Electric vacuum cleaner

A vacuum cleaner and electric technology, applied in the field of control, can solve the problems of decreased dust attraction, decreased performance of dust removal, decreased performance of dust attraction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

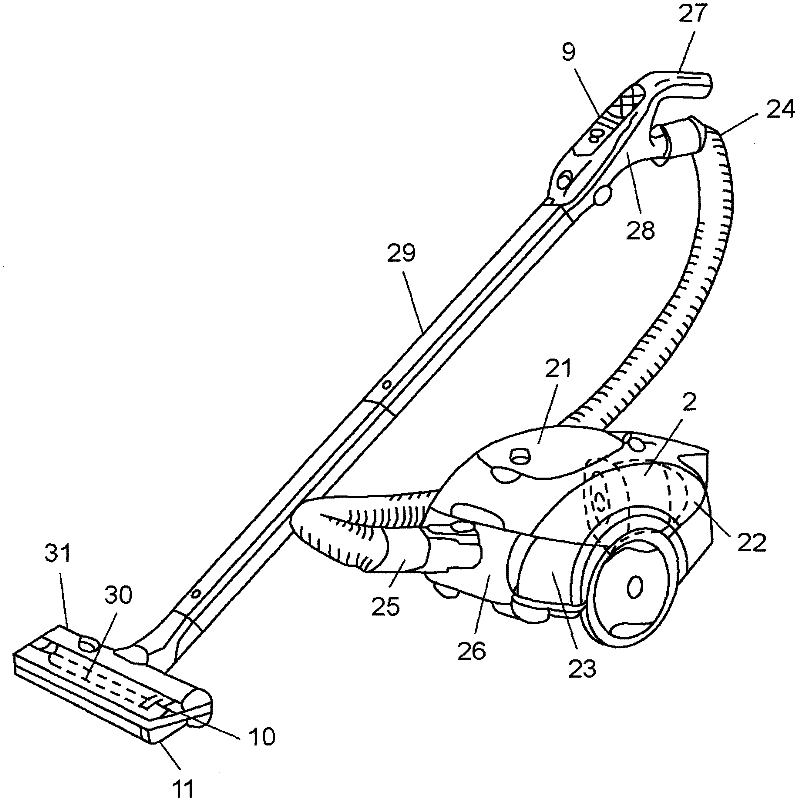

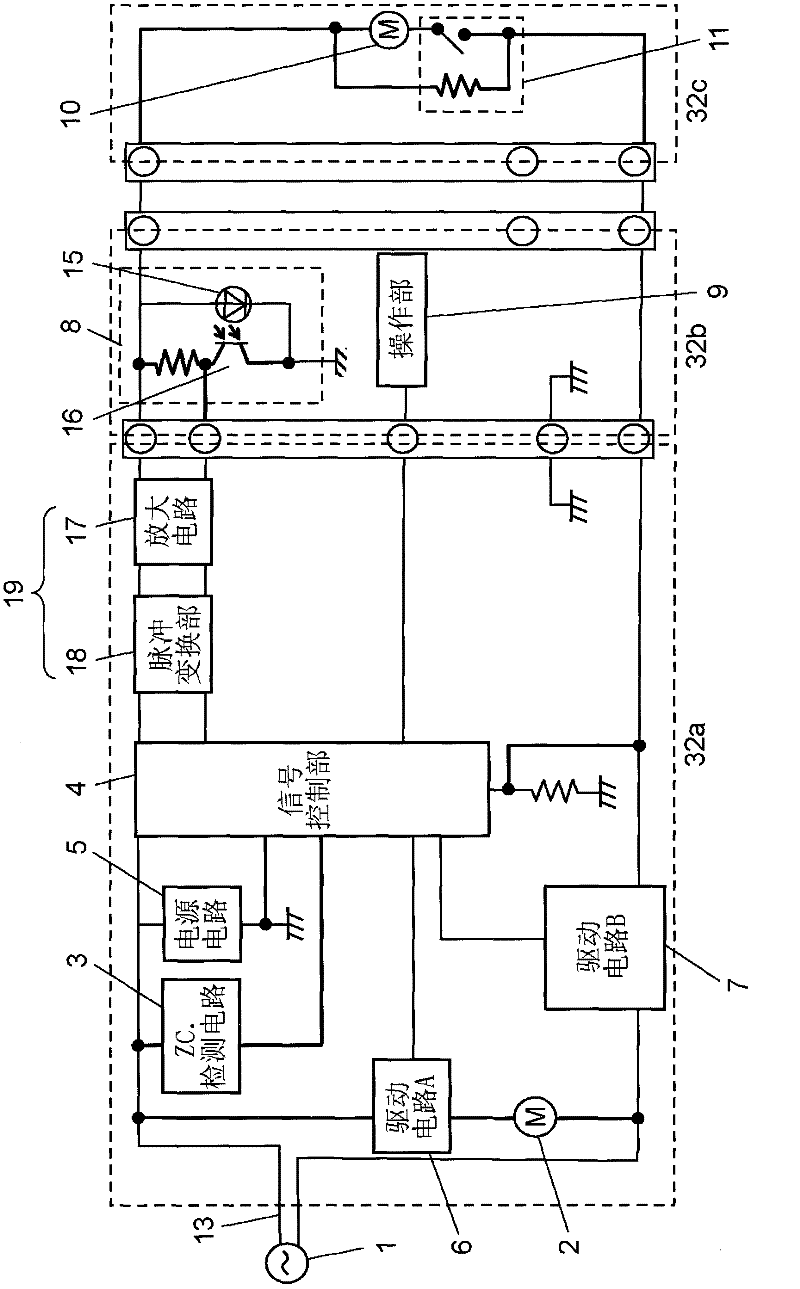

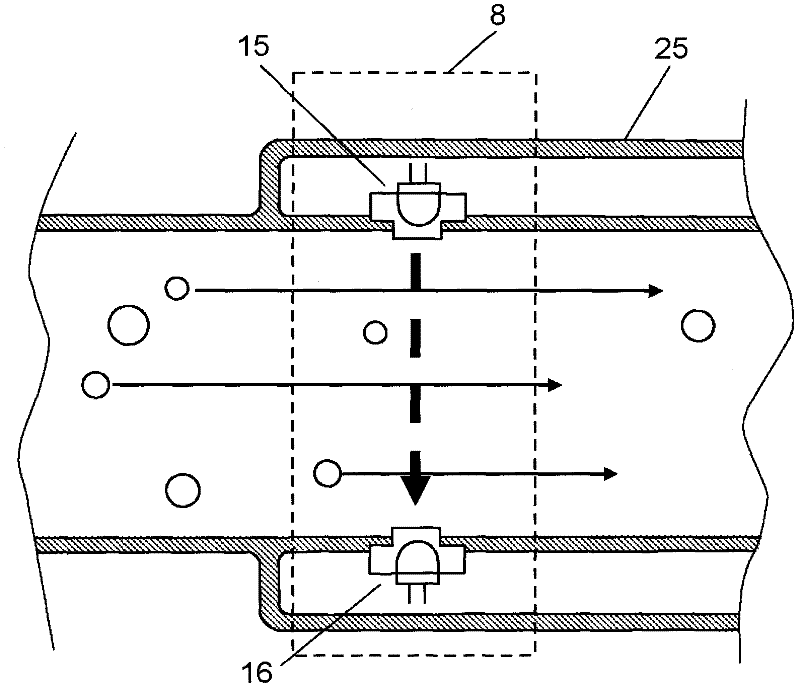

[0036] use figure 1 The vacuum cleaner according to Embodiment 1 of the present invention will be described through FIG. 5 .

[0037] figure 1 It is an overall perspective view of the electric vacuum cleaner of this embodiment. figure 2 Is the circuit block diagram of the electric vacuum cleaner. image 3 It is a sectional view showing the structure of the dust sensor of this electric vacuum cleaner. Figure 4A It is a figure which shows the output waveform (in the case of a floor) of the dust sensor of this electric vacuum cleaner. Figure 4B It is a figure which shows the output waveform (in the case of a carpet) of this dust sensor. Figure 5A , Figure 5B It is a flowchart explaining the control of this electric vacuum cleaner.

[0038] figure 1 The vacuum cleaner main body 21 of the electric vacuum cleaner of this embodiment shown has the electric blower chamber 22 arrange|positioned in the rear part, and the electric blower 2 built in, and the dust collection cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com