Cloth-cutting apparatus of sewing machine

A sewing machine and cloth cutting technology, which is applied to sewing machine components, sewing equipment, textiles and papermaking, etc., can solve problems such as inability to eliminate the inside of the device, serious sintering of the device, and poor mechanical action.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

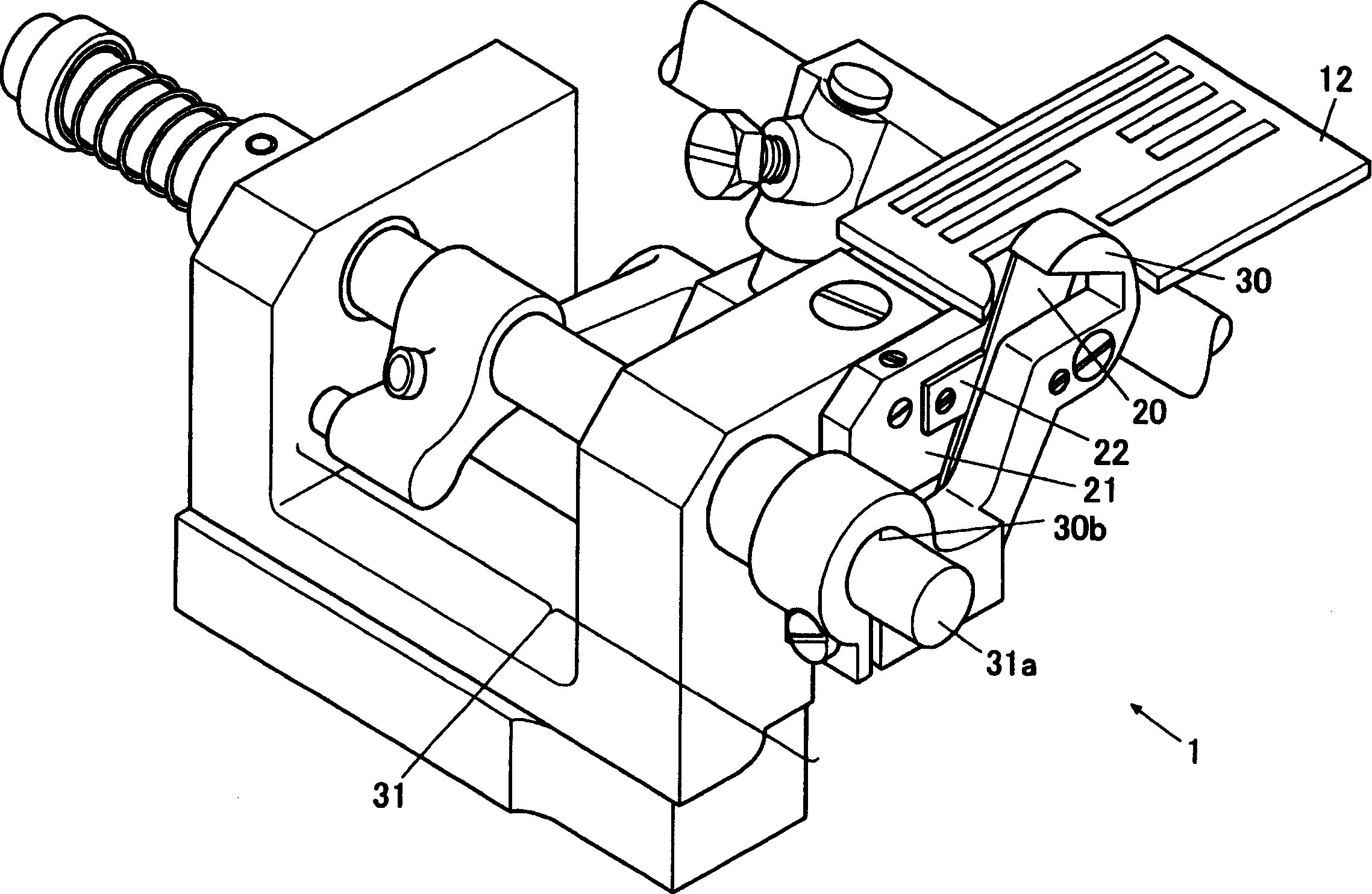

[0029] Embodiments of the cloth cutting device (hereinafter referred to as the cloth cutting device) of the sewing machine of the present invention will be described in detail below with reference to the accompanying drawings. In addition, in this embodiment, a right cutter device that cuts the cloth on the right side in the cloth feeding direction will be described as an example.

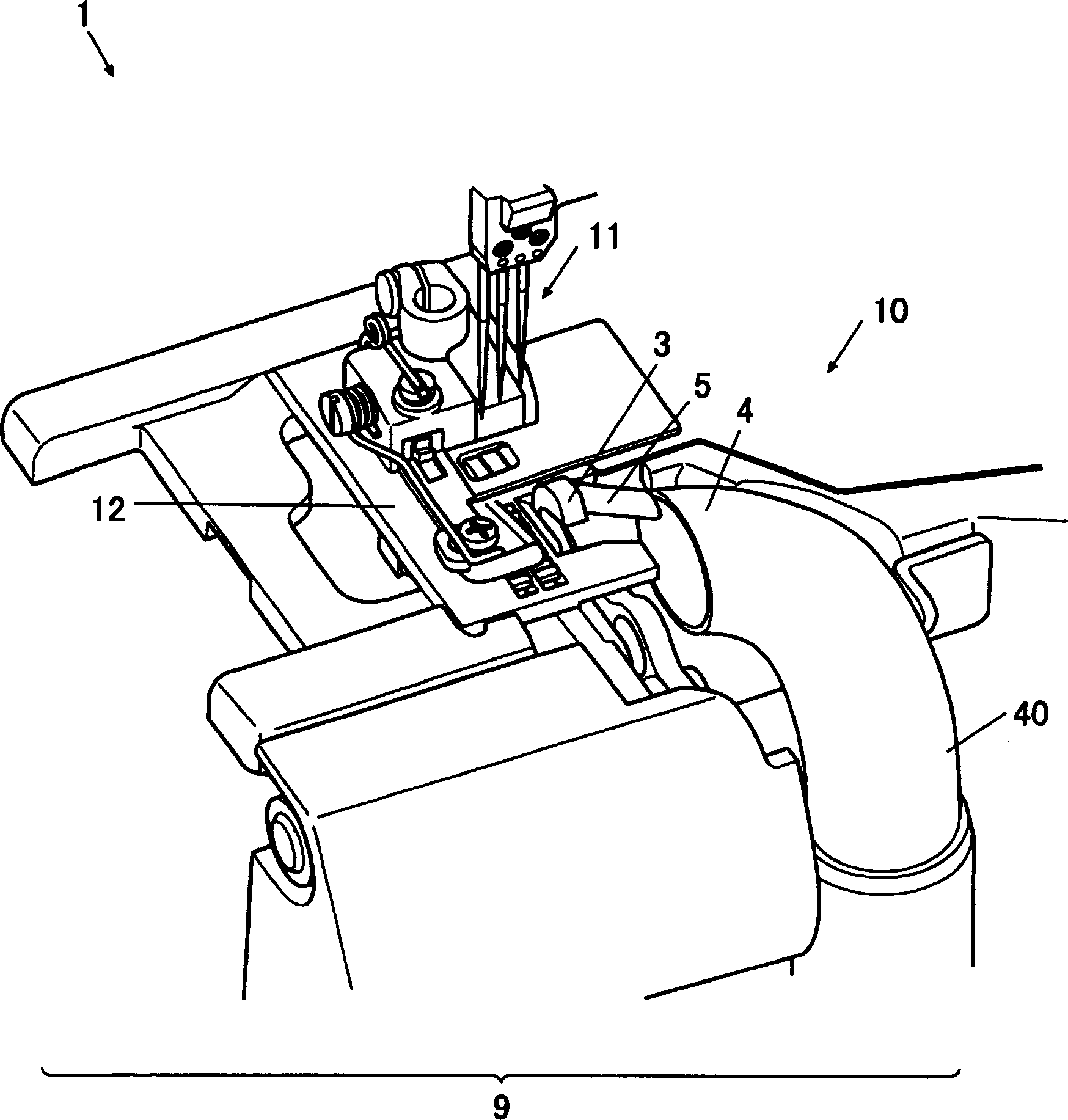

[0030] Such as figure 1 As shown, the cloth cutting device 1 is arranged near the needle plate 12 of the sewing machine frame 10, and the cloth cutting position is set at approximately the same height as the needle plate 12.

[0031] This cloth cutting device 1 has: a fixed knife unit 2 and a movable knife unit 3 for cutting cloth; The cloth waste guide part 5 of the suction part 4.

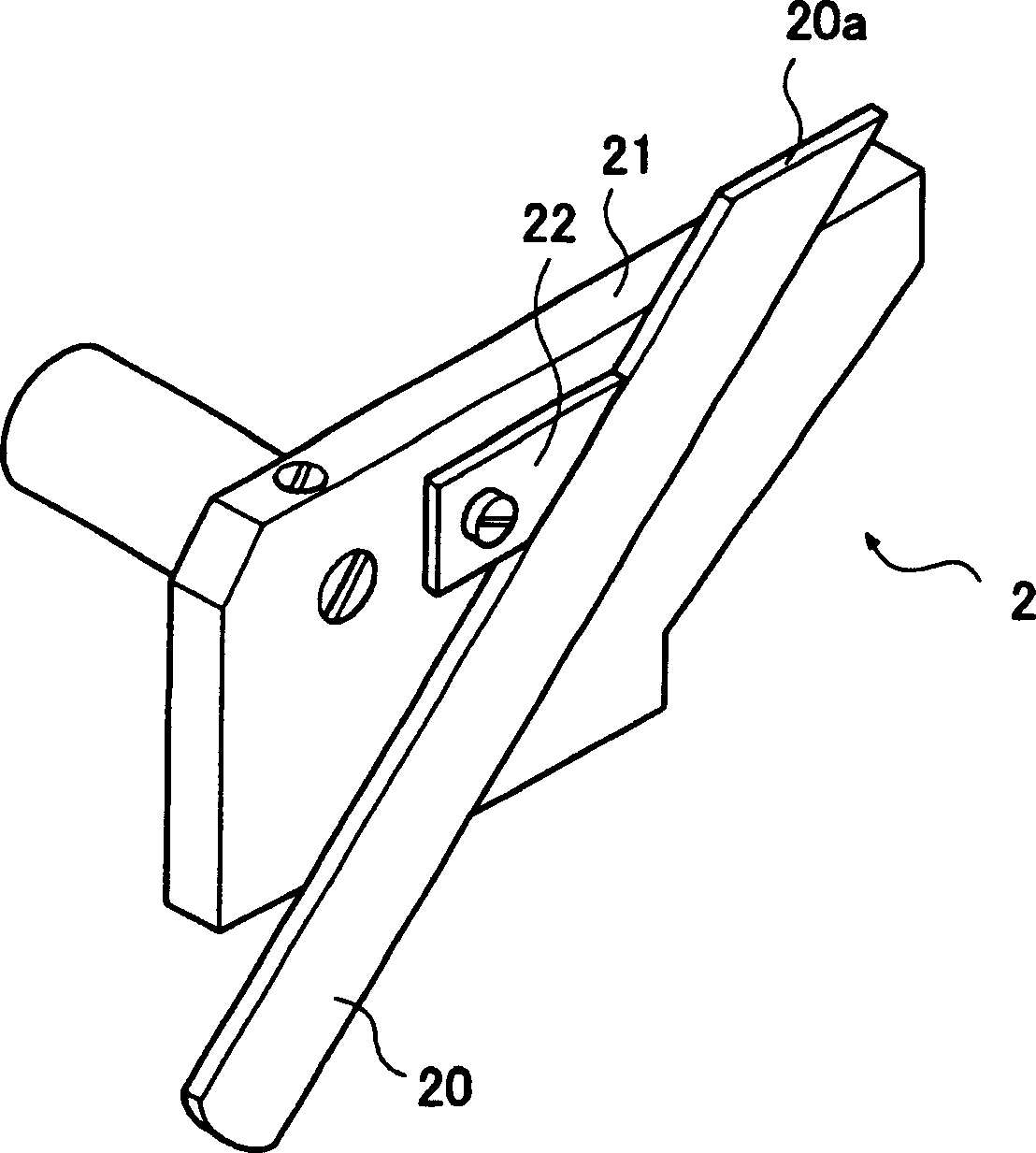

[0032] Fixed cutter part 2, such as figure 2 As shown, there are: an elongated fixed cutter 20 with a blade portion 20a at the upper end, a fixed cutter mounting seat 21 that is arranged on the sewing machine fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com