Rice washer

A funnel and main body technology, applied in the field of rice washing machines, can solve problems such as rice residue and achieve the effect of easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

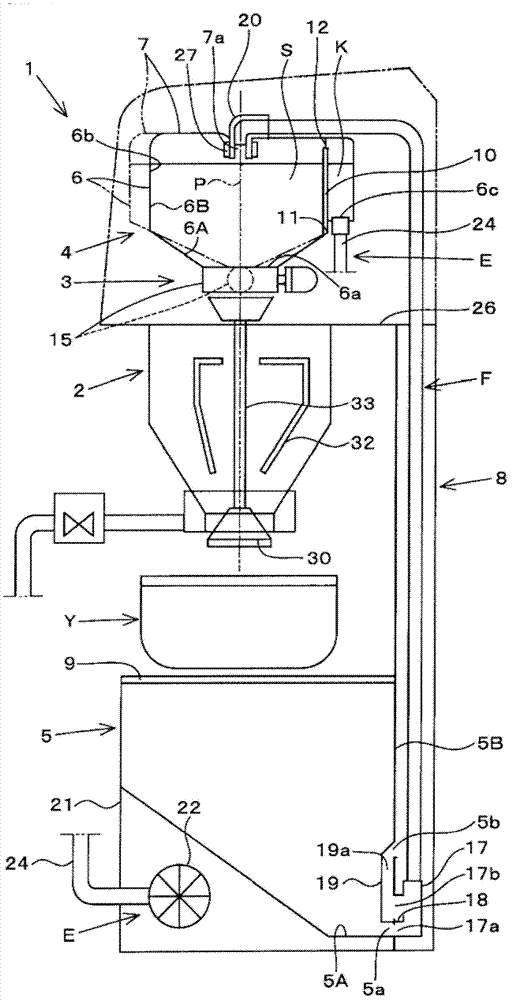

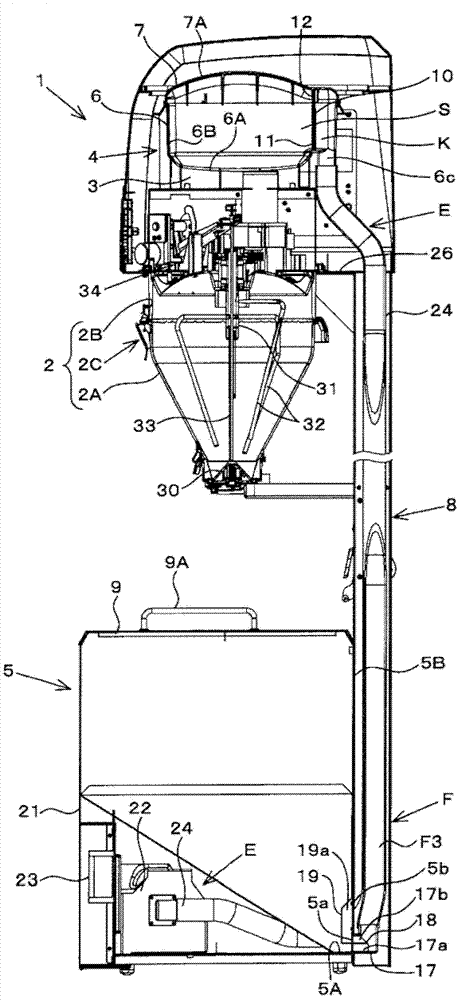

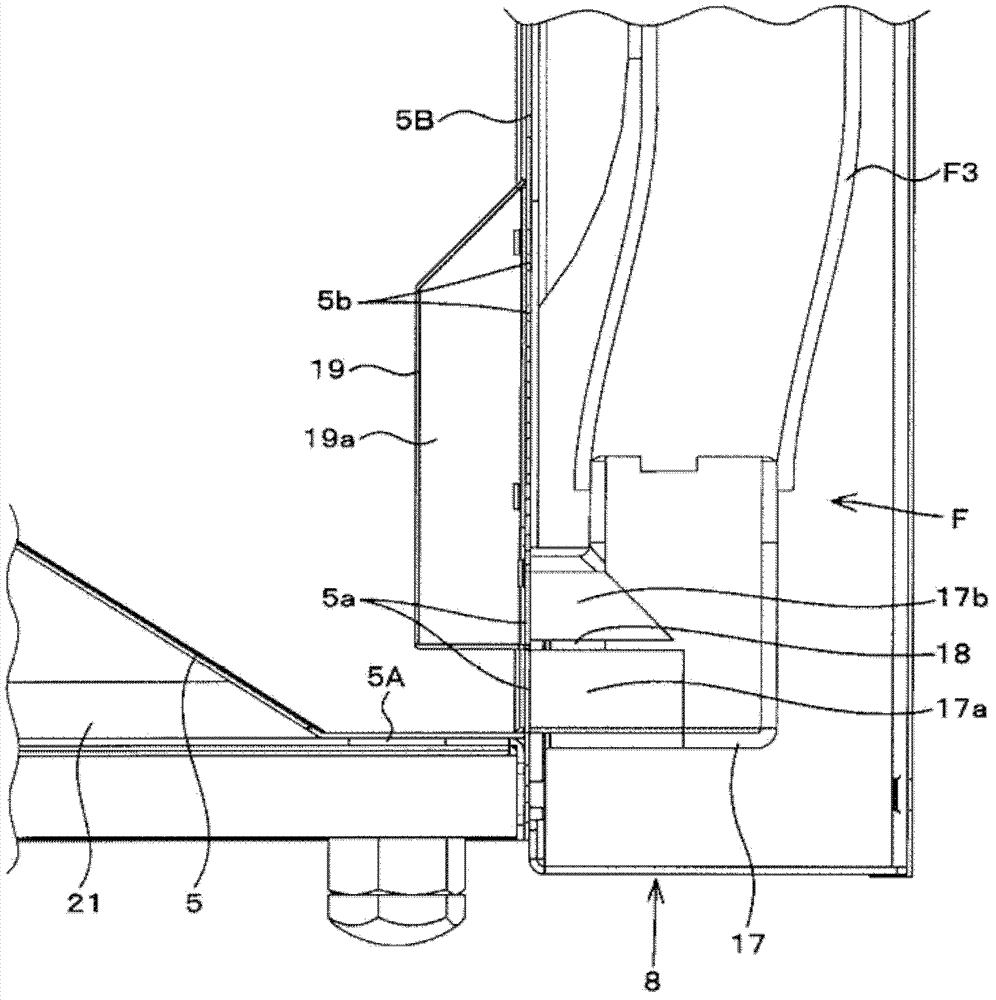

[0099] Next, embodiments of the present invention will be described with reference to the drawings.

[0100] exist figure 1 , 2 , 13, and 14, 1 represents the whole of the commercial rice washing machine, the top of the rice washing box 2 of the rice washing machine 1 is configured with an upper funnel 4 with a meter 3, and the rice storage box 5 is configured below the rice washing box 2. The above-mentioned upper funnel 4 is connected with a negative pressure unit E that makes the inside of the negative pressure. Between the described rice storage 5 and the upper funnel 4, the rice (comprising grains such as wheat) in the rice storage 5 is sucked and transported to The rice conveying unit F in the upper funnel 4, these rice washing boxes 2, the upper funnel 4 and the rice storage 5 are supported by the frame 8, and there is a loading platform 9 on the upper side of the rice storage 5, and the loading platform 9 The rice container Y that can receive nanometers such as rice ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com