Onion cutting device

A cutting device and onion technology, applied in the direction of wrapping paper bending device, packaging, transportation packaging, etc., can solve the problems of low efficiency, cumbersome, laborious, etc., and achieve the effect of prolonging the service life and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

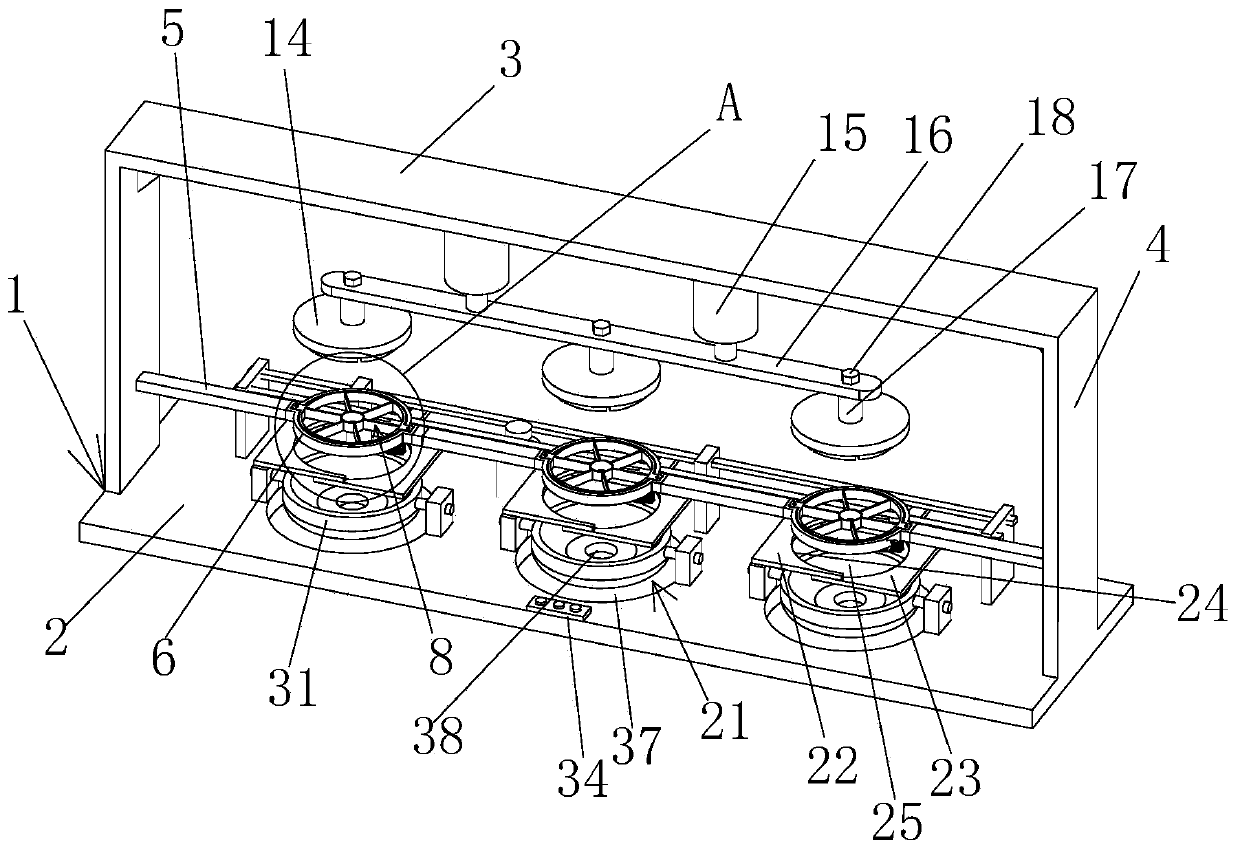

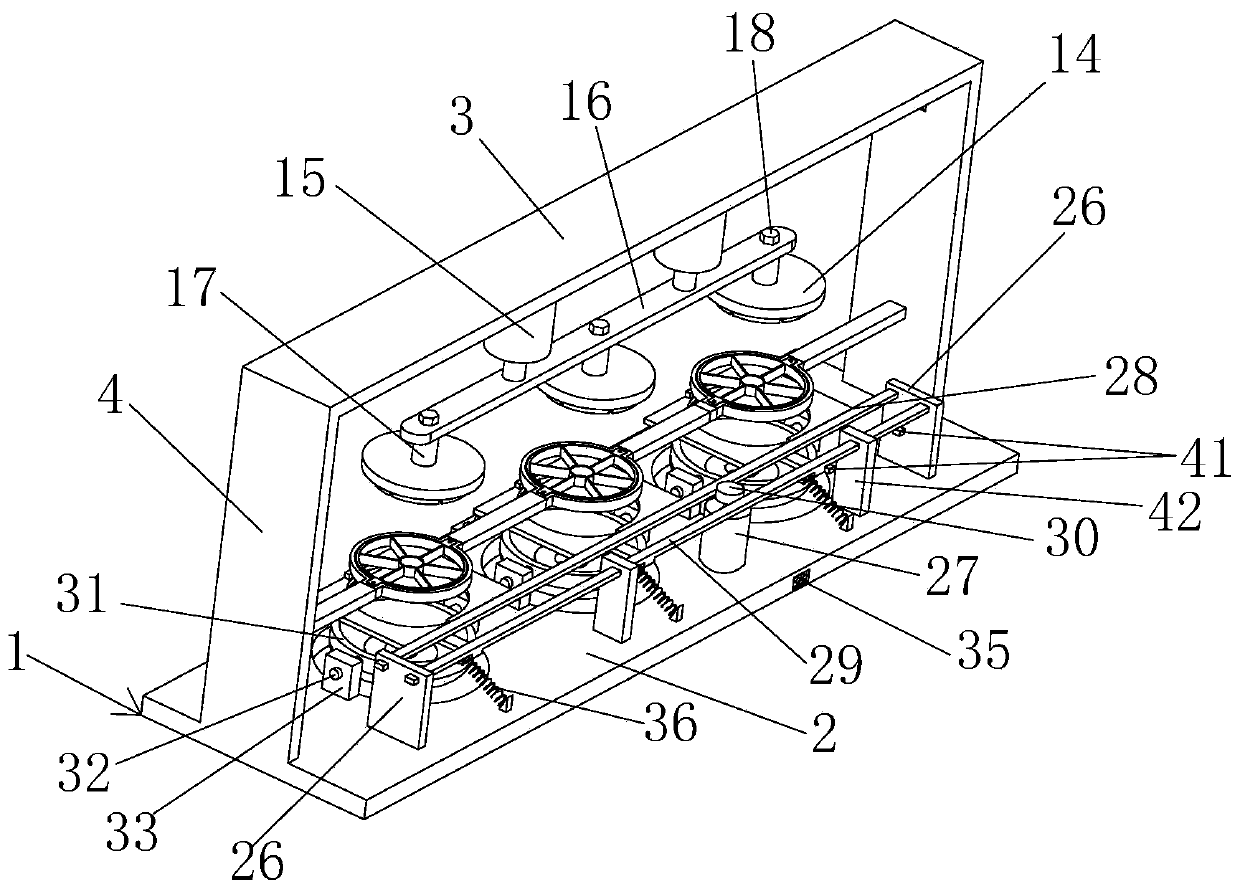

[0031] Such as Figure 1-5As shown, an onion cutting device includes a frame 1, the frame 1 includes a base plate 2, a beam 3 located above the base plate 2 and parallel to the base plate 2, and the upper end surface of the base plate 2 is fixedly connected with two supporting plates 4 parallel to each other. , The beam 3 is fixedly connected to the upper end of the support plate 4 .

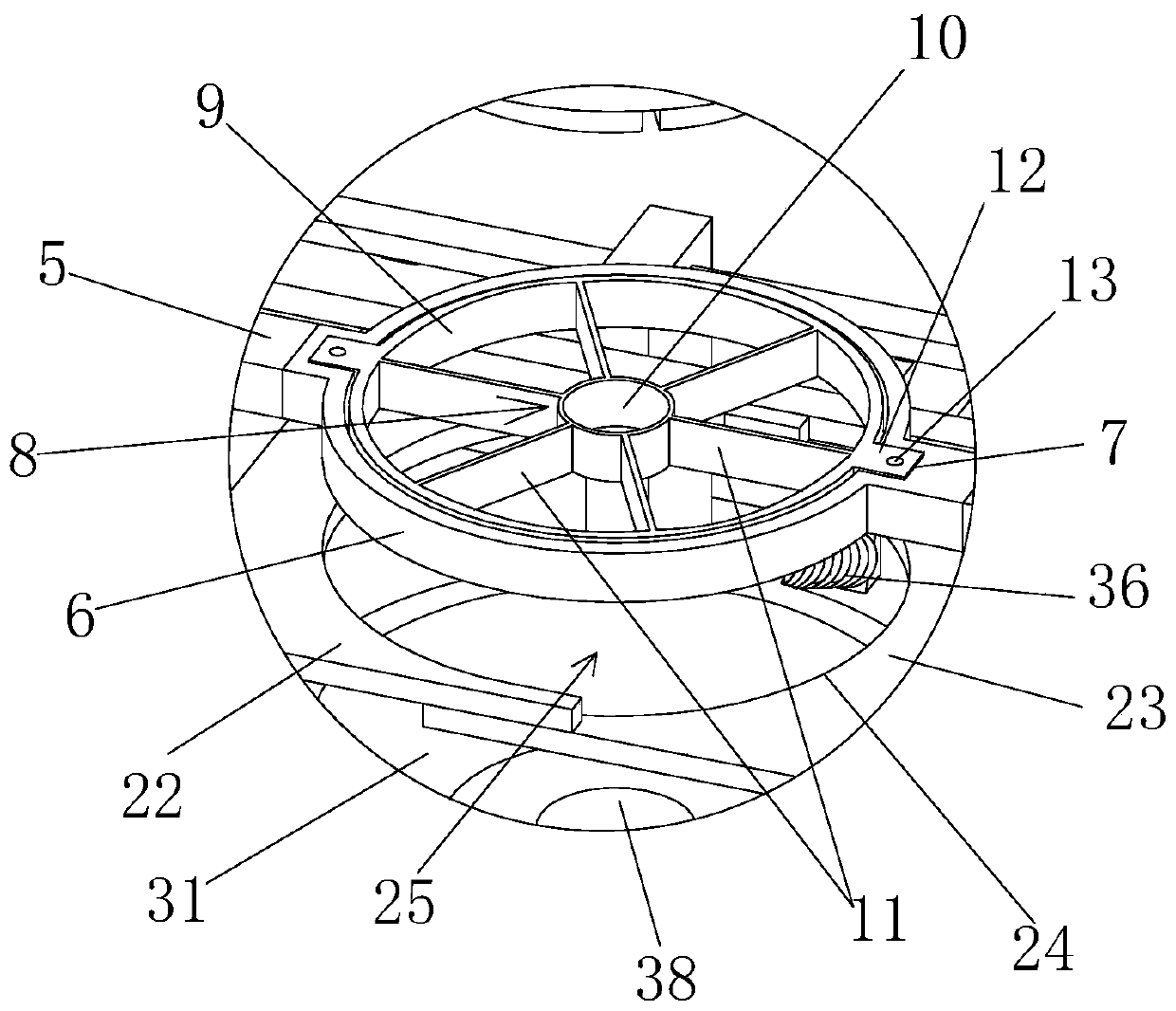

[0032] A cross bar 5 is fixedly connected between the two support plates 4, and three tool mounting frames 6 are fixedly connected to the cross bar 5, and the three tool mounting frames 6 are located on the same straight line, and the tool mounting frames 6 are circular structure, two draw-in grooves 7 are evenly arranged on the annular cutter mount 6, and the draw-in groove 7 communicates with the upper end surface and the inner surface of the cutter mount 6 at the same time, and each cutter mount 6 is detachably and fixedly connected with A cutting tool 8 arranged laterally, the cutting tool ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com