Fully automatic capacitor seat plate assembly test packaging machine

A seat plate group and packaging machine technology, which is applied in the direction of packaging capacitor devices, capacitors, capacitor manufacturing, etc., can solve the problems of not being able to meet the needs of machine work efficiency, heavy product stress, product damage, etc., and achieve easy product quality assurance, The effect of small product stress and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The fully automatic capacitor seat board assembly test packaging machine is a mechanized capacitor automatic processing equipment that is used in the capacitor production and processing process to assemble bare capacitors and seat boards together for printing, performance testing and packaging.

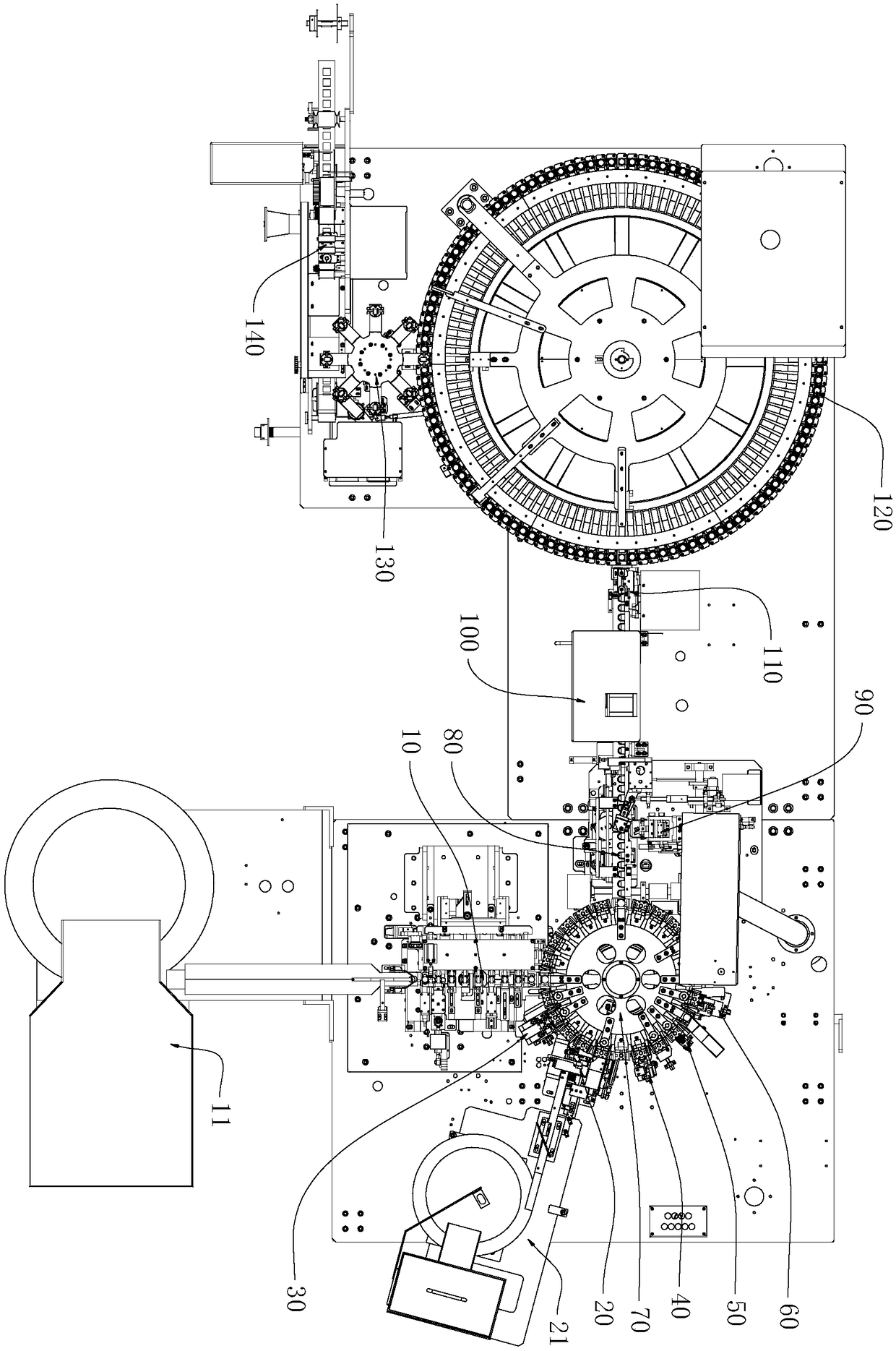

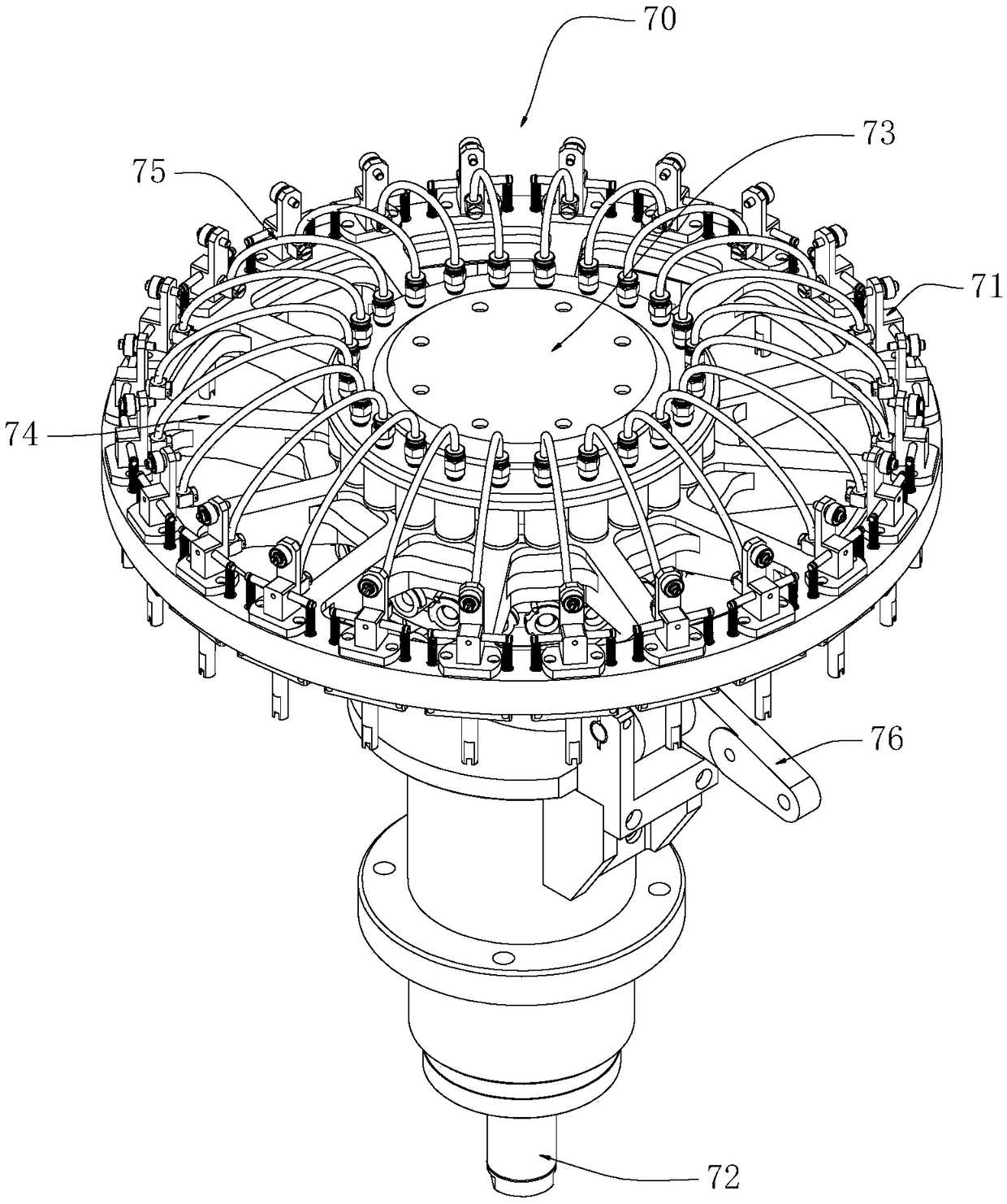

[0038] refer to figure 1 and figure 2 , the present invention provides a fully automatic capacitor plate assembly test packaging machine, the packaging machine is a purely mechanized capacitor automatic processing equipment, the capacitor plate assembly test packaging machine includes a frame and is arranged on the frame The feeding mechanism 10, the rotary multi-station vacuum transfer mechanism 70, the printing transfer mechanism 80, the printing mechanism 90, the printing baking mechanism 100, the printing transfer mechanism 110, the charging test mechanism 120, the rotary transfer mechanism 130, the upper pit belt Mechanism 150, packaging mechanism 140 and man-machine con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com