Suction roll in a machine for producing a fibrous web

a technology of suction roll and fibrous web, which is applied in the direction of drying machine, press section, light and heating apparatus, etc., can solve the problems of insufficient removal of boundary air layer between paper web and roll or fabric which rests on it, difficulty in transfer of paper web, and inability to quickly remove boundary air layer or fabric, etc., to achieve the effect of reliably transferring over the web width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

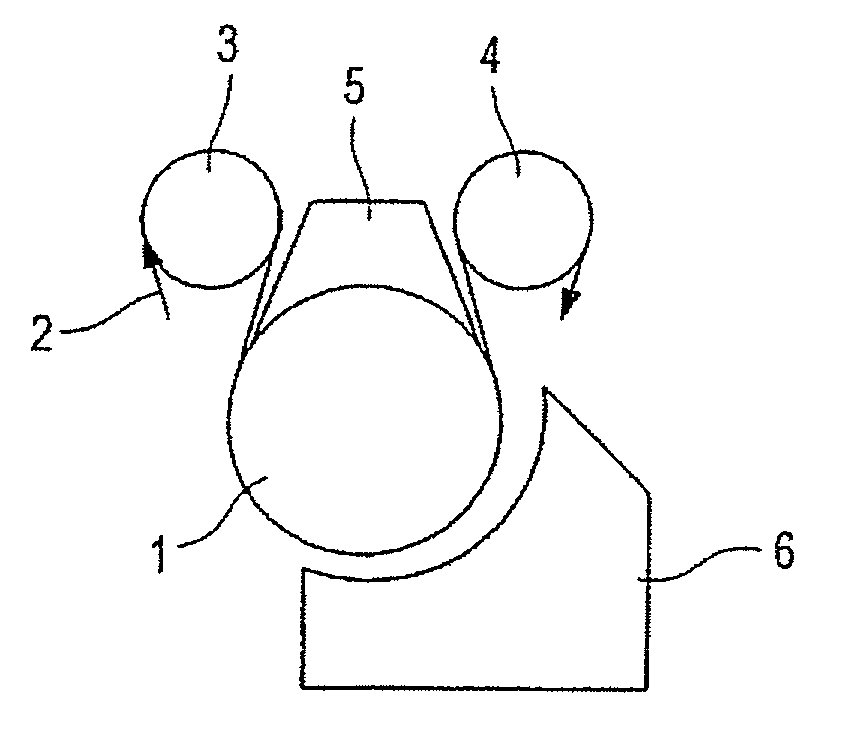

[0031] Referring now to the drawings, and more particularly to FIG. 1, there is shown a suction roll 1 is arranged behind a pressing section of a machine for producing a fibrous web 2, at the inlet of a drying section. A fibrous web 2 is guided over a first deflection roll 3 together with a dryer fabric, downward around the cover of the suction roll 1, and is guided further upward over a further deflection roll 4. A stabilizer 5 is positioned between the deflection rolls 3, 4 above the suction roll 1, which stabilizer 5 supplies the required vacuum, in order that the suction roll 1 can suck the fibrous web 2 onto its circumferential surface through the dryer fabric.

[0032] An impingement dryer 6 which covers substantially the outlet-side (as viewed in the web running direction) lower quadrant of the suction roll 1 and dries the fibrous web 2 is arranged on the underside of the suction roll 1.

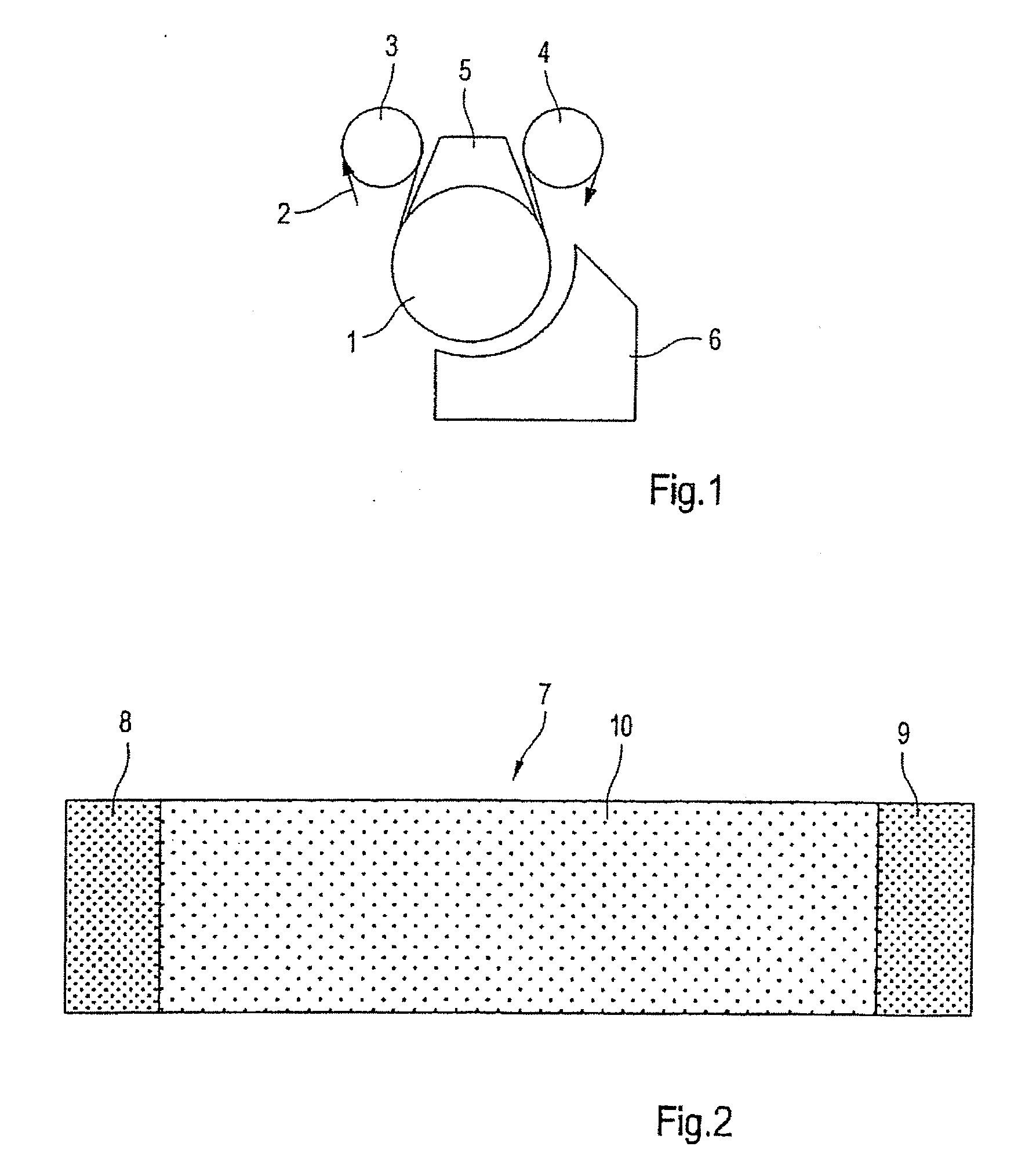

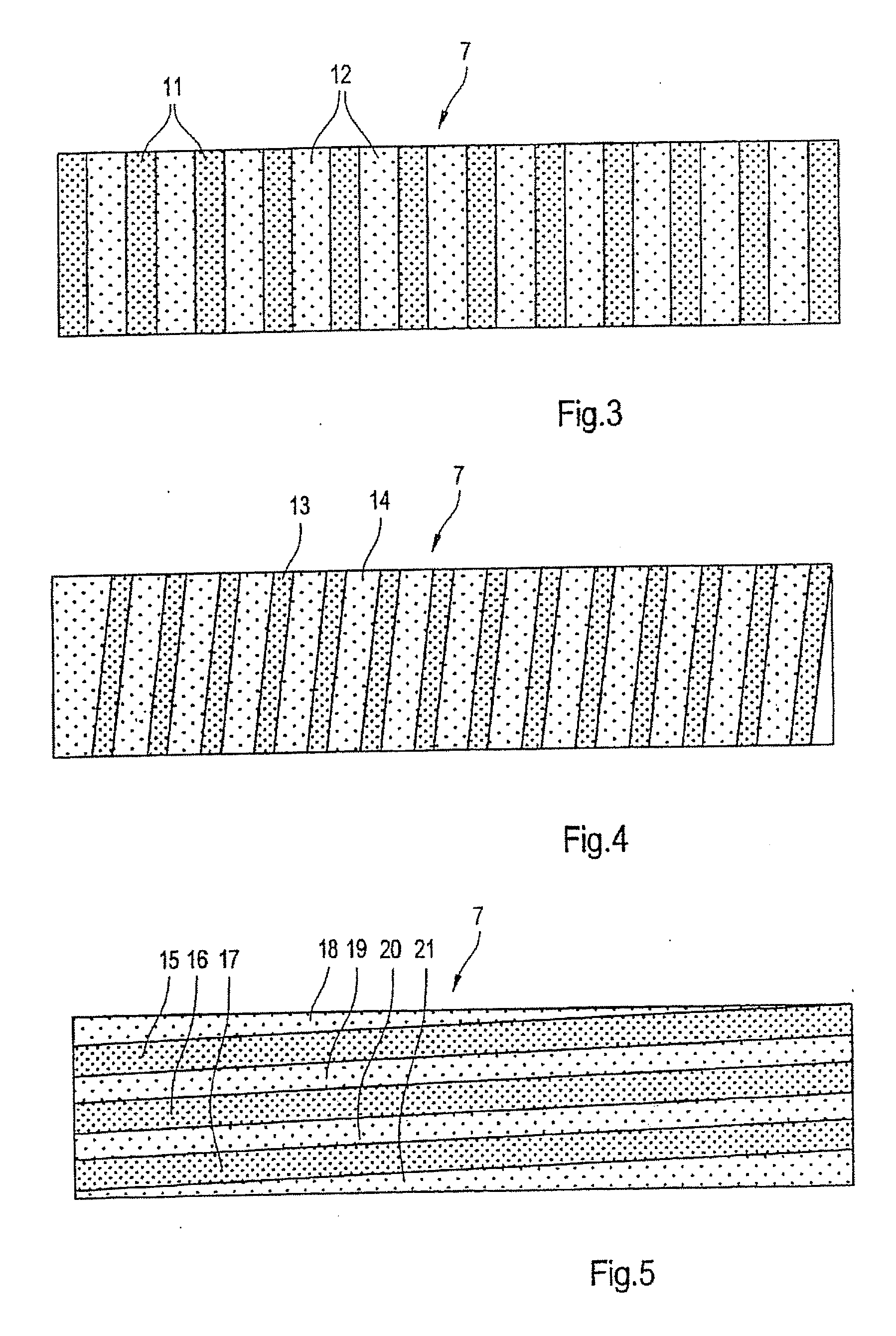

[0033] In one embodiment of the present invention, the suction roll 1 (FIG. 2) has at the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com