Automatic pre-pressing mechanism applicable to multi-specification capacitor cover plates

A capacitor cover, multi-specification technology, applied in the direction of capacitors, capacitor manufacturing, packaging capacitor devices, etc., can solve the problems of unstable cover preload quality, low automation, low production efficiency, etc., and achieve high automation and preload The effect of high yield and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

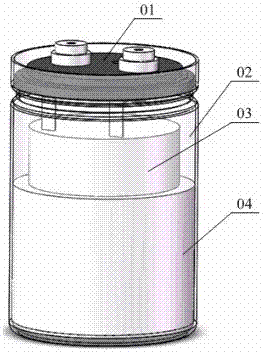

[0028] After completing the process of puncturing the pins of the capacitor core package, riveting the cover plate, and pouring glue on the aluminum shell, the core package after the puncture and the riveted cover plate need to be put into the aluminum shell that has been filled with glue to form a semi-finished capacitor. The preloading mechanism preloads the cover plate, and the schematic diagram of the cover plate after preloading is as follows: figure 1 shown. Aluminum electrolytic capacitors are mainly composed of cover plate 01, aluminum shell 02, core pack 03, fixative 04, etc. Aluminum electrolytic capacitors have various specifications, and the corresponding capacitor cover plate 01, aluminum shell 02 and core package 03 also have various specifications. For capacitors of different specifications, the diameter of the cover p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com