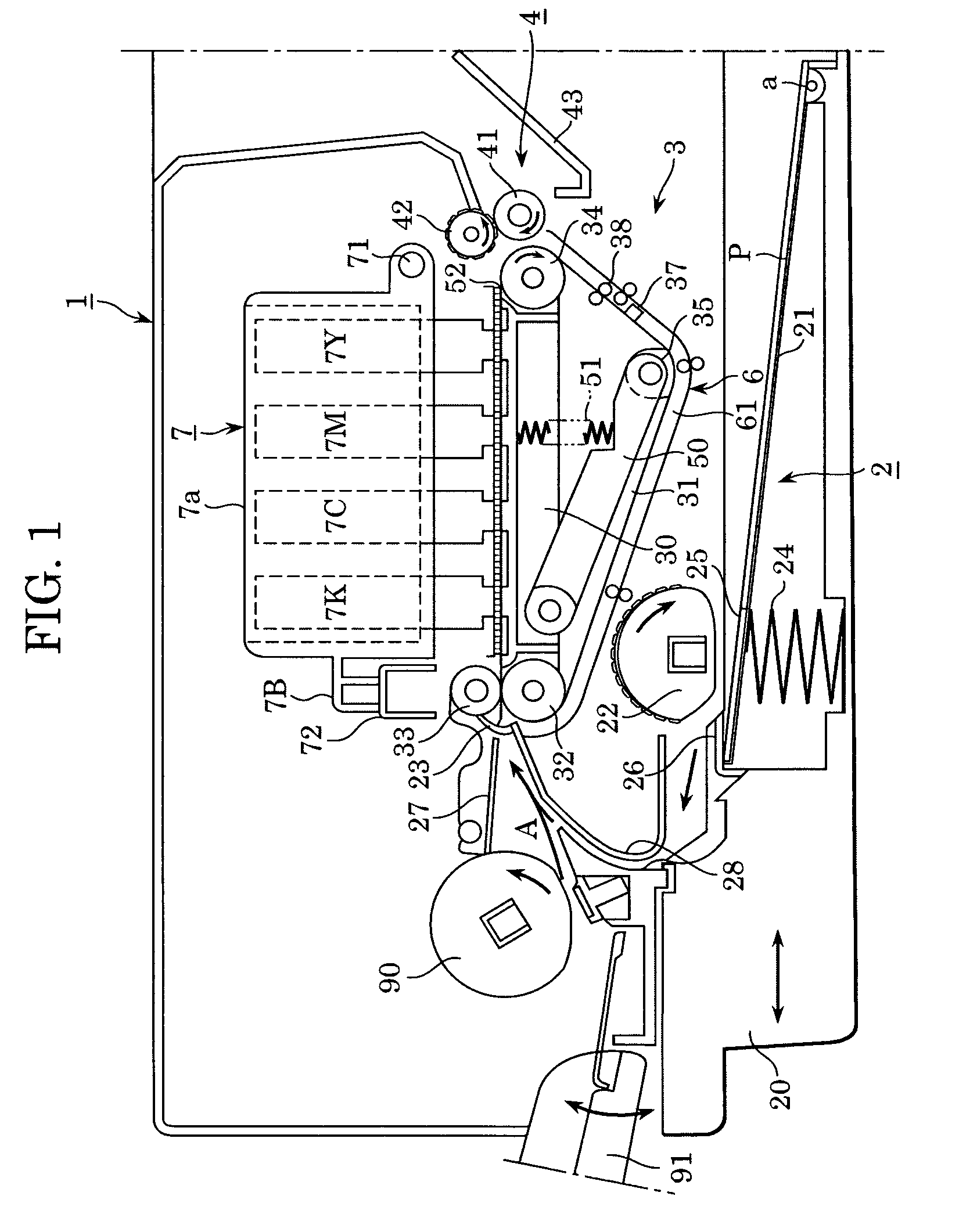

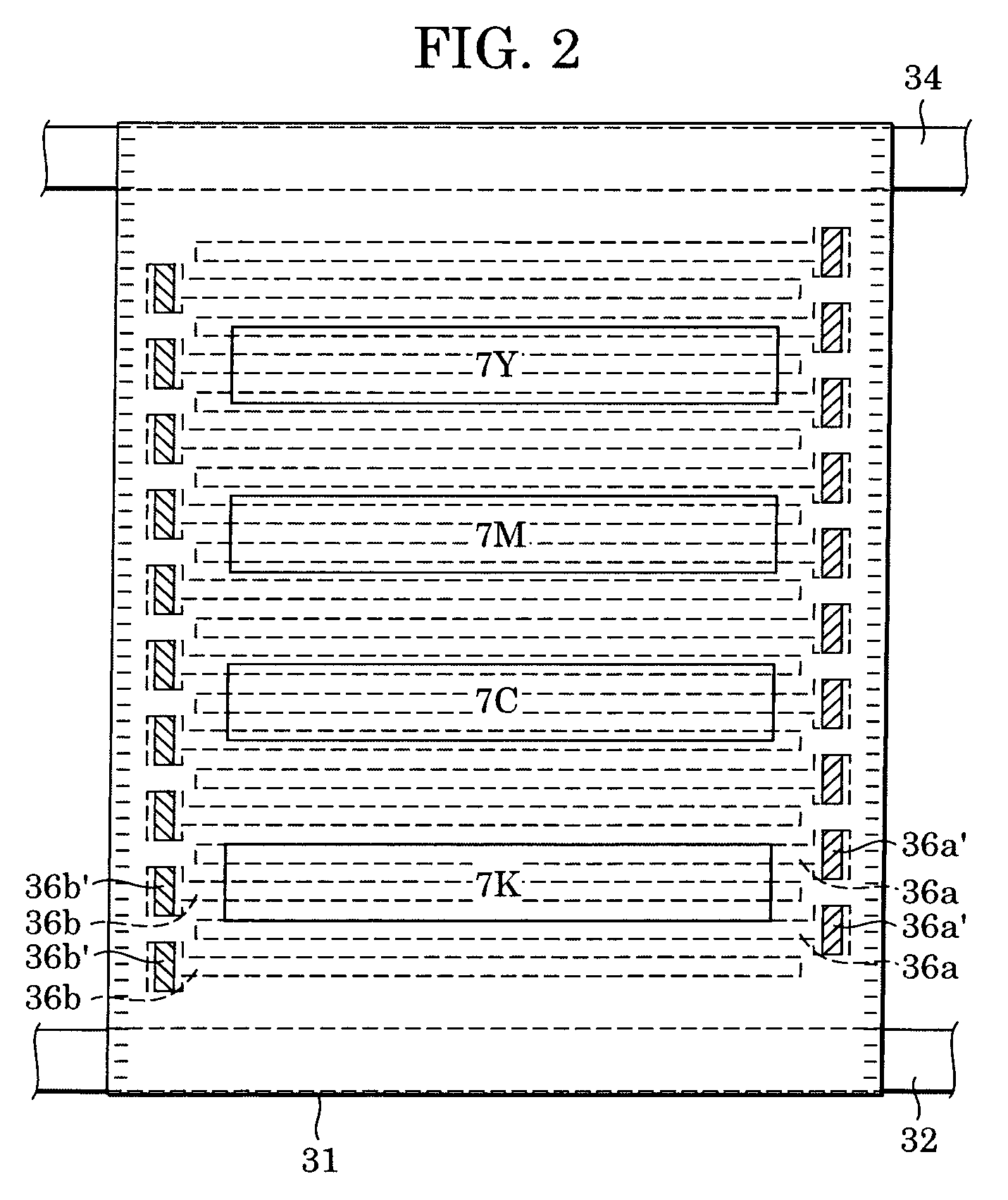

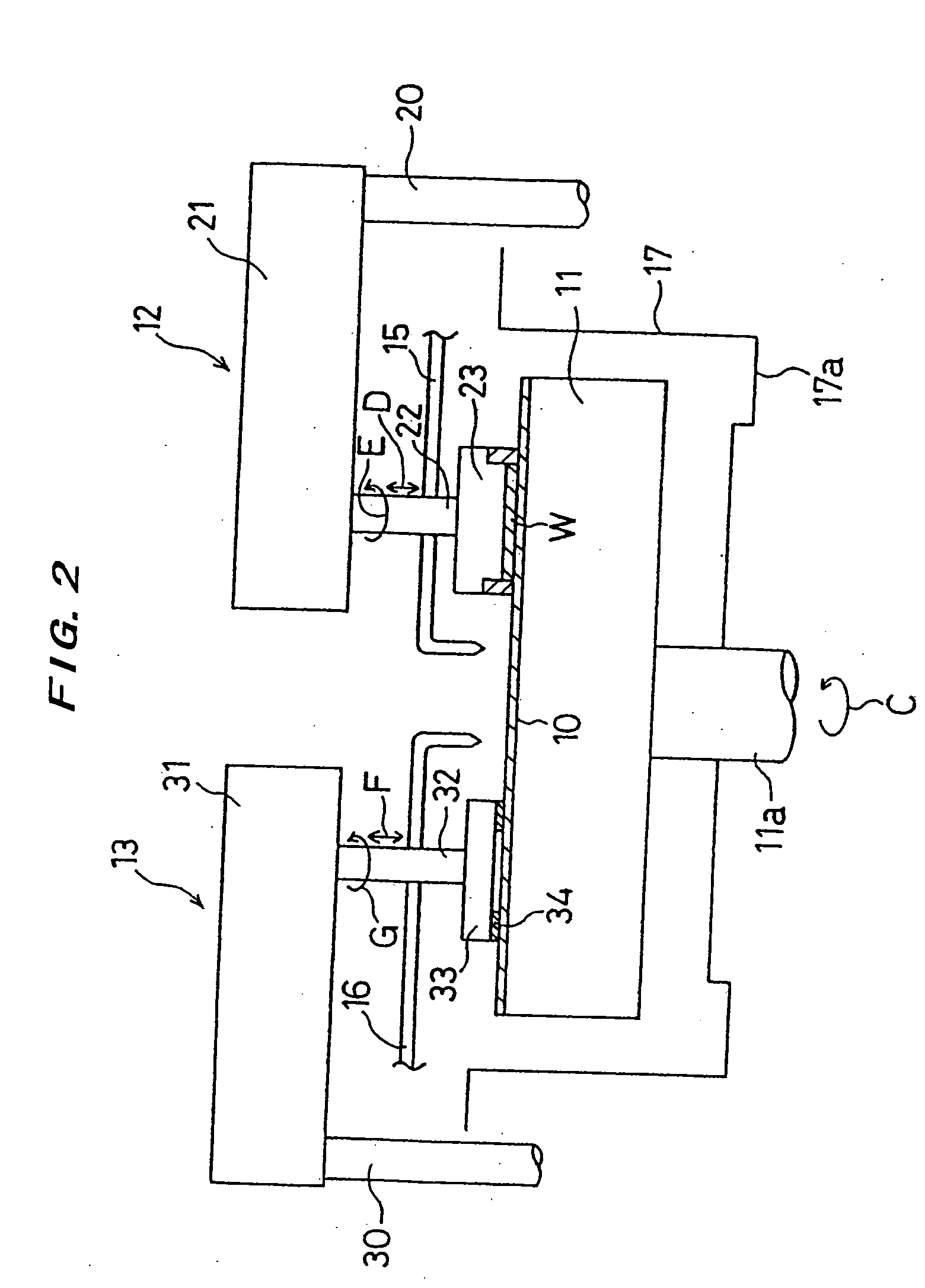

Transport apparatus and recording apparatus

InactiveUS7396123B2Reliable attractionIncrease forceOverturning articlesTypewritersPotential differenceEngineering

A recording apparatus includes a recording unit for recoding on a recording medium by ejecting ink, a conveyor belt for transporting the medium, first and second electrode groups including a plurality of electrodes inside the conveyor belt, a charging unit for charging the first and second electrode groups to provide a potential difference between the first and second electrode groups in order to generate an electrostatic force for attracting the medium to the conveyor belt, a duplex transport unit for turning over the medium transported by the conveyor belt from a first surface upward to a second surface upward and delivering the medium to the conveyor belt with the second surface upward, and a control unit for controlling the charging unit so that a difference between the potentials of the first and second electrode groups during transportation of the medium with the second surface upward is different from that during transportation of the medium with the first surface upward.

Owner:CANON KK

Polishing method

InactiveUS7163895B2Reliable attractionReliable releaseSemiconductor/solid-state device manufacturingLapping machinesSemiconductorFluid pressure

Owner:EBARA CORP

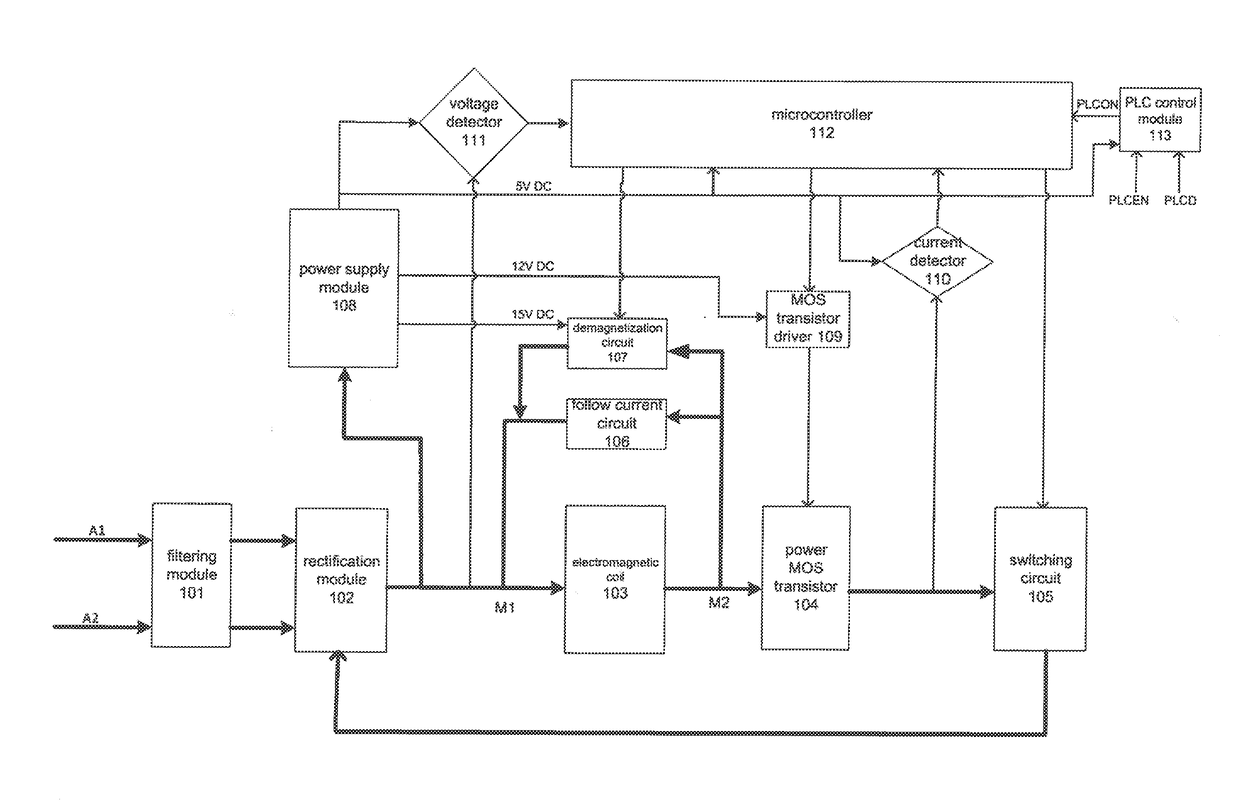

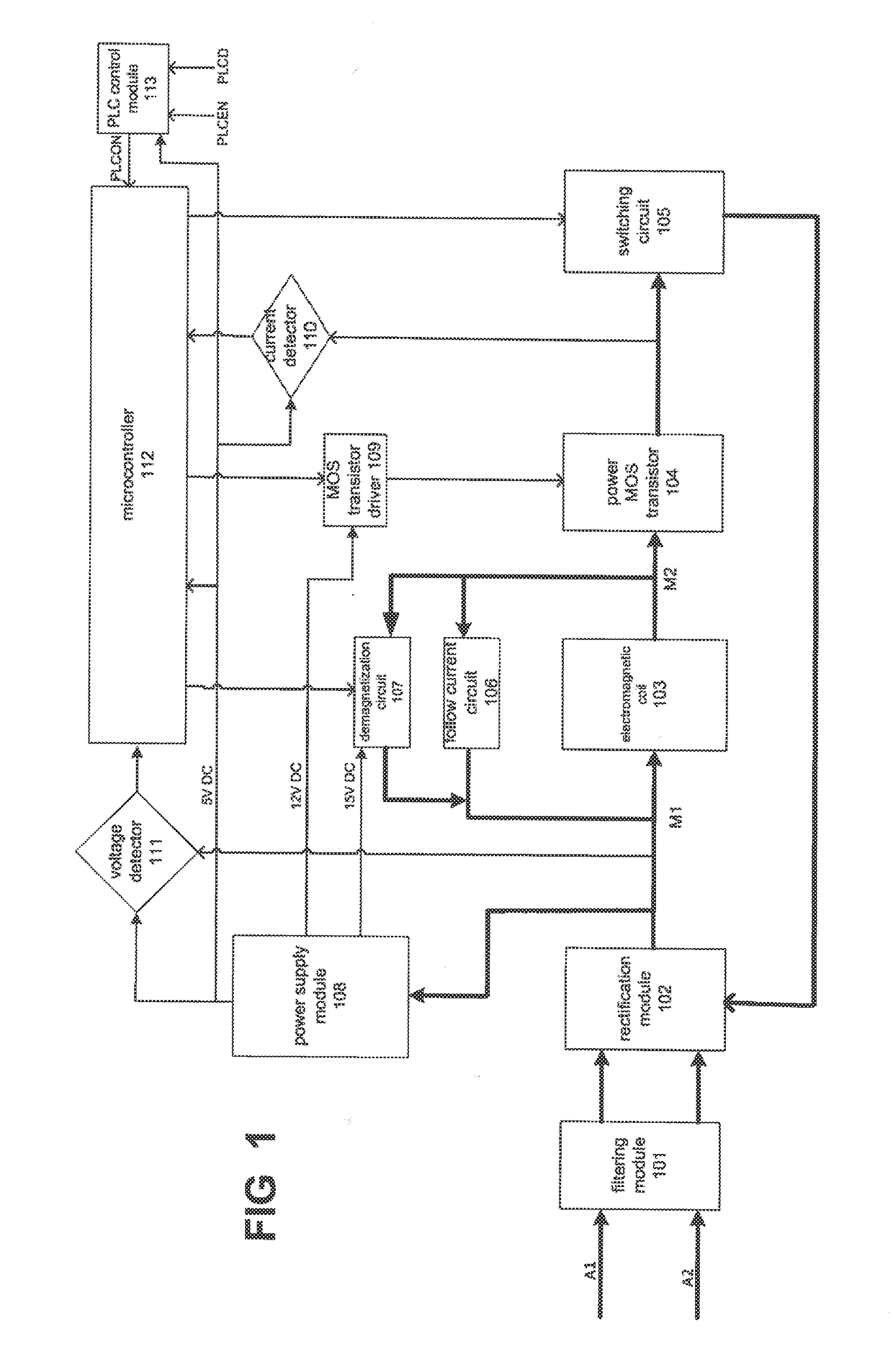

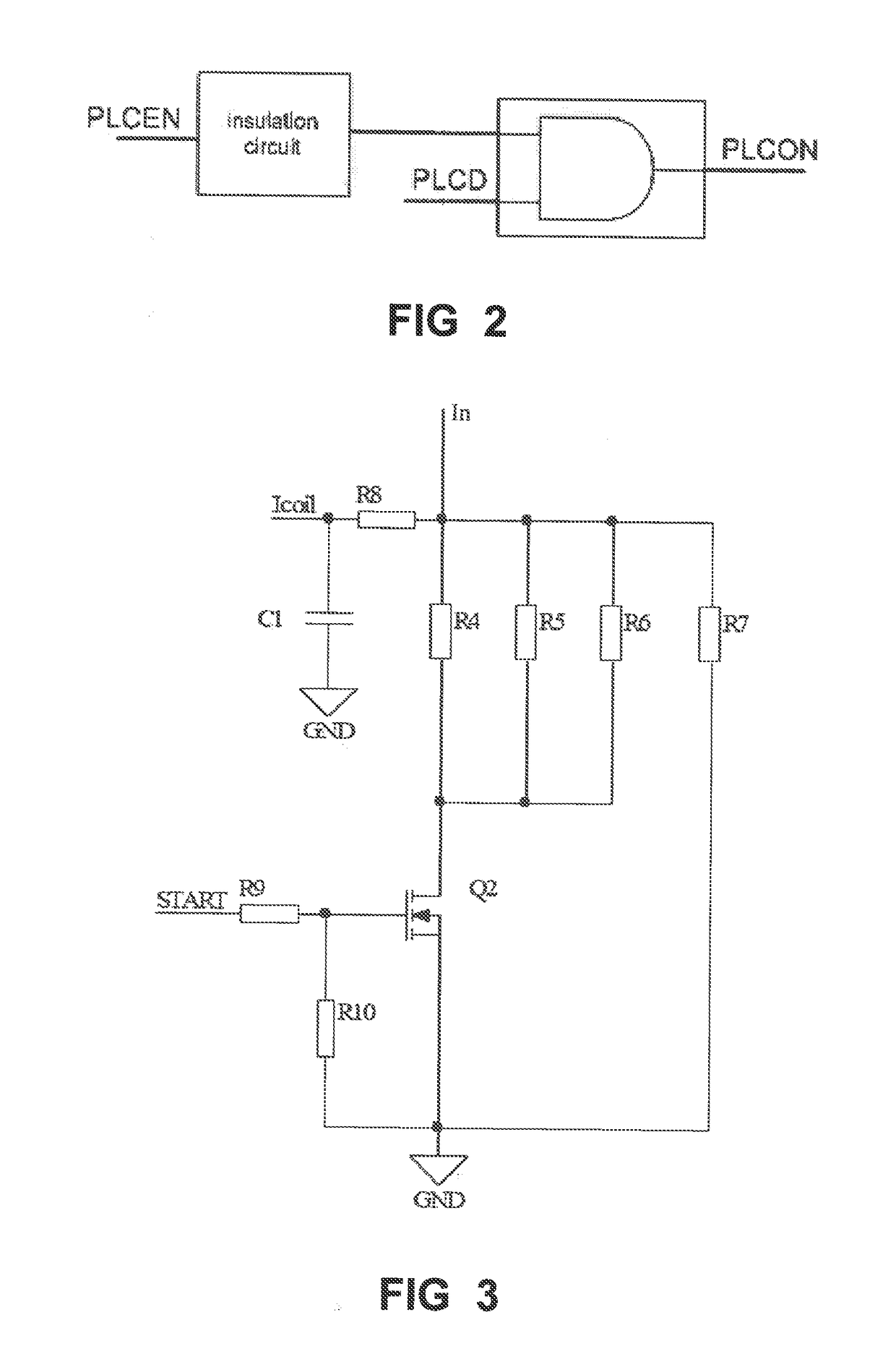

Controller and control method for alternating current contactor

ActiveUS20170213677A1Low power consumptionSmall sizeAc-dc conversion without reversalArrangements responsive to excess currentContactorVoltage control loop

A controller for an alternating current contactor includes: a filtering and rectification circuit that filters and rectifies external alternating current; an electromagnet component driven by an output of the filtering and rectification circuit that performs actions of attraction, holding or releasing; a power transistor circuit connected to the electromagnet component; and a microcontroller that controls the power transistor circuit to control the actions performed by the electromagnet component. The controller further includes a voltage control loop that provides a voltage feedback signal and a current control loop that provides a current feedback signal to the microcontroller. The microcontroller generates a control signal according to the voltage feedback signal. The control signal is a PWM control signal having different duty cycles during the attraction and holding of the electromagnet component so that the current does not exceed a predetermined current threshold during the attraction and bolding of the electromagnet component.

Owner:SEARI ELECTRIC TECH +1

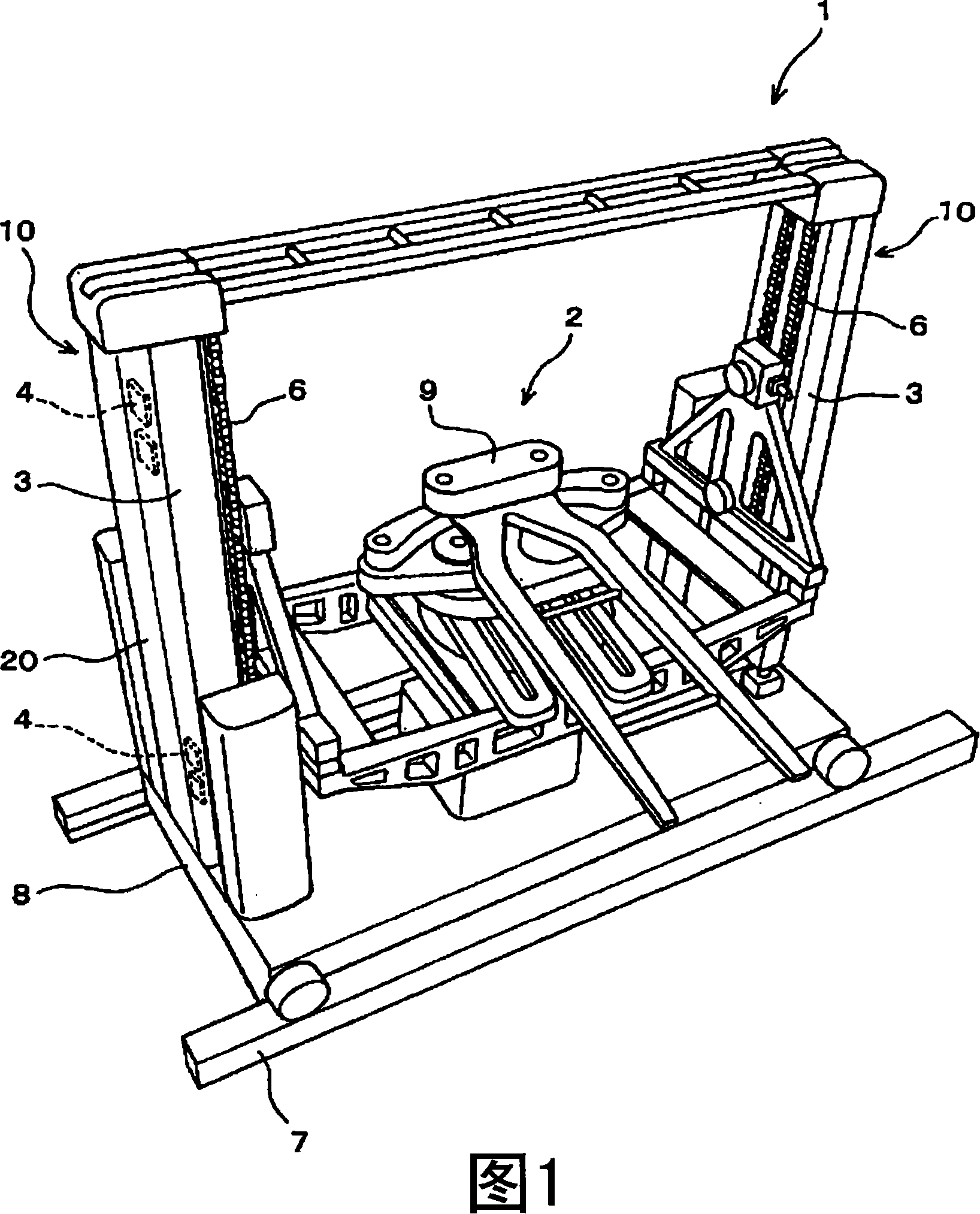

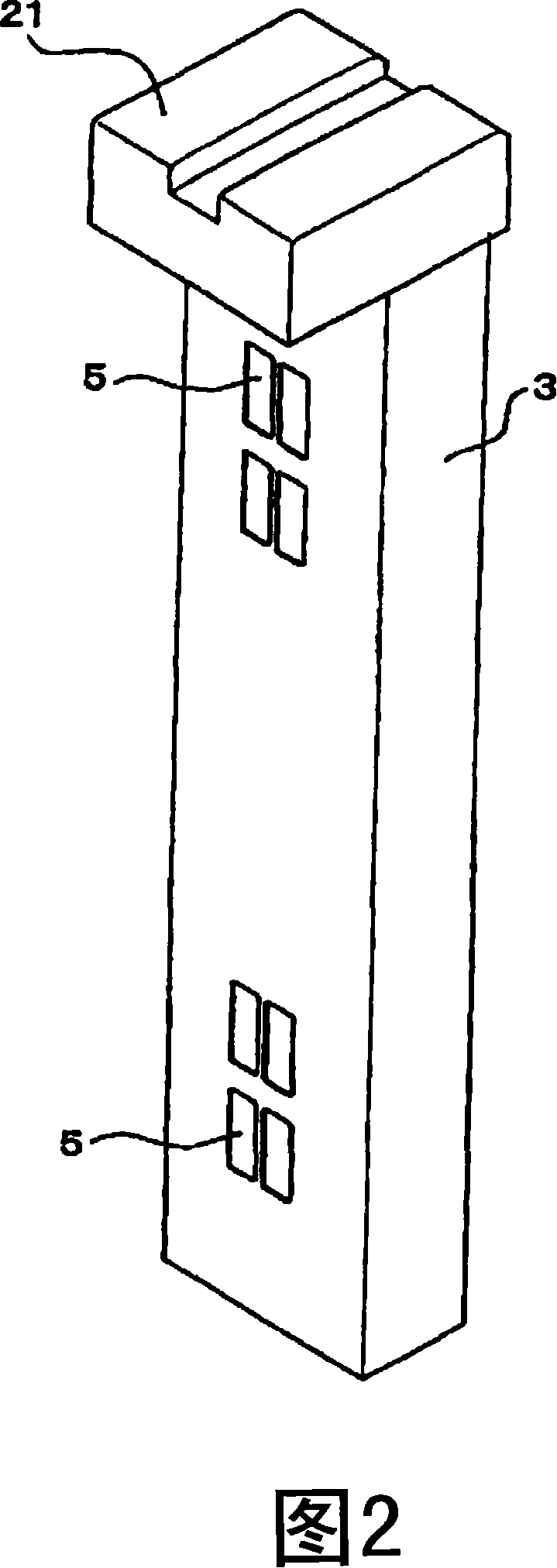

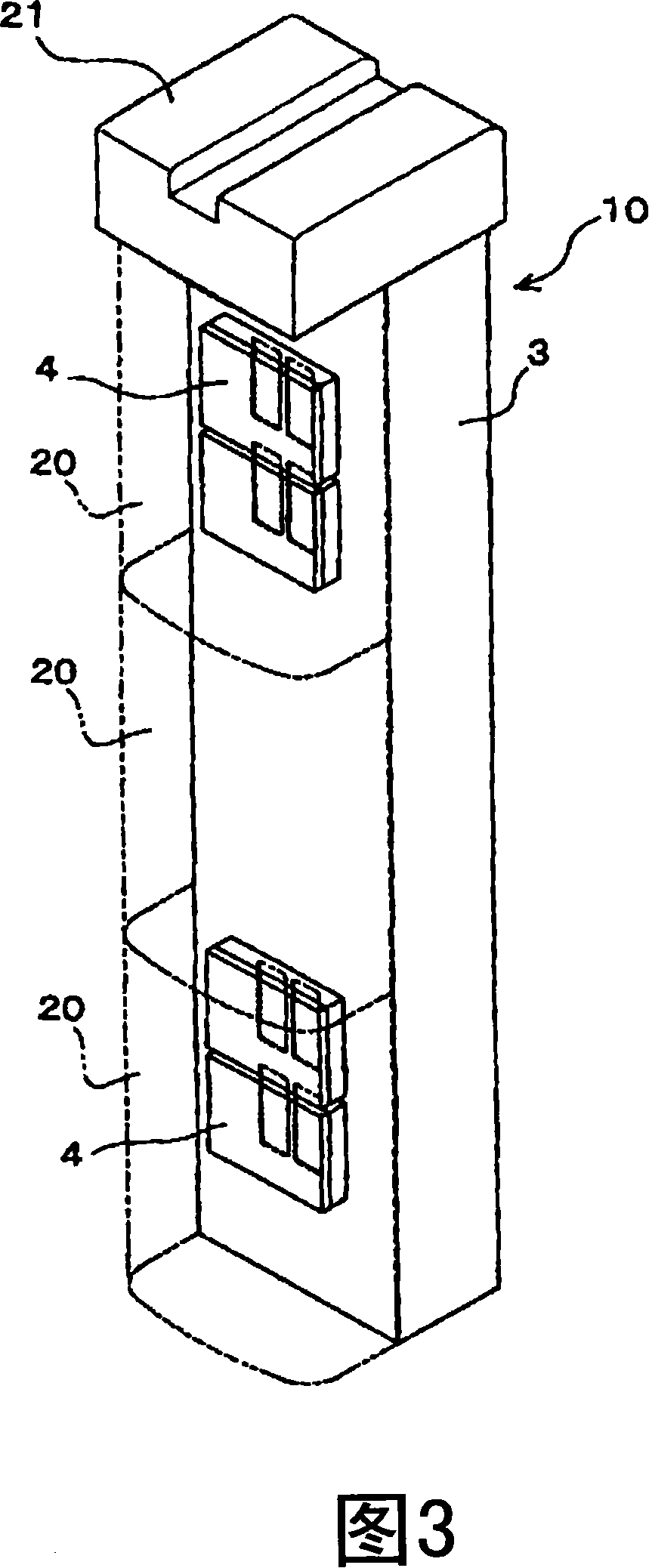

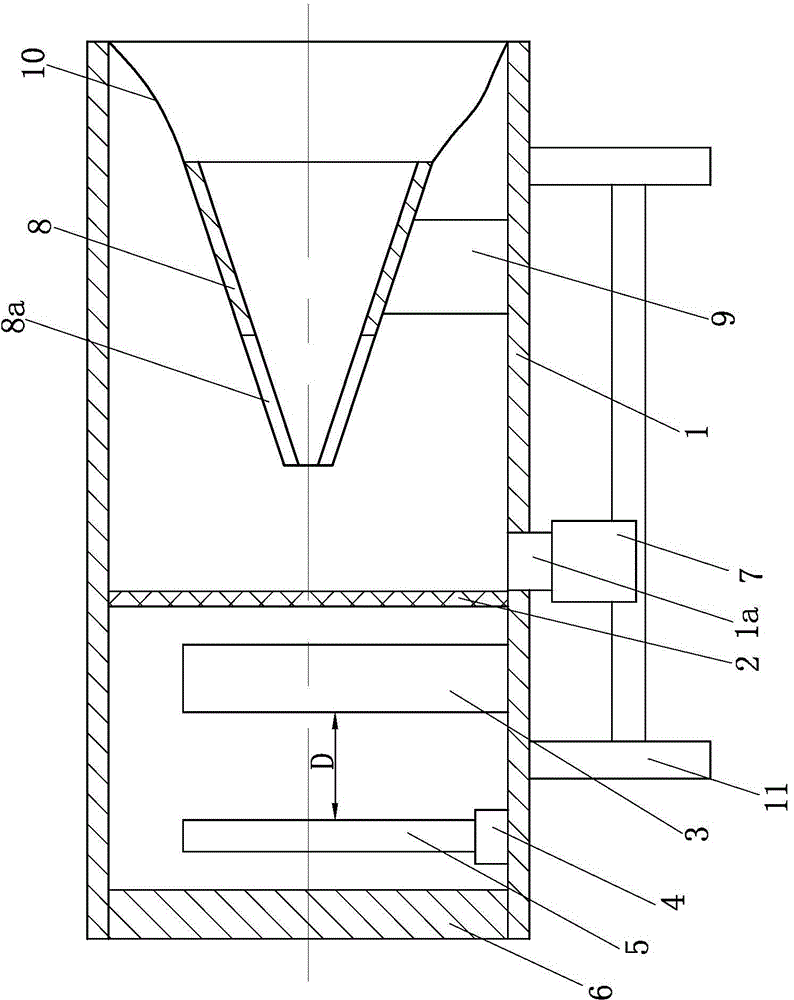

Lifting device

InactiveCN101148217AReliable attractionReliable captureDispersed particle filtrationStorage devicesEngineeringMechanical engineering

A lifting device is provided, reliably catching generated dust and leading clean-room to avoid pollution. A support main body (3) of the lifting device (1) has opening part (5), built-in a fan filter unit (4) and is integrated.

Owner:MURATA MASCH LTD

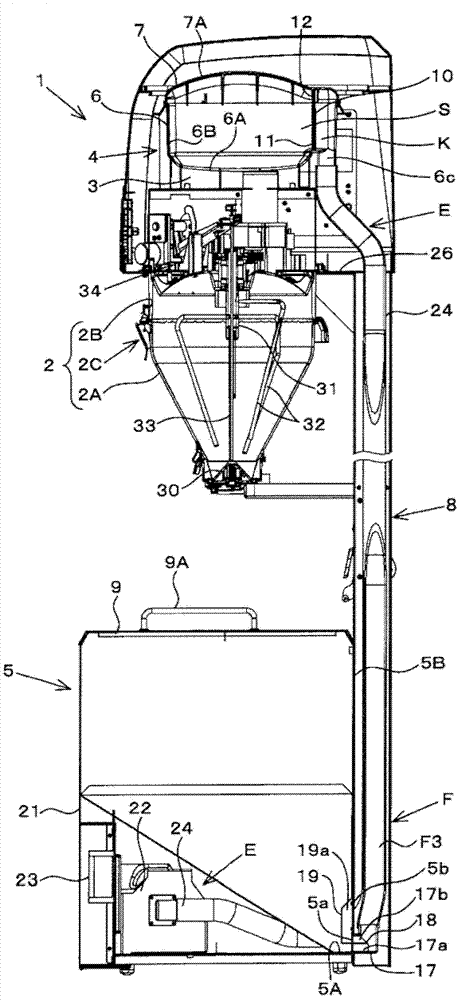

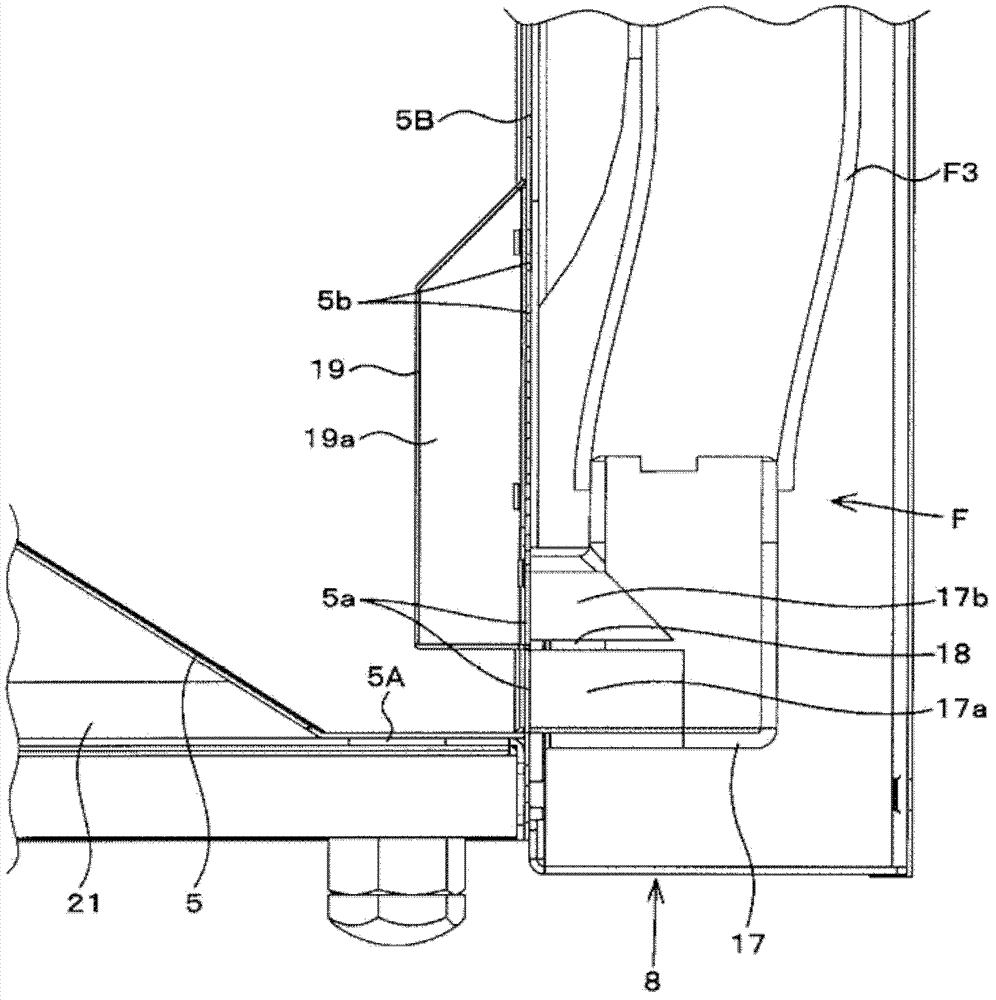

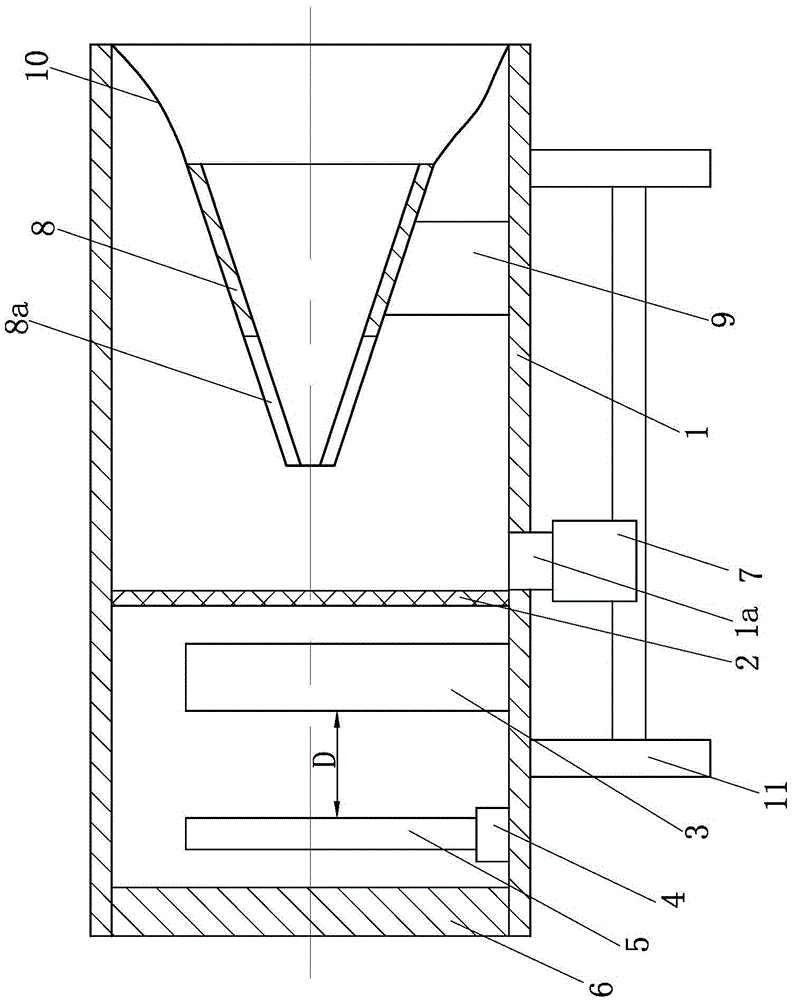

Rice washer

ActiveCN103028458AReliable attractionInternal volume reductionGrain millingEngineeringPressure units

Provided is a rice washer, comprising a rice washing case for washing rice, a meter which conducts counting on rice and feeds rice into the rice washing case, an upper hopper which can store rice and supply rice to the meter, a negative pressure unit which enables the internal part of the upper hopper to have negative pressure, a rice storing warehouse which is disposed below the rice washing case and stores rice, and a rice conveying unit which attracts and conveys rice in the rice storing warehouse by means of the negative pressure in the upper hopper. The rice conveying unit is provided with a suction port which is disposed at the lowest part of the side wall of the rice storing warehouse and is used for rice fetching. The suction port is connected to a rice channel for attracting rice and is connected to a rice attracting component communicated with the upper hopper, forming an air channel which is adjacent to the rice channel (17a) of the rice attracting component, and attracts air from outside of the rice storing warehouse to generate negative pressure of the rice channel. With the rice washer, rice at the bottom of the rice storing warehouse can be reliably attracted.

Owner:KUBOTA LTD

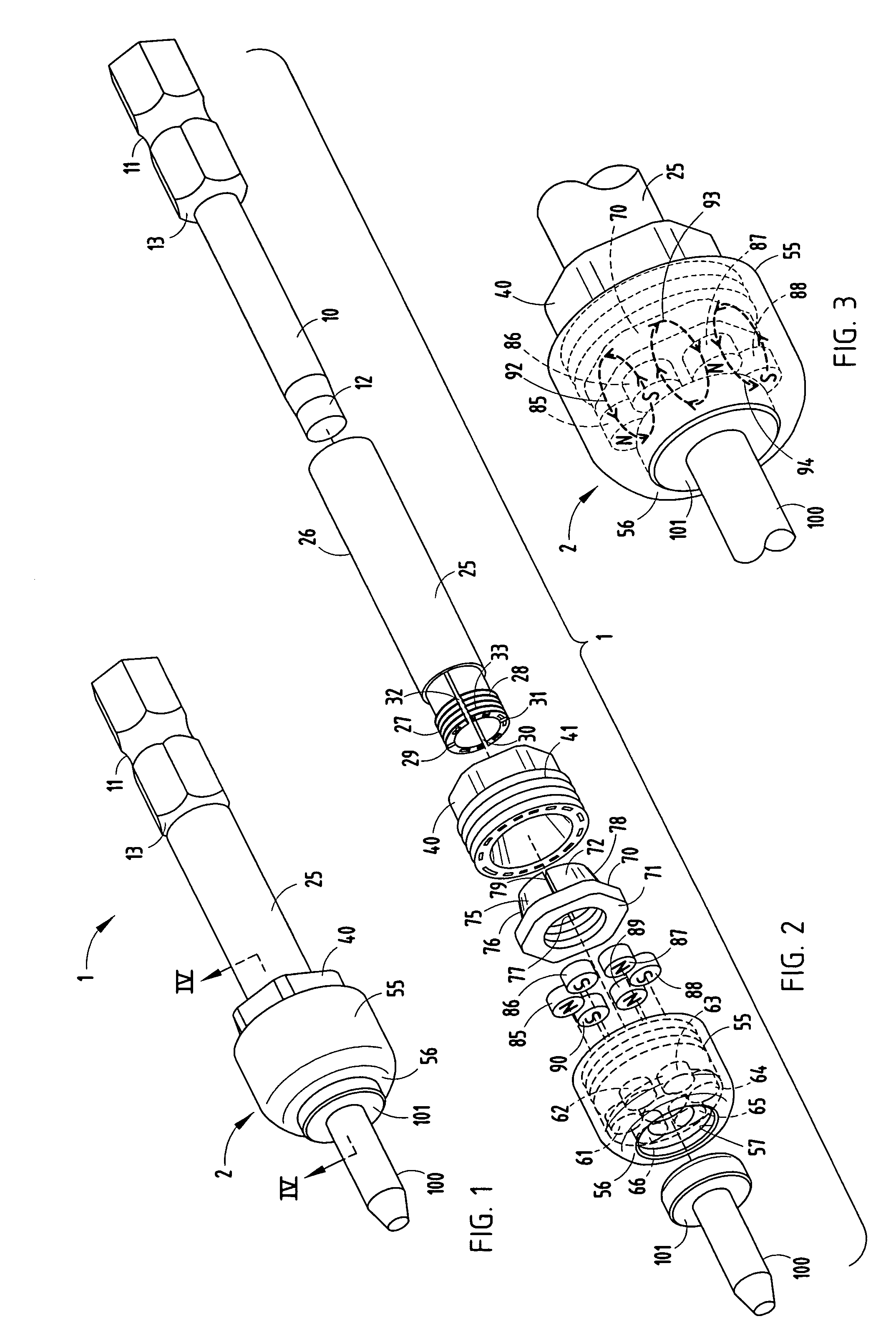

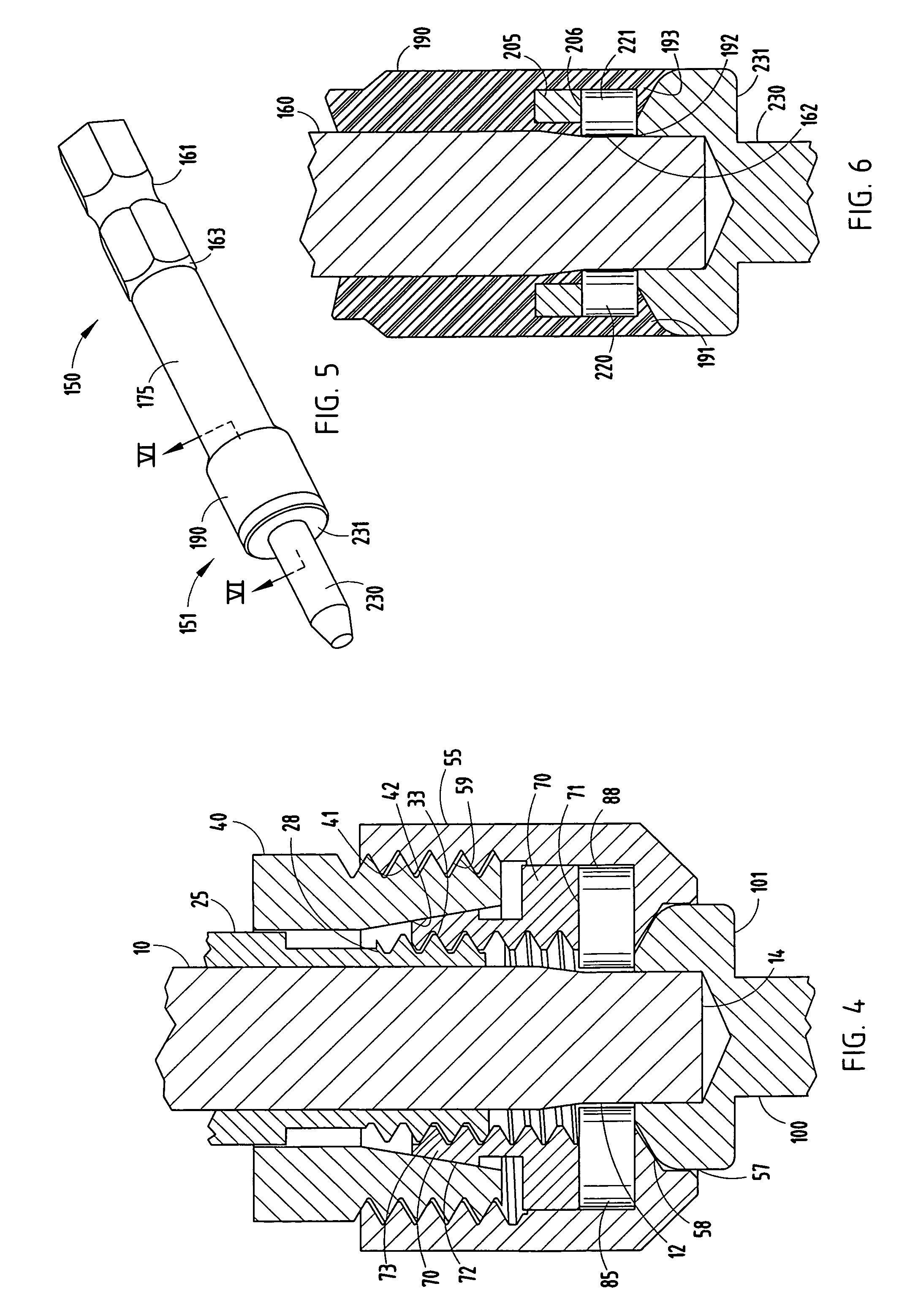

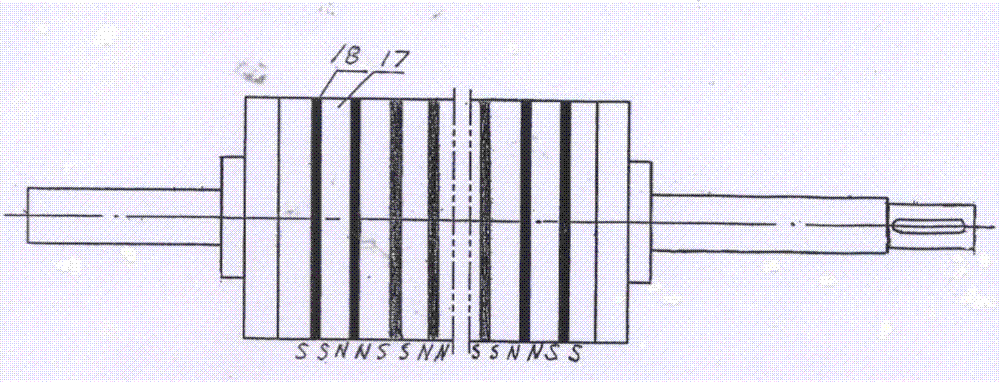

Magnetic device for attracting and retaining fasteners

A magnetic device for attracting and retaining a fastener which has a bit, a generally ring-shaped keeper having a bottom surface, at least some portion of which bottom surface is magnetized, at least one pair of magnets, each pair of magnets having two magnets with alternating poles, adjacent to the magnetic bottom surface of the keeper and arranged around the bit such that an even number of magnets with alternating poles is arranged around the bit, and a non-magnetic holder that secures the keeper and the magnets and surrounds the bit. The magnets provide magnetic flux to the keeper and the fastener. Each pair of adjacent magnets provides a closed magnetic flux path through a first magnet of the pair, the keeper, a second magnet of the pair, and the fastener. The location of the magnetic device along the bit may be adjustable or fixed.

Owner:DELPHI TECH IP LTD

Autonomous travel-type cleaner

ActiveCN109982624AReliable attractionImprove cleaning efficiencySuction nozzlesElectric equipment installationEngineering

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

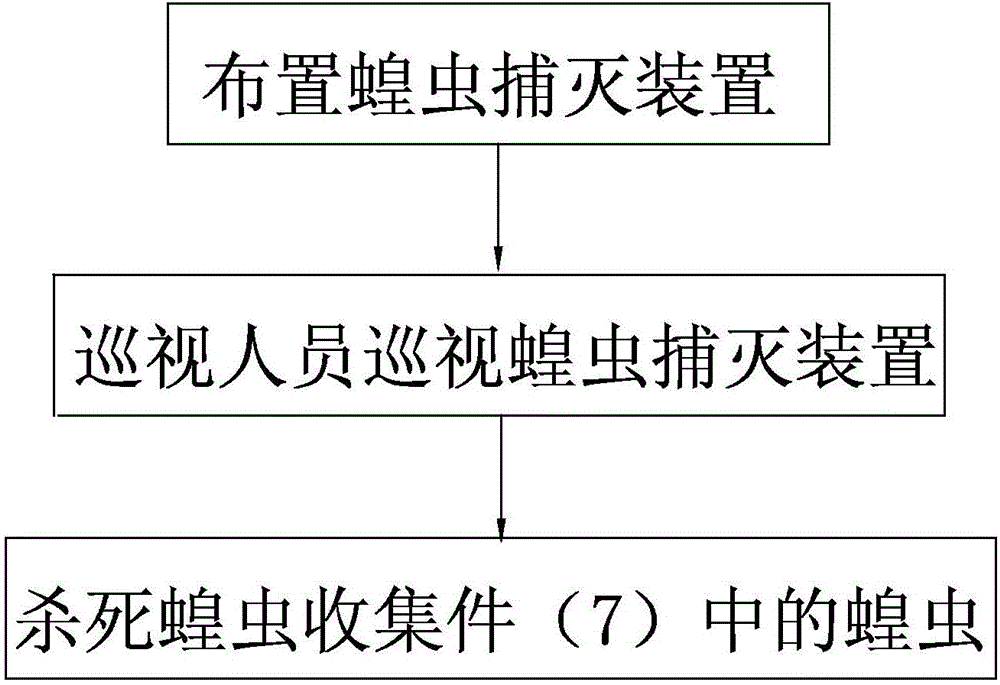

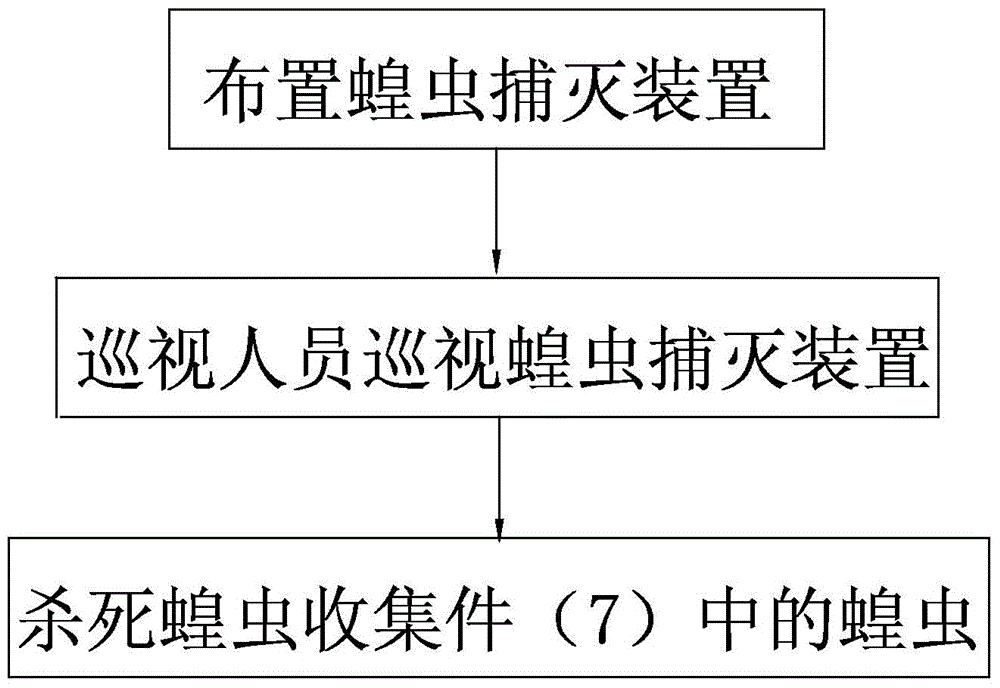

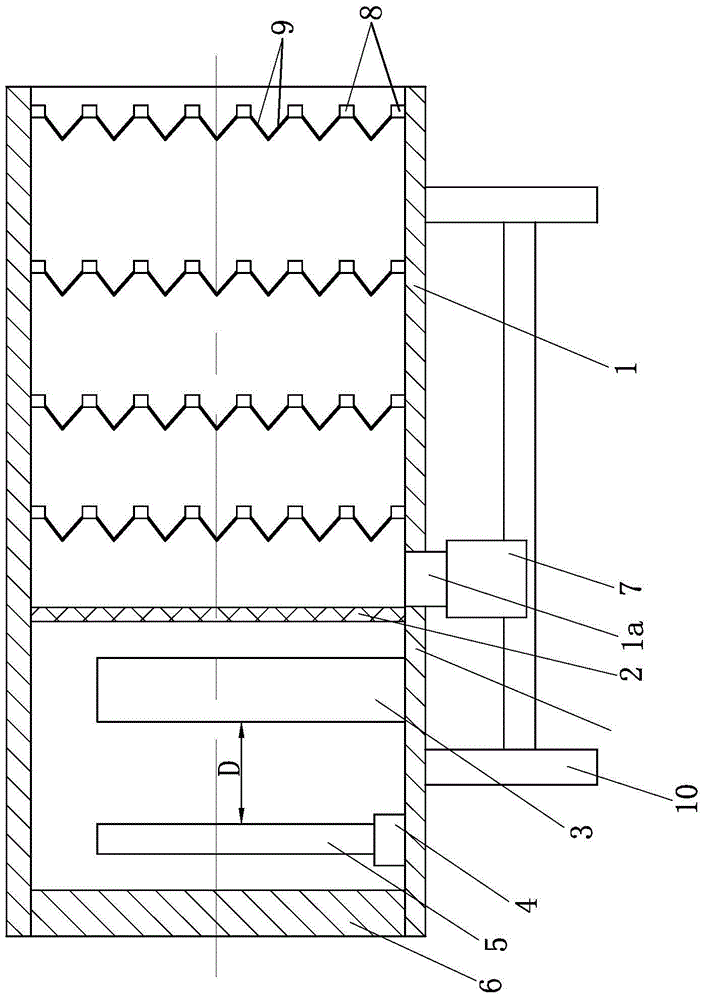

Locust catching and killing method

InactiveCN104521919AReliable attractionAttract effectiveAnimal repellantsInsect catchers and killersBristleLocust

The invention discloses a locust catching and killing method. The method is characterized by including the following steps that (1) a group of locust catching killing devices is arranged in a area where locusts gather, and a layer of barrier net is arranged in a locust killing box in each locust catching killing device; groups of heaters and fixing sleeves are vertically arranged on inner surfaces of lower box bodies of the locust killing boxes on left sides of the barrier nets respectively; a bristle brush is inserted into each fixing sleeve, and sex pheromone adheres to the bristle brush; locust outlets are vertically designed in lower box walls of the locust killing boxes on right sides of the barrier nets, and locust collecting parts are fixed on the lower portions of the locust outlets; (2) an inspecting person inspects the locust killing device one by one at set intervals; (3) the locusts in the locust collecting parts that are taken down at the step (2) are totally killed. According to the locust catching and killing method, the locusts are allured by means of the sex pheromone on the bristle brush and infrared radiation during heating of the heaters, the locusts can be reliably and effectively allured, finally, the locusts are gathered and totally killed, the locust killing is convenient and efficient, locust catching killing costs are quite low, and the labor intensity of workers is extremely low.

Owner:CHONGQING LIZHENYUAN AGRI & FORESTRY TECH

Chain Conveyor System

ActiveUS20120241291A1Avoid damageAvoid vibration noiseConveyorsSupporting framesEngineeringChain conveyor

The invention provides a chain conveyor system capable of avoiding damages and vibration noise by securely attracting and retaining metallic magnetic articles in inclined conveyor lines or slippery wet conveyor lines and of providing ready transfer or relay of the articles to other conveyors or equipment also in a conveyor terminal carry-out area. The chain conveyor system comprises a conveyor chain having article-attracting magnet pieces for attracting and retaining articles on loading surfaces thereof and an article-separating means that is disposed coaxially with a sprocket wrapped by and engaging with the conveyor chain and has article-separating magnet pieces that cut the attraction of the article-attracting magnet pieces with the articles on an outer circumferential parts of a free roller.

Owner:TSUBAKIMOTO CHAIN CO

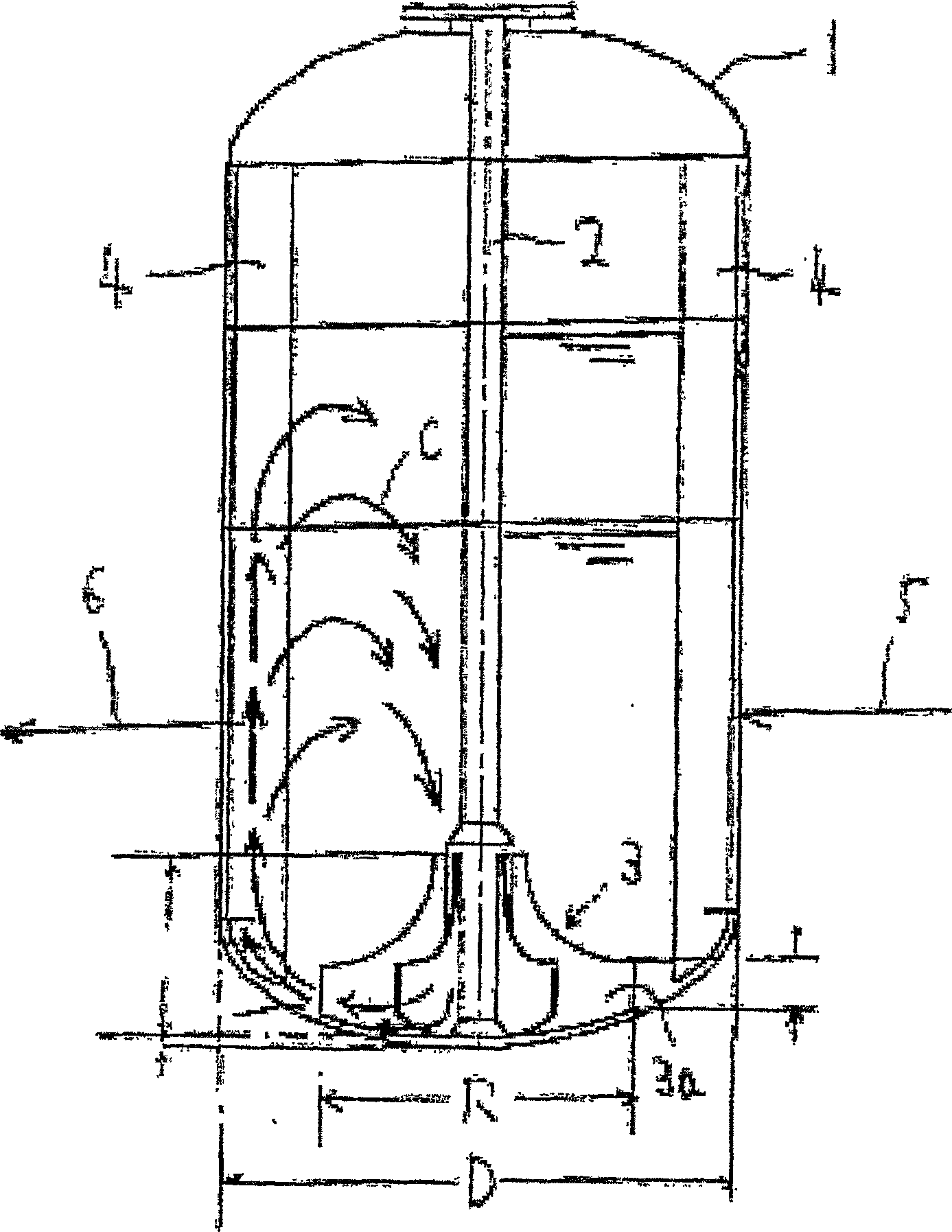

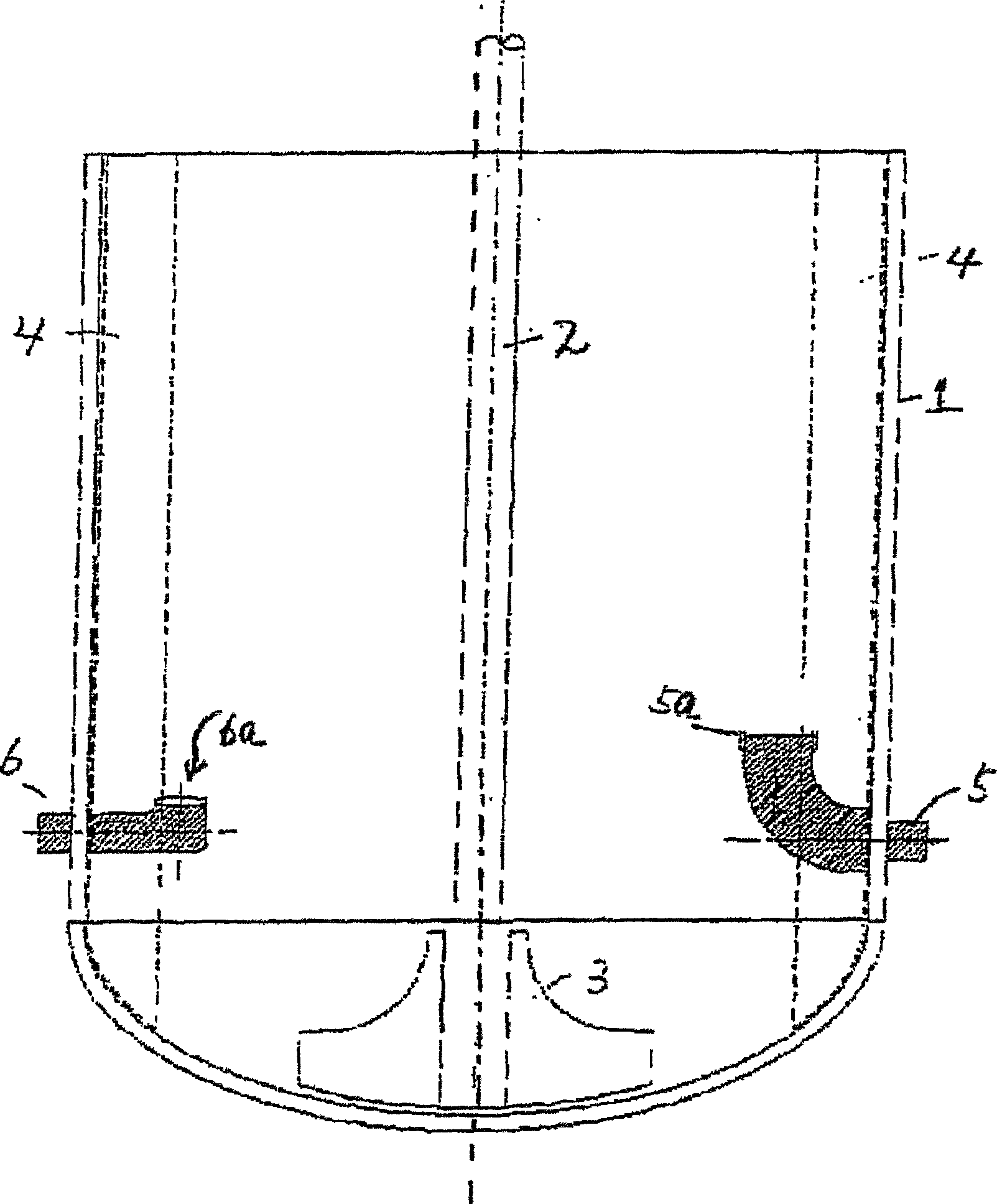

Method for producing terephthalic acid and terephthalic acid

ActiveCN1832914AImprove discharge efficiencyAvoid windingOrganic compound preparationCatalystsAqueous solutionParticle-size distribution

A method for producing terephthalic acid wherein an aqueous terephthalic acid solution is purified with a platinum group metal catalyst and then terephthalic acid is crystallized from the resultant aqueous solution, which comprises carrying out the crystallization in an agitating vessel which has, in the bottom portion thereof, an agitating blade being formed in a shape of an approximately trapezoidal plate and being capable of changing a rotating number; and a terephthalic acid product having a narrow particle size distribution. The above method allows the production with good efficiency of terephthalic acid crystals which are excellent in powder characteristics, slurry characteristics and reactivity, and can be controlled with respect to the particle size distribution.

Owner:MITSUI CHEM INC

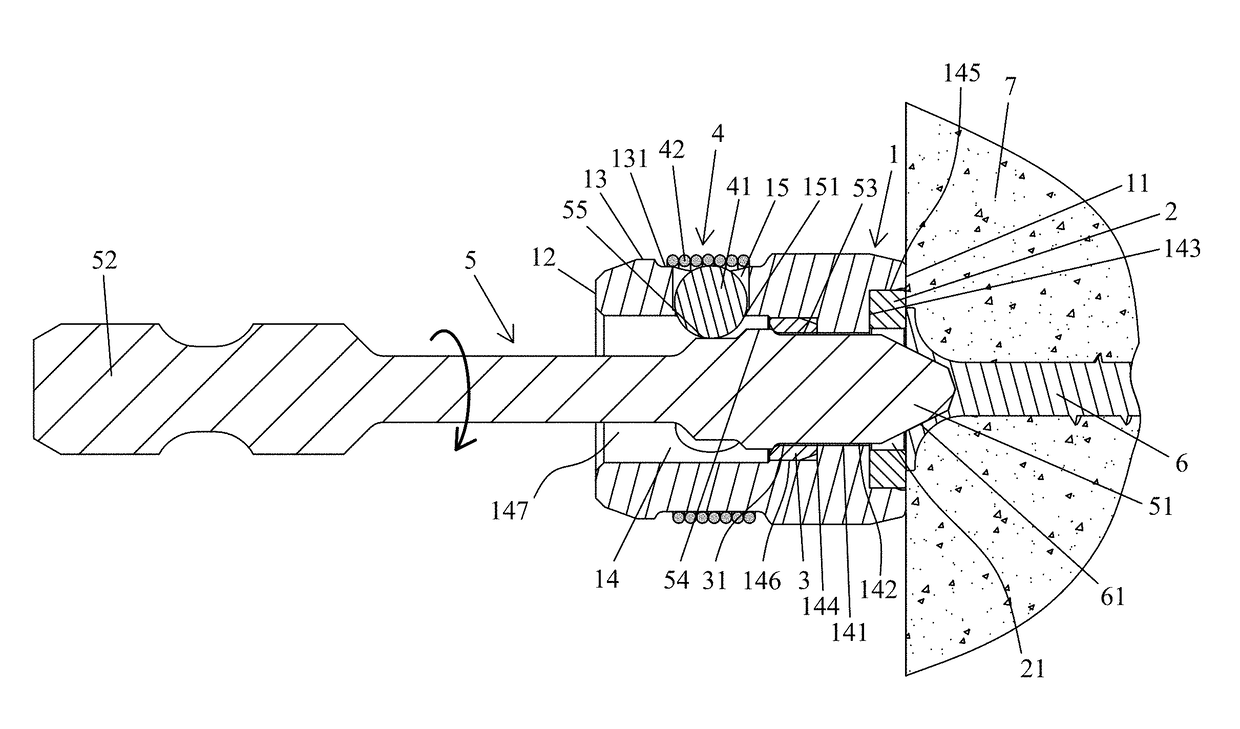

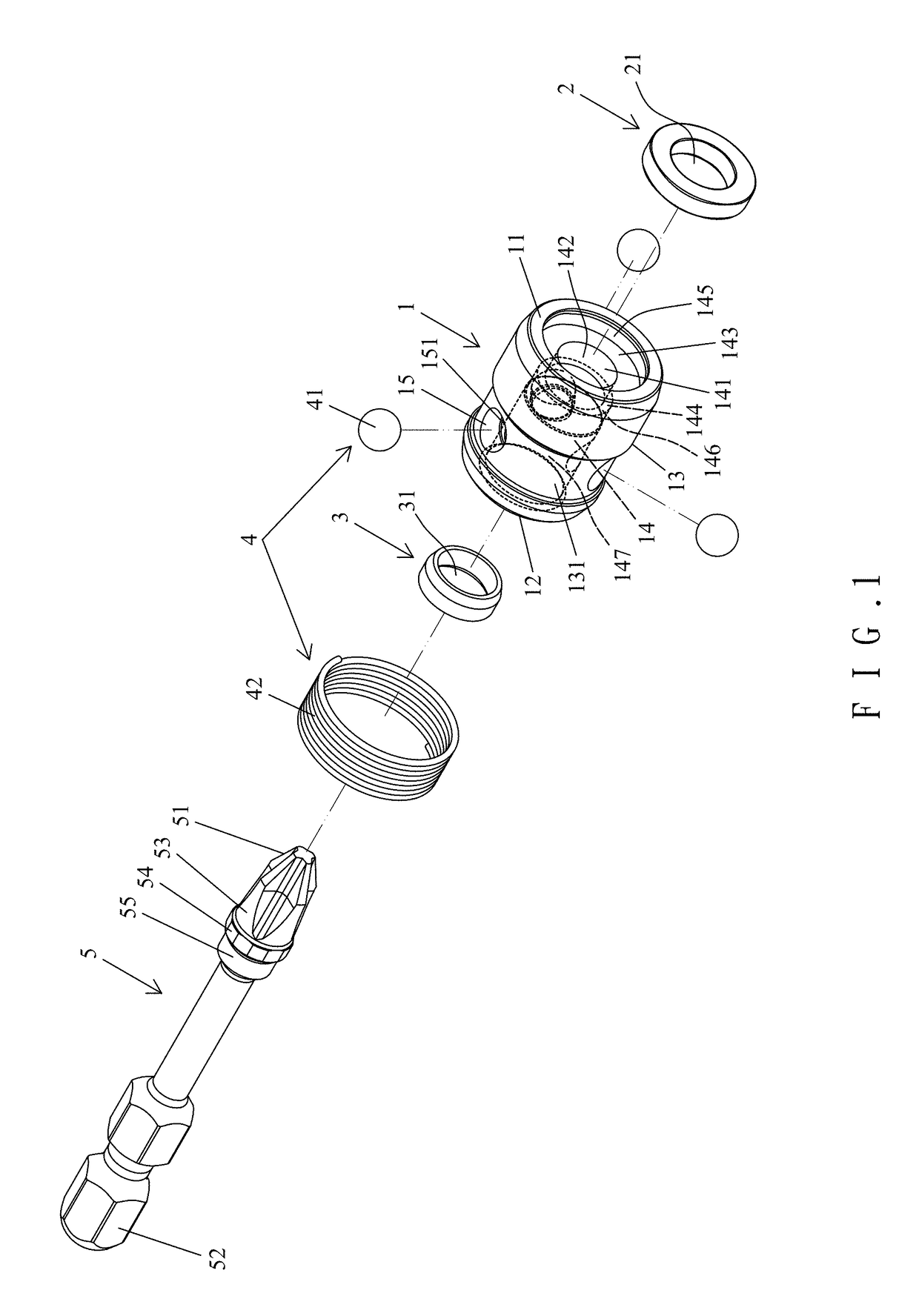

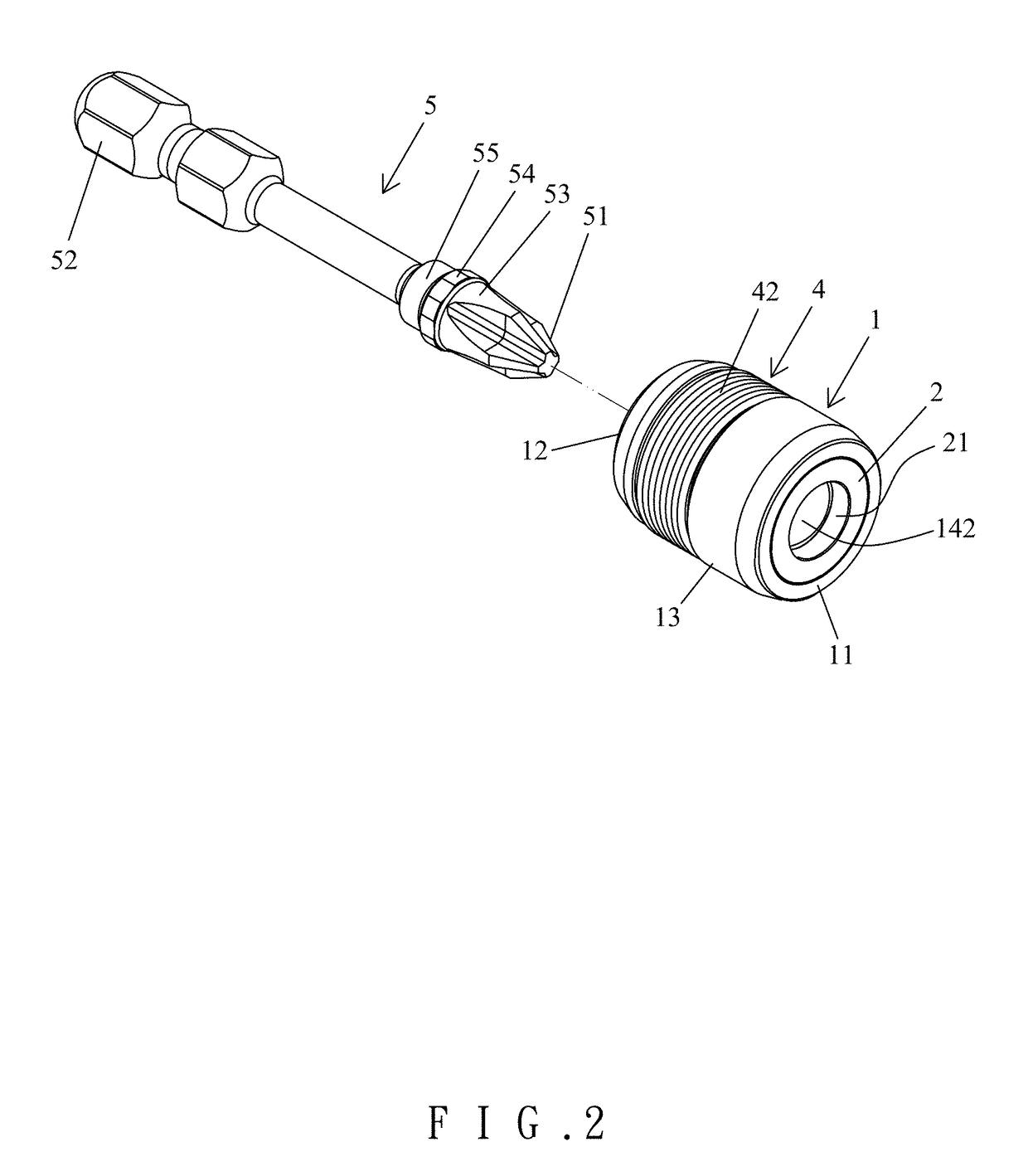

Screwdriver bit assembly with a magnetic structure

A screwdriver bit assembly includes a magnetic ring mounted in a front end of a sleeve hole of a sleeve. A retaining ring is made of a material more rigid than the sleeve, is mounted in the sleeve hole, and is located behind the magnetic ring. A screwdriver bit includes an insertion end, an extending section behind the insertion end, a flange section behind the extending section, and a clamping section behind the flange section. The front end of the screwdriver bit extends through the sleeve hole of the sleeve, the retaining ring, and the magnetic ring. The insertion end extends beyond the sleeve and is located in front of a front end face of the sleeve. The flange section abuts the retaining ring. The clamping section is held by a holding device mounted on the sleeve, providing a holding force towards a longitudinal axis of the sleeve hole.

Owner:COMPASS

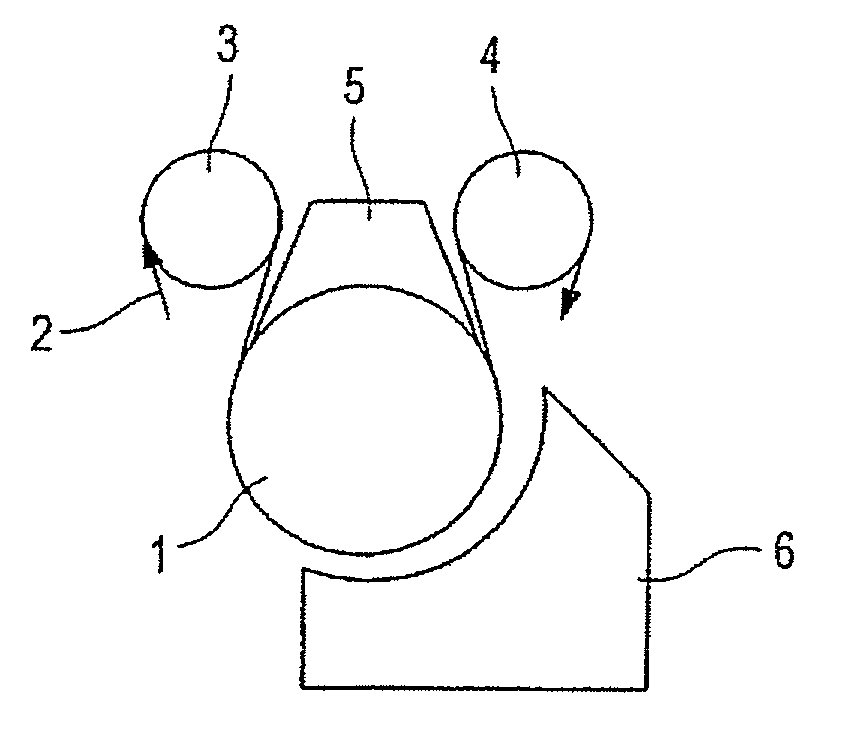

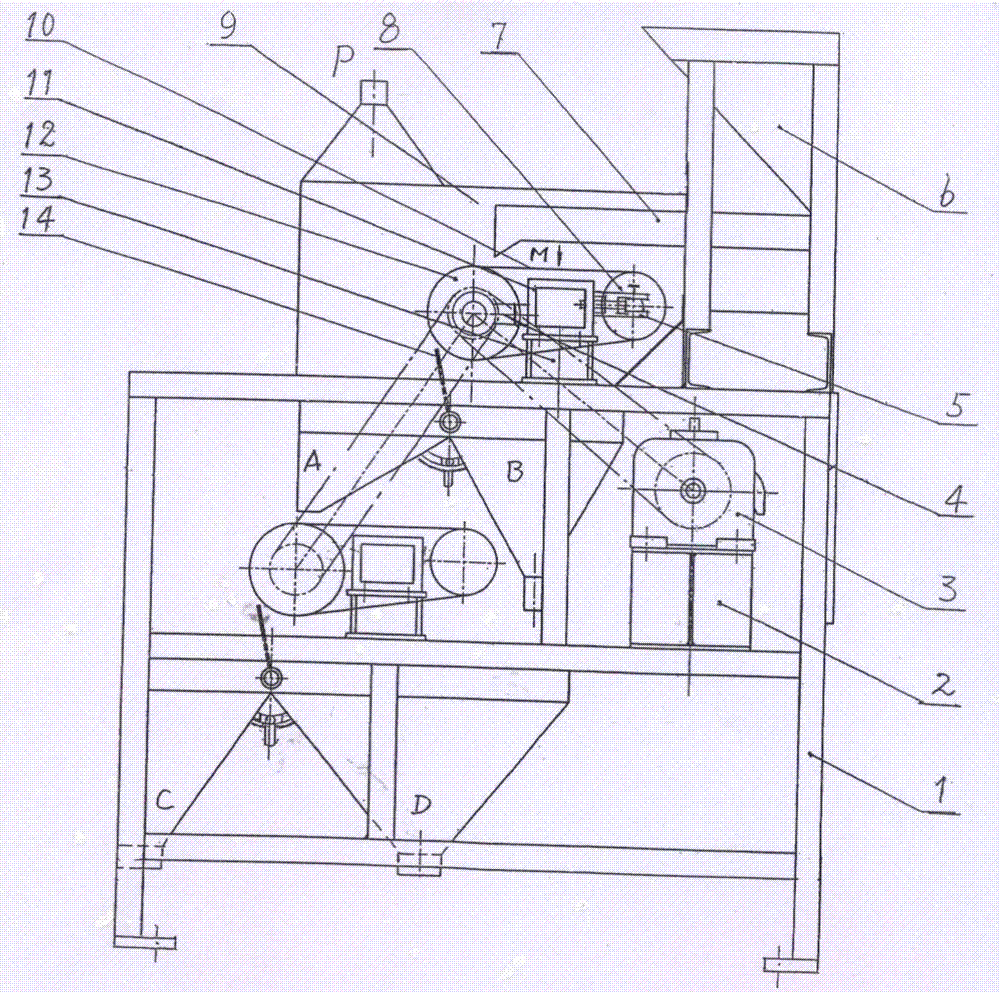

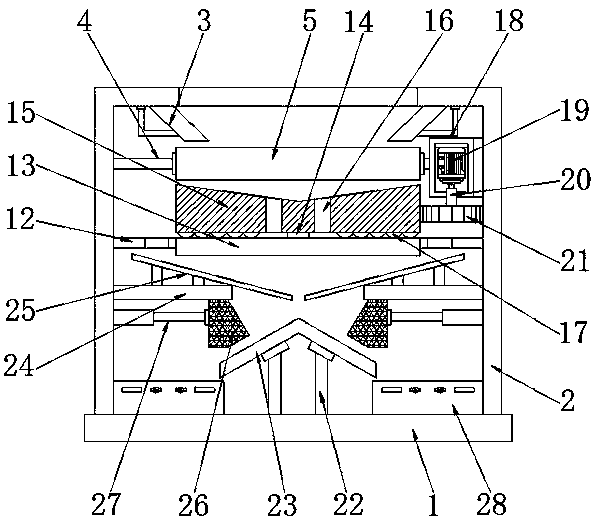

Weak-magnetic material recovering machine

InactiveCN102728464AHigh recovery rateReliable attractionMagnetic separationNeodymium iron boronEngineering

The invention discloses a weak-magnetic material recovering machine, which is characterized in that: the machine comprises a frame; a material storage is arranged above the frame; a vibration feeding apparatus is arranged in the frame below the material storage; a delivering belt tensioned by a magnetic roller and a redirecting roller is arranged below the vibration feeding apparatus; the rotation speed of the magnetic roller is changed through a variable-frequency and variable-speed motor connected therewith; a plurality of discharging hoppers are arranged below the delivering belt; and the magnetic roller and the redirecting roller are respectively arranged on two sides of the crossbeam with a ball bearing with an eccentric sleeve and an adjusting seat. The magnetic roller is formed by round disks manufactured by using a neodymium-iron-boron rare earth permanent magnetic material; a pole piece of soft iron is adopted between two round disks with a same polarity; the two round disks are alternately superposed, and are compressed to form a whole. According to the invention, precious weak-magnetic particles in mixed particles can be separated from other non-magnetic particles. A recovery rate is high, the purity is high, and a high economic benefit can be provided.

Owner:杭州太阳铸造工程技术有限公司

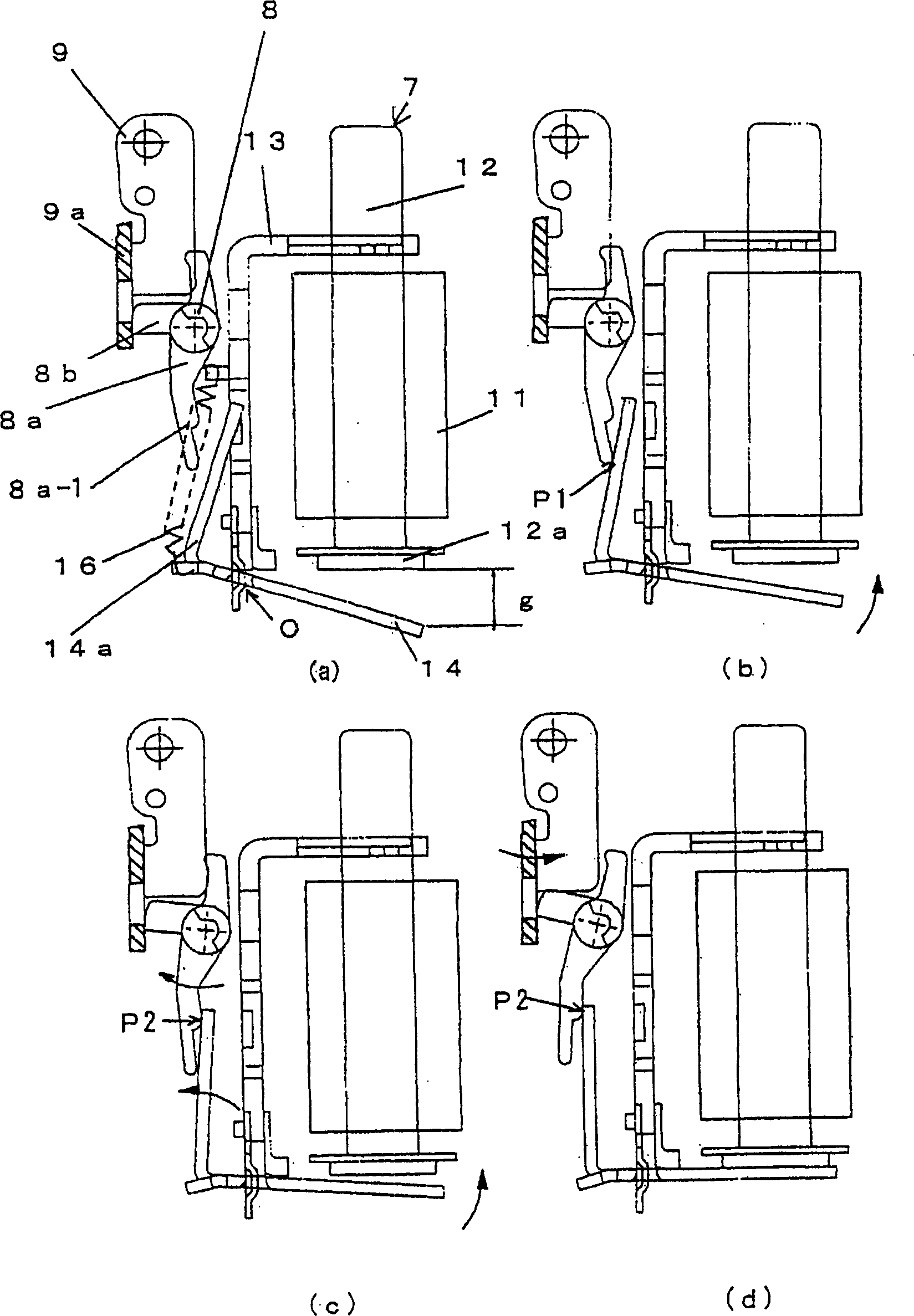

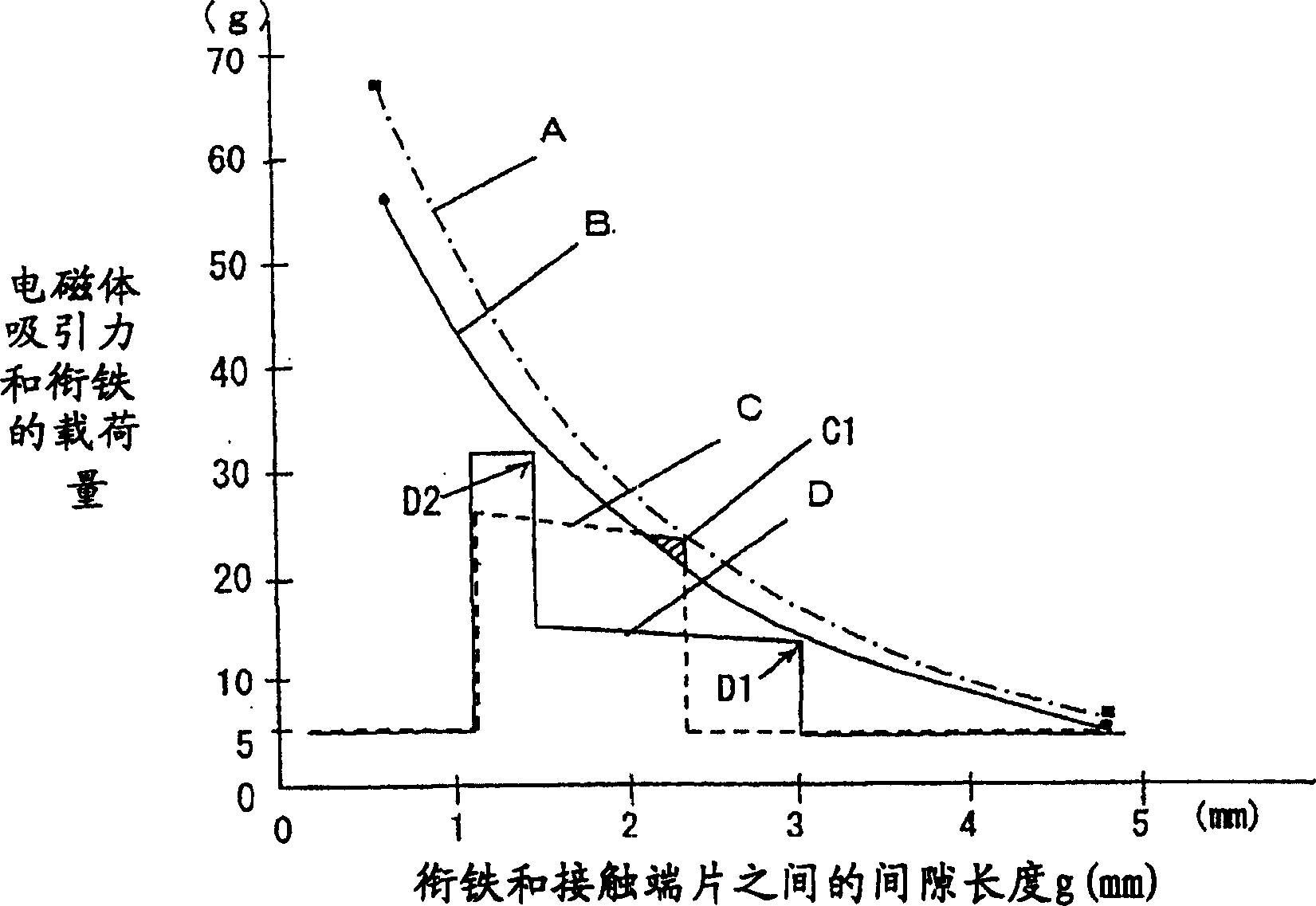

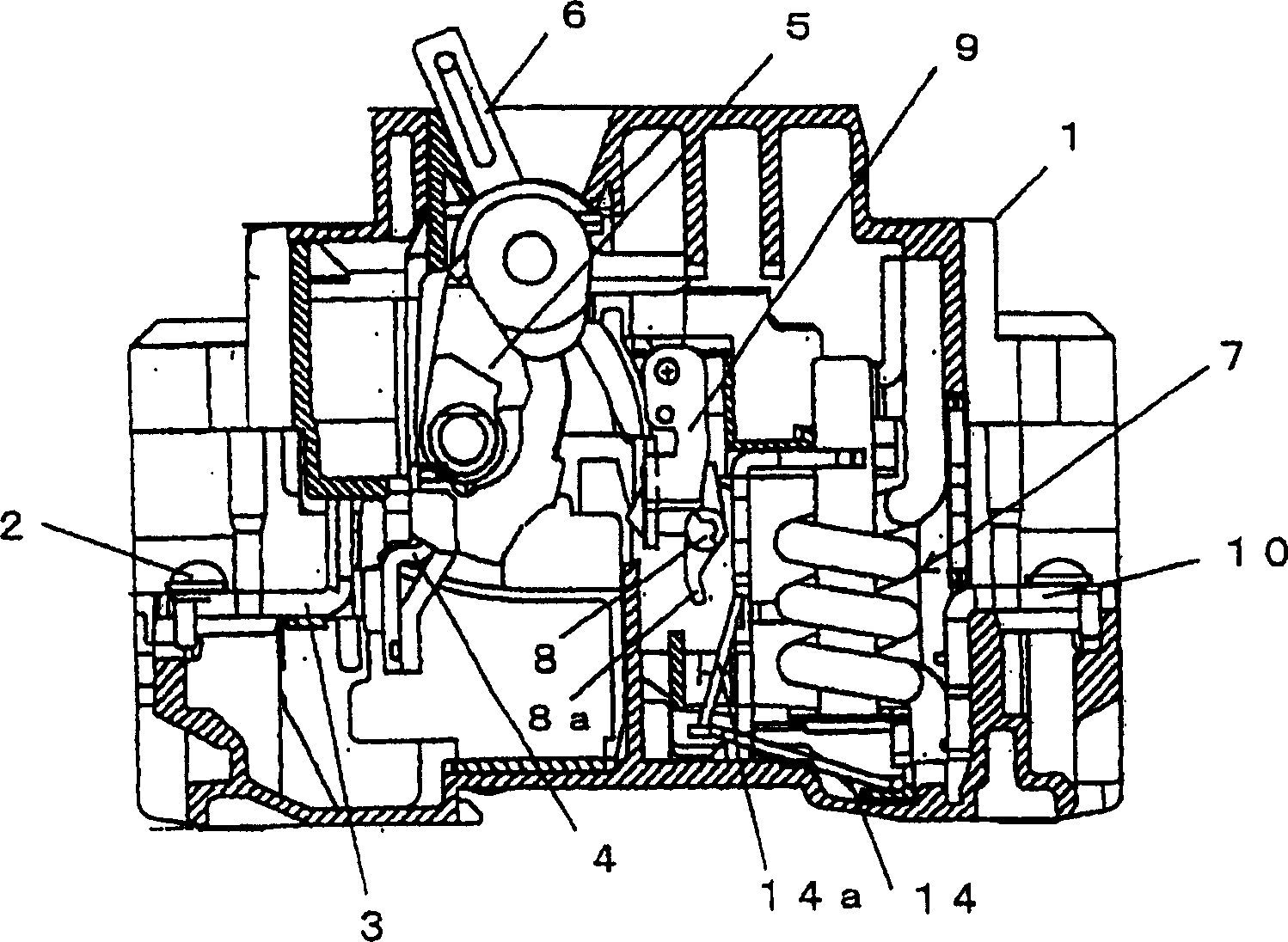

Electromagnetic tripping apparatus in circuit breaker

InactiveCN1276453CIncrease attractivenessAttraction effectively generatesSwitches with electromagnetic releaseProtective switch operating/release mechanismsOvercurrentCircuit breaker

The present invention provides an electromagnetic tripping device, this electromagnetic trip device is used for tripping a circuit breaker by detecting an overcurrent in the main circuit and is so structured that an operation arm (14a) formed on the armature (14) of an electromagnet unit (7) is faces a trip arm (8a) of the trip crossbar (8), the operation arm presses the trip arm of the trip crossbar in the attracting operation of the electromagnet, and thus the breaker is tripped by releasing a latch receiver (9). By changing the force application point between the operation arm and the trip arm from a point P1 to a point P2 in line with the change of an air gap between the armature and the electromagnet in the attracting operation of the electromagnet, the load weight applied to the armature is kept low in the first half causing small attraction, and the force application point is moved to the point P2 in the second half increasing the attraction of the electromagnet so that the trip crossbar is driven to a release position.

Owner:FUJI ELECTRIC FA COMPONENTS & SYST CO LTD

How to catch locusts

The invention discloses a method for trapping and killing grasshoppers. The method is characterized by comprising steps that a, a group of grasshopper trapping and killing devices is arranged in grasshopper gathering regions, a metal stopping net is arranged in a grasshopper killing tank of each grasshopper trapping and killing device, a group of heater and fixing sleeve is arranged on a lower tank plate of each grasshopper killing tank and is positioned on the left of the corresponding metal stopping net, a brush stained with sex pheromone is inserted in each fixing sleeve, a grasshopper outlet is vertically formed in the lower tank plate of each grasshopper killing tank and is positioned on the right of the corresponding metal stopping net, grasshopper collecting components are fixed onto the grasshopper outlets, exiting preventive assemblies are arranged in the grasshopper killing tanks, and each exiting preventive assembly comprises horizontal beams and exiting preventive sheets; b, inspection staffs inspect grasshopper killing devices one by one every once in a while; c, the grasshoppers in the grasshopper collecting components are completely killed. The method has the advantages that the grasshoppers are attracted by the sex pheromone on the brushes and infrared radiation when heaters generate heat, and ultimately enter the grasshopper collecting components from the grasshopper outlets, accordingly, trapped and killed grasshoppers can be collected, and the grasshoppers can be killed conveniently and efficiently.

Owner:CHONGQING LIZHENYUAN AGRI & FORESTRY TECH

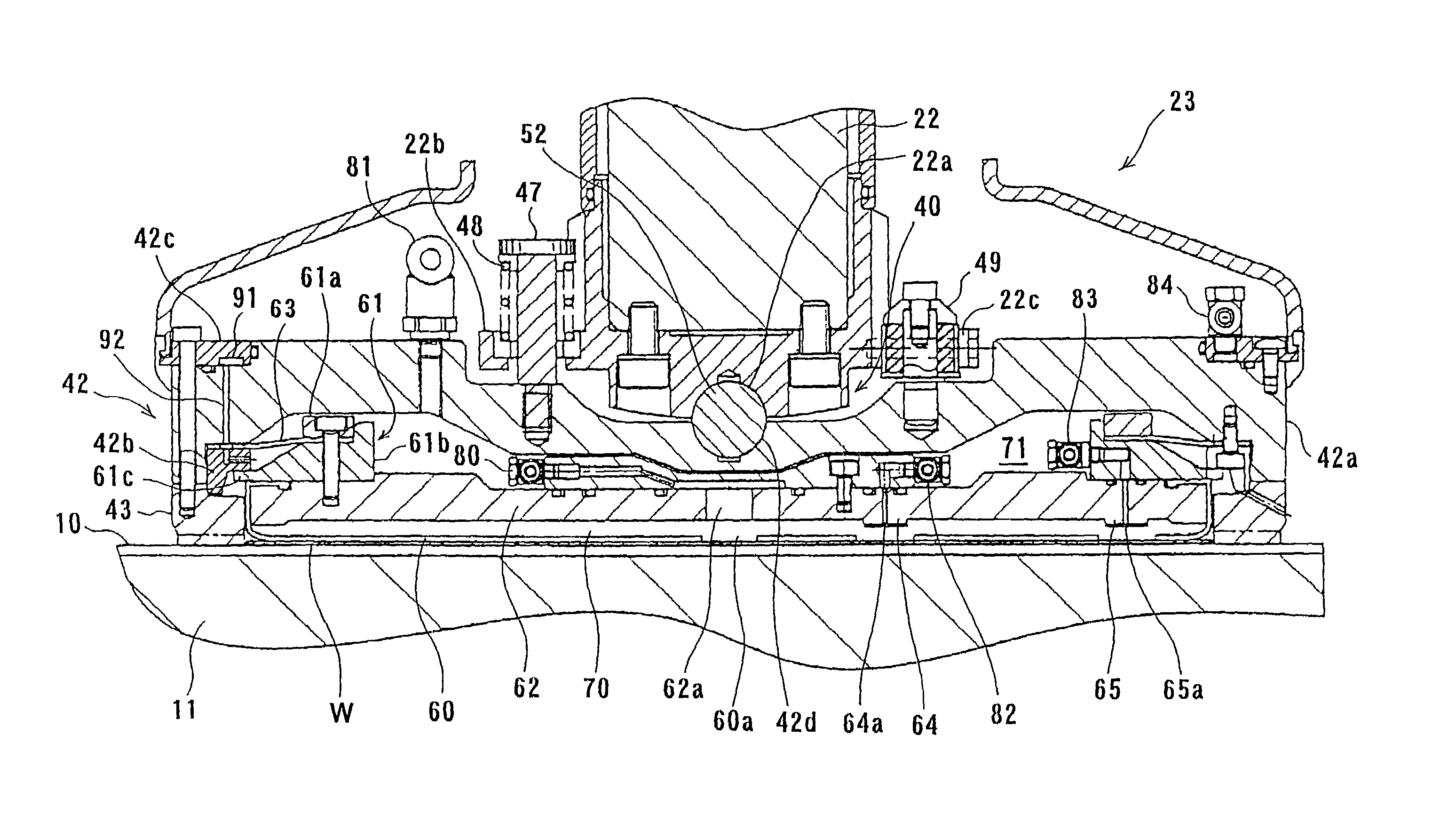

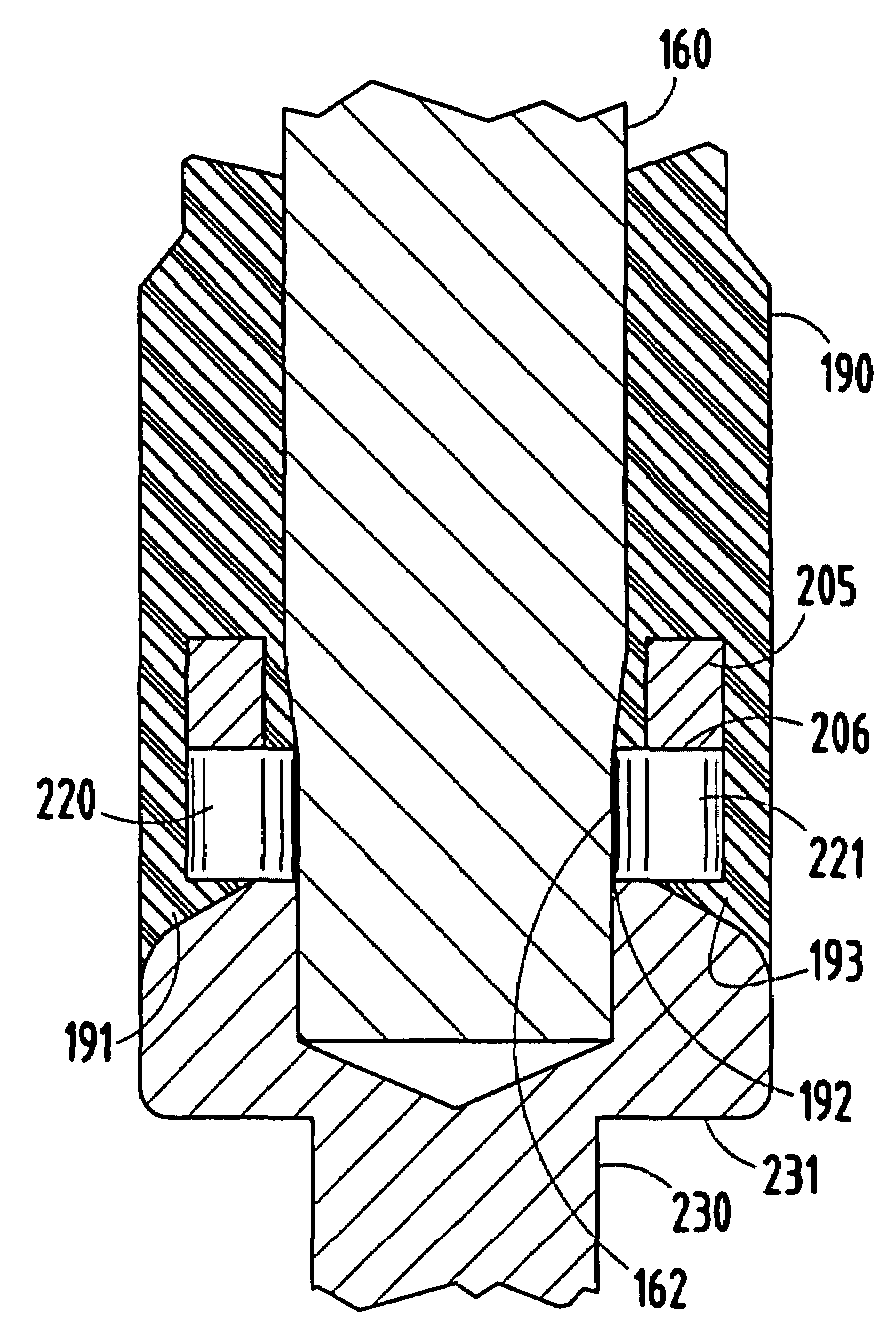

Polishing method

InactiveUS20060079092A1Avoid damageReliable attractionSemiconductor/solid-state device manufacturingLapping machinesEngineeringSemiconductor

The present invention is relates to a polishing method for polishing a semiconductor wafer (W) by pressing the semiconductor wafer (W) against a polishing surface (10) with use of a top ring (23) for holding the semiconductor wafer (W). A pressure chamber (70) is defined in the top ring (23) by attaching an elastic membrane (60) to a lower surface of a vertically movable member (62). The semiconductor wafer (W) is polished while a pressurized fluid is supplied to the pressure chamber (70) so that the semiconductor wafer (W) is pressed against the polishing surface (10) by a fluid pressure of the fluid. The semiconductor wafer (W) which has been polished is released from the top ring (23) by ejecting the pressurized fluid from an opening (62a) defined centrally in the vertically movable member (62).

Owner:TOGAWA TETABUJI +5

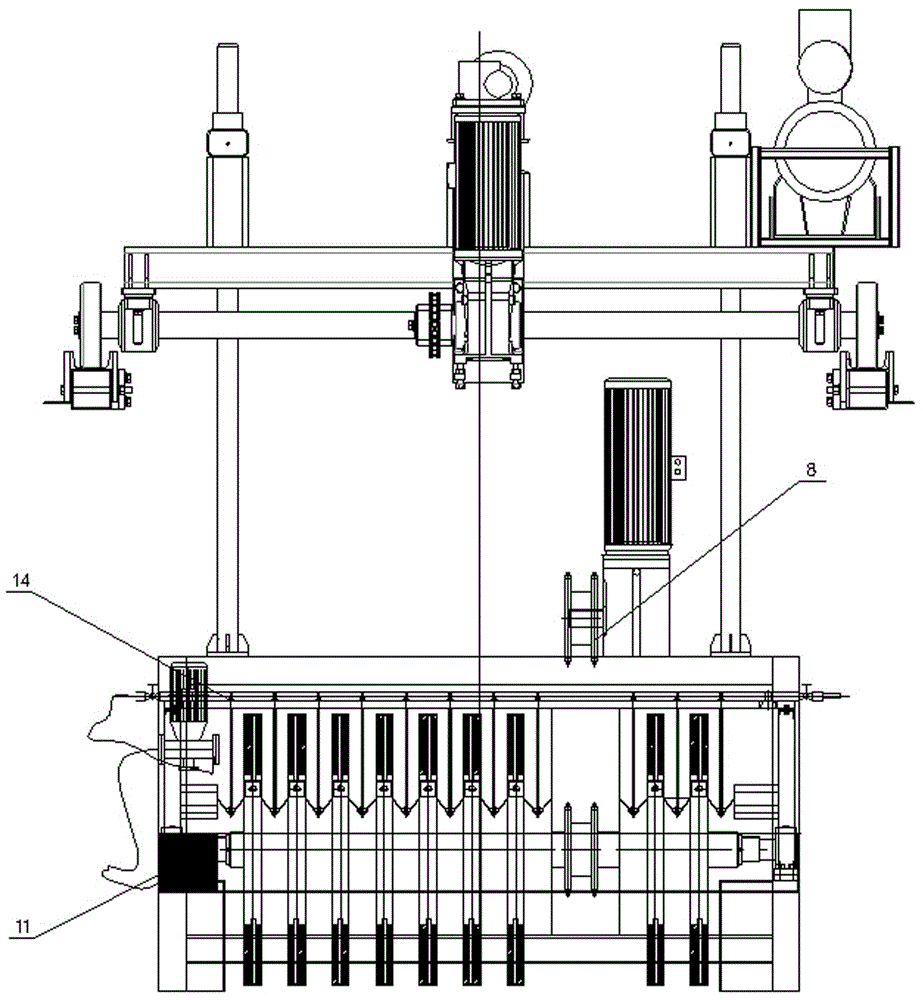

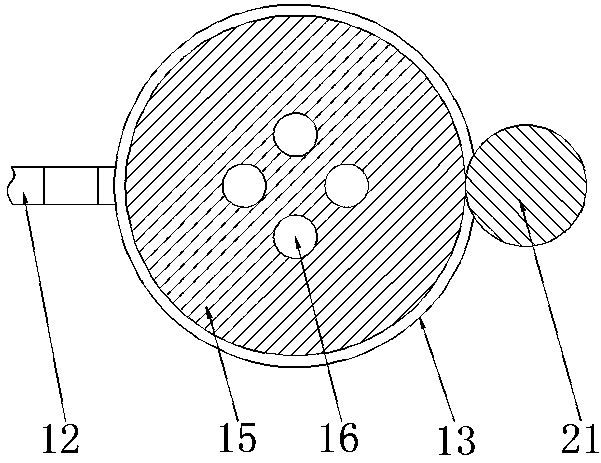

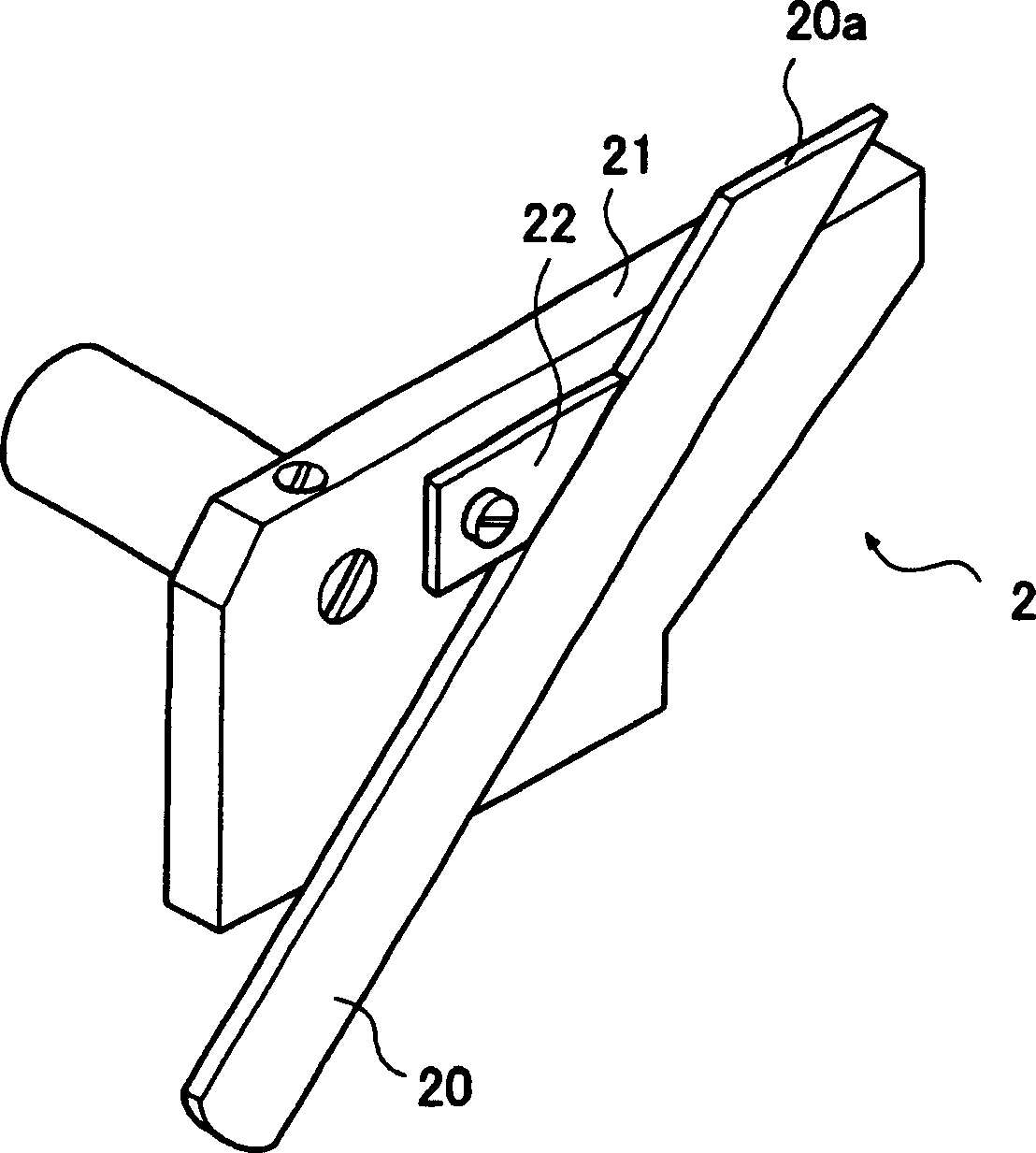

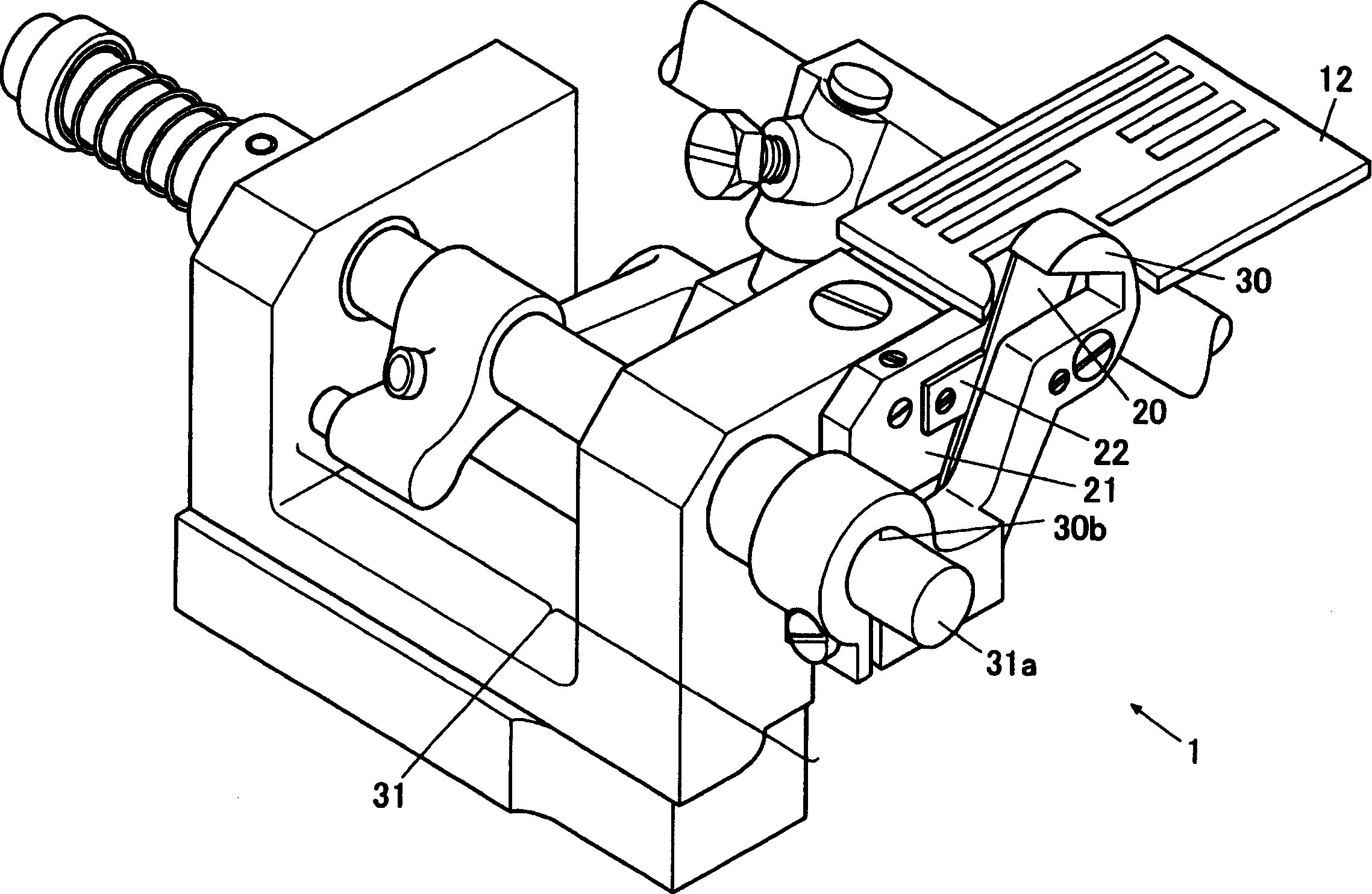

Separating and feeding device with head stick

ActiveCN100368270CEasy to take outInhibit sheddingConveyor partsRotary conveyorsSteel barEngineering

The invention provides a separating supply device with a head steel bar which can lead the head steel bar to be easily fetched out from a supporting hole on a fetching out position and improves the attracting maintaining rate in the supporting hole of the head steel bar. The invention is provided with a separating plate (9) which can rotate in hopper part (3) of the head steel bar that can store a plurality of small screws. On the outer circle part of the separating plate, a plurality of supporting holes (9b) that can be embedded with the head steel bar are collocated in equal distance. The supporting holes (9b) on the corresponding position of the head steel bar stored in the hopper part are communicated with an air absorption hole (5a) used for maintenance; besides, the supporting hole (9b) on a fixed fetching out position is communicated with an air absorption hole (5b) used for confirmation. Air is pumped in respectively from the absorption holes used for maintenance and confirmation. When maintaining the head steel bar in the supporting holes (9b) arranged on the fetching out position, the air absorption from the absorption hole used for confirmation and the air absorption from the absorption hole used for maintenance is continued.

Owner:NITTO SEIKO KO

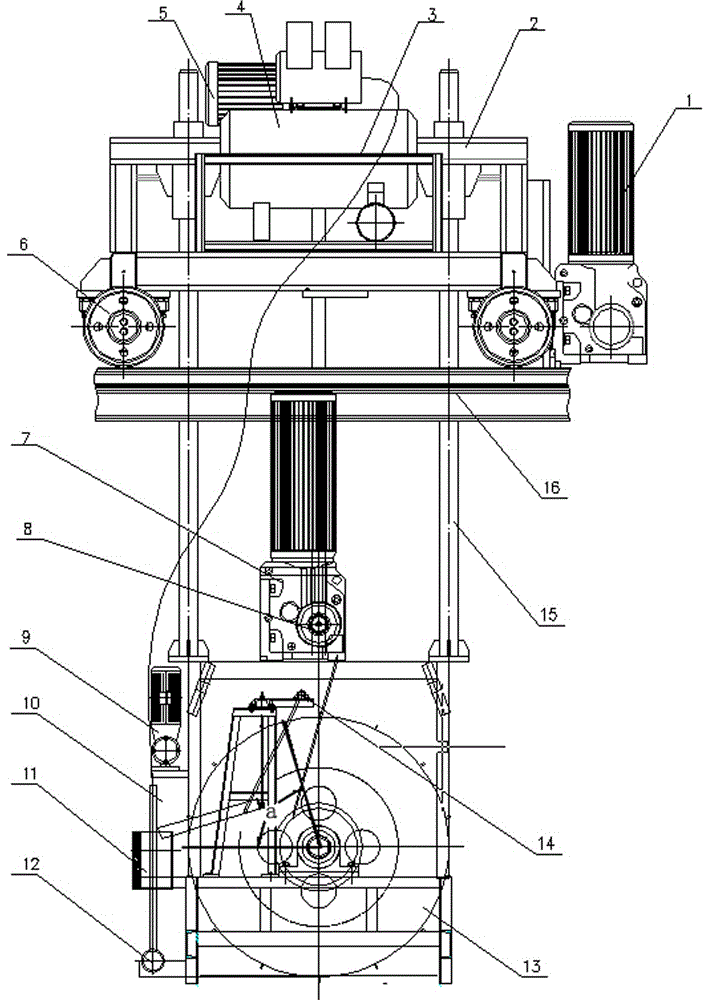

Rotary magnetic disk combined-type soil magnetic enrichment and purification in-situ recovery device

InactiveCN106269224AReliable attractionFully contactedMagnetic separationRare earthEconomic benefits

The invention discloses a rotary magnetic disk combined-type soil magnetic enrichment and purification in-situ recovery device which is provided with a rack. The rack is provided with travelling wheels. A lifting device and an aeration stirring device are arranged on the upper portion of the rack. A rotary magnetic disk is arranged below the lifting device. The rotary magnetic disk is connected with a variable frequency motor through a chain wheel transmission device. The rotary magnetic disk is made of a neodymium iron boron rare earth permanent magnetic material, and a stainless steel housing is arranged outside the magnetic disk. A small-sized washing water circulation system is arranged at the top of the rotary magnetic disk. The small-sized washing water circulation system is composed of a water pump, a water tank and a spraying pipe. A magnet block is arranged inside the water tank, and thus sedimentation of the magnetic material can be accelerated. The aeration stirring device is composed of an air compressor and a stirring pipe. The air compressor is arranged on the rack, and the stirring pipe is arranged on the rotary magnetic disk. By means of the rotary magnetic disk combined-type soil magnetic enrichment and purification in-situ recovery device, magnetic particles in paddy field mud can be sorted out directly, position change of the mud is needless, the recovery rate is high, and the economic benefits are also high.

Owner:CUG WUHAN GOLDEN SHIELD ENVIRONMENTAL TECH CO LTD

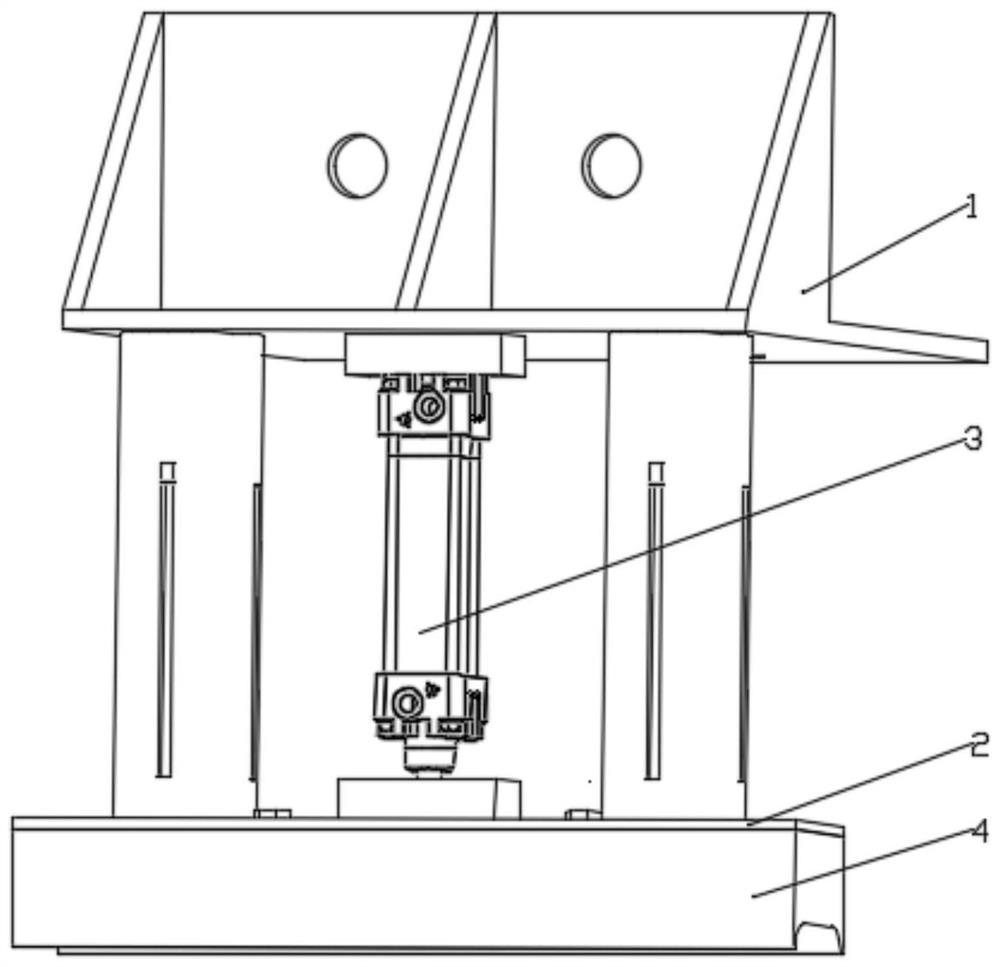

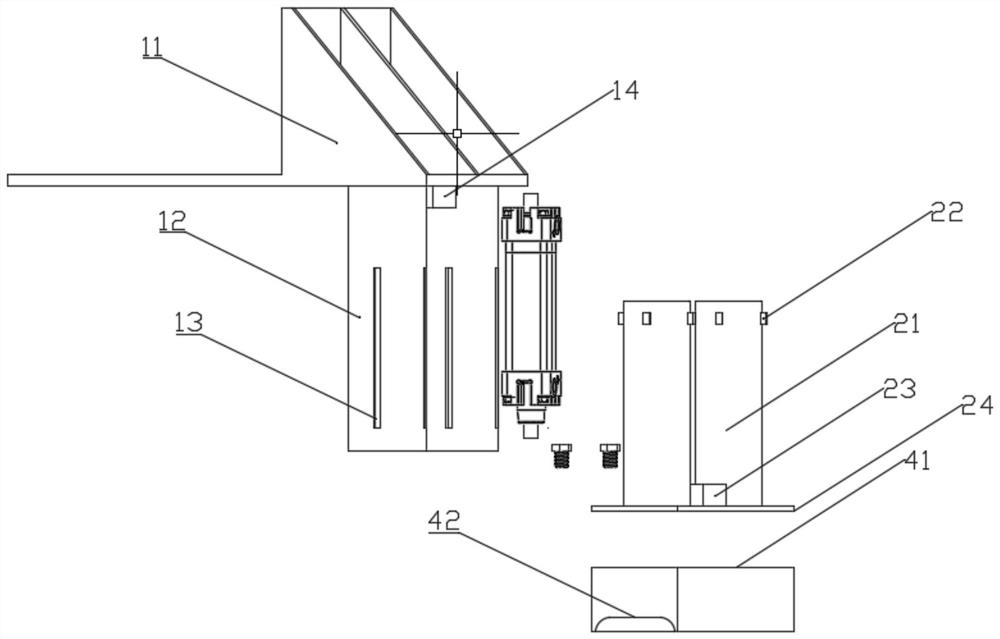

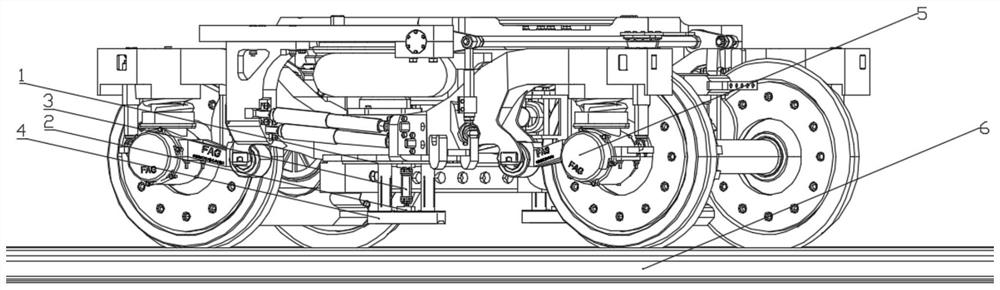

Magnetic attraction type railway vehicle anti-overturning device

InactiveCN112644552ASimple structureImprove performanceRail derailment preventionBogiesBogieElectromagnet

The invention discloses a magnetic attraction type railway vehicle anti-overturning device. The device comprises a device mounting base, an electromagnet mounting base, an air cylinder and an electromagnet, the device mounting base is arranged in the middle of a railway vehicle bogie frame, one end of the air cylinder is connected with the device mounting base, and the other end of the air cylinder is connected with the electromagnet mounting base; one end of the electromagnet installation base is connected with the air cylinder and connected with the device installation base through a positioning sleeve, and the other end of the electromagnet installation base is connected with the electromagnet; and the air cylinder extends or contracts along with normal operation or overturning accidents of the railway vehicle, so the electromagnet installation base and the electromagnet are driven to move in the direction of the positioning sleeve. The device is small in size, low in cost, high in reliability, easy to maintain and capable of well improving the safety performance of the rail vehicle under the overturning accident.

Owner:CENT SOUTH UNIV +1

a locust trap

The invention discloses a locust trap. A barrier mesh is disposed within a trap box. A group of heaters and fixing sleeves are vertically arranged on the inner surface of the lower portion of the trap box on the left of the barrier mesh. The heaters and the fixing sleeves are arranged side by side with one before another; the heaters are arranged on the right of the fixing sleeves; a brush is inserted into each fixing sleeve and dipped with sexual pheromone; the lower wall of the trap box on the right of the barrier mesh is provided with a locust exit; a locust collector is fixed under the locust exit; the periphery of a right opening of a cloth bag is fixed to the periphery of a right opening of the locust box; a left opening of the cloth bag fixedly sleeves the outside of a large opening end of an anti-exiting hopper. The sexual pheromone applied to the brushes and infrared generated by the heater during heating attract the locusts, the locusts enter the locust collector from the locust exit, and the locusts are collected accordingly and can be conveniently killed later; the locust trap allows the locusts to be killed conveniently and efficiently at low cost, and the whole killing process is basically unattended.

Owner:CHONGQING LIZHENYUAN AGRI & FORESTRY TECH

Novel coal feeder iron removing device for thermal power plant

The invention discloses a novel coal feeder iron removing device for a thermal power plant and relates to the technical field of iron removing devices. The novel coal feeder iron removing device for the thermal power plant comprises a base plate. The top of the base plate is fixedly connected with a work frame. The two sides of the inner wall of the work frame are fixedly connected with feeding pipes. The two sides of the inner wall of the work frame are both fixedly connected with moving guide plates. The sides, far away from the work frame, the moving guide plates are movably connected witha horizontal screen plate. The bottom of the inner wall of the work frame is fixedly connected with a screening motor frame. According to the novel coal feeder iron removing device for the thermal power plant, by means of combined arrangement of a static plate, a gravity crushing disk, pressing nails, a grinding motor box, a grinding motor and a driving shaft, coal blocks can be further grinded and crushed in the device by the pressing nails at the bottom of the gravity crushing disk, so that the coal block smashing degree is further improved, the operation reliability of the novel coal feederiron removing device for the thermal power plant is greatly improved, it is guaranteed that the novel coal feeder iron removing device can attract small iron fragments out of a coal pile, and the novel coal feeder iron removing device is simple in overall structure.

Owner:华电呼图壁能源有限公司热电厂

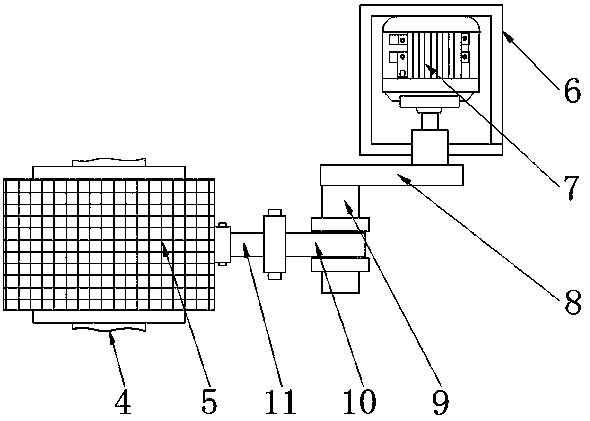

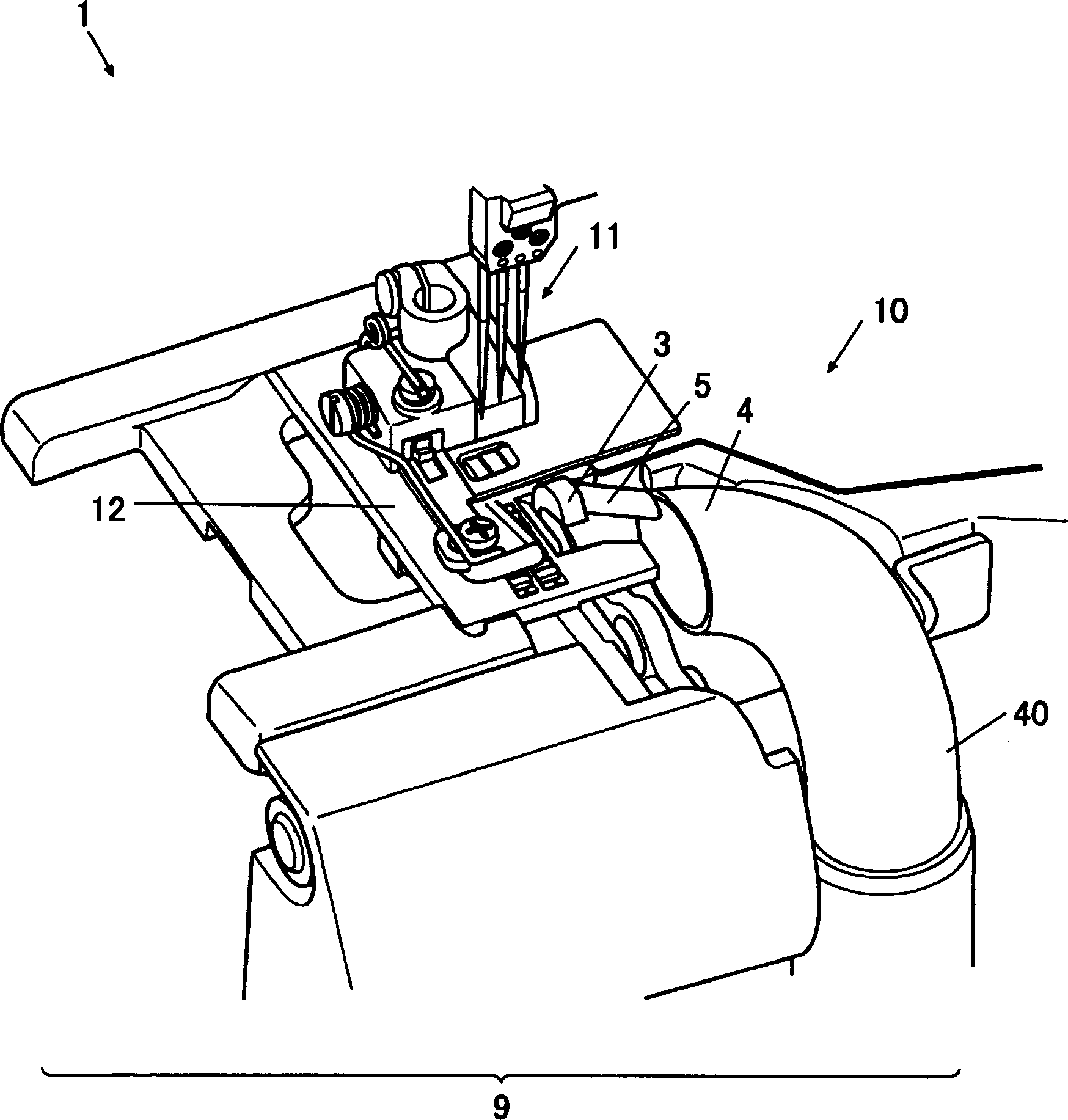

Cloth-cutting apparatus of sewing machine

InactiveCN1743530AEliminate problems such as sinteringReliable suction removalWorkpiece carriersSuction forceEngineering

A lint guide part 5 is provided in a clearance between a moving knife 30 and an opening part 40a. The end face of the lint guide part 5 opposed to the opening part 40a is formed into the same shape to that of the opening part 40a to efficiently exert a suction force. The lint guide part 5 is connected to the moving knife 30 and vertically move integrated therewith, and the opening part 40a and the end face of the lint guide part 5 are disposed on the same height at the lowermost end position to improve the lint collecting efficiency. To provide a cloth cutting knife device of a sewing machine causing neither malfunction due to the intrusion of lint produced when cutting a cloth by the cloth cutting knife device nor seizure of the sewing machine due to the lint absorbing oil.

Owner:JUKI CORP

Separating and feeding device with head stick

The invention provides a separating supply device with a head steel bar which can lead the head steel bar to be easily fetched out from a supporting hole on a fetching out position and improves the attracting maintaining rate in the supporting hole of the head steel bar. The invention is provided with a separating plate (9) which can rotate in hopper part (3) of the head steel bar that can store a plurality of small screws. On the outer circle part of the separating plate, a plurality of supporting holes (9b) that can be embedded with the head steel bar are collocated in equal distance. The supporting holes (9b) on the corresponding position of the head steel bar stored in the hopper part are communicated with an air absorption hole (5a) used for maintenance; besides, the supporting hole (9b) on a fixed fetching out position is communicated with an air absorption hole (5b) used for confirmation. Air is pumped in respectively from the absorption holes used for maintenance and confirmation. When maintaining the head steel bar in the supporting holes (9b) arranged on the fetching out position, the air absorption from the absorption hole used for confirmation and the air absorption from the absorption hole used for maintenance is continued.

Owner:NITTO SEIKO KO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com