Aluminum electrolytic capacitor and manufacturing method thereof

A technology of an aluminum electrolytic capacitor and a manufacturing method, applied in the field of capacitors, can solve the problems of inconvenient use of lamps, large space occupied by electrolytic paper, increased volume and weight of lamps, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A manufacturing method of an aluminum electrolytic capacitor, the manufacturing method comprising the following steps:

[0046] 1) Foil cutting: Cut the capacitor paper, anode foil, cathode foil, and aluminum lead-out strips into specified sizes for use in the next process; the withstand voltage of the anode foil is selected as 1.2 times the working voltage;

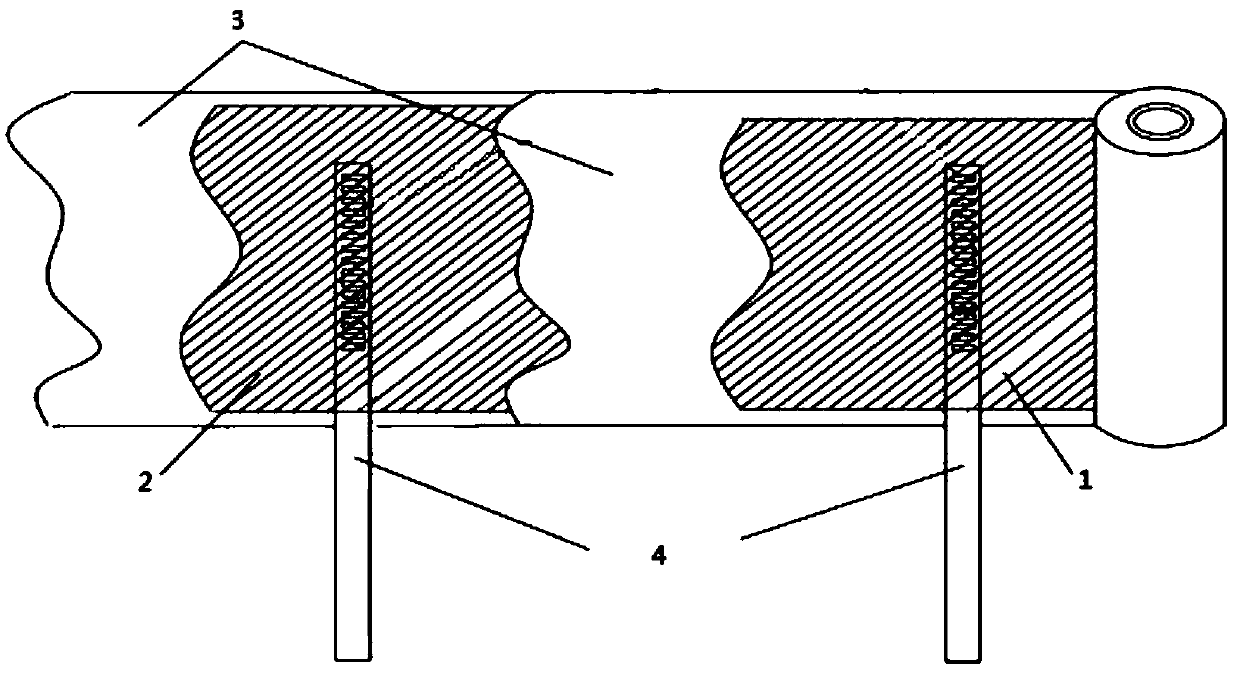

[0047] 2) Winding: Rivet the lead bar or lead wire on the corresponding aluminum foil, and roll the riveted anode and cathode foils and electrolytic paper into a capacitor core; the thickness of the electrolytic paper is 70% of the general thickness, and the density of the electrolytic paper is 110% of the general density;

[0048] 3) Impregnation: After the core is dried, it is impregnated with the electrolyte of the corresponding working voltage, which acts as the cathode to repair the oxide film;

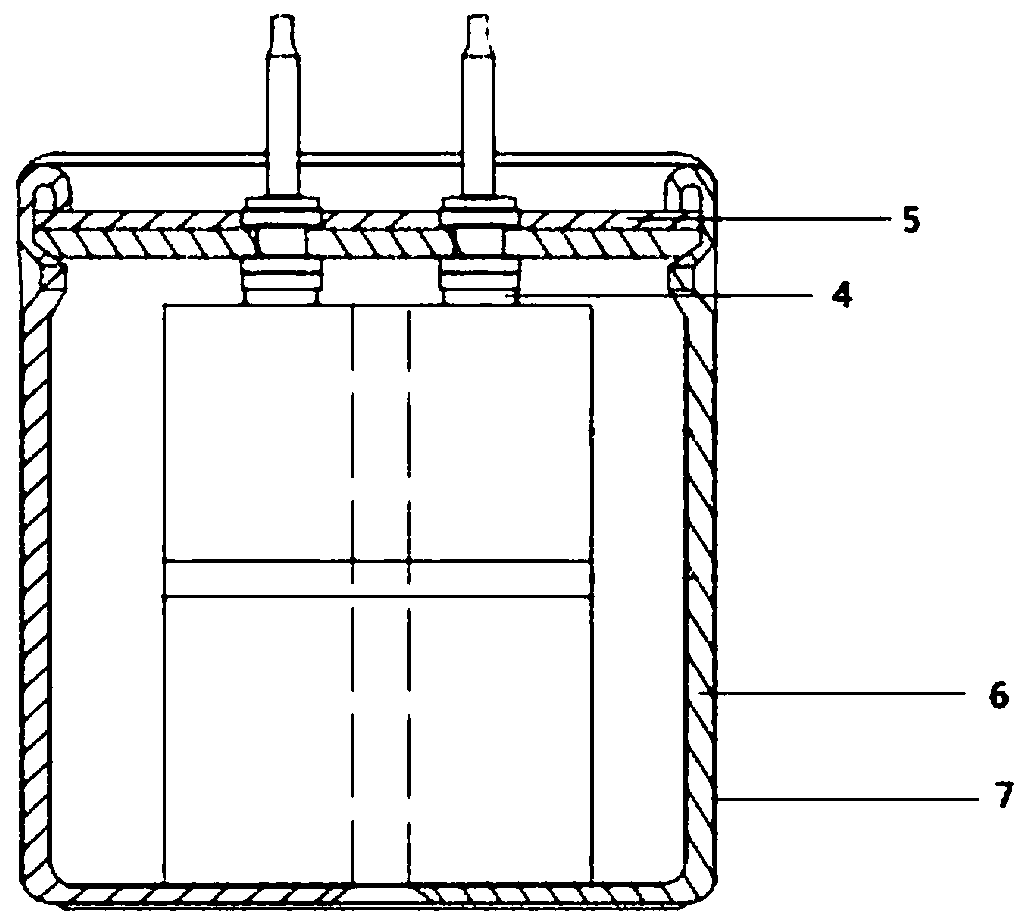

[0049] 4) Assembly and sealing: riveting or welding the core and the cover plate, lead products: the two leads of...

Embodiment 2

[0059] A manufacturing method of an aluminum electrolytic capacitor, the manufacturing method comprising the following steps:

[0060] 1) Foil cutting: Cut the capacitor paper, anode foil, cathode foil, and aluminum lead-out strips into specified sizes for use in the next process; the withstand voltage of the anode foil is selected as 1.25 times the working voltage;

[0061] 2) Winding: Rivet the lead bar or lead wire on the corresponding aluminum foil, and roll the riveted anode and cathode foils and electrolytic paper into a capacitor core; the thickness of the electrolytic paper is 75% of the general thickness, and the density of the electrolytic paper is 112% of the general density;

[0062] 3) Impregnation: After the core is dried, it is impregnated with the electrolyte of the corresponding working voltage, which acts as the cathode to repair the oxide film;

[0063] 4) Assembly sealing: riveting or welding the core and the cover plate, lead products: insert the two lead...

Embodiment 3

[0073] A manufacturing method of an aluminum electrolytic capacitor, the manufacturing method comprising the following steps:

[0074] 1) Foil cutting: Cut the capacitor paper, anode foil, cathode foil, and aluminum lead-out strips into specified sizes for use in the next process; the withstand voltage of the anode foil is selected as 1.3 times the working voltage;

[0075] 2) Winding: Rivet the lead bar or lead wire on the corresponding aluminum foil, and roll the riveted anode and cathode foils and electrolytic paper into a capacitor core; the thickness of the electrolytic paper is 80% of the general thickness, and the density of the electrolytic paper is 115% of the general density;

[0076] 3) Impregnation: After the core is dried, it is impregnated with the electrolyte of the corresponding working voltage, which acts as the cathode to repair the oxide film;

[0077] 4) Assembly sealing: riveting or welding the core and the cover plate, lead products: insert the two leads...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com