Fully automatic assembly device

An assembling device and fully automatic technology, applied in packaging capacitor devices, capacitor manufacturing, electrical components, etc., can solve the problems of incomplete sealing waist, damage to products, etc., to avoid false short-circuits, reduce waste, and improve product quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

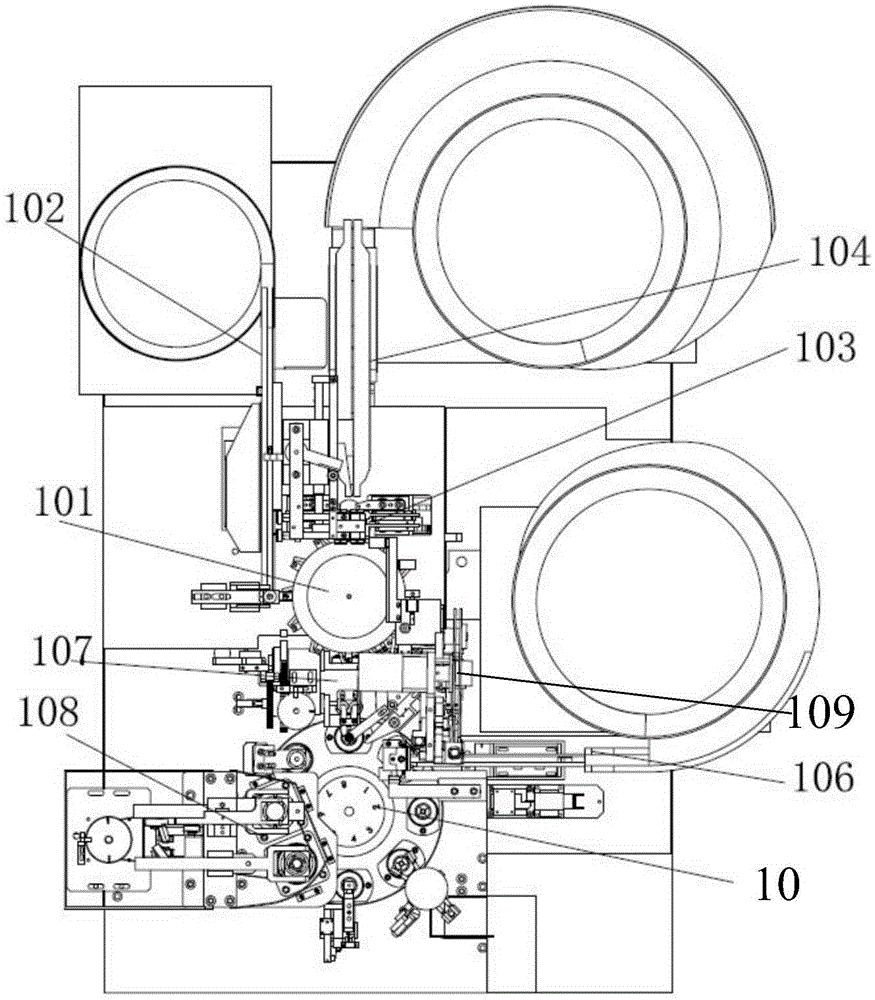

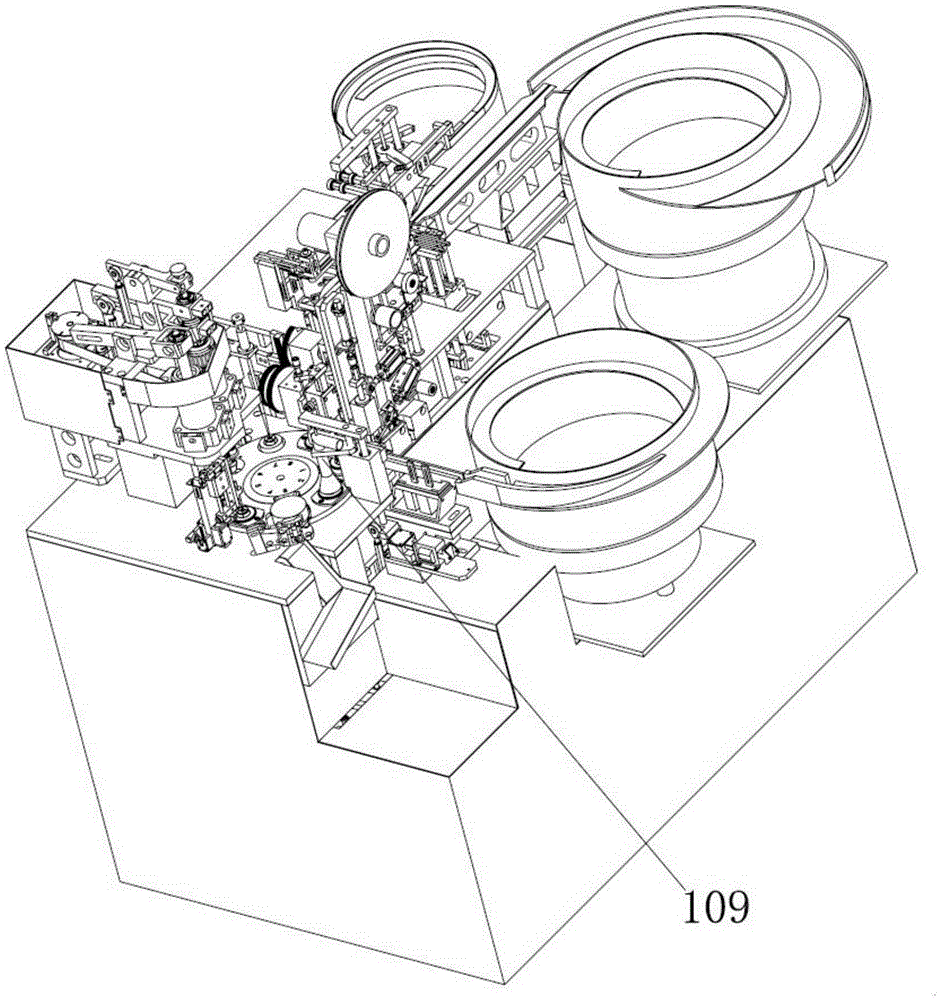

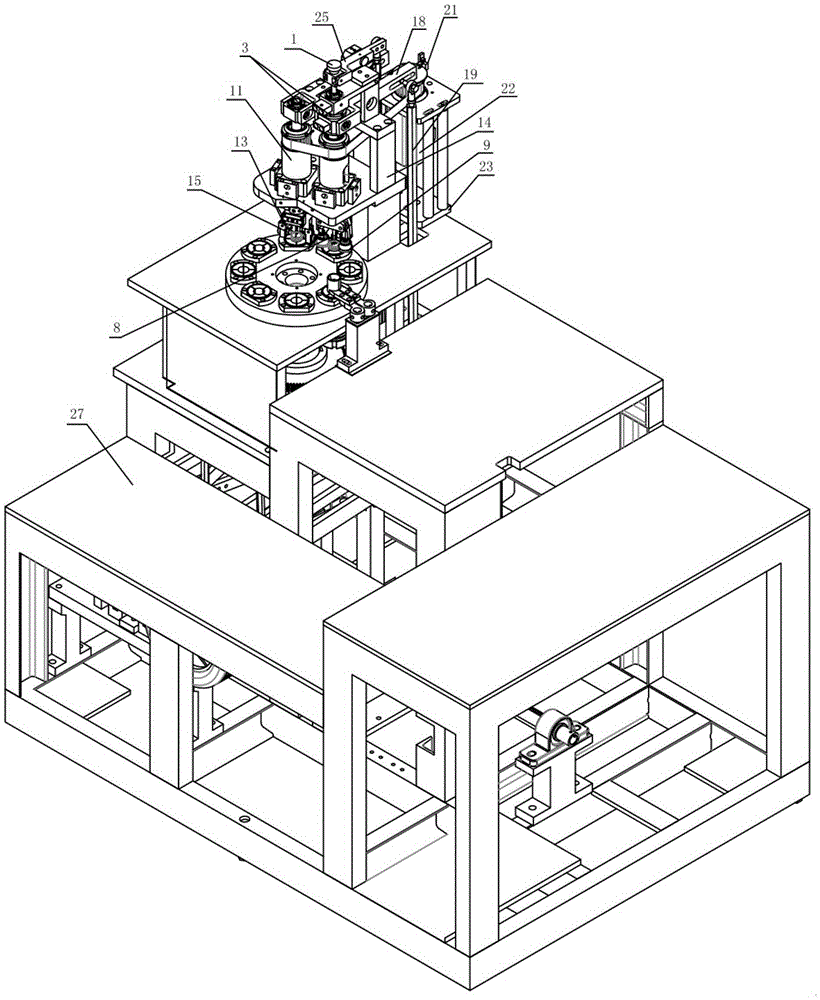

[0040] The electronic components in this application are mainly aimed at capacitors. The fully automatic assembly device in this application is mainly for the assembly of capacitor core packs, rubber plugs, and aluminum shells.

[0041] A fully automatic assembly device, comprising: a material tray 101 provided with multiple chucks, a rubber plug feeding device 102 for transporting rubber plugs to the material tray, and a device for installing core packs for the rubber plugs on the material tray The core package installation device 103, the core package feeding device 104 for delivering the core package to the core package installation device, the multi-station chuck plate 10 provided with a plurality of aluminum shell chucks, and the aluminum shell is transported to the multi-station The aluminum shell feeding device 106 of the chuck plate, the flip feeding clamp device 107 and the sealing waist device 108 for transferring the electronic components initially assembled on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com