Capacitor gummed paper machine

A technology of capacitors and tapes, which is applied in the direction of capacitors, capacitor manufacturing, packaging capacitor devices, etc., can solve the problems of high labor costs, consumption of tape scraps, and processing of the top of the capacitor body and the curved body of the body, etc., to achieve The effect of good glue quality and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

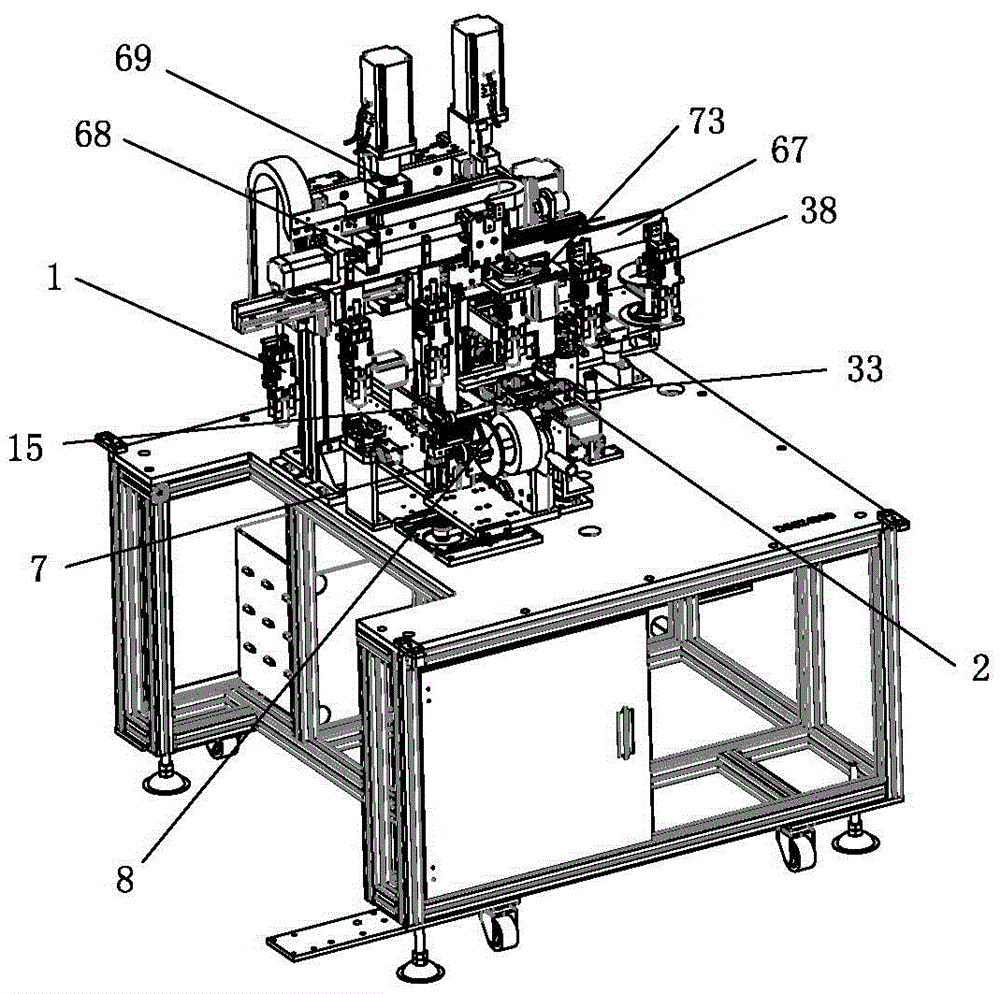

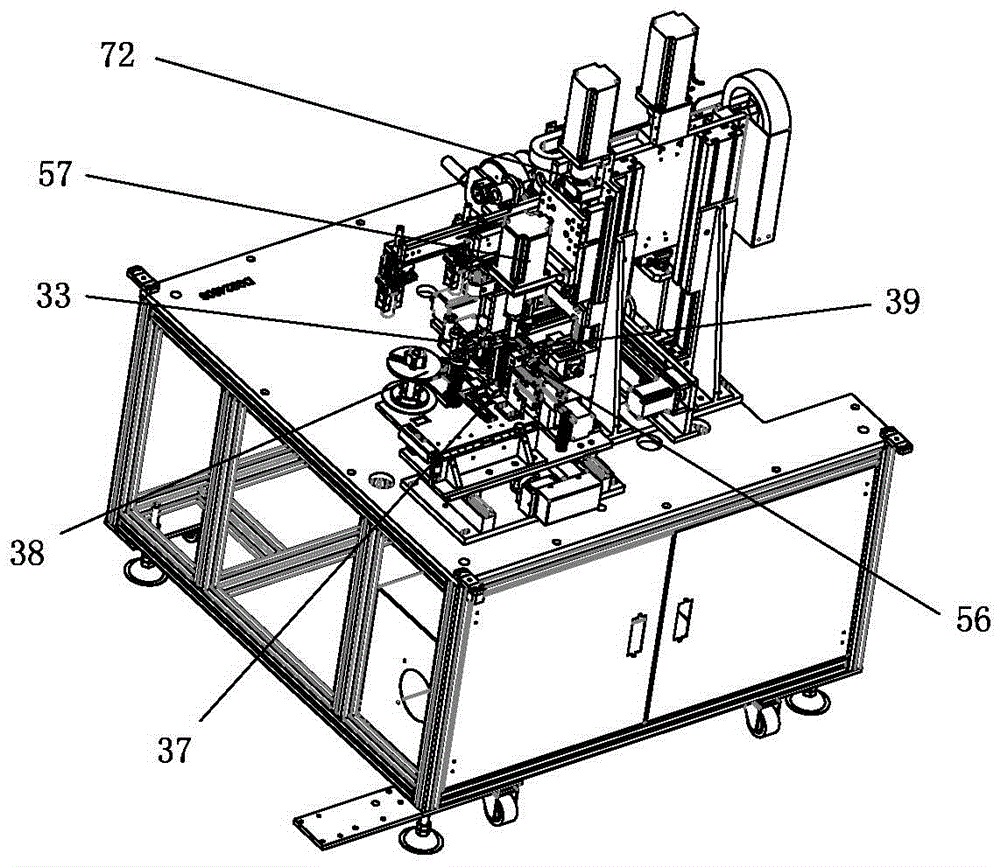

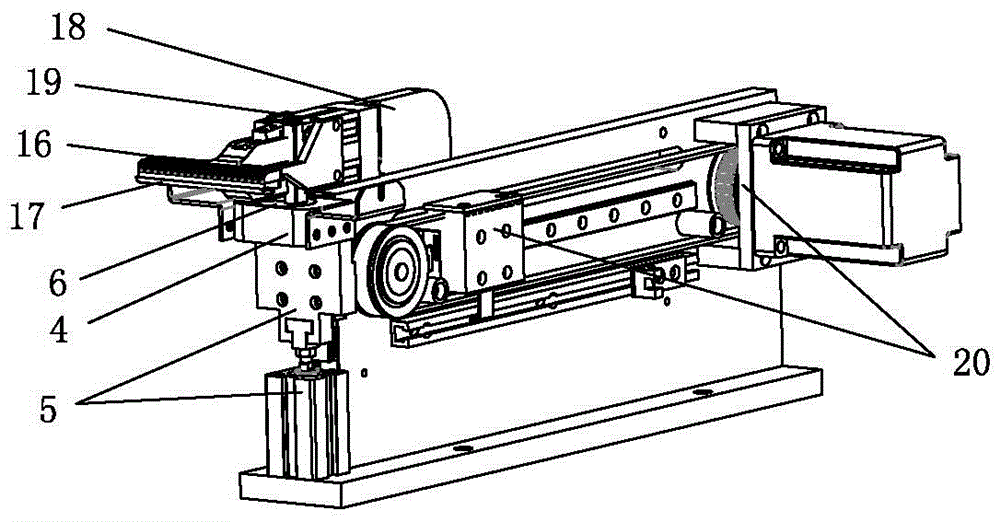

[0027] For the convenience of those skilled in the art to understand, below in conjunction with embodiment and appended Figure 1-Figure 10 To further illustrate the present invention, the content mentioned in the embodiment is not to limit the present invention.

[0028] A capacitor wrapping paper machine, including a feeding mechanism for transporting capacitors to be processed, a top wrapping mechanism for wrapping the top of the capacitor, and a wrapper for wrapping the curved surface of the capacitor set at the discharge end of the feeding mechanism The main body rubber covering mechanism, the feeding mechanism includes a plurality of manipulators 1 arranged alternately for clamping the capacitor to be processed and a feeding drive device for driving a plurality of manipulators 1 to move left and right or up and down, the top rubber covering The mechanism includes the first adhesive paper feeding device for feeding and cutting the adhesive paper and the tightening assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com