Patents

Literature

108 results about "Magneto hydrodynamic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

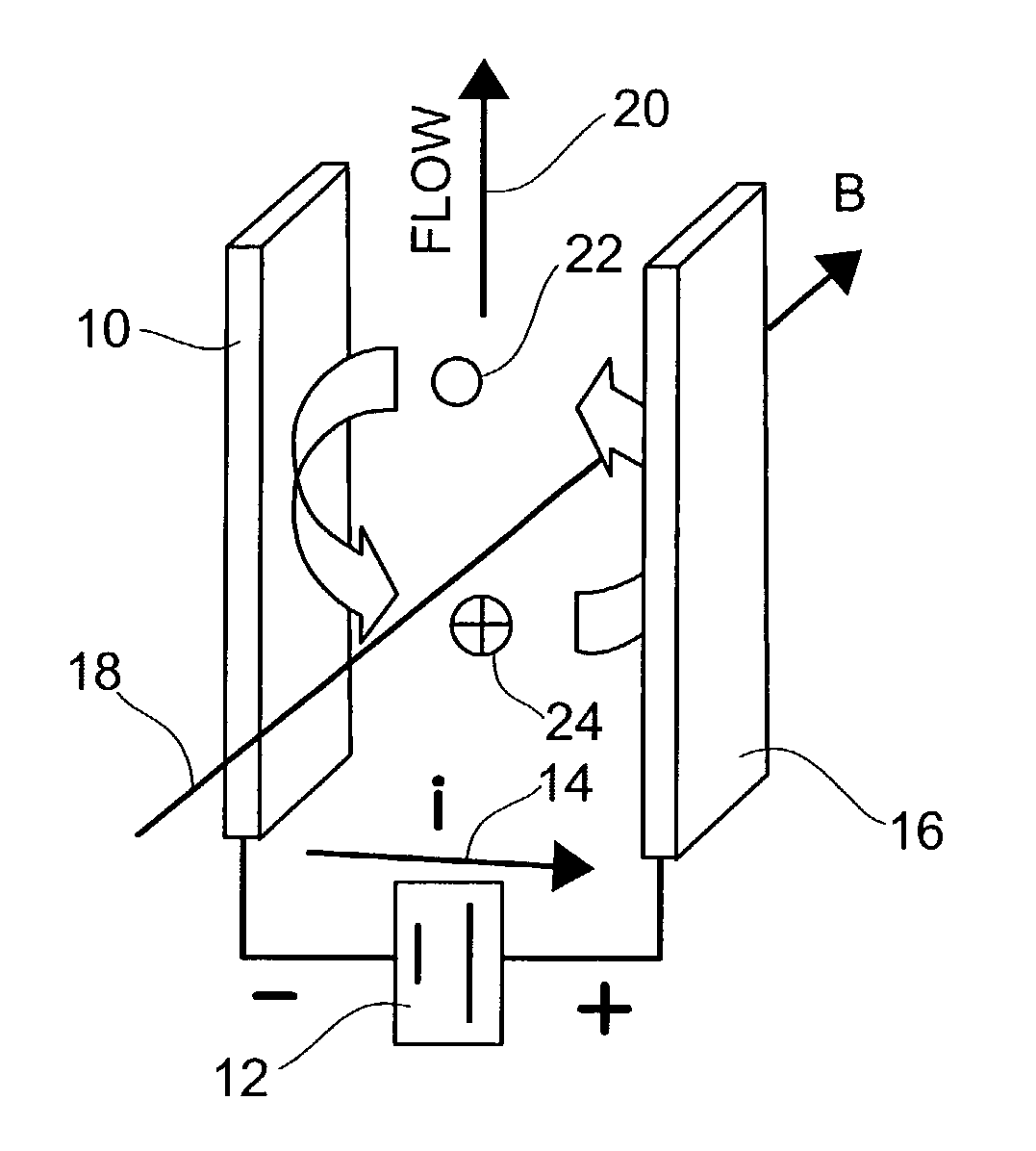

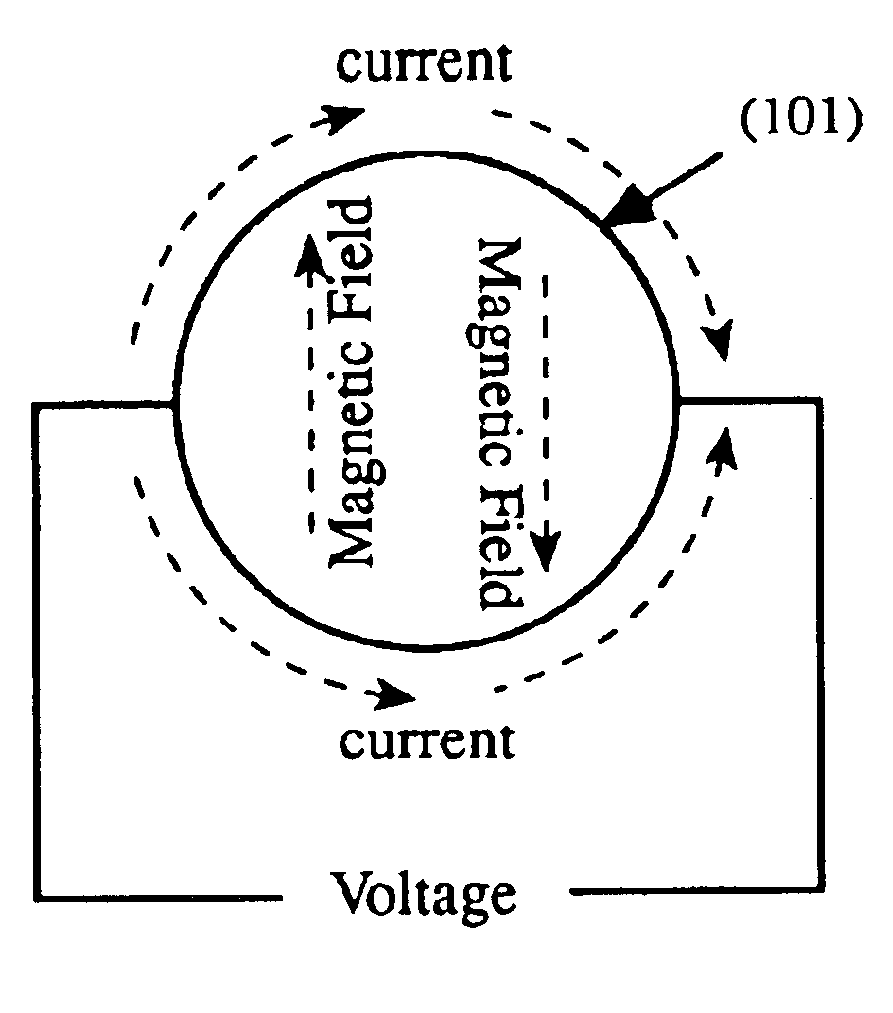

The magneto hydrodynamic generation system converts heat energy into electrical energy based on the principle of Faraday’s law of electromagnetic induction. This law states that an EMF is induced in a conductor that is moving in a magnetic field.

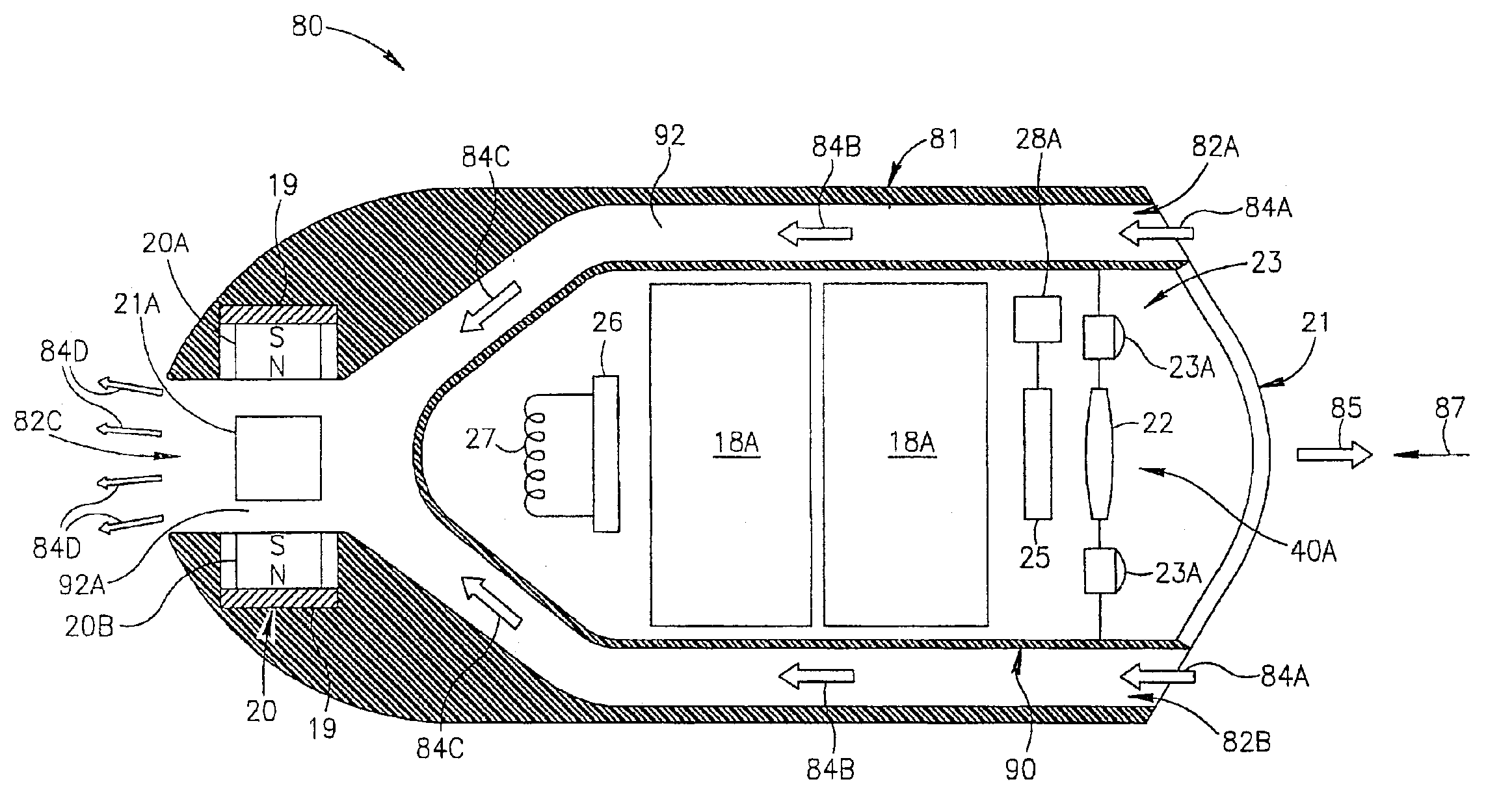

Self propelled device having a magnetohydrodynamic propulsion system

InactiveUS6939290B2Optical radiation measurementOesophagoscopesMagnetohydrodynamic driveMagneto hydrodynamic

Owner:GIVEN IMAGING LTD

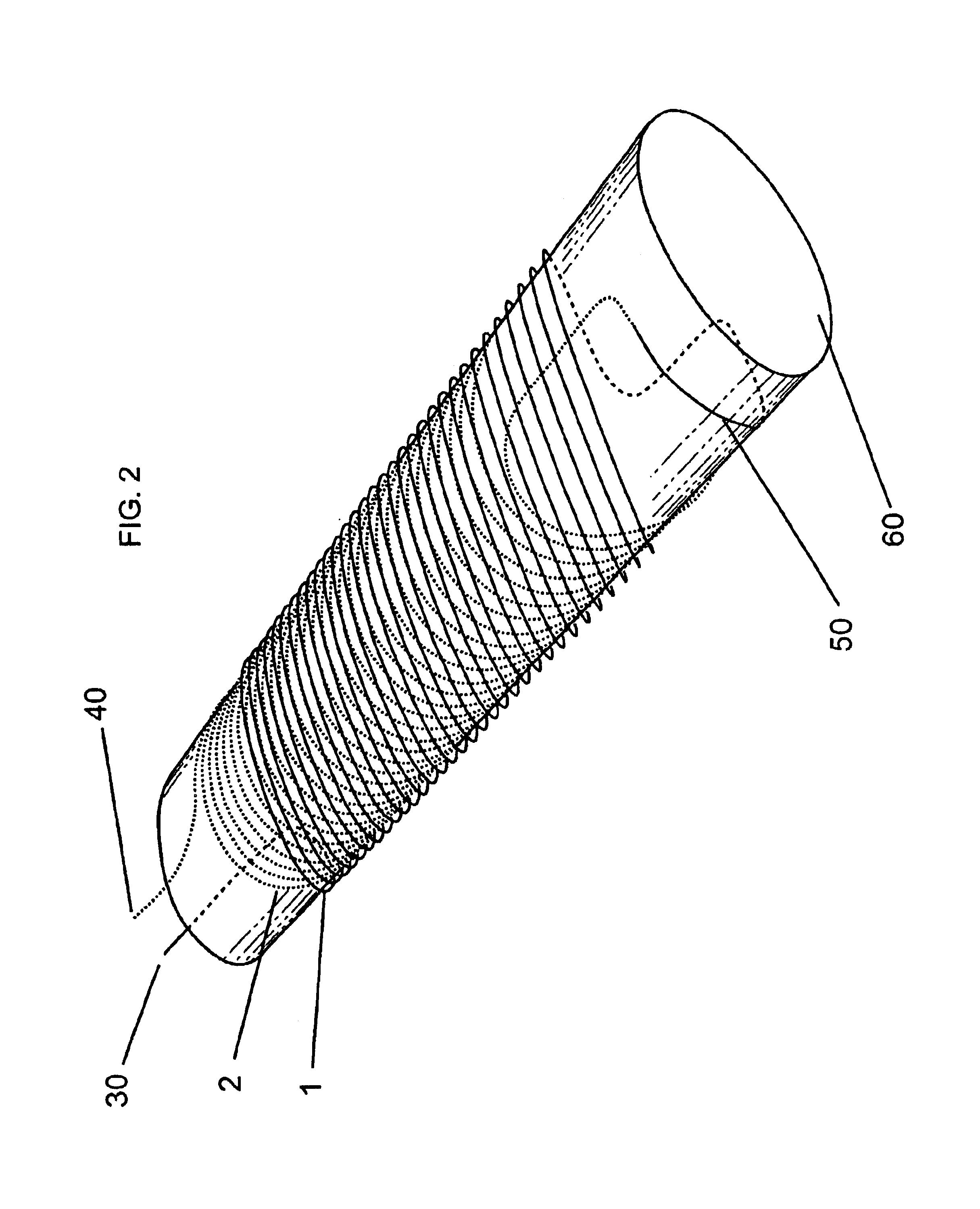

Concentric tilted double-helix dipoles and higher-order multipole magnets

InactiveUS6921042B1Simple processLess costlyElectromagnets without armaturesFilament handlingElectric machineryMagneto hydrodynamic

Concentric tilted double-helix magnets, which embody a simplified design and construction method for production of magnets with very pure field content, are disclosed. The disclosed embodiment of the concentric tilted double-helix dipole magnet has the field quality required for use in accelerator beam steering applications, i.e., higher-order multipoles are reduced to a negligibly small level. Magnets with higher multipole fields can be obtained by using a simple modification of the coil winding procedure. The double-helix coil design is well-suited for winding with superconducting cable or cable-in-conduit conductors and thus is useful for applications that require fields in excess of 2 T. The coil configuration has significant advantages over conventional racetrack coils for accelerators, electrical machinery, and magneto-hydrodynamic thrusting devices.

Owner:GOODZEIT CARL L +2

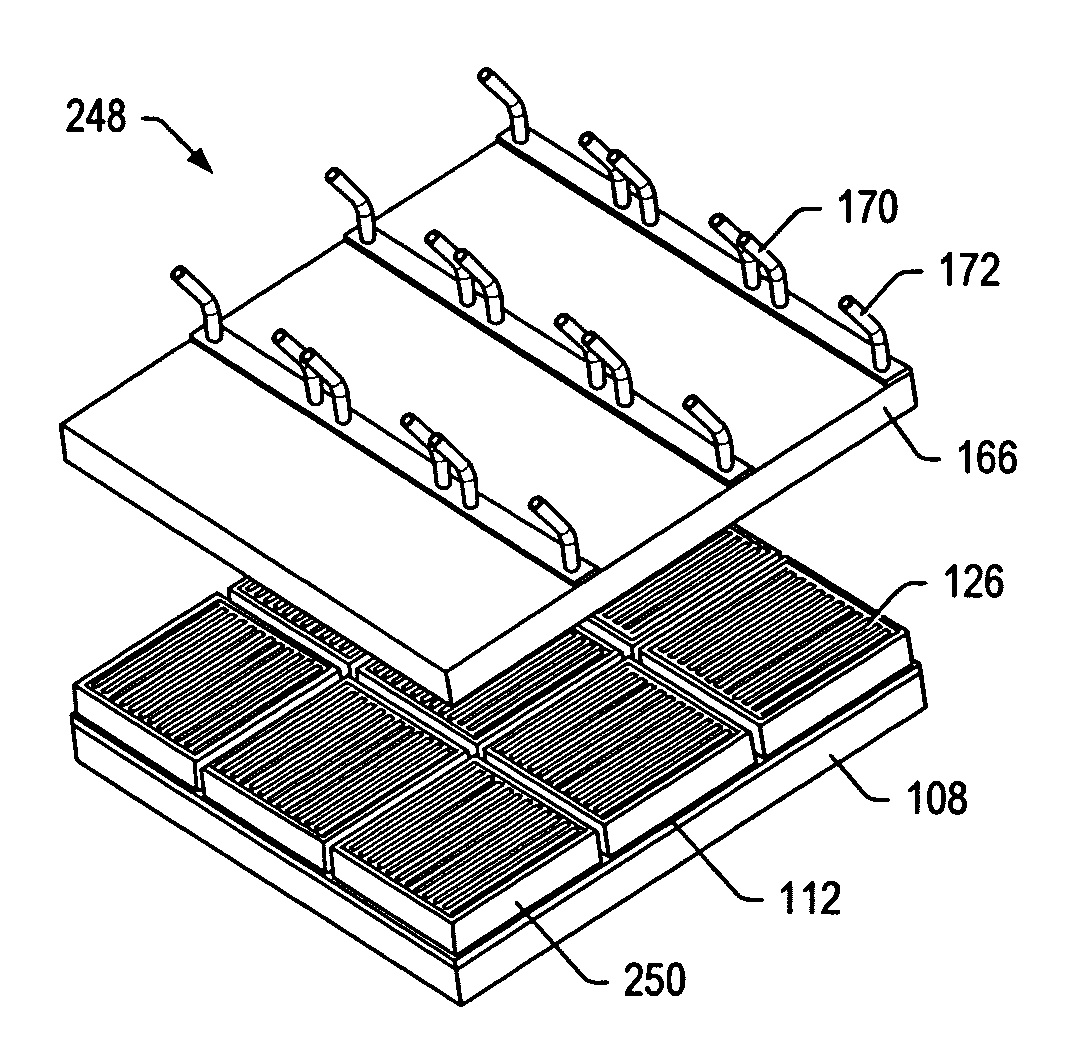

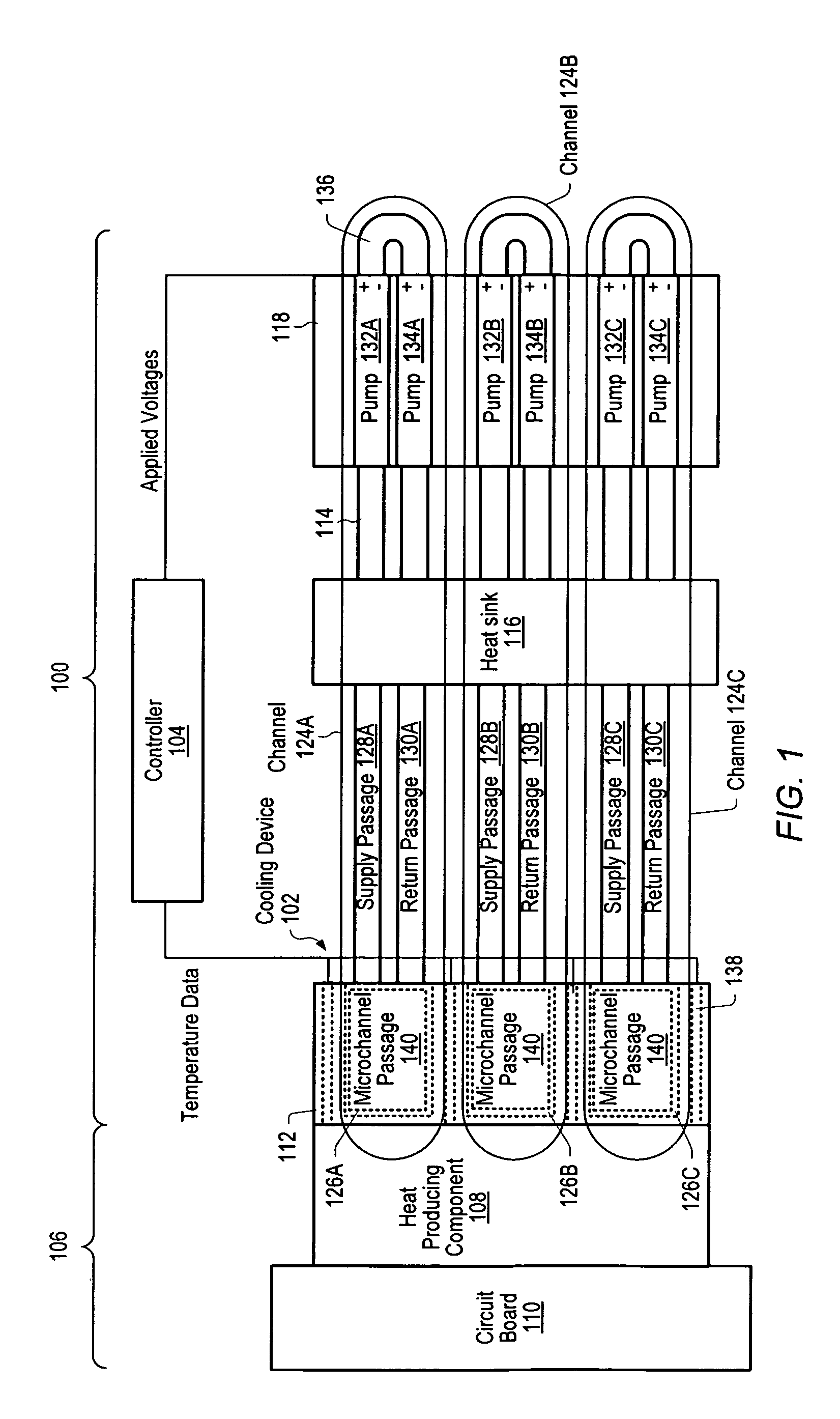

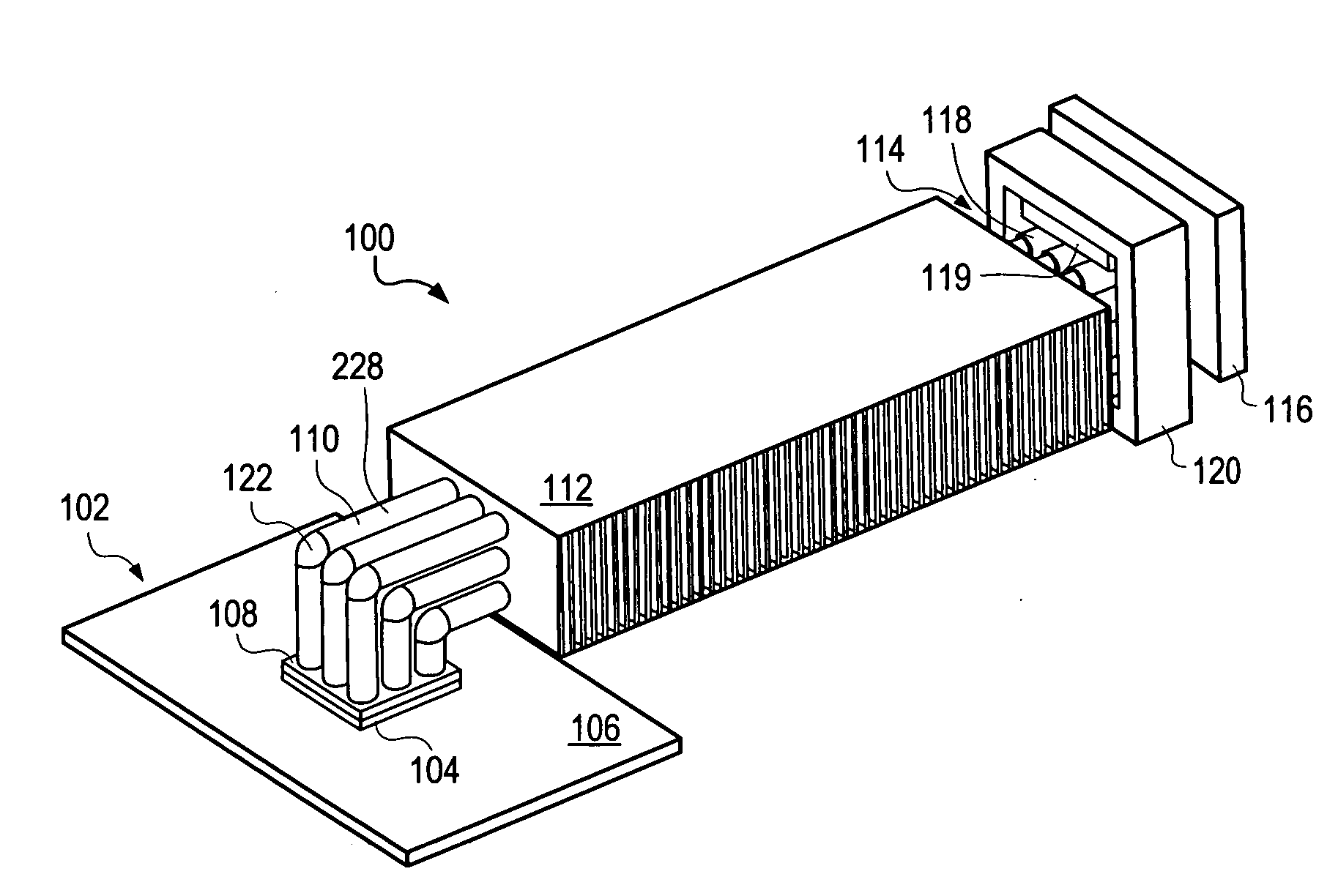

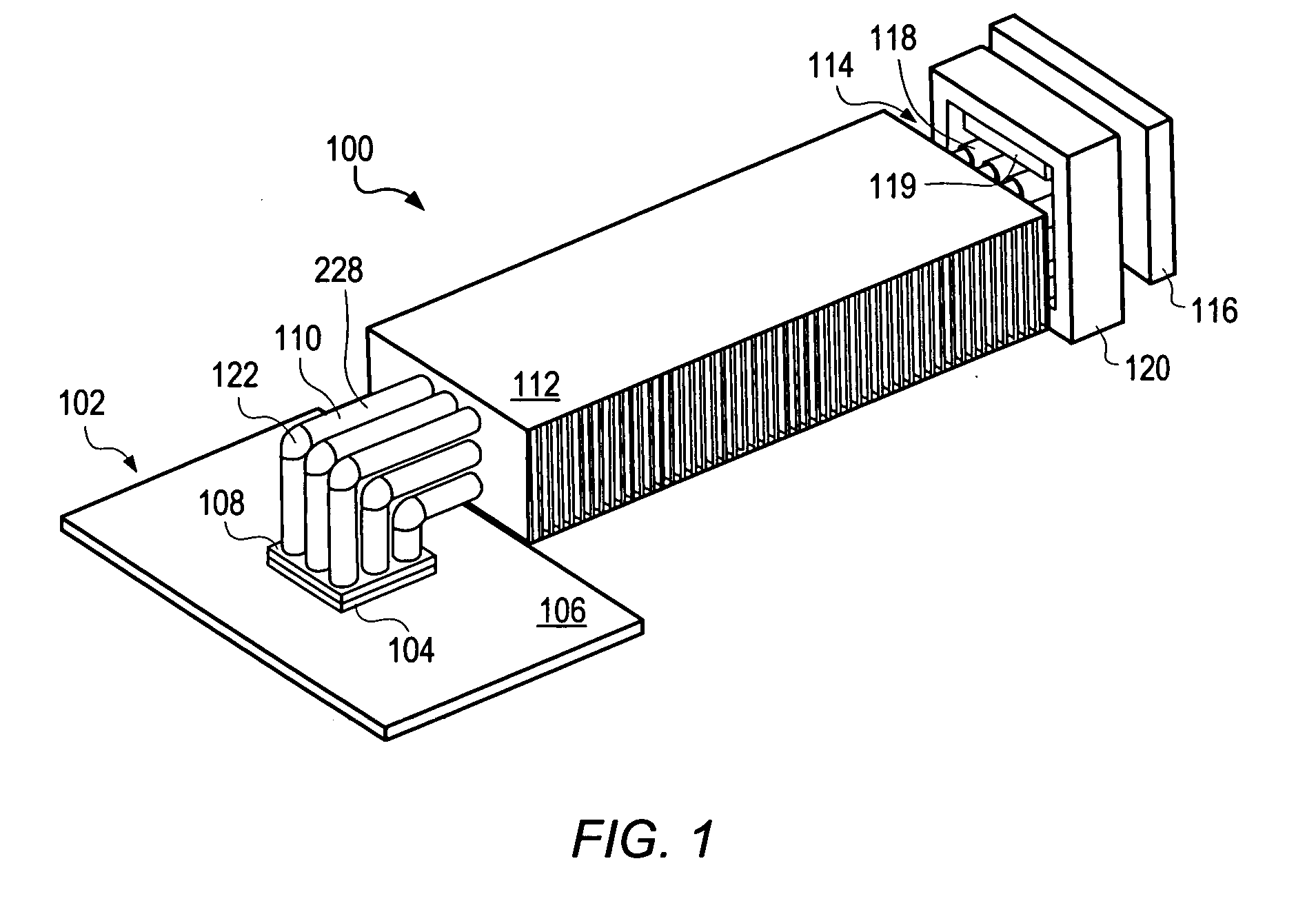

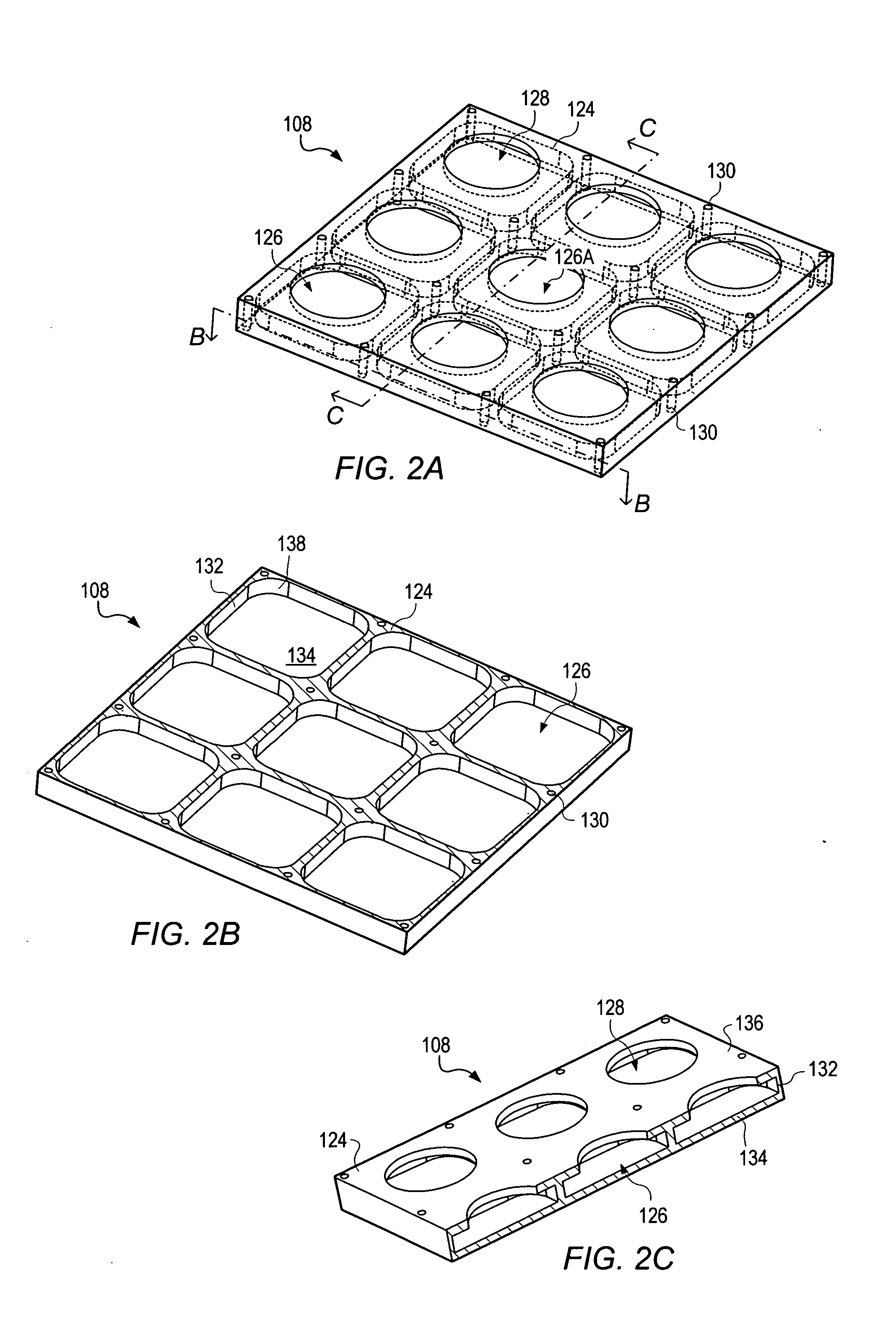

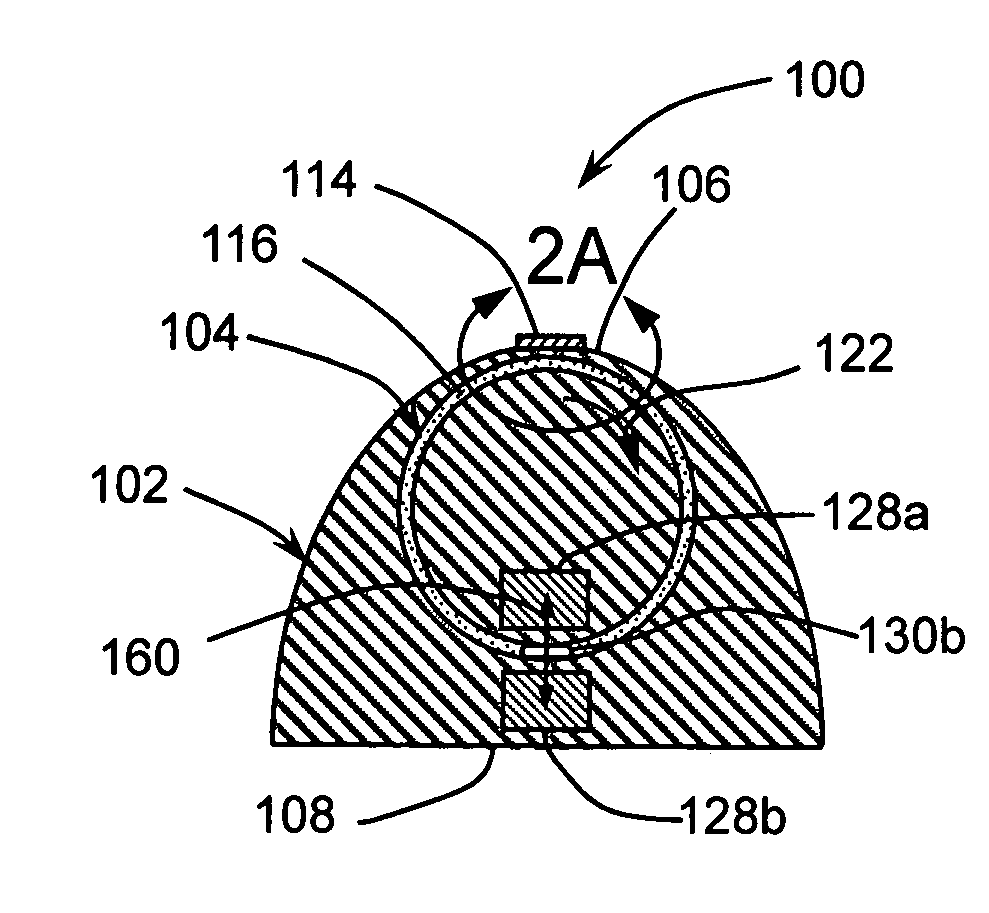

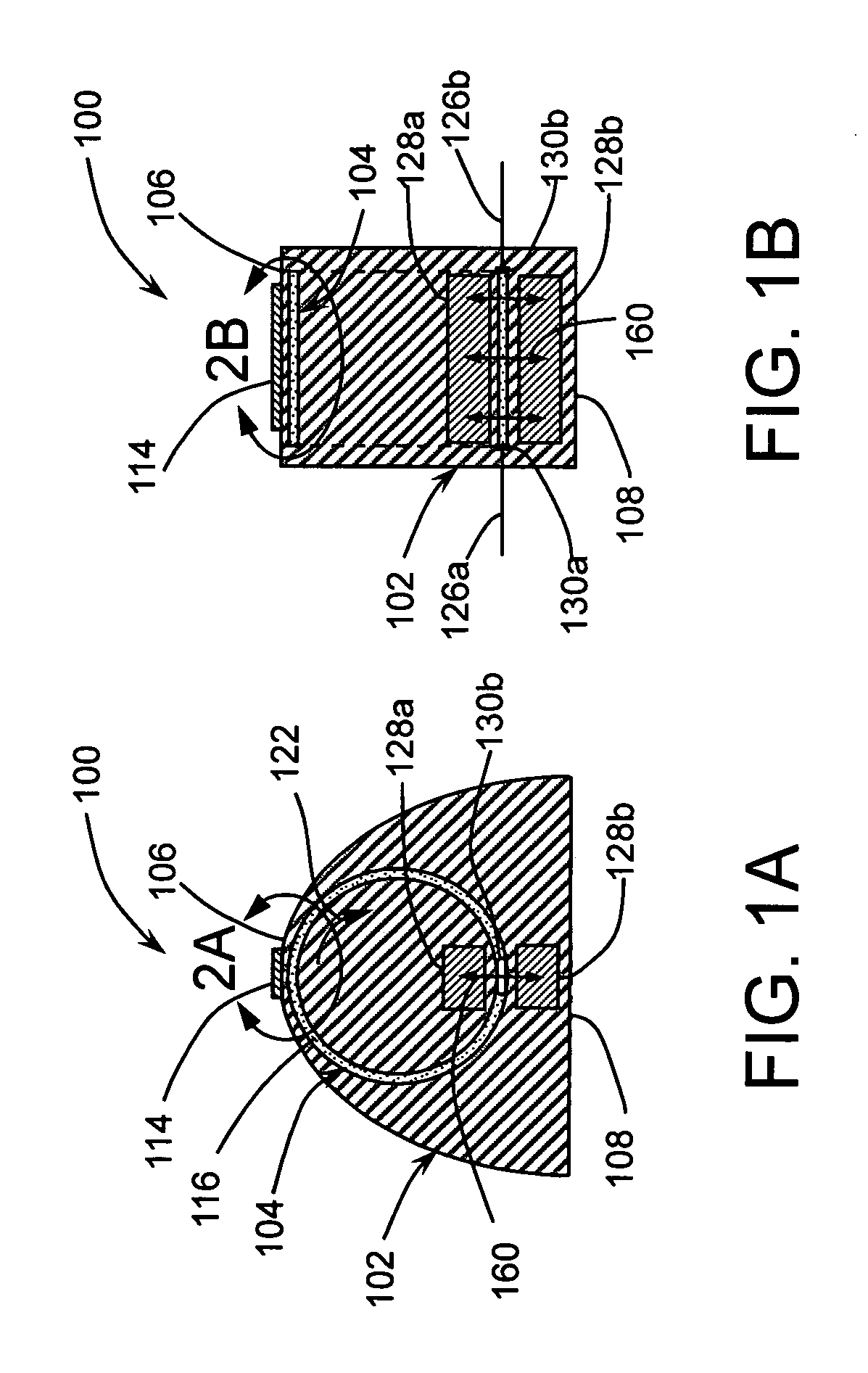

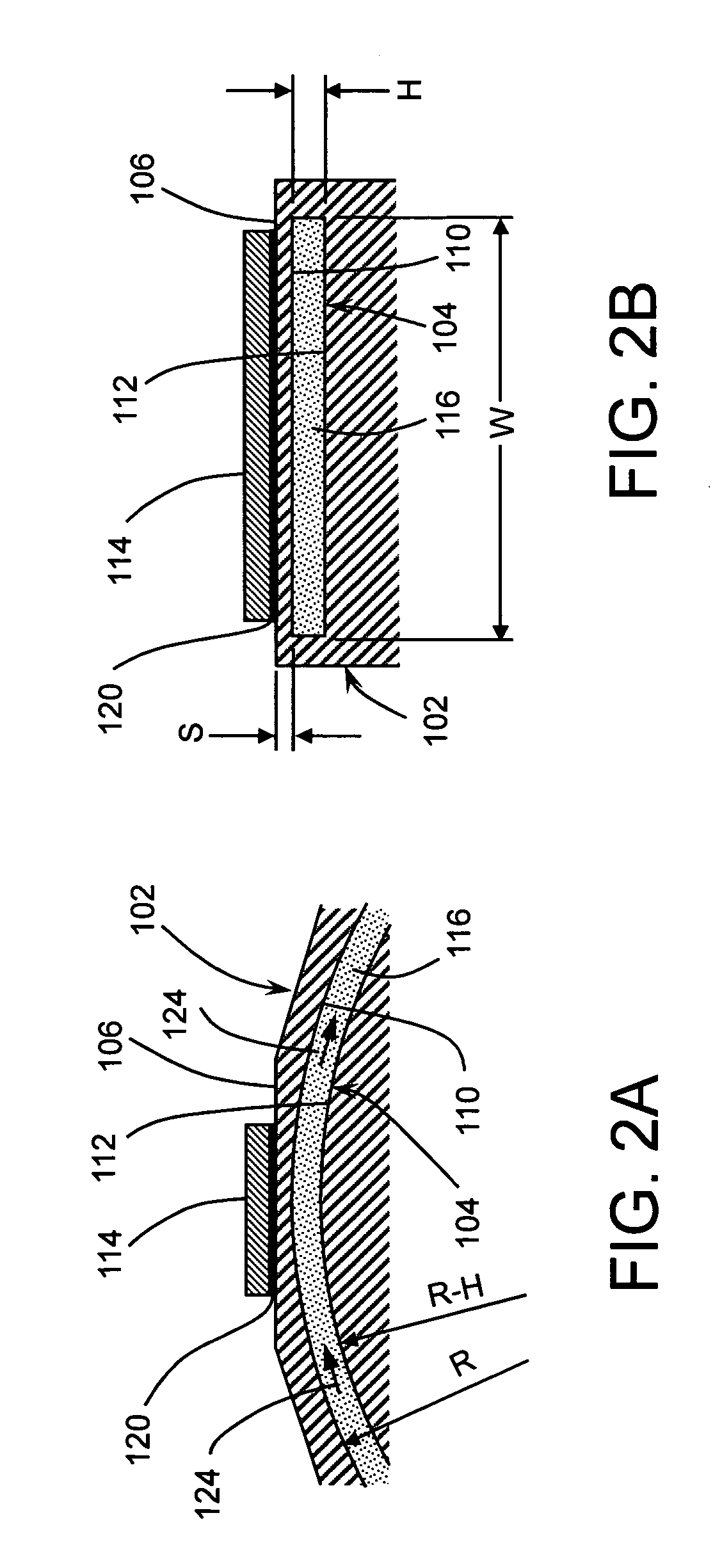

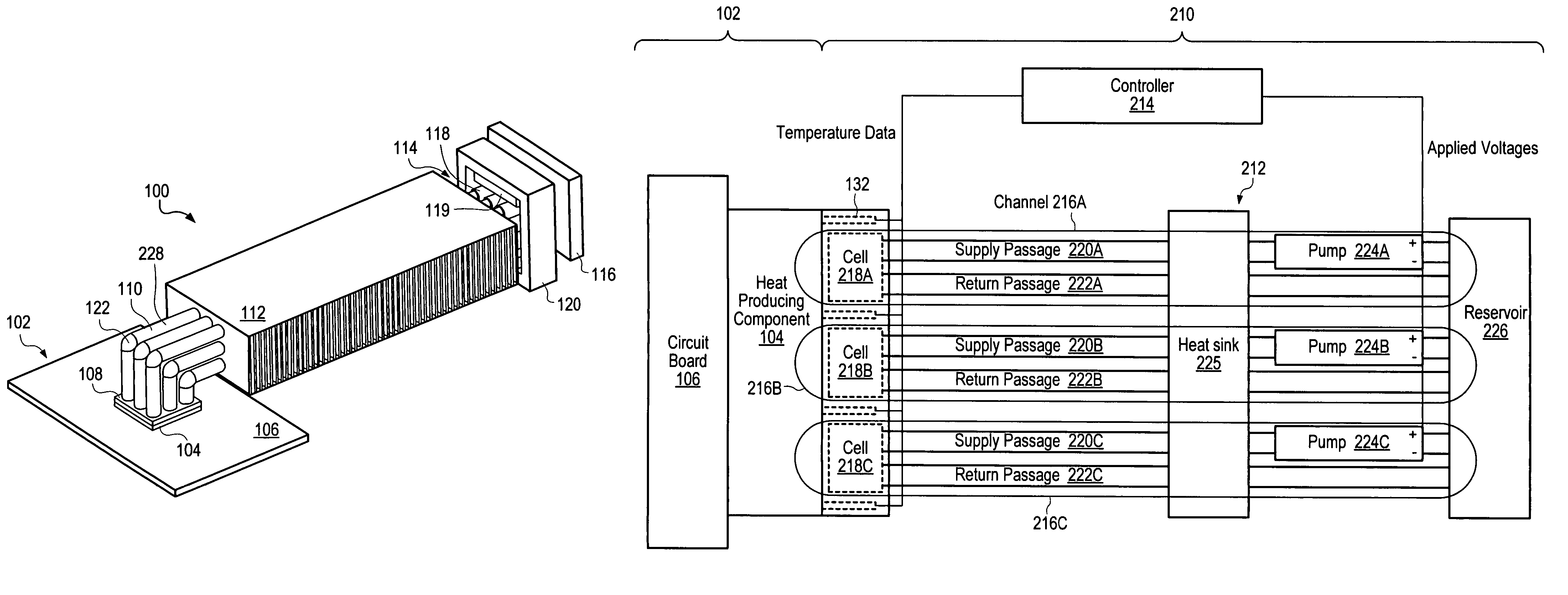

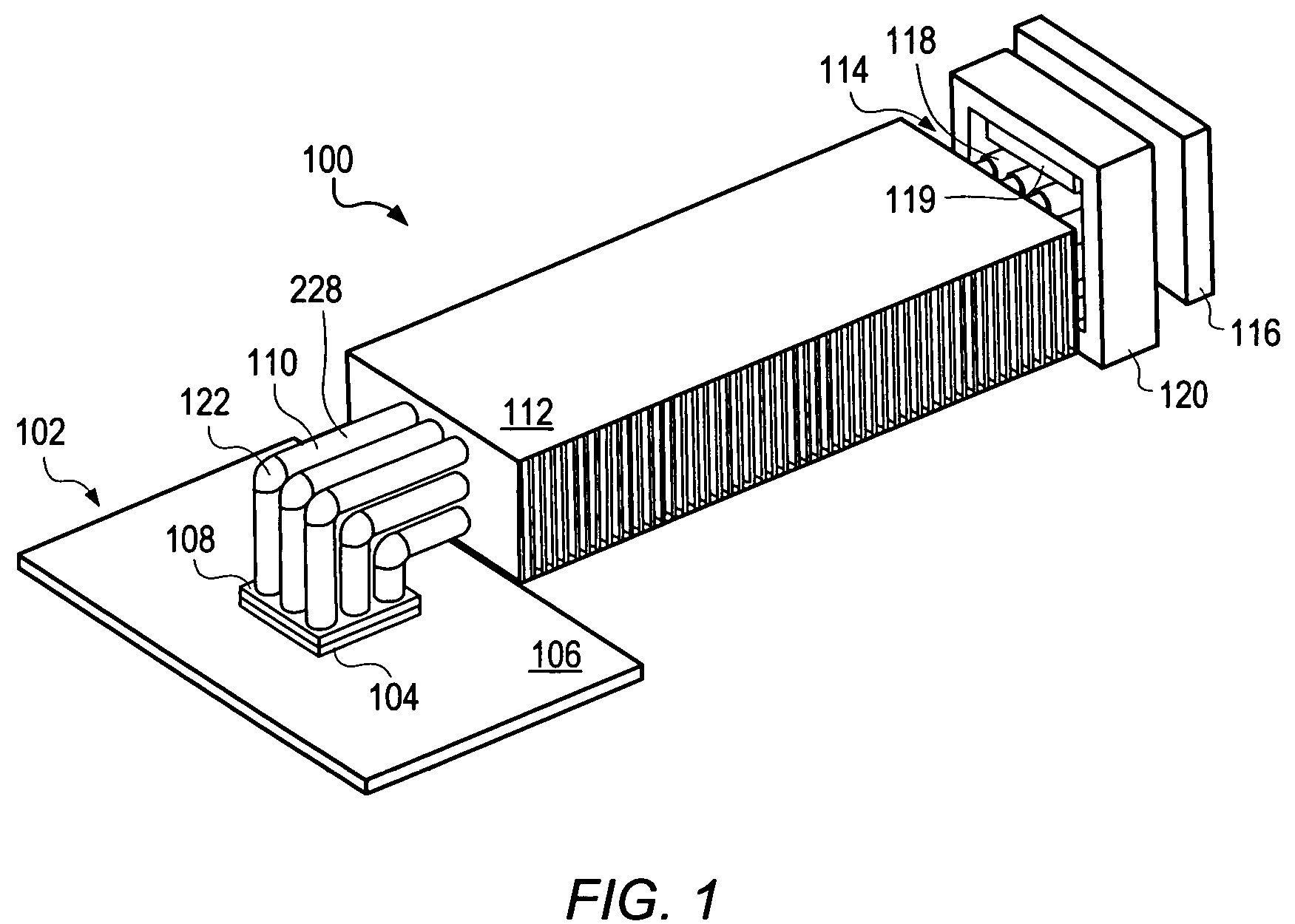

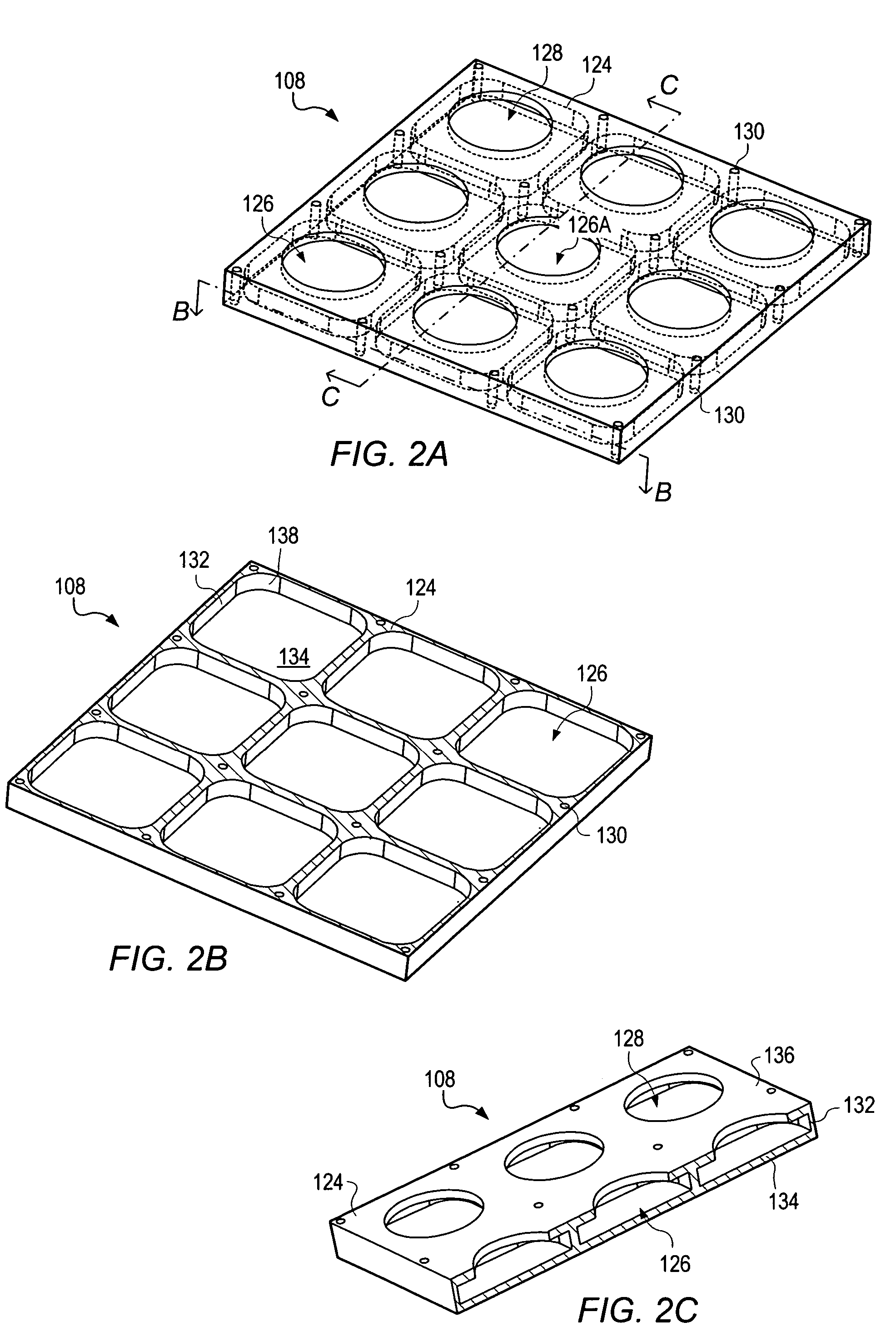

Intelligent microchannel cooling

ActiveUS7672129B1Semiconductor/solid-state device detailsSolid-state devicesMagneto hydrodynamicEngineering

A cooling system for a heat producing component includes a base having two or more cells. The cells may include microchannel passages. A pump system may be coupled to the base. The pump system may circulate fluid independently in each of two or more of the cells. The pump system may include an array of two more magnetohydrodynamic pumps. Each magnetohydrodynamic pump may provide fluid to a different cell. A controller may control a flow rate in each one of cell of the cooling system independently one or more of other cells of the cooling system.

Owner:ORACLE INT CORP

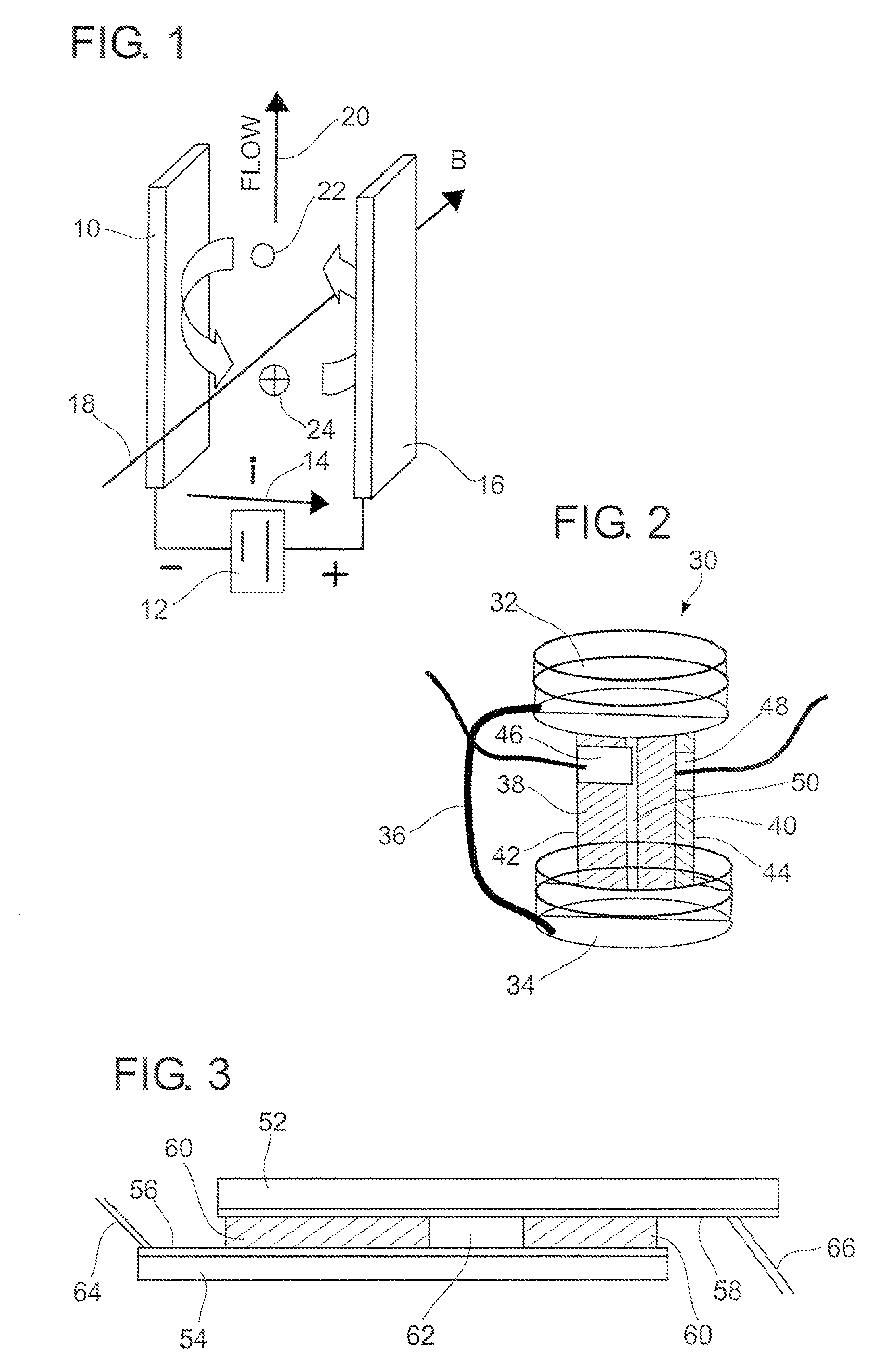

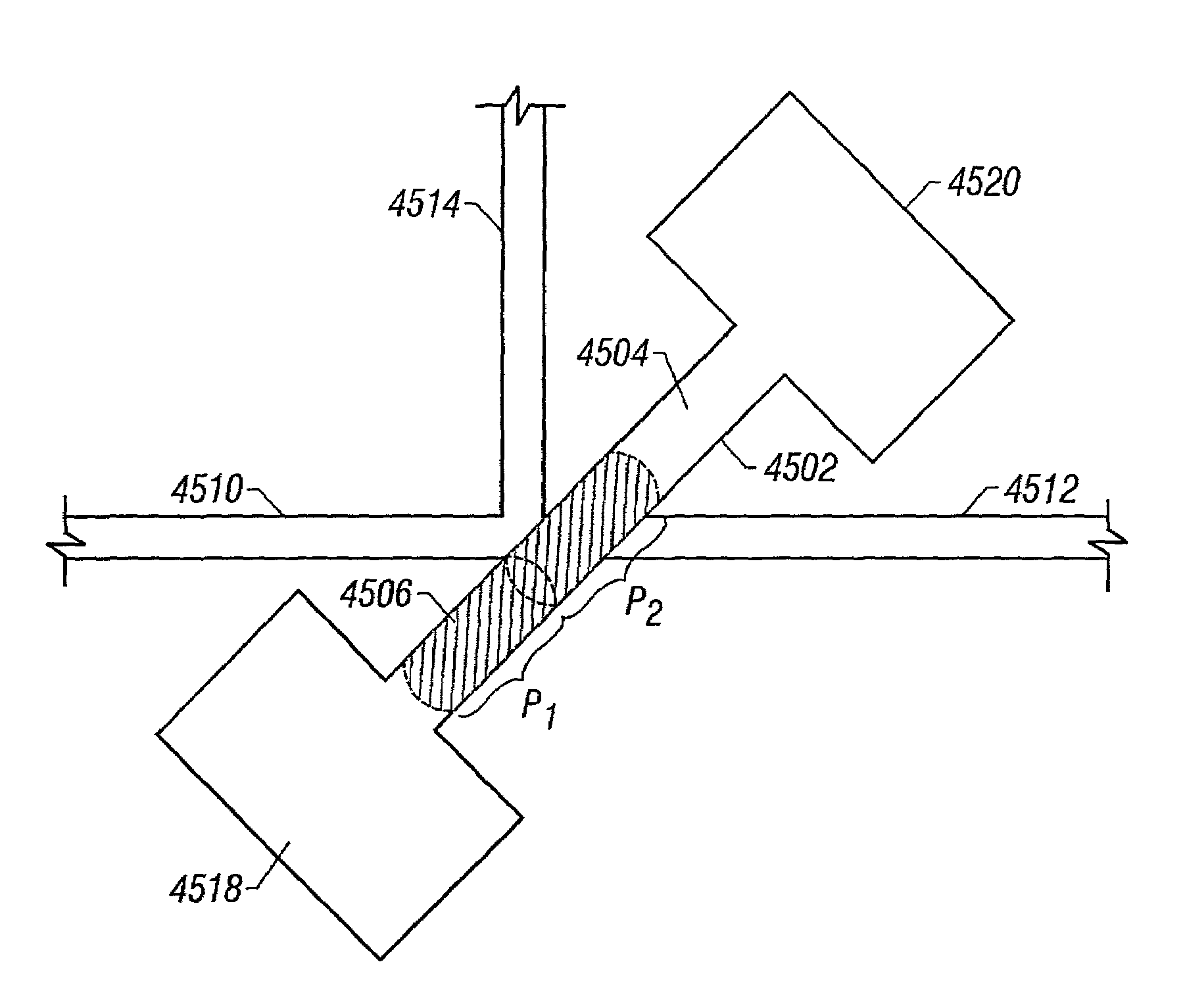

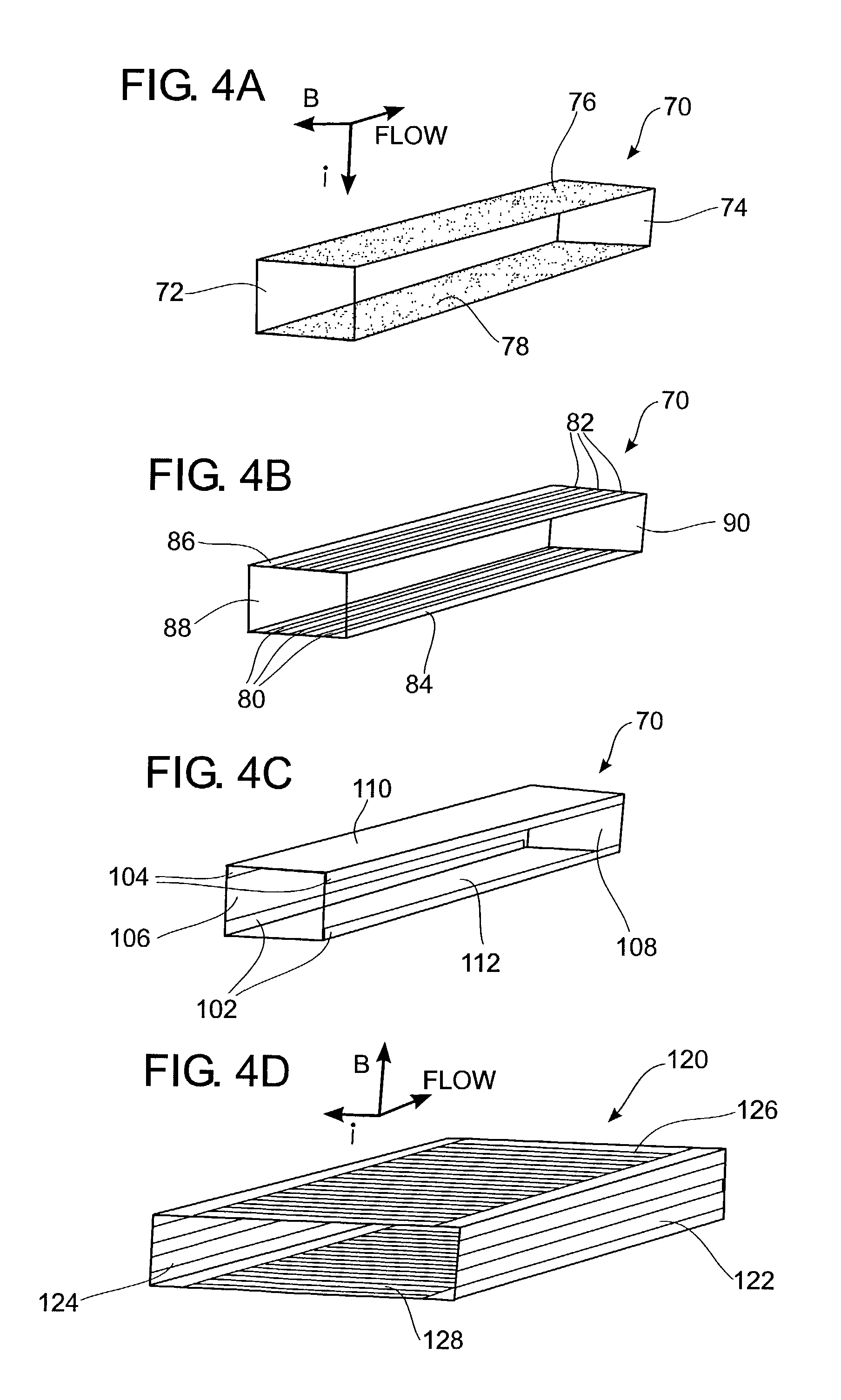

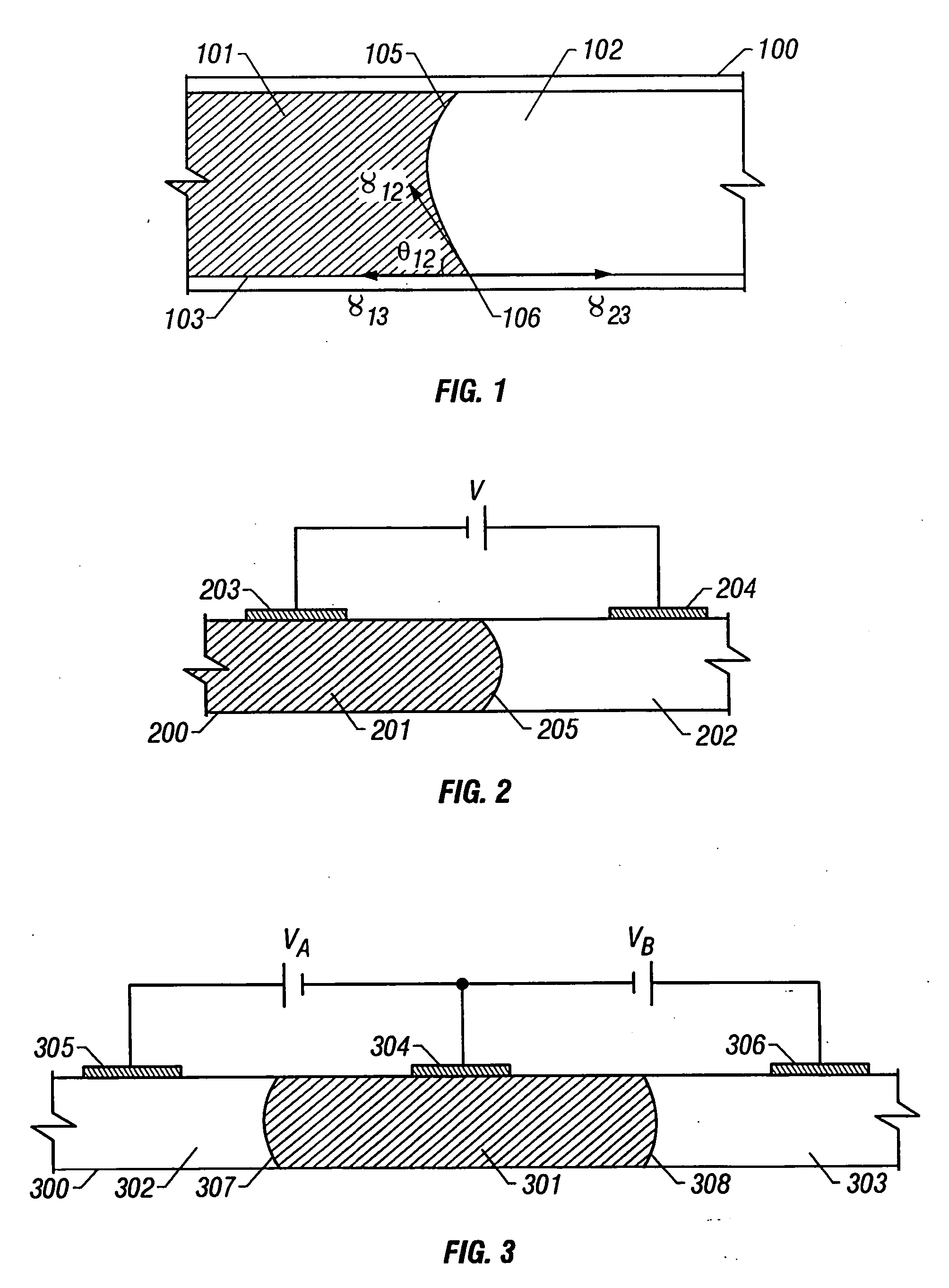

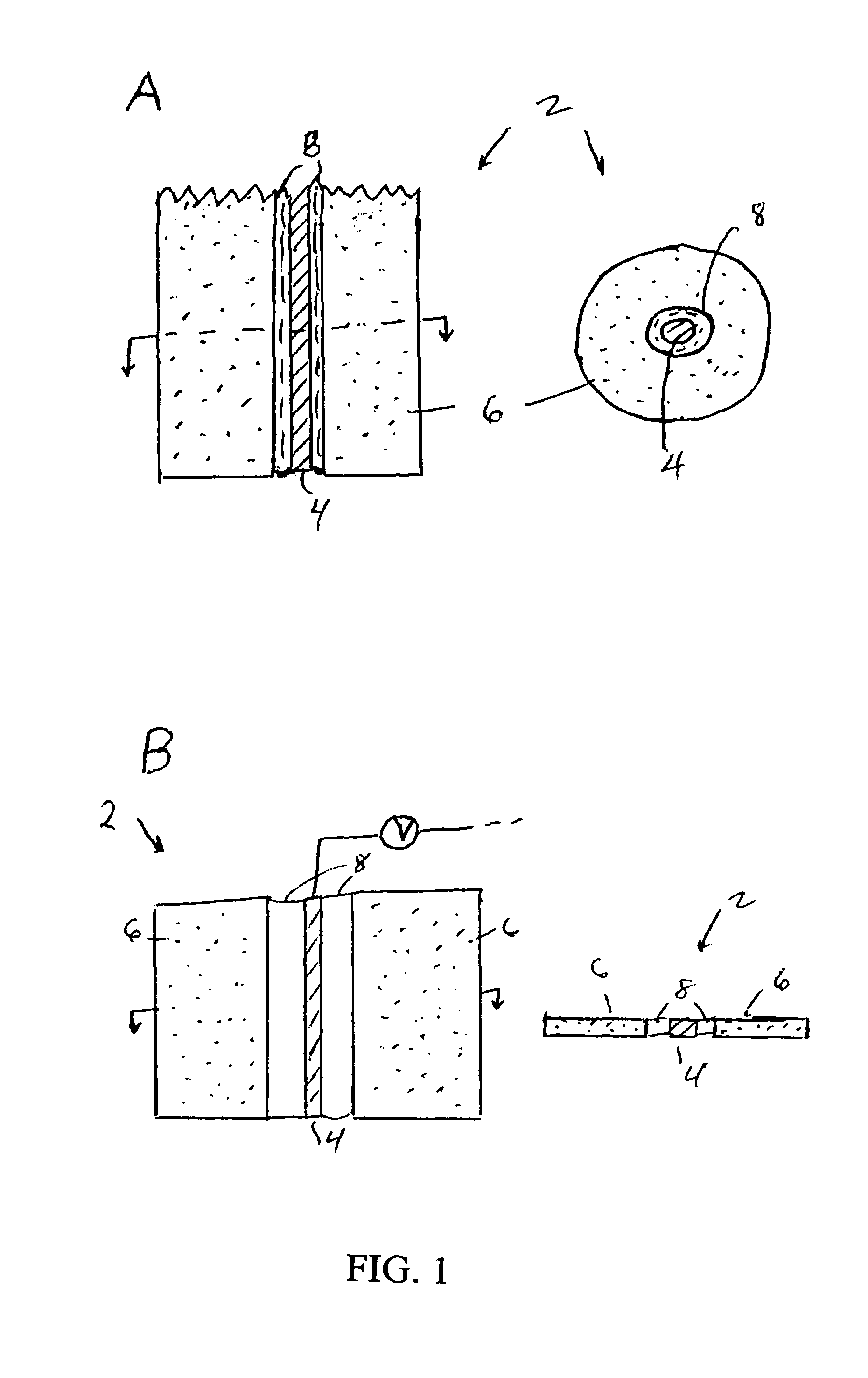

Microfluidic device utilizing magnetohydrodynamics and method for fabrication thereof

InactiveUS7467928B2Readily reversible methodSmall, constant magnetic fieldsMaterial nanotechnologyInking apparatusPower flowMagneto hydrodynamic

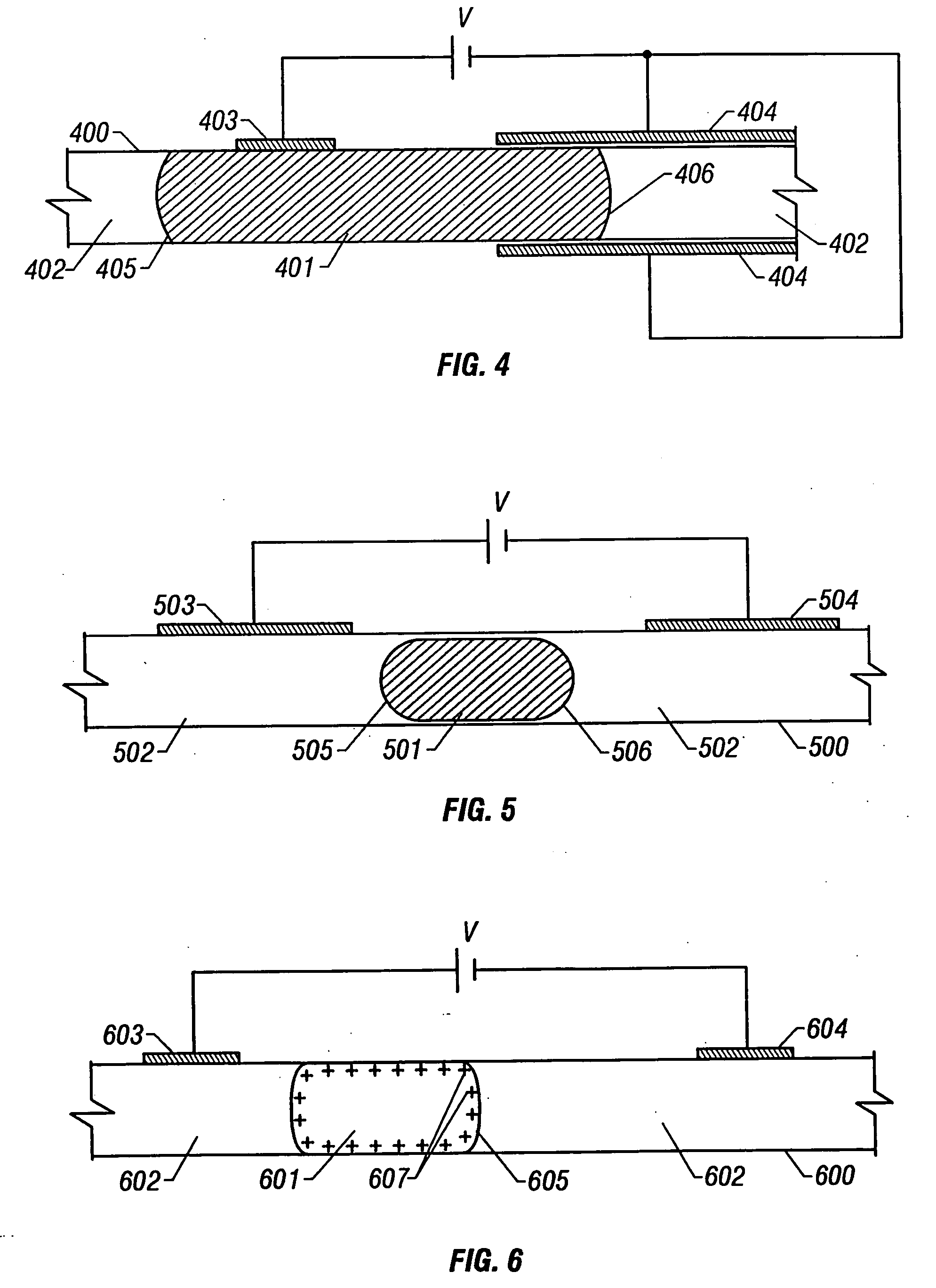

Microfluidic channels utilizing magnetohydrodynamics are used to pump very small volumes of solution. The channels have electrodes along the walls and a current carrying species within a solution carries current through the solution. The combination of the electric and magnetic fields causes the solution to flow through the channel.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ARKANSAS

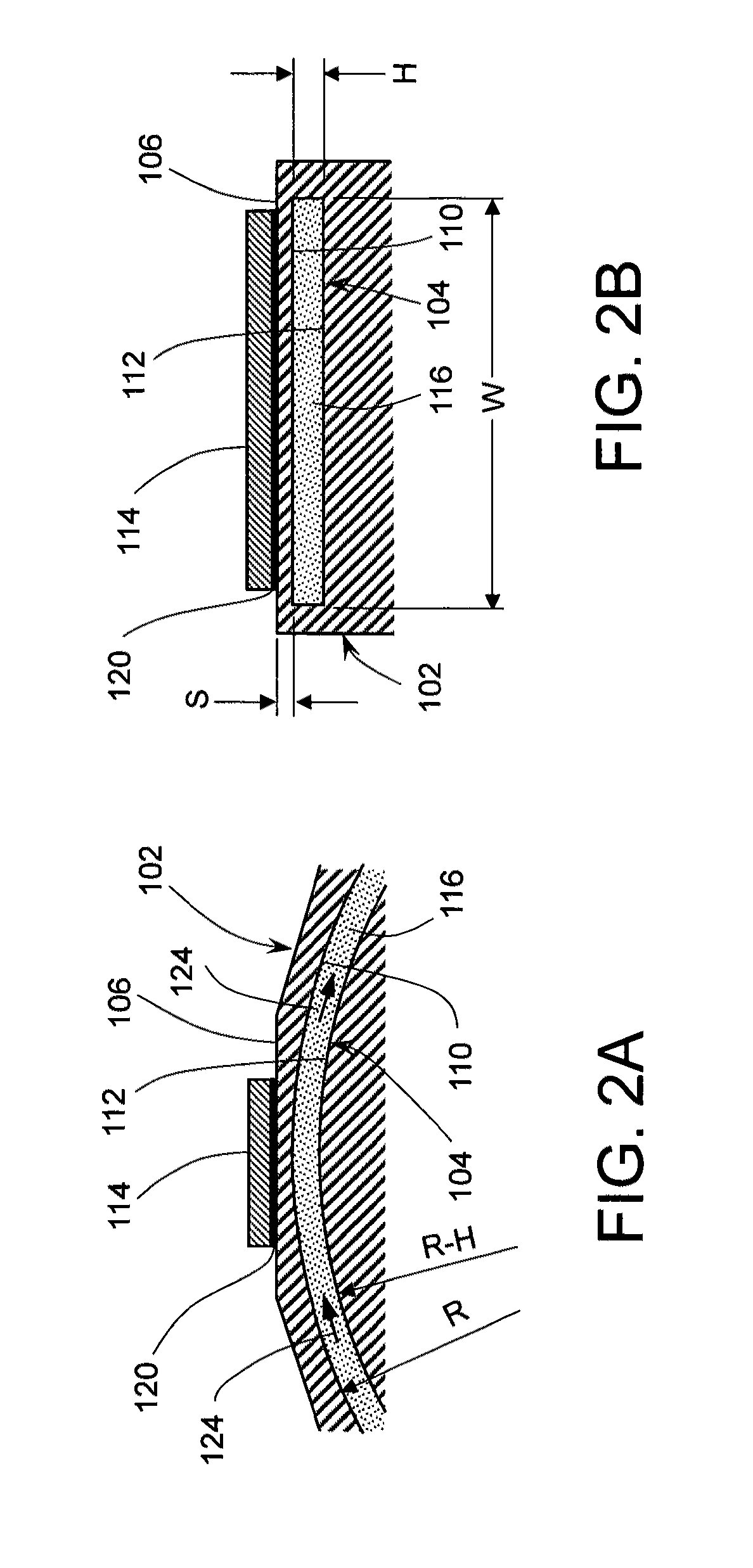

Microfluidic control for waveguide optical switches, variable attenuators, and other optical devices

InactiveUS7016560B2Reduce power consumptionGood workmanshipTransportation and packagingMixersDifferential pressureThermal expansion

Devices utilize elements carried by a fluid in a microchannel toswitch, attenuate, shutter, filter, or phase shift optical signals. In certain embodiments, a microchannel carries a gaseous or liquid slug that interacts with at least a portion of the optical power of an optical signal traveling through a waveguide. The microchannel may form part of the cladding of the waveguide, part of the core and the cladding, or part of the core only. The microchannel may also have ends or may be configured as a loop or continuous channel. The fluid devices may be self-latching or may be semi-latching. The fluid in the microchannel is moved using e.g., e.g., electrocapillarity, differential-pressure electrocapillarity, electrowetting, continuous electrowetting, electrophoresis, electroosmosis, dielectrophoresis, electro-hydrodynamic electrohydrodynamic pumping, magneto-hydrodynamic magnetohydrodynamic pumping, thermocapillarity, thermal expansion, dielectric pumping, and / or variable dielectric pumping.

Owner:NEOPHOTONICS CORP

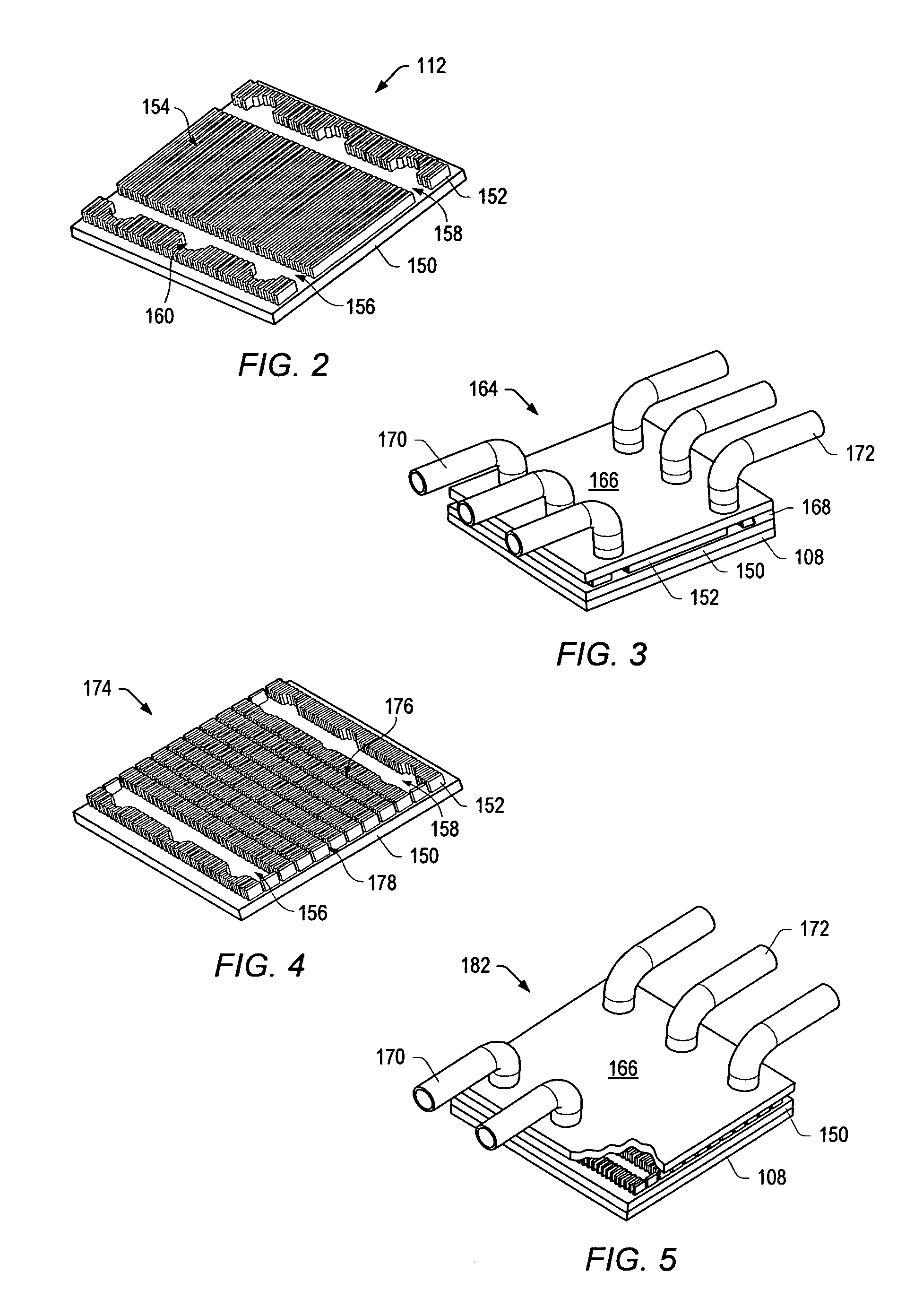

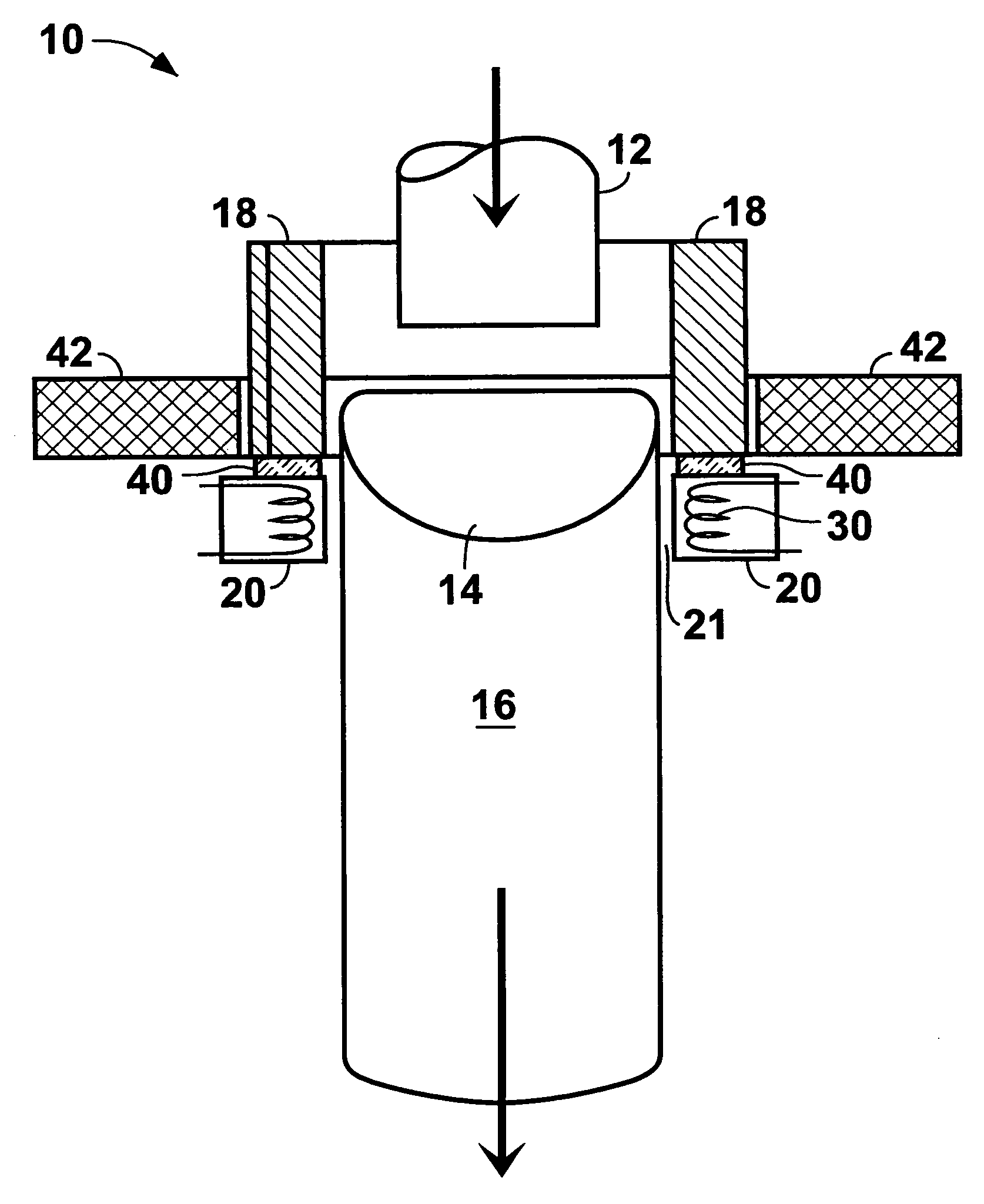

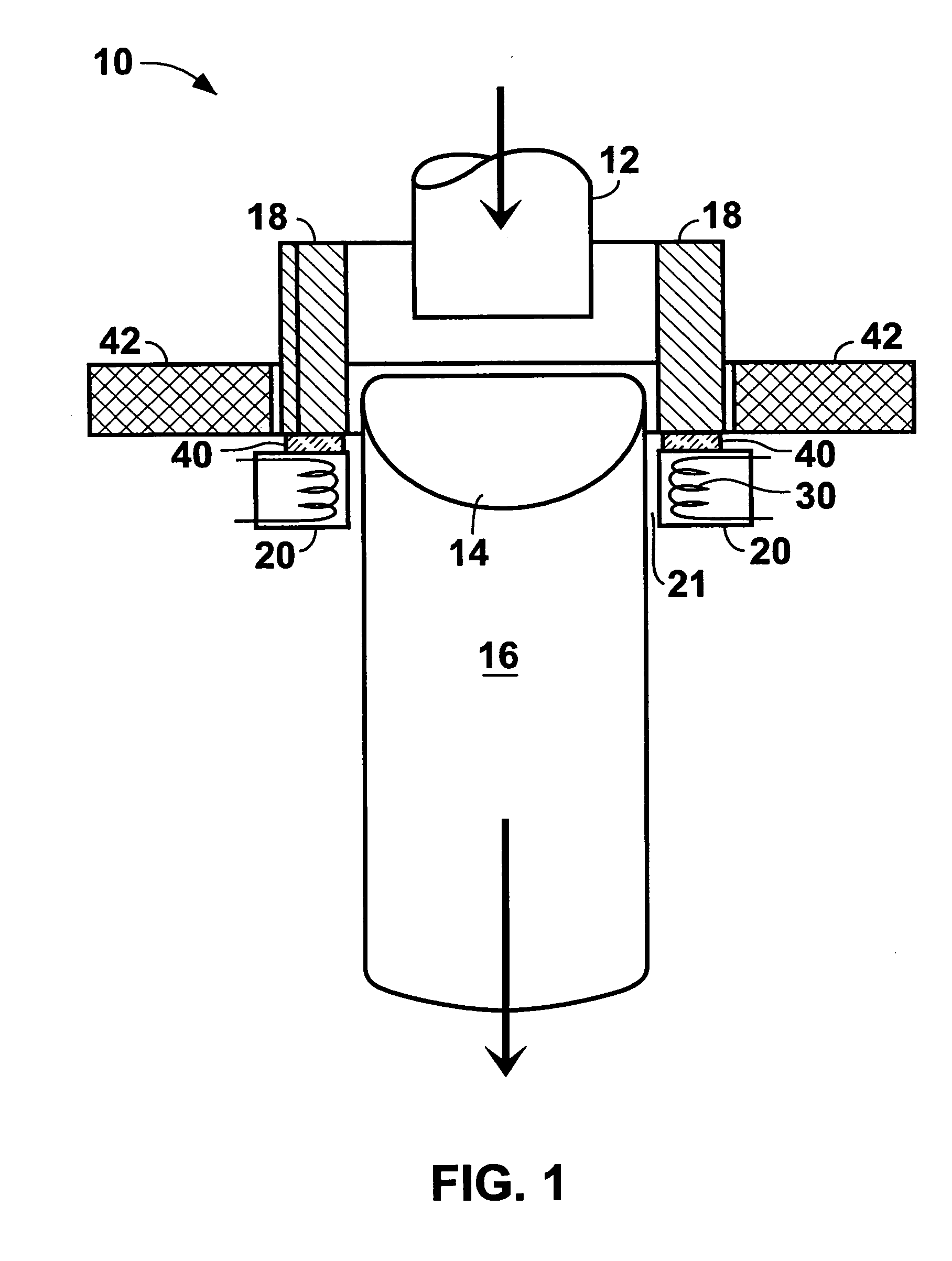

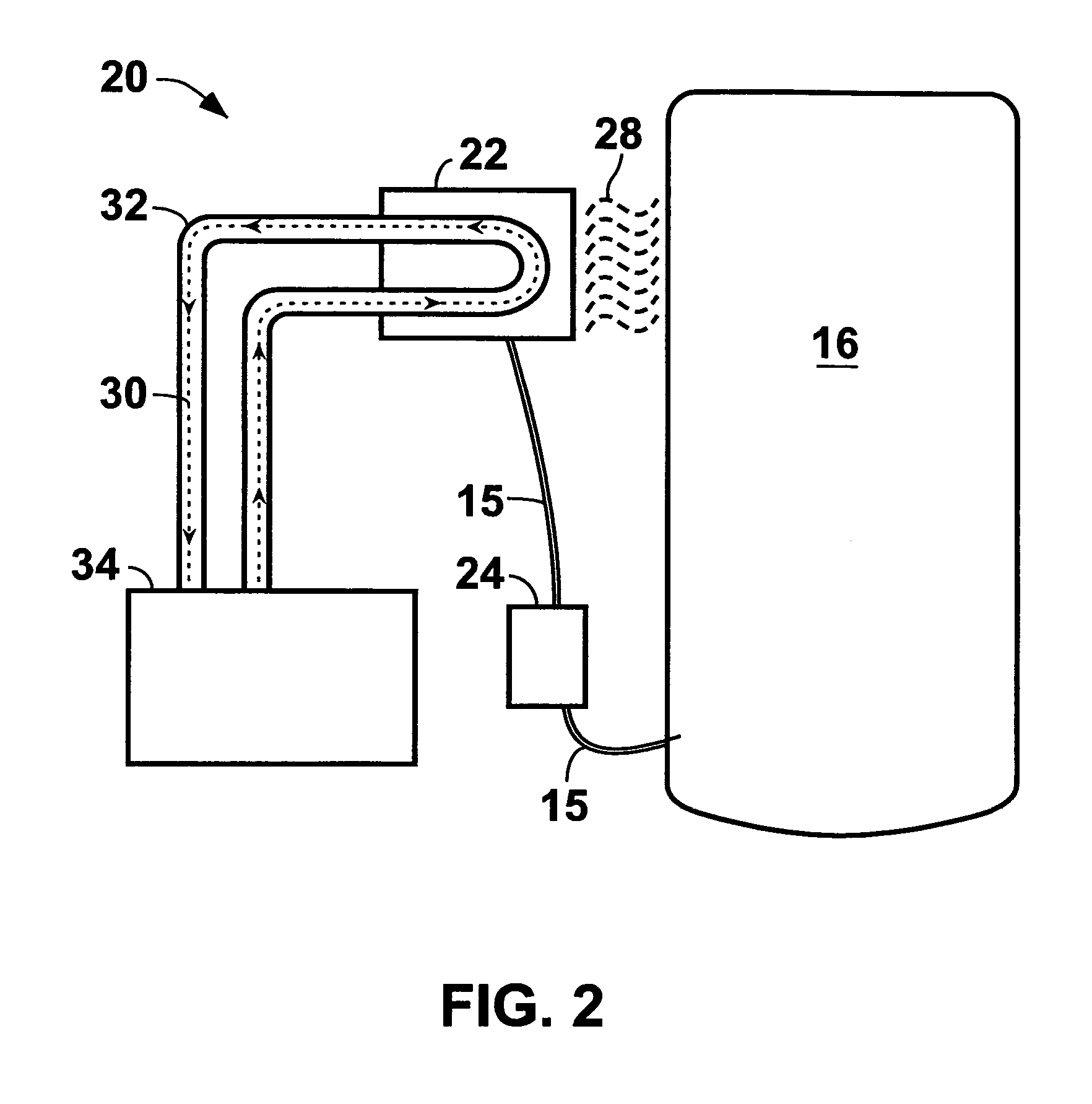

Multichannel cooling system with magnetohydrodynamic pump

ActiveUS20070235180A1Temperature control using plurality of sensorsSemiconductor/solid-state device detailsMagneto hydrodynamicEngineering

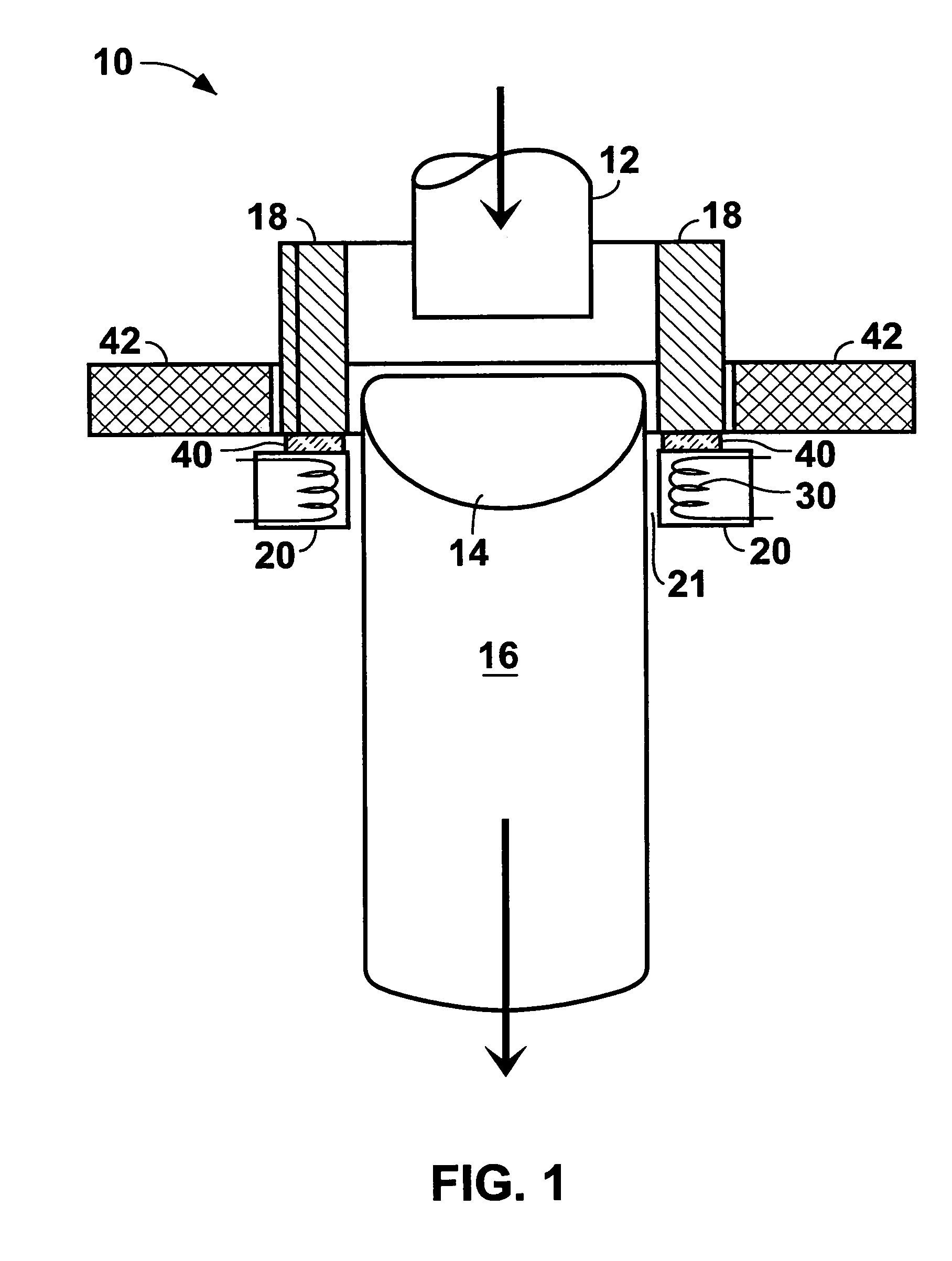

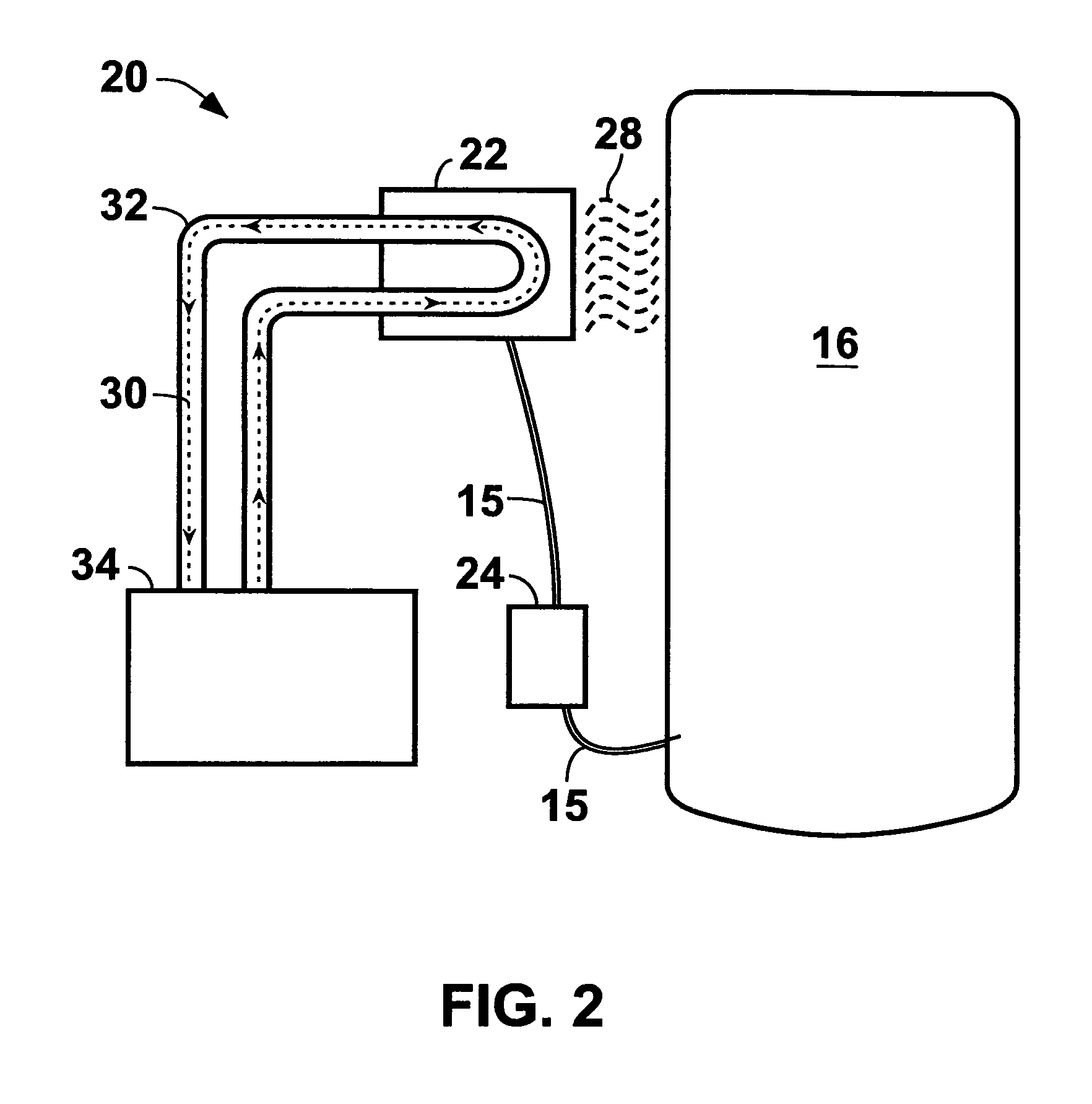

A cooling device includes a base having cells. A pipe is coupled to the base for each of the cells. The pipes include passages that carry fluid toward the cell and away from the cell. A magnetohydrodynamic pump system coupled to the pipe circulates an electrically conductive cooling fluid within the passages and the cell. An orifice may emits jets of fluid into the cells. A controller coupled to the cooling device may independently control flow rates in two or more cells of the cooling device. The controller may receive information from the temperature sensors on the base of the cooling device for use in controlling the flow rates in the cells.

Owner:ORACLE INT CORP

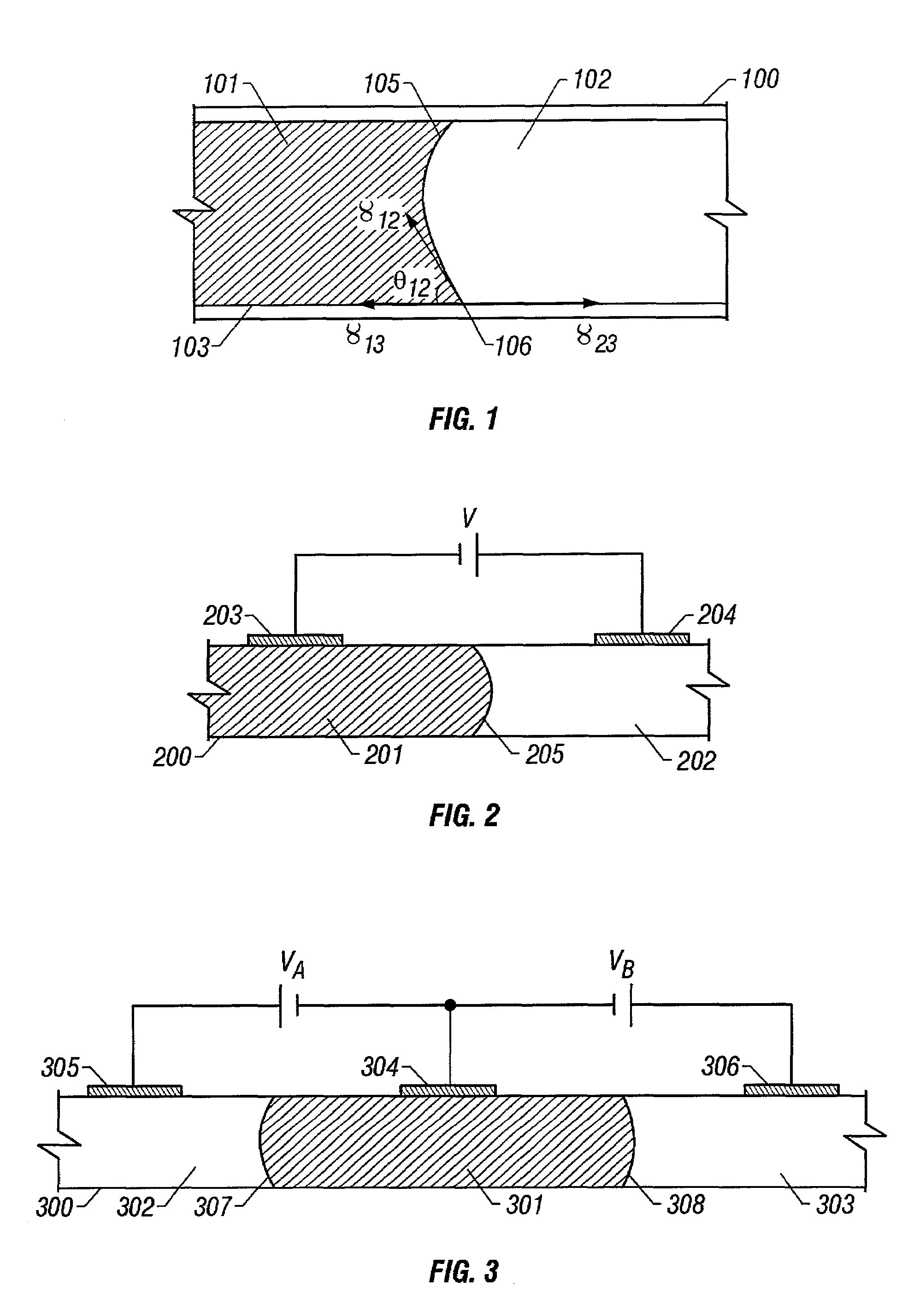

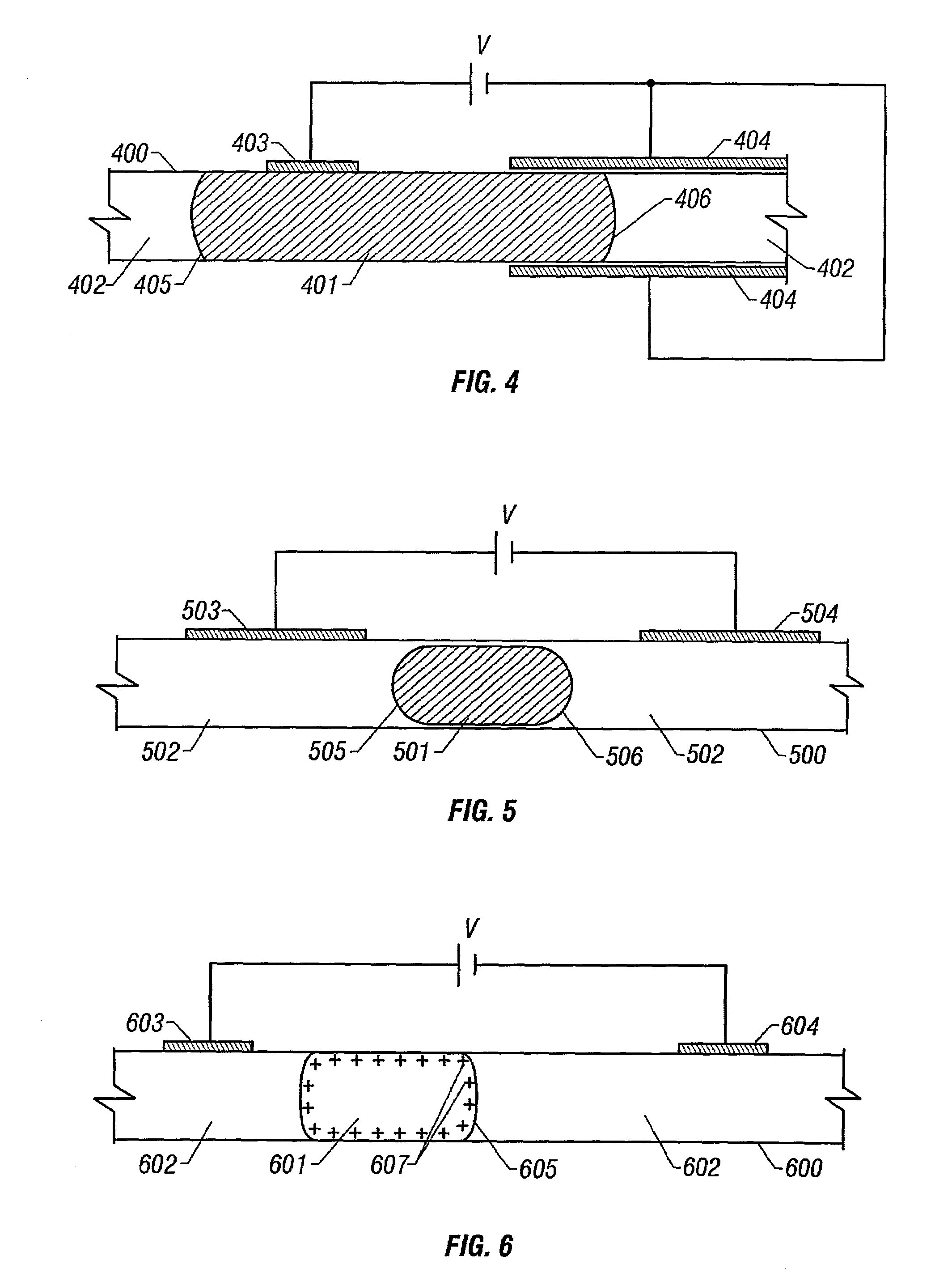

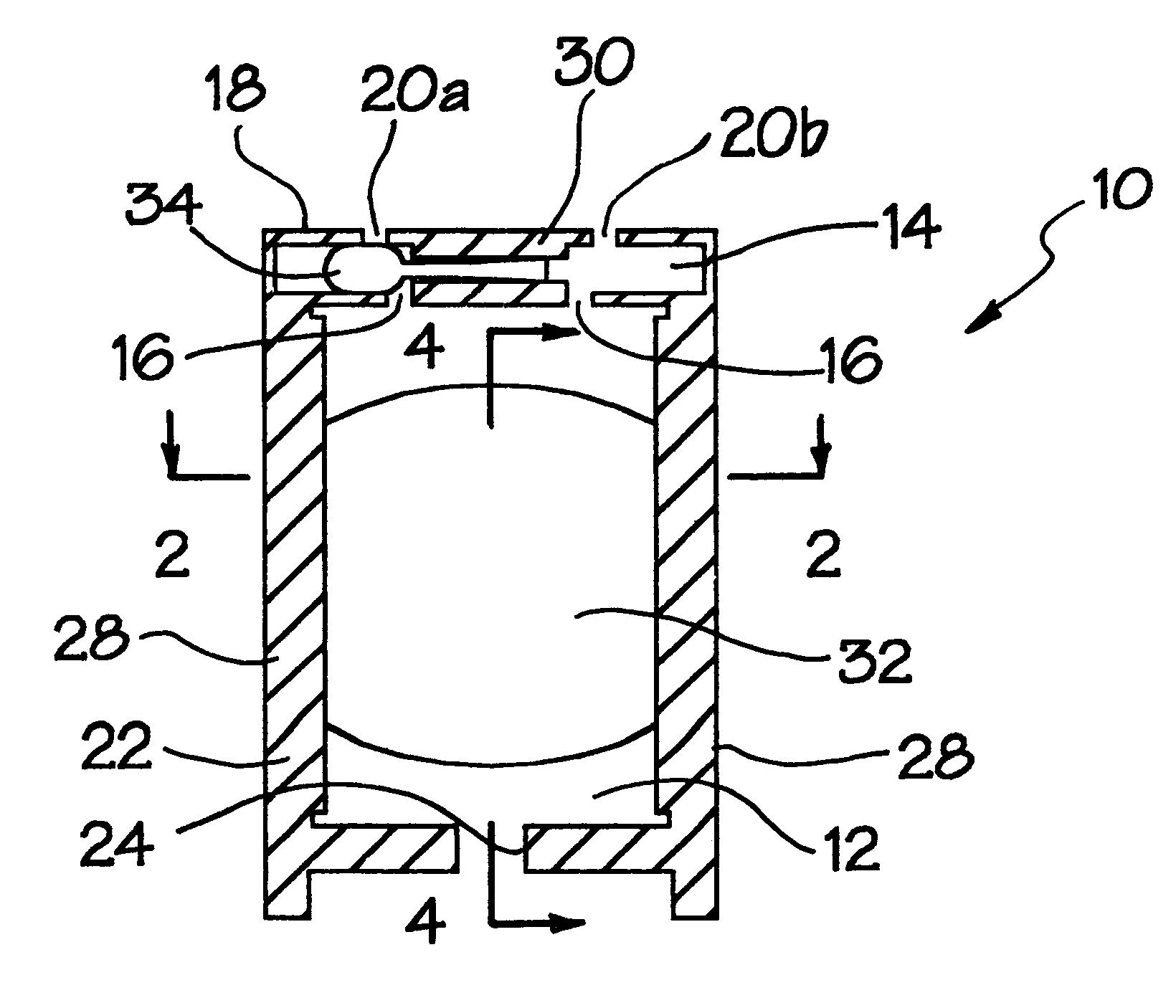

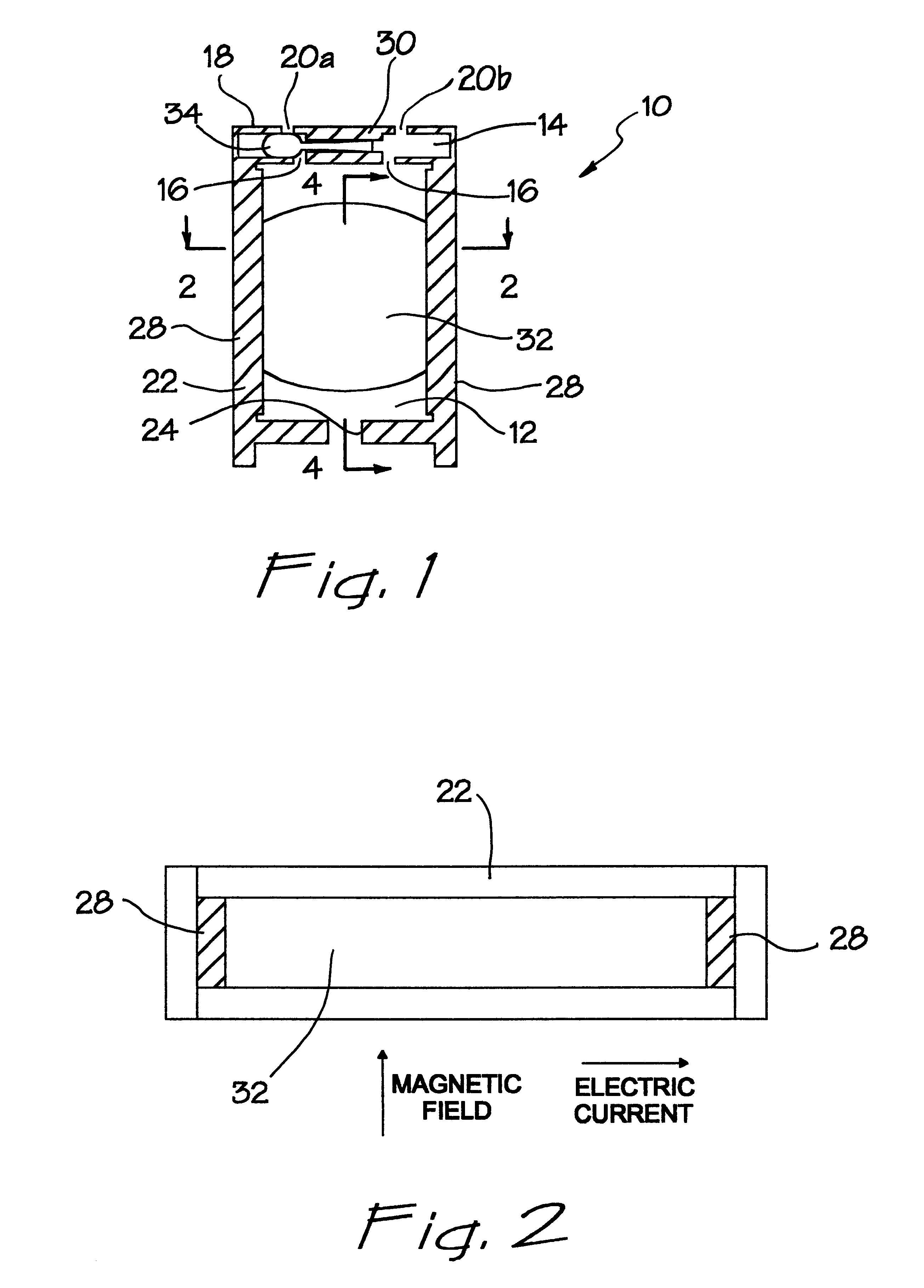

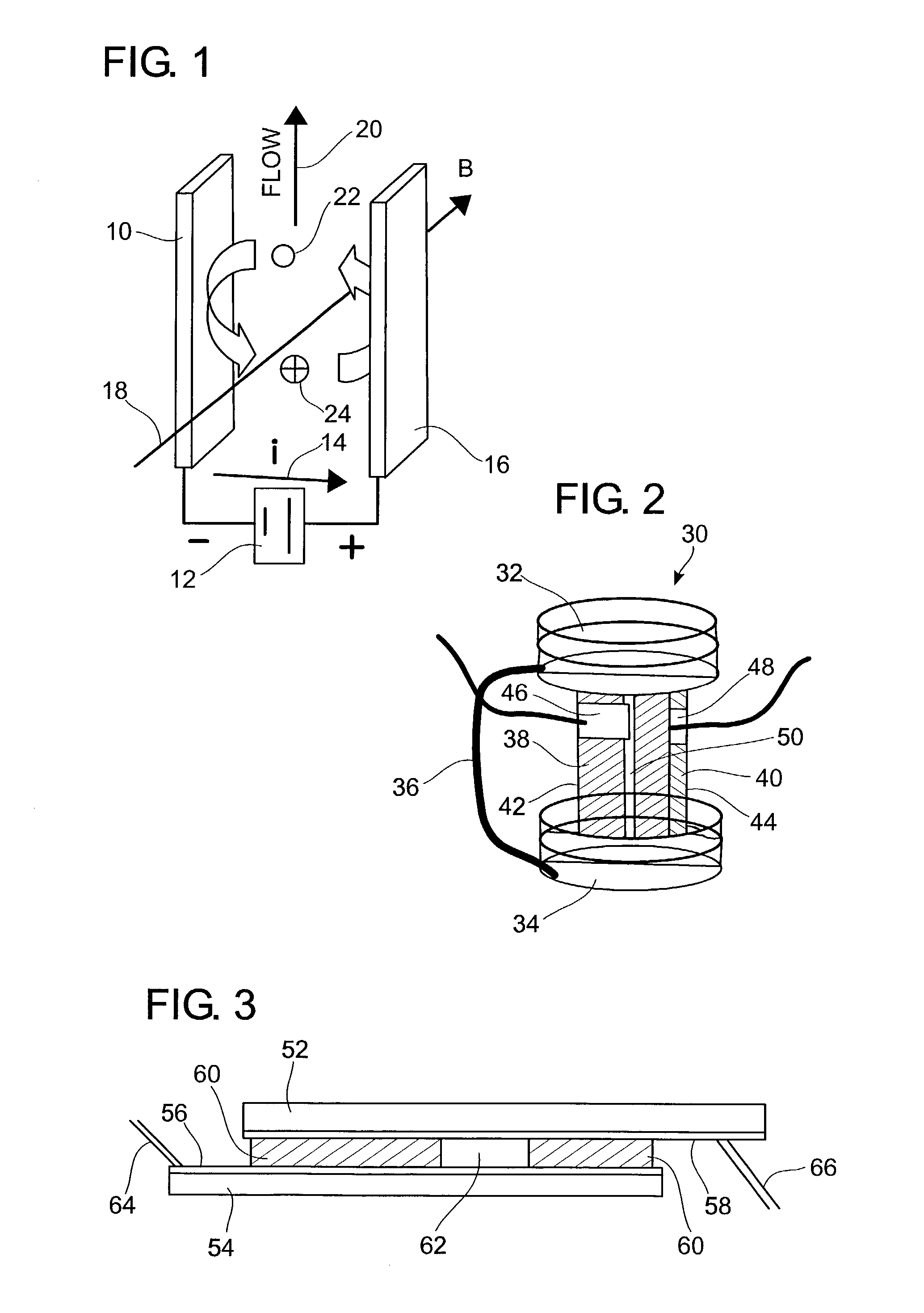

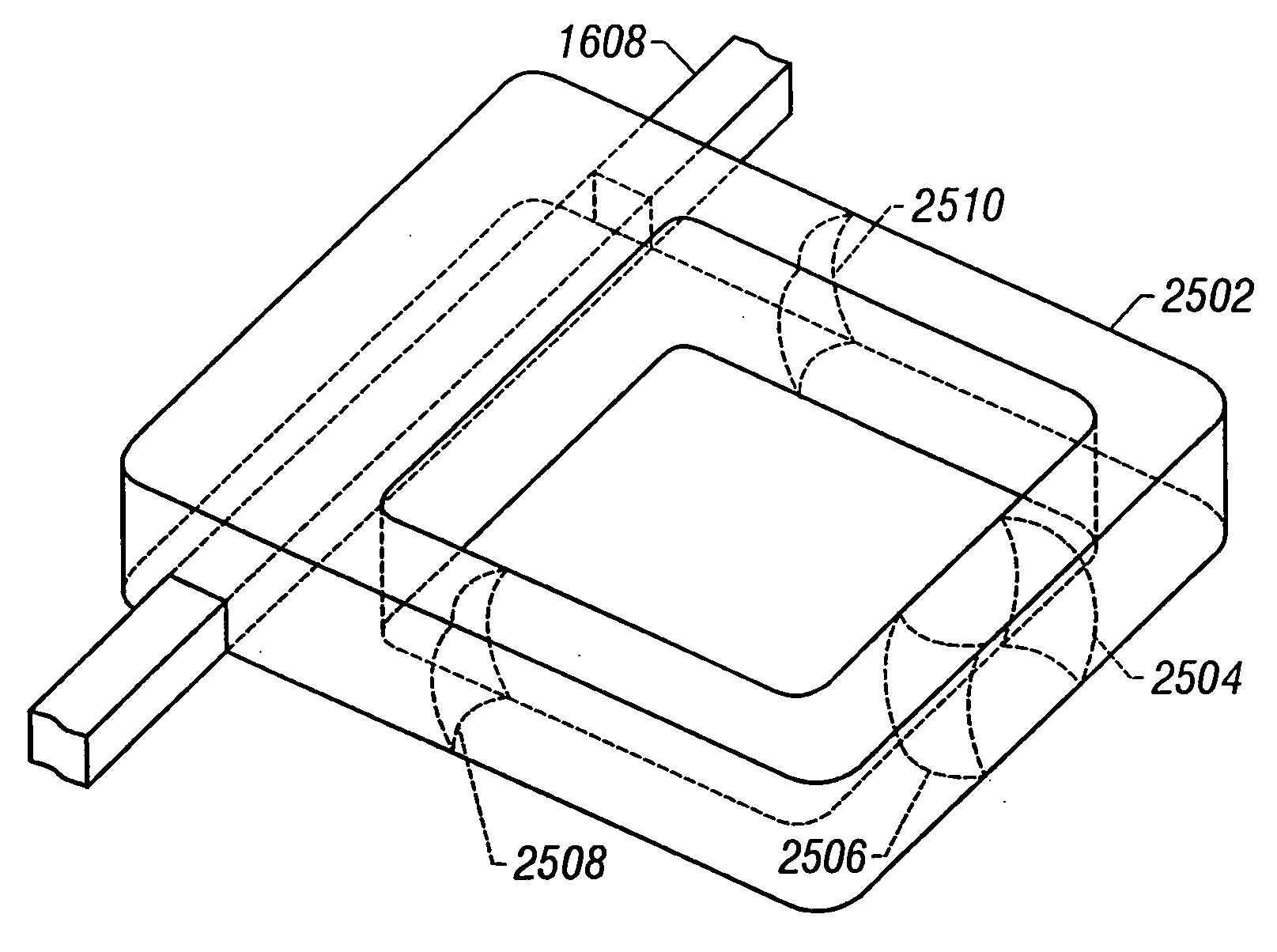

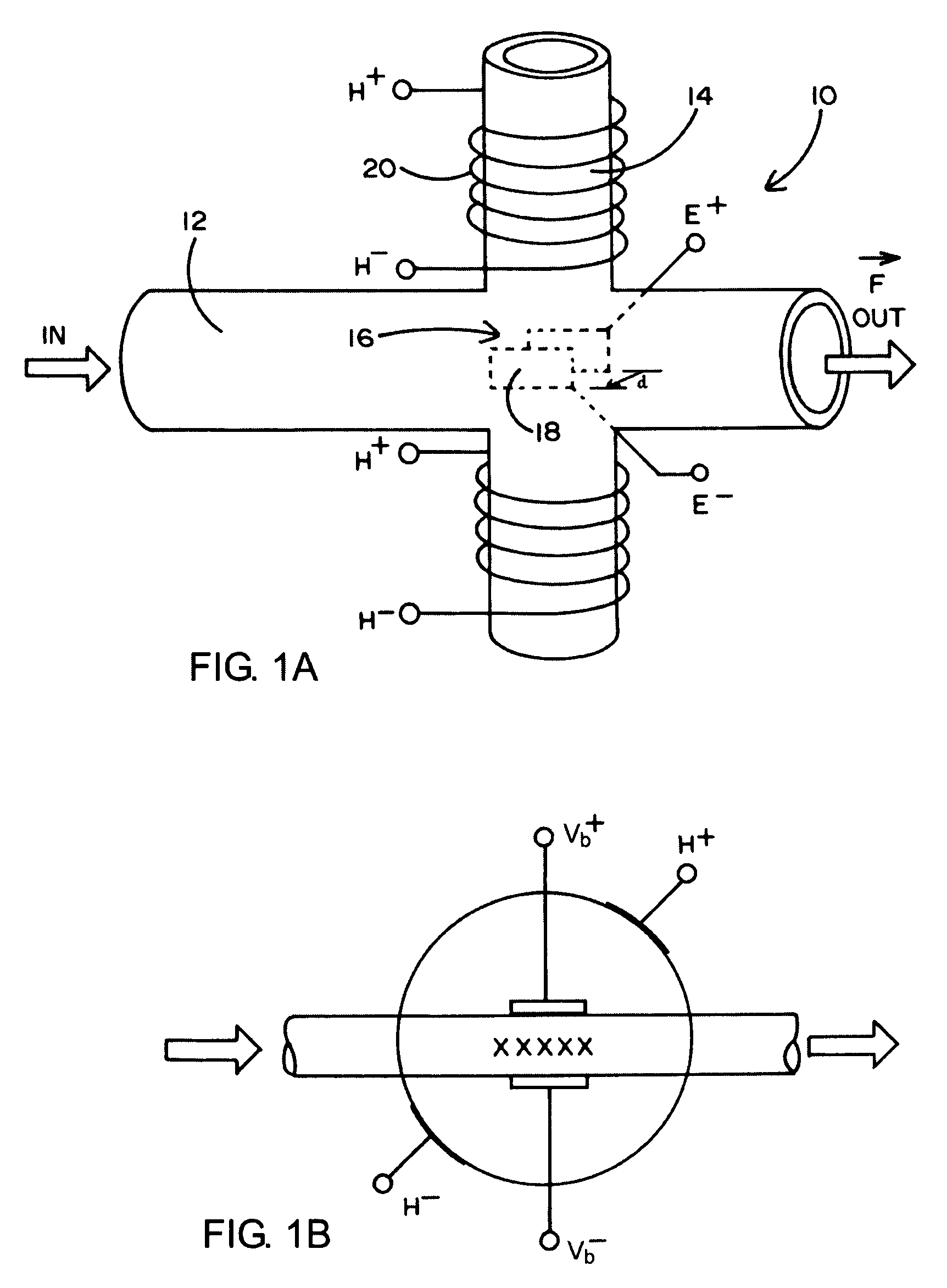

Micro-magnetohydrodynamic pump and method for operation of the same

InactiveUS6241480B1Simple and effective energy transfer meanLow working voltagePositive displacement pump componentsPiston pumpsWorking fluidPump chamber

A micropump fabricated in a planar substrate is provided with a valving chamber which is communicated to a pumping chamber. The valving chamber has an inlet and outlet port. Both the valving chamber and pumping chamber have a liquid, electrically conductive piston disposed therein, which liquid piston is nonmiscible with the pumped working fluid and nonreactive with the substrate in which the chambers are formed. The valving piston is magnetohydrodynamically driven to selectively close either the inlet port or the outlet port. The pumping piston is magnetohydrodynamically driven to pull or push the working fluid through one of the inlet or outlet ports, through the valving chamber, into the pumping chamber, back out of the pumping chamber and through the other one of the inlet or outlet ports after activation of the valving piston. Both direct current and inductive magnetohydrodynamic drives are contemplated. The valving and / or pumping chambers may be shaped or narrowed in their dimensions to impose a mechanical bias on the respective valving and / or pumping pistons to assume a preferred position in their respective chambers when the magnetohydrodynamic drive is turned off.

Owner:RGT UNIV OF CALIFORNIA

Method and apparatus for treating articles during formation

A method of making an article includes forming a molten material by melting at least a portion of a mass of a metal and an alloy. The method further includes forming the article by solidifying at least a portion of the molten material within a mold, and contacting the article with plasma during formation of the article. A method for making an article also is disclosed wherein a molten material is formed by melting at least a portion of a mass of one of a metal and an alloy, the molten material is collected within a mold, and at least a portion of the molten material is magnetohydrodynamically stirred within the mold.

Owner:ATI PROPERTIES

Microfluidics and small volume mixing based on redox magnetohydrodynamics methods

InactiveUS7147441B2Readily reversible methodUse of technologyMaterial nanotechnologyPump componentsOxidation-Reduction AgentRedox

Microfluidic channels utilizing magnetohydrodynamics are used to pump very small volumes of solution. The channels have electrodes along the walls of the channel and a current carrying species within the solution carries the current through the solution. The electric field generated by the use of the current carrying species is perpendicular to a magnetic field applied to the channel. The combination of the electric and magnetic fields causes the solution to flow through the channel.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ARKANSAS

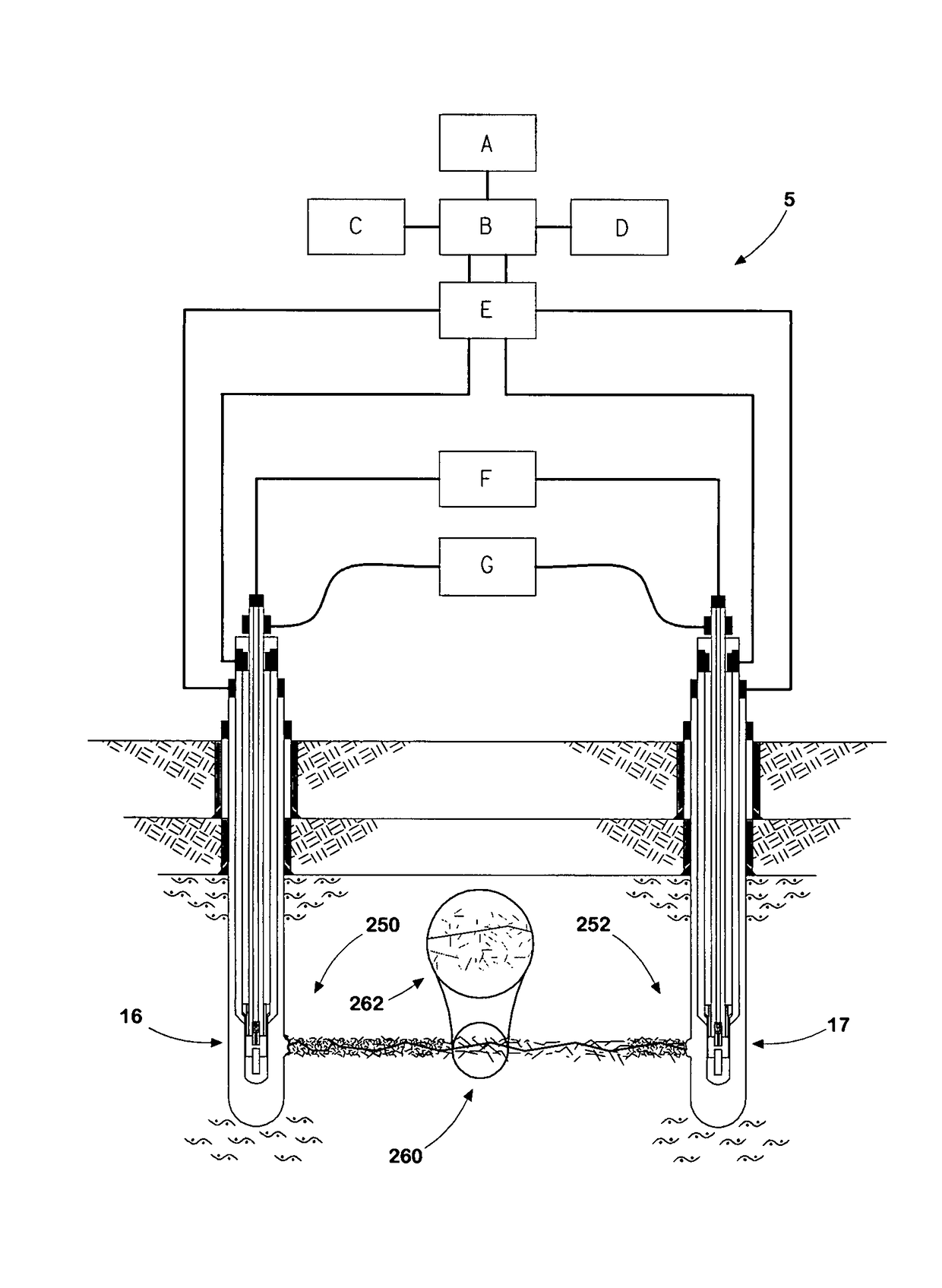

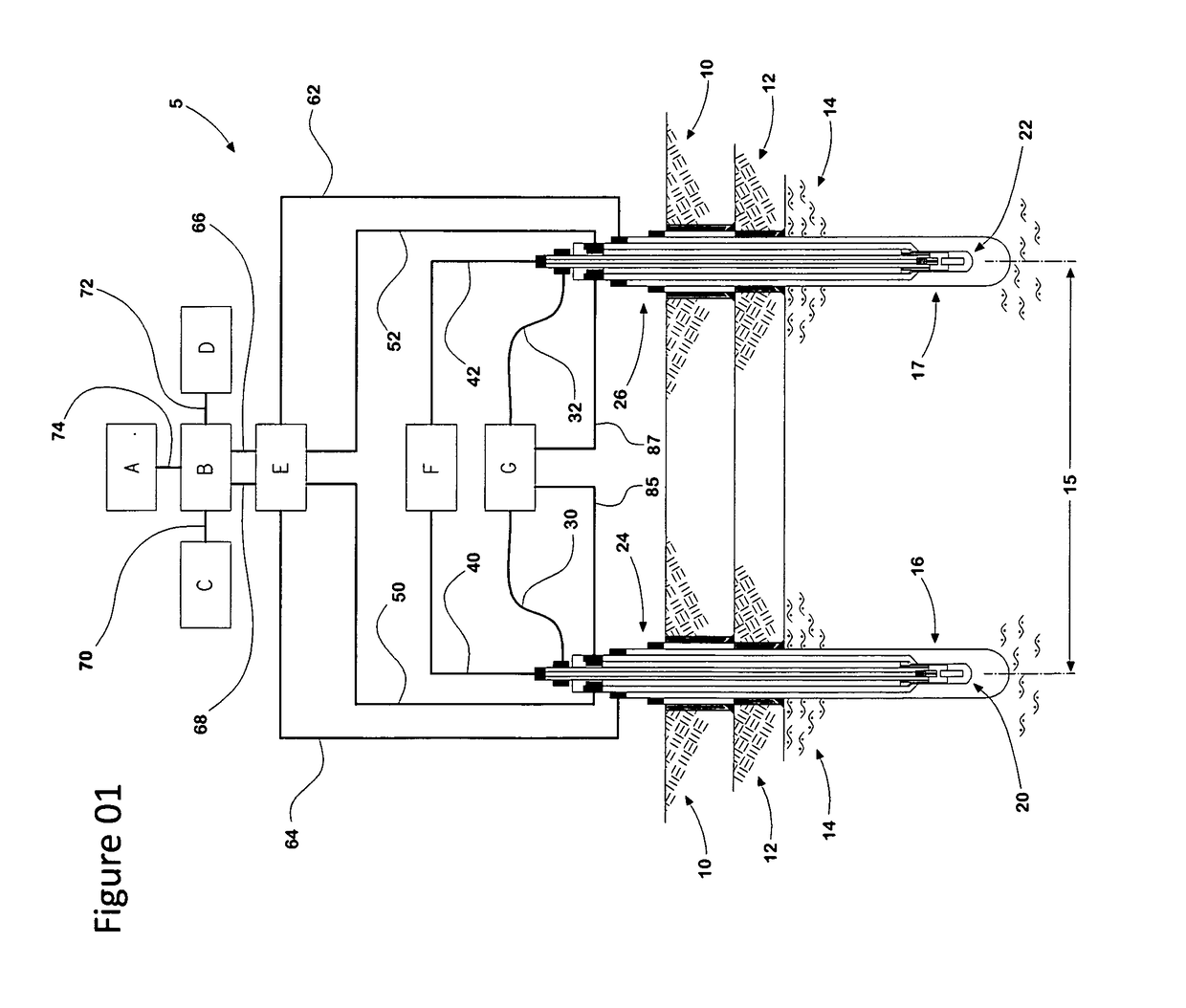

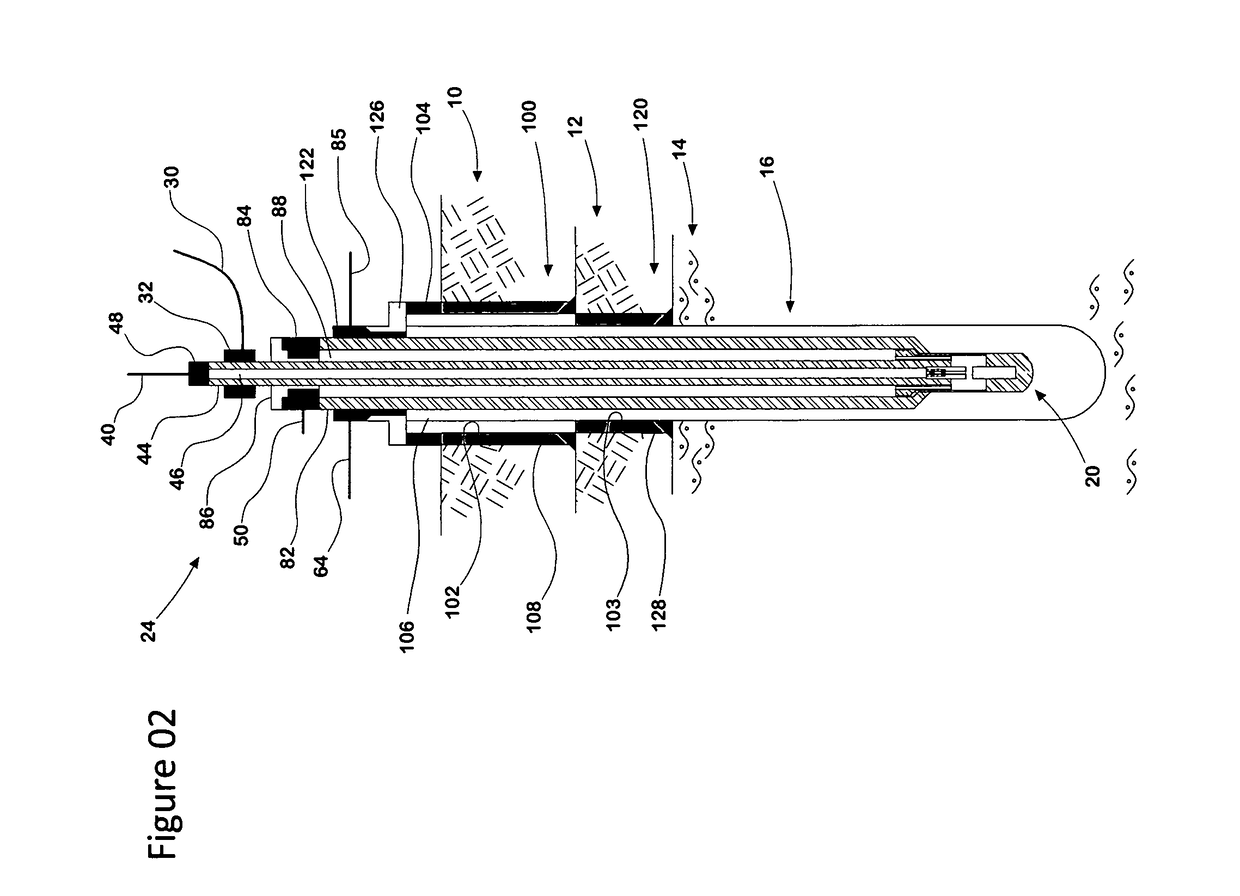

Method and System for Subsurface Resource Production

ActiveUS20170175505A1Improve breathabilityHigh densityGeothermal energy generationFluid removalPower flowMagneto hydrodynamic

A means to generate increasing geological permeability to produce greater volumes of various subsurface geological resources when compared to the current conventional production methods is disclosed. The means include a Pulsed Power Plasma Emitter System capable of substantially increasing the available electrical energy for use in high power compression surge currents that can be discharged and transmitted to power a simplified downhole Plasma Emitter Tool subsystem. The simplified downhole Plasma Emitter Tool sub-system is capable of generating a broad range of precisely controlled magnetohydrodynamic plasma spark discharges that produce a broad range of high power electromagnetic, acoustic and hydrodynamic surge waves. These powerful surge waves are generated at energy and power levels that are necessary to physically modify all types of geological formation permeability and to energize the mobilization of various subsurface fluids and fluidized resources.

Owner:GREEN CHEM ENERGY LLC

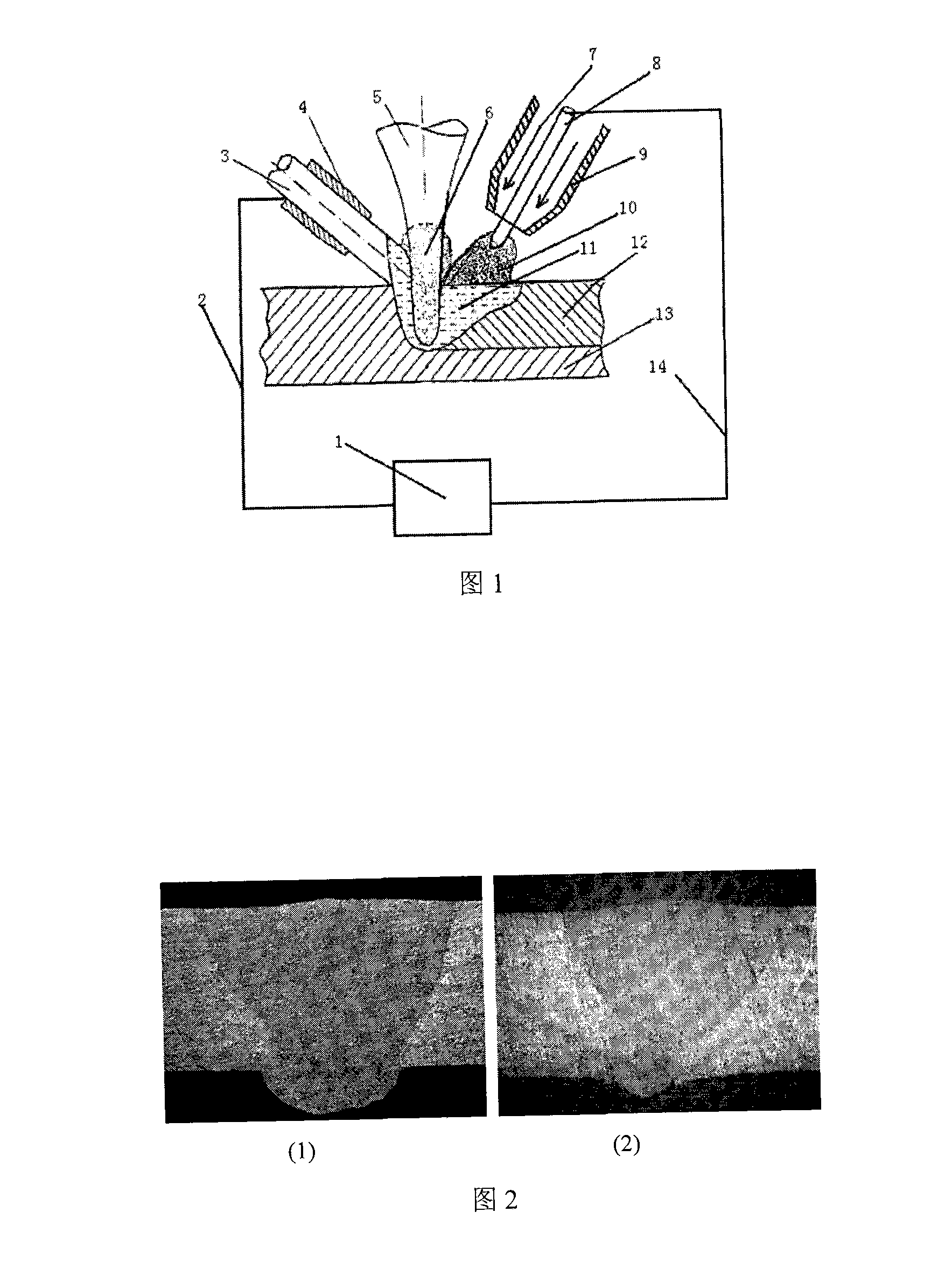

Laser electrical arc complex welding method for intensifying current magnetohydrodynamics effect

InactiveCN101176954AEasy to shapeImprove energy coupling efficiencyArc welding apparatusLaser beam welding apparatusARC complexEnergy coupling

The invention relates to a laser-arc hybrid welding method which reinforces dynamic effect of current and magnetic fluid, belonging to technical field of laser material processing. The invention is characterized in that: a synergistic arrangement of laser and electric arc is adopted and a filler wire is added simultaneously; wherein, the electric arc and the wire are arranged at both sides of a laser beam; the wire is arranged in the front and is contacted with a workpiece, and the electric arc is arranged at the back; the two polarities of the welding power are connected with a tungsten electrode and the wire respectively; the welding power forms a current loop by flowing through a weld pool and the electric arc by the wire, and most of the welding power flows through the weld pool and produces electromagnetic force. The invention has the advantages that the energy coupling efficiency and the stability in the welding process are both highly improved by fully utilizing influence of dynamic effect of arc current and magnetic fluid on the heat exchange situation and the flowing state of the weld pool, and the surface forming state of a weld joint is greatly improved because of the significantly improved tolerance of the electric arc arranging at the back of the weld pool to the wire fluctuation.

Owner:BEIJING UNIV OF TECH

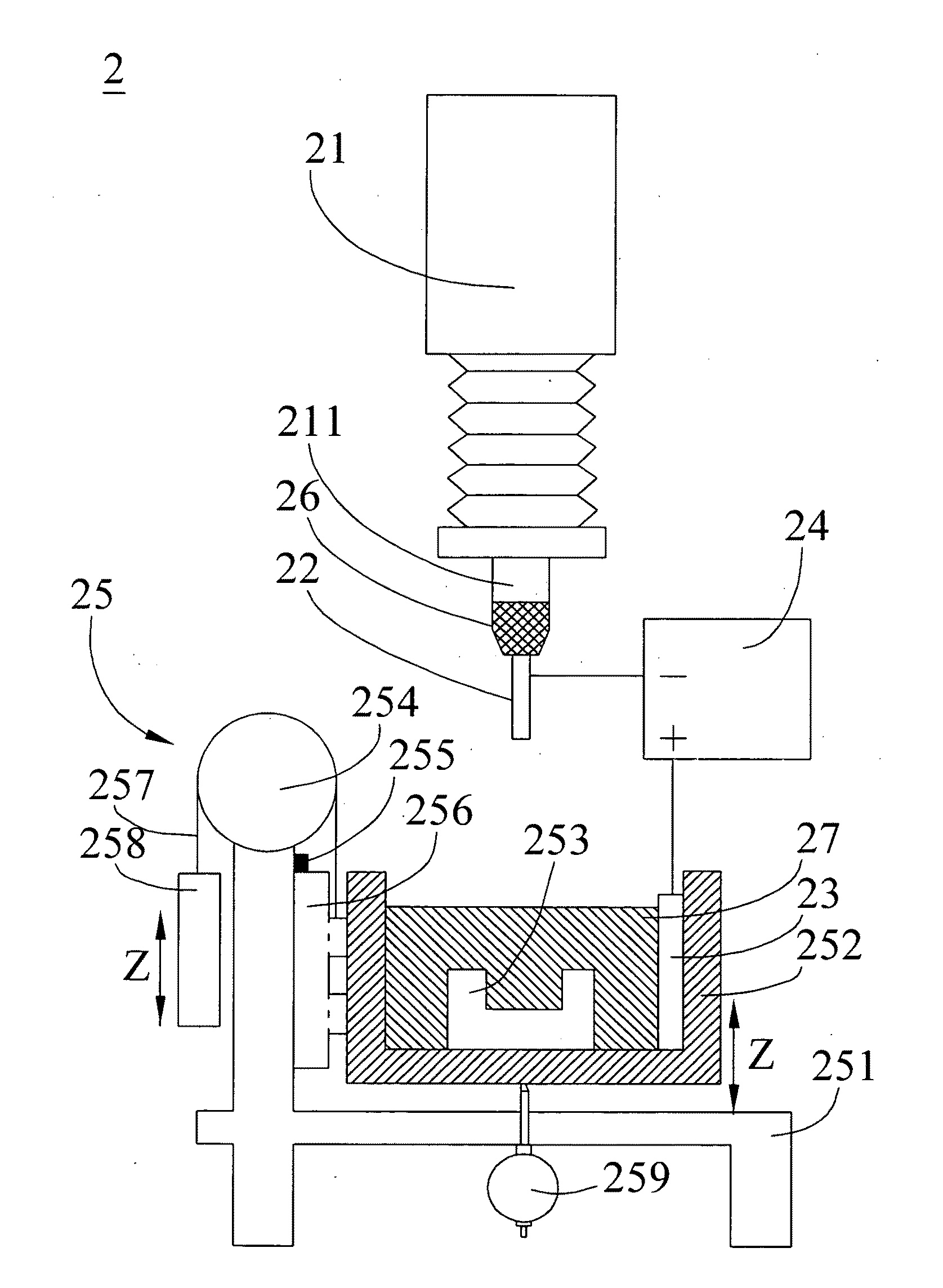

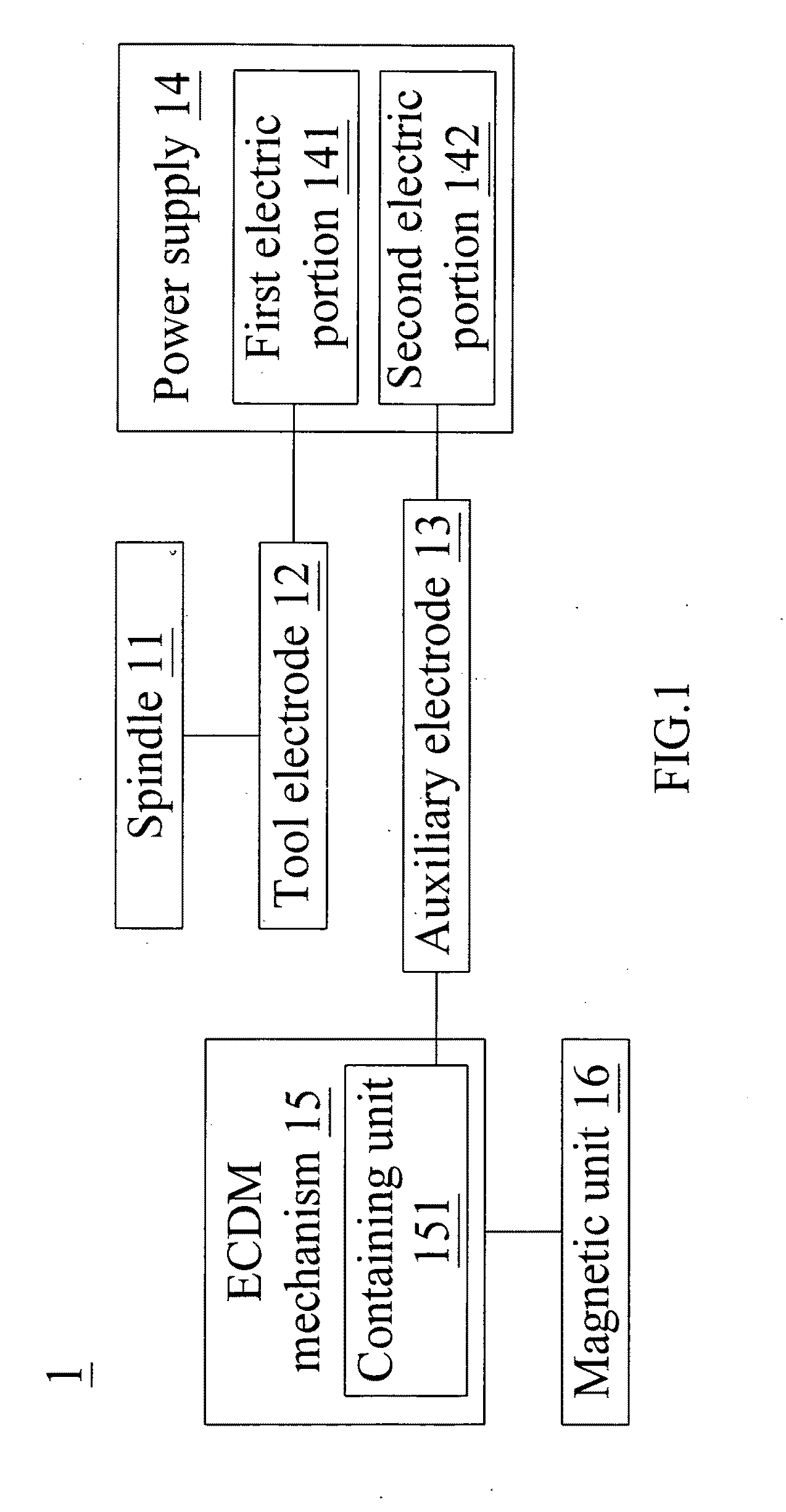

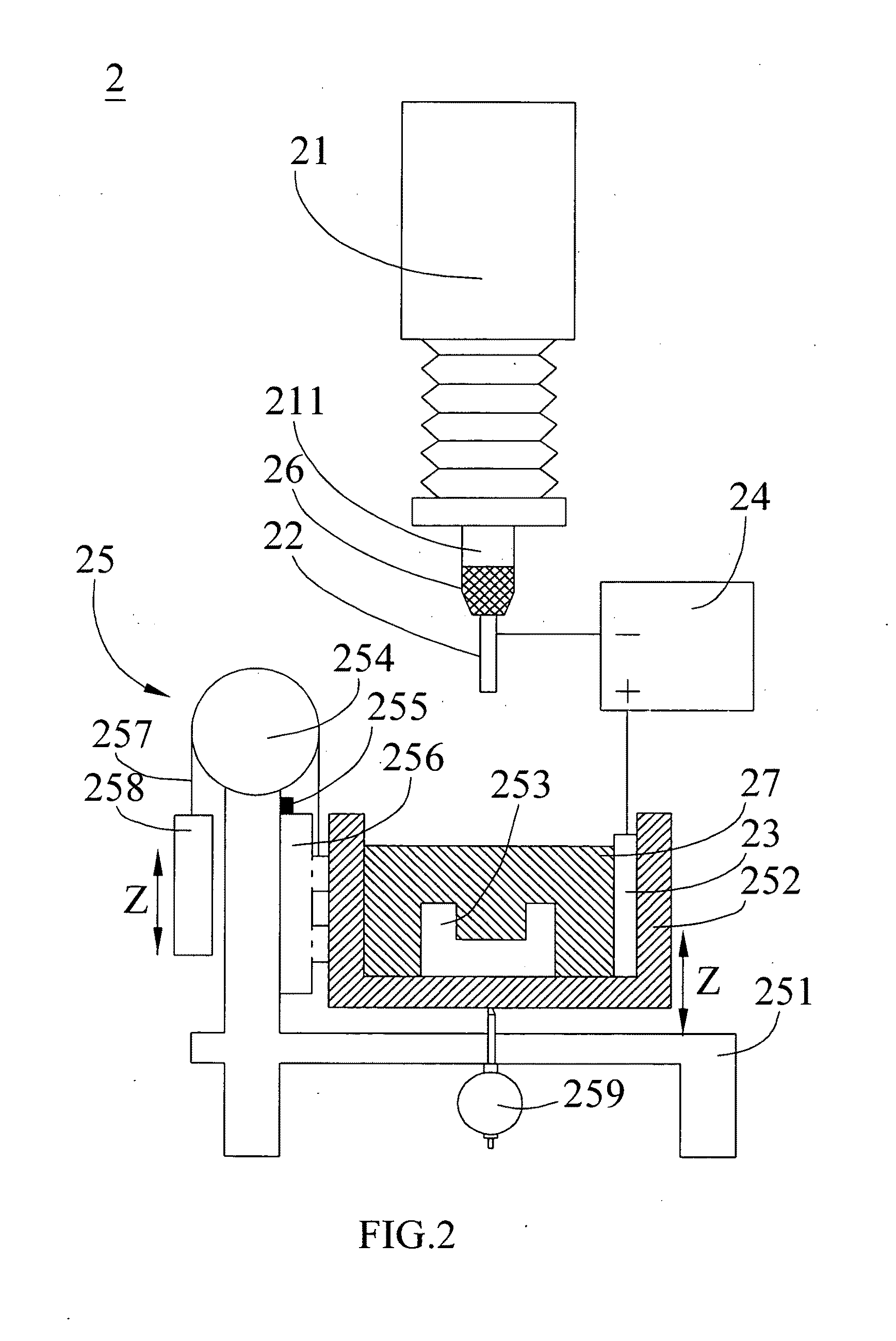

Apparatus and method for magnetic field assisted electrochemical discharge machining

ActiveUS20100243430A1Reduce thicknessIncrease loopCellsVacuum evaporation coatingElectrolysisMachined surface

In an apparatus and method for magnetic field assisted electrochemical discharge machining (ECDM), the magneto hydrodynamic (MHD) effect is utilized to improve the thickness of bubble film and the electrolyte circulation so as to enhance the machining accuracy and efficiency. Since charged ions in a magnetic field are induced by Lorenz force to move, and the electrolysis bubbles generated in the ECDM process are suffused with electrification ions on their surfaces, the electrolysis bubbles can be forced to move in the direction of the magnetic field without the need of mechanical disturbance. The present invention can be widely applied in the micro-machining of non-conductive brittle materials of different dimensions and shapes, comprising the forming of microchannels and microholes on a biochip, and in the micro-opto-electro-mechanical system (MOEMS) and various kinds of micro-machining fields. The machined surface is smooth and does not require a second time machining.

Owner:NAT CENT UNIV

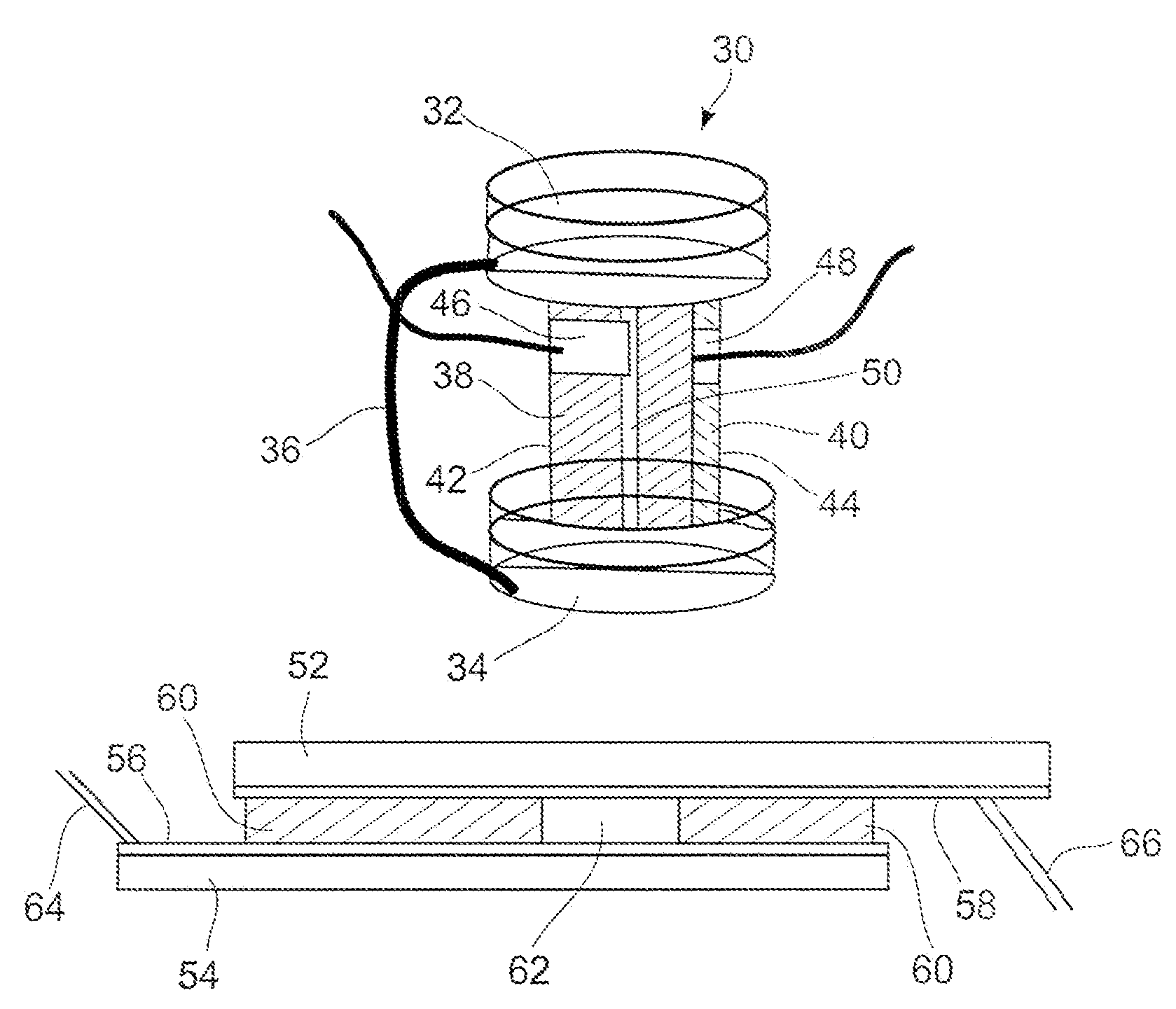

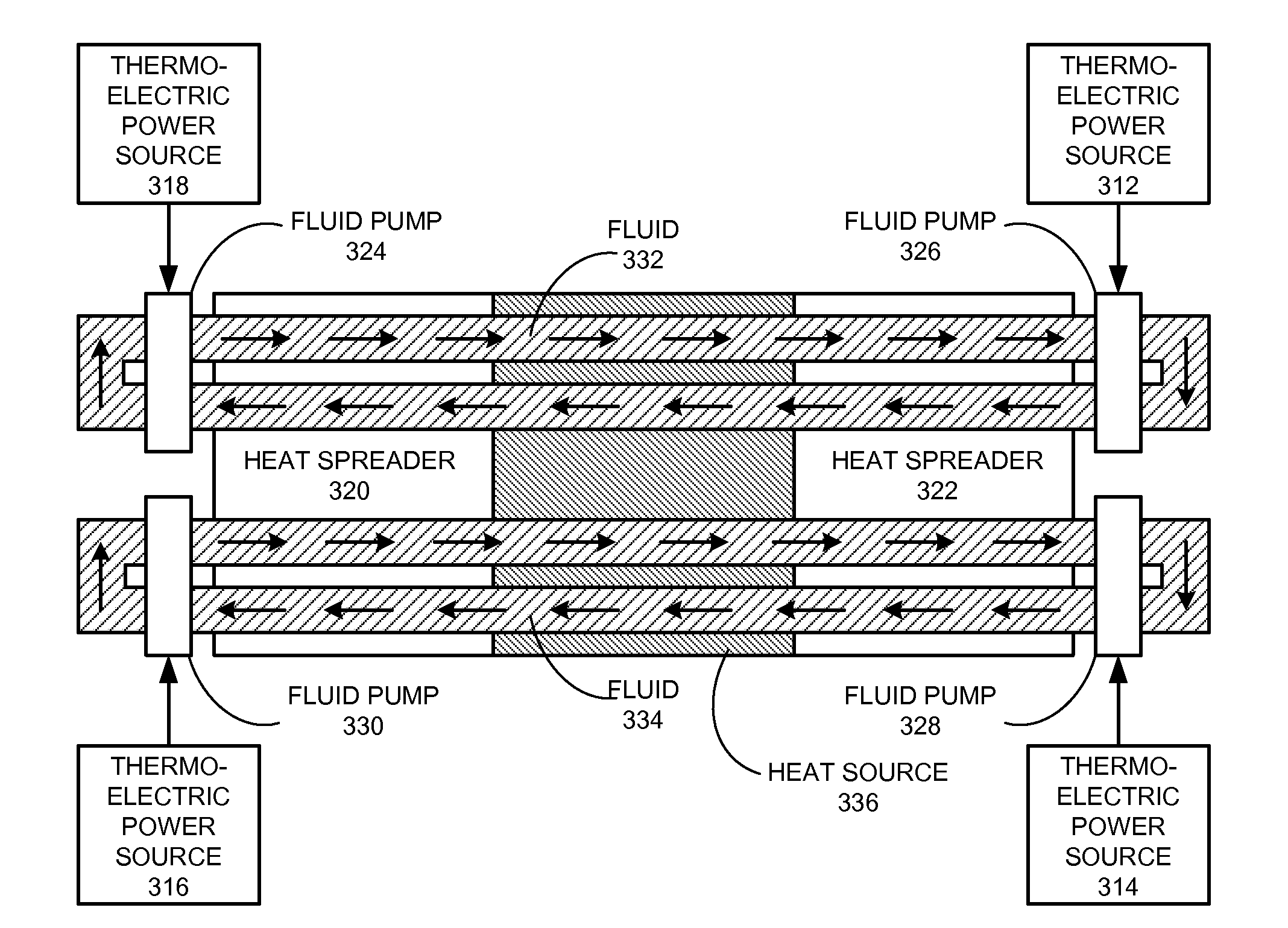

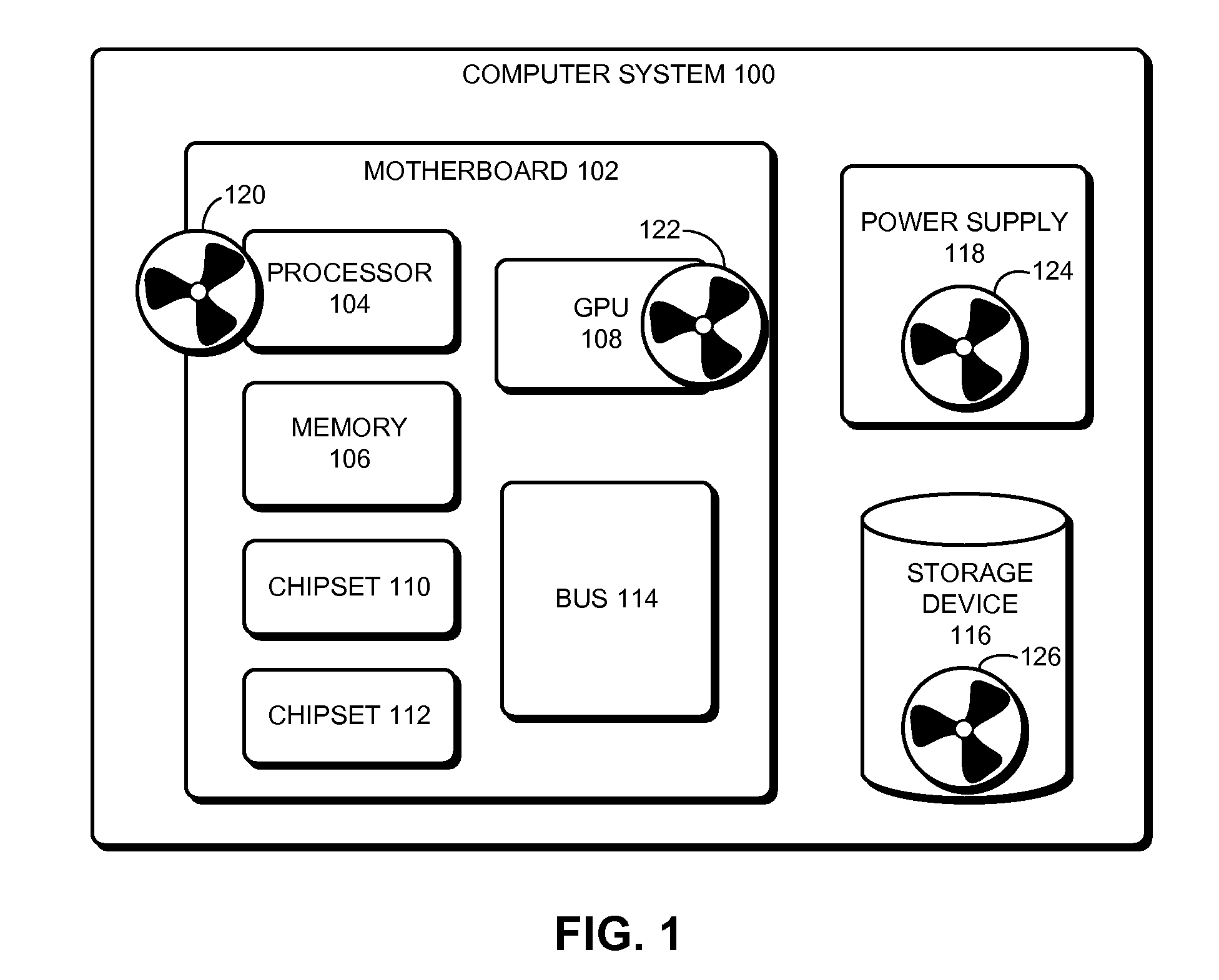

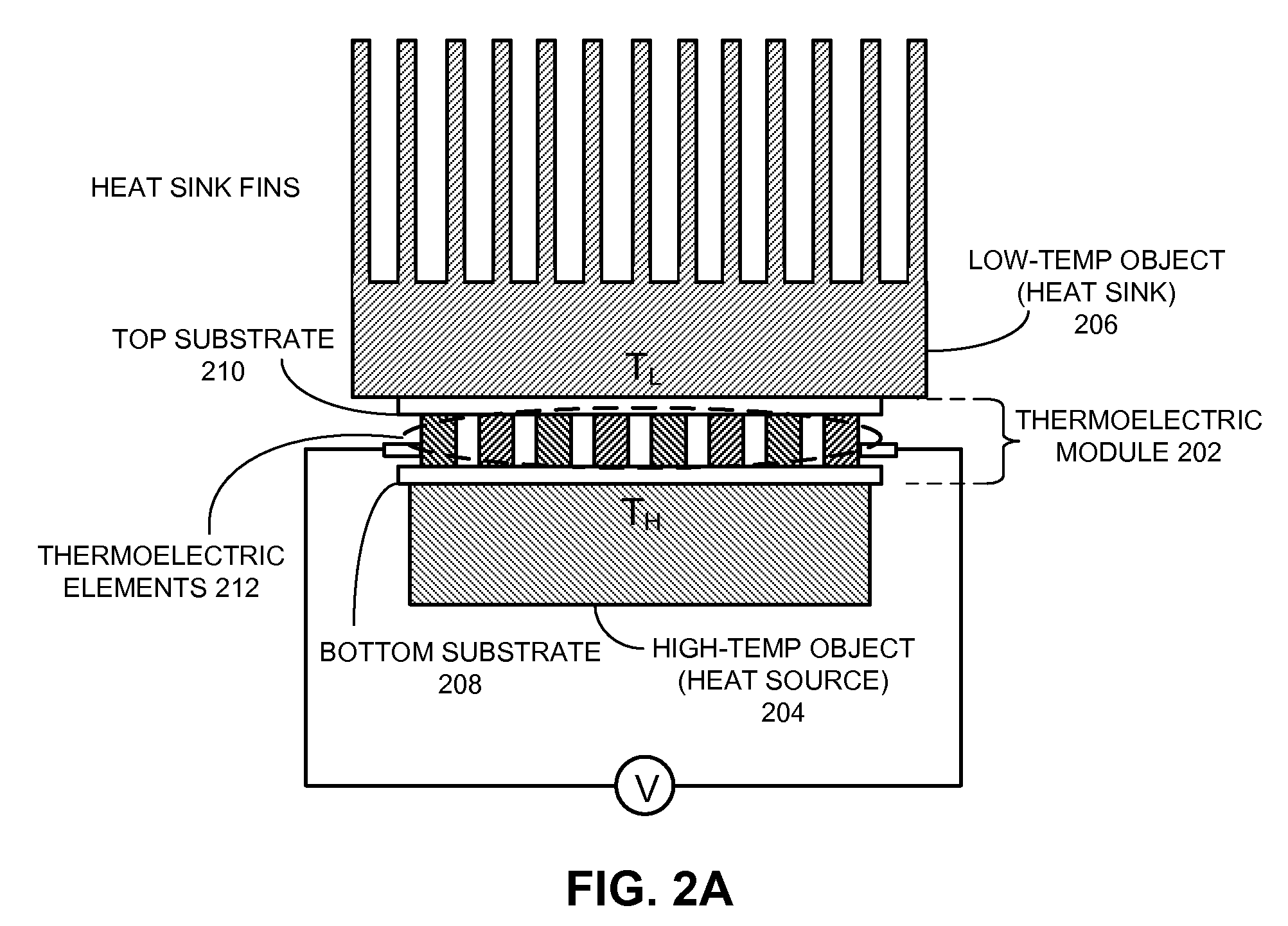

Integrated circuit chip cooling using magnetohydrodynamics and recycled power

ActiveUS20090308081A1Thermoelectric device with peltier/seeback effectSemiconductor/solid-state device detailsComputerized systemMagneto hydrodynamic

Some embodiments of the present invention provide a system that cools an integrated circuit (IC) chip within a computer system. During operation, the system converts heat generated by a heat-generating device within the computer system during operation of the computer system into thermoelectric power. Next, the system supplies the thermoelectric power to drive a fluid pump. Finally, the system uses the fluid pump to conduct heat away from the IC chip.

Owner:ORACLE INT CORP

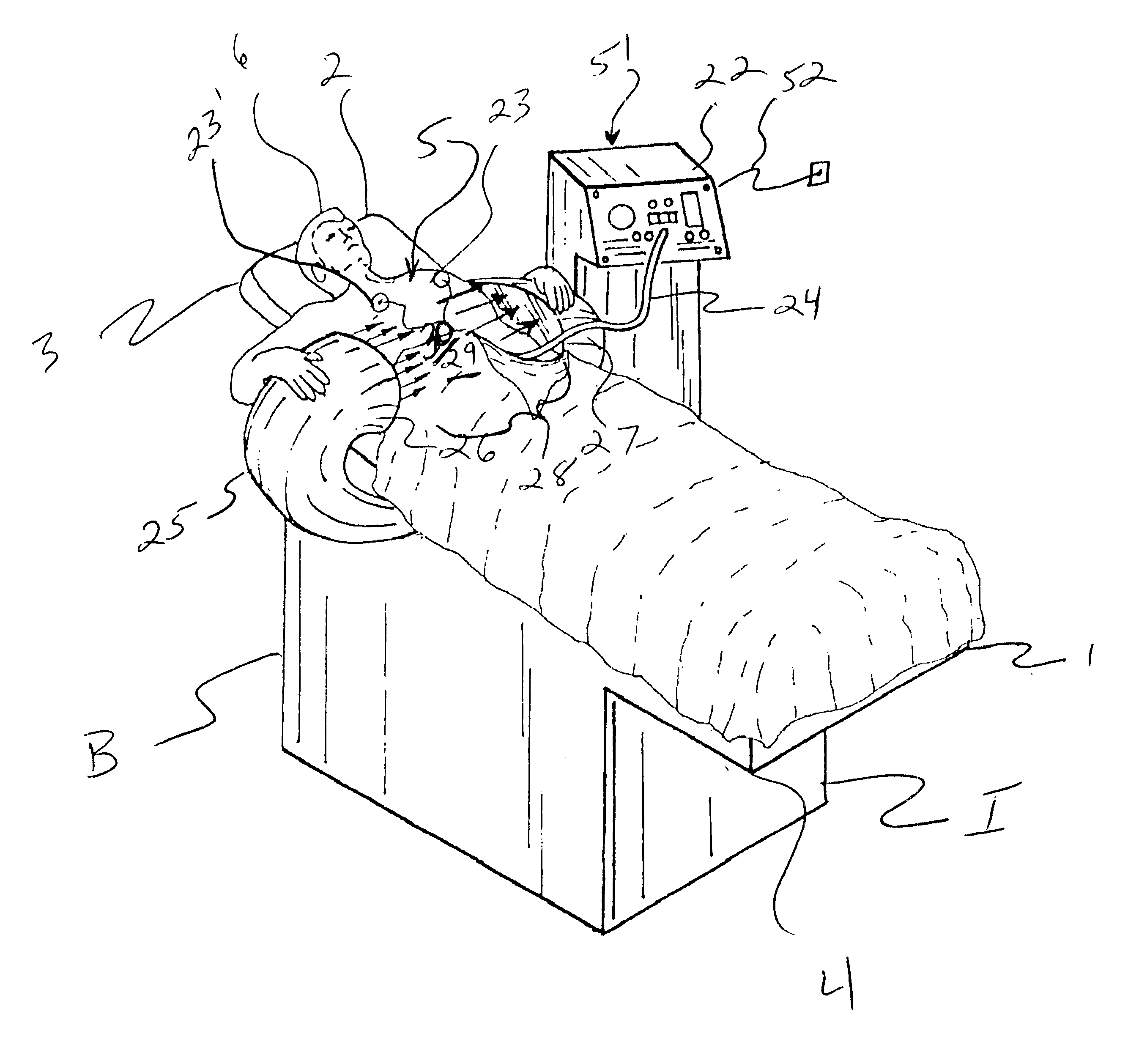

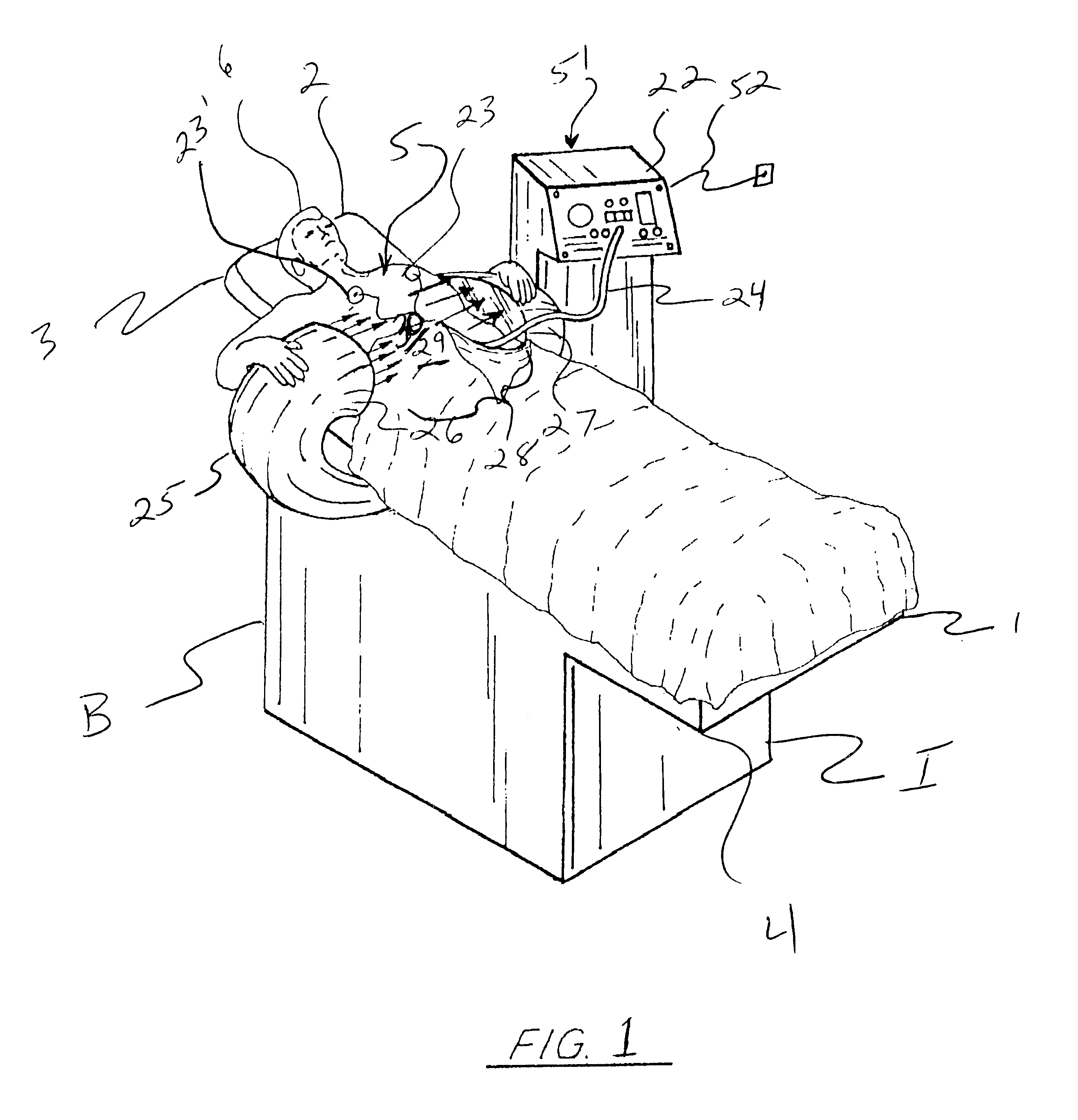

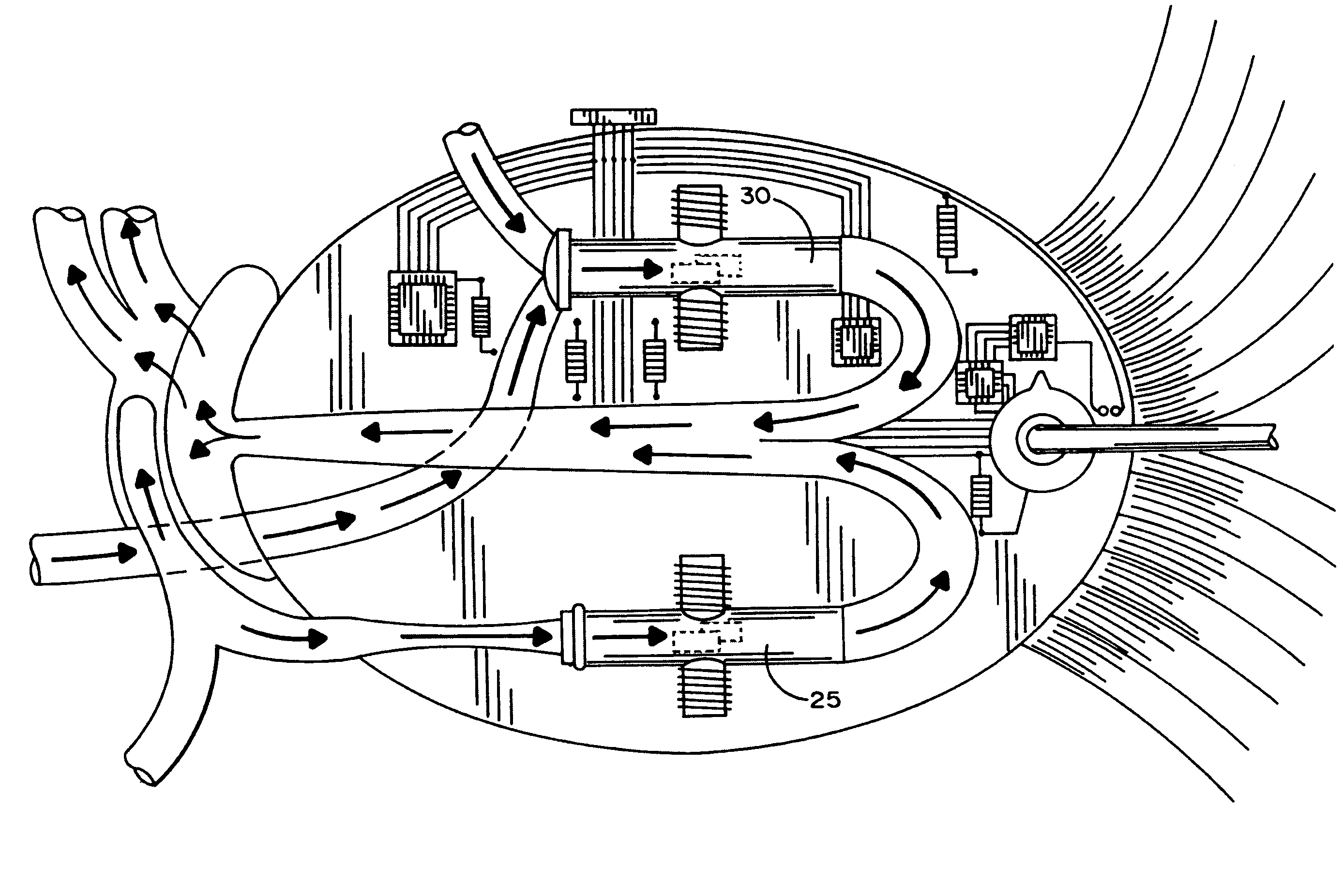

Magnetohydrodynamic cardiac assist device

InactiveUS6440059B1Less invasive procedureReduce morbidityControl devicesSurgeryLeft ventricular sizeElectrode polarity

A left ventricular assist device (LVAD) utilizing MHD principles, wherein an aortic electrode assembly is located within a main femoral artery in the aorta, in the vicinity of the heart of a patient, which electrode assembly is exposed to a high density magnetic field generated outside of the patient. The high density magnetic field urges electrified blood within the artery in the vicinity of the electrode along the length of the electrode in a uniform direction, thereby providing a fluid pumping force and pressure commensurate with the magnetic field strength and electrode current in accordance with MHD theory and practice. A cardio bypass system is also taught, wherein in addition to the aortic electrode assembly, as second electrode assembly is placed in the inferior vena cava having an opposite electrode polarity to the aortic electrode assembly, such that the second electrode assembly directs blood flow toward the heart. In the preferred embodiment of the invention, the magnetic field is generated exterior of the patient via a superconducting magnet which is designed to bridge the torso of the patent, such that the electrodes are generally centrally disposed within the magnetic field, along a longitudinal axis aligned with the aorta (and inferior vena cava), and generally orthogonal to the magnetic field. Sensors monitoring the patient may utilize ECG, blood pressure, and other data to control the magnet, varying the magnetic field so as to emulate the pumping action and intensity of the patents heart in real time, or simulate same.

Owner:CIMEX BIOTECH L C

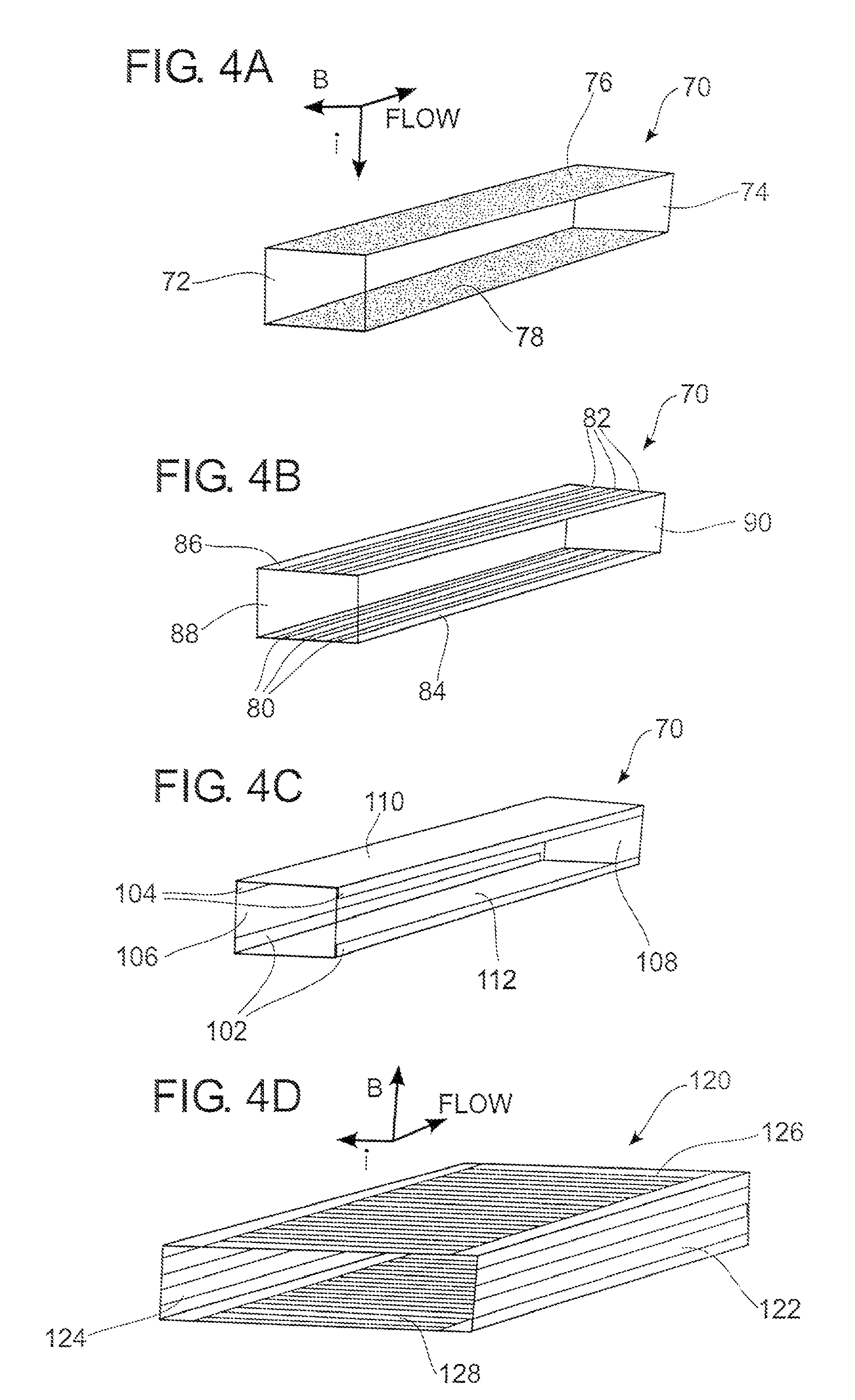

Heat transfer device

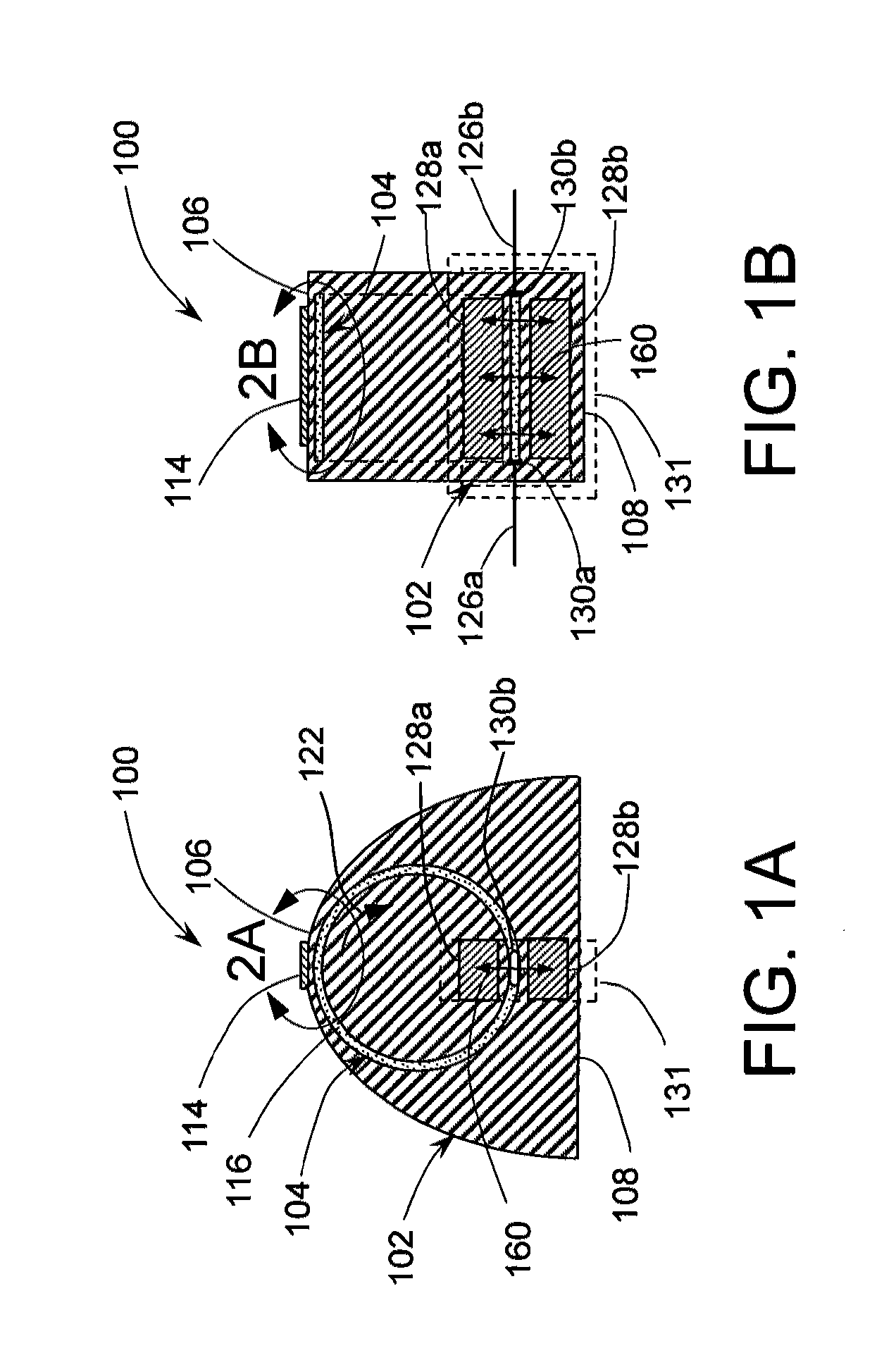

InactiveUS20100071883A1Little powerSuitable for large volumeDigital data processing detailsSemiconductor/solid-state device detailsLiquid metalElectric vehicle

The invention is for an apparatus and method for removal of waste heat from heat-generating components including high-power solid-state analog electronics such as being developed for hybrid-electric vehicles, solid-state digital electronics, light-emitting diodes for solid-state lighting, semiconductor laser diodes, photo-voltaic cells, anodes for x-ray tubes, and solids-state laser crystals. Liquid coolant is flowed in one or more closed channels having a substantially constant radius of curvature. Suitable coolants include liquid metals and ferrofluids. The former may be flowed by magneto-hydrodynamic effect or by electromagnetic induction. The latter may be flowed by magnetic forces. Alternatively, an arbitrary liquid coolant may be used and flowed by an impeller operated by electromagnetic induction or by magnetic forces. The coolant may be flowed at very high velocity to produce very high heat transfer rates and allow for heat removal at very high flux.

Owner:VETROVEC JAN

Multichannel cooling system with magnetohydrodynamic pump

ActiveUS7870893B2Temperature control using plurality of sensorsSemiconductor/solid-state device detailsControl flowMagneto hydrodynamic

A cooling device includes a base having cells. A pipe is coupled to the base for each of the cells. The pipes include passages that carry fluid toward the cell and away from the cell. A magnetohydrodynamic pump system coupled to the pipe circulates an electrically conductive cooling fluid within the passages and the cell. An orifice may emits jets of fluid into the cells. A controller coupled to the cooling device may independently control flow rates in two or more cells of the cooling device. The controller may receive information from the temperature sensors on the base of the cooling device for use in controlling the flow rates in the cells.

Owner:ORACLE INT CORP

Microfluidic control for waveguide optical switches, variable attenuators, and other optical devices

InactiveUS20060083473A1Improve efficiencyIncrease functional densityTransportation and packagingMixersDifferential pressureEngineering

Devices utilize elements carried by a fluid in a microchannel to switch, attenuate, shutter, filter, or phase shift optical signals. In certain embodiments, a microchannel carries a gaseous or liquid slug that interacts with at least a portion of the optical power of an optical signal traveling through a waveguide. The microchannel may form part of the cladding of the waveguide, part of the core and the cladding, or part of the core only. The microchannel may also have ends or may be configured as a loop or continuous channel. The fluid devices may be self-latching or may be semi-latching. The fluid in the microchannel is moved using e.g., e.g., electrocapillarity, differential-pressure electrocapillarity, electrowetting, continuous electrowetting, electrophoresis, electroosmosis, dielectrophoresis, electro-hydrodynamic electrohydrodynamic pumping, magneto-hydrodynamic magnetohydrodynamic pumping, thermocapillarity, thermal expansion, dielectric pumping, and / or variable dielectric pumping.

Owner:NEOPHOTONICS CORP

Thermal management for solid state high-power electronics

InactiveUS20120273164A1Little powerSuitable for large volumeEnergy efficient heating/coolingSemiconductor/solid-state device detailsMagnetic tension forceLiquid metal

The invention is for an apparatus and method for removal of waste heat from heat-generating components including high-power solid-state analog electronics such as being developed for hybrid-electric vehicles, solid-state digital electronics, light-emitting diodes for solid-state lighting, semiconductor laser diodes, photo-voltaic cells, anodes for x-ray tubes, and solids-state laser crystals. Liquid coolant is flowed in one or more closed channels having a substantially constant radius of curvature. Suitable coolants include liquid metals and liquids with low vapor pressure. The former may be flowed by magneto-hydrodynamic effect or by electromagnetic induction. The latter may be flowed by magnetic forces. Alternatively, an arbitrary liquid coolant may be used and flowed by an impeller operated by electromagnetic induction or by magnetic forces. The coolant may be flowed at very high velocity to produce very high heat transfer rates and allow for heat removal at very high flux.

Owner:VETROVEC JAN

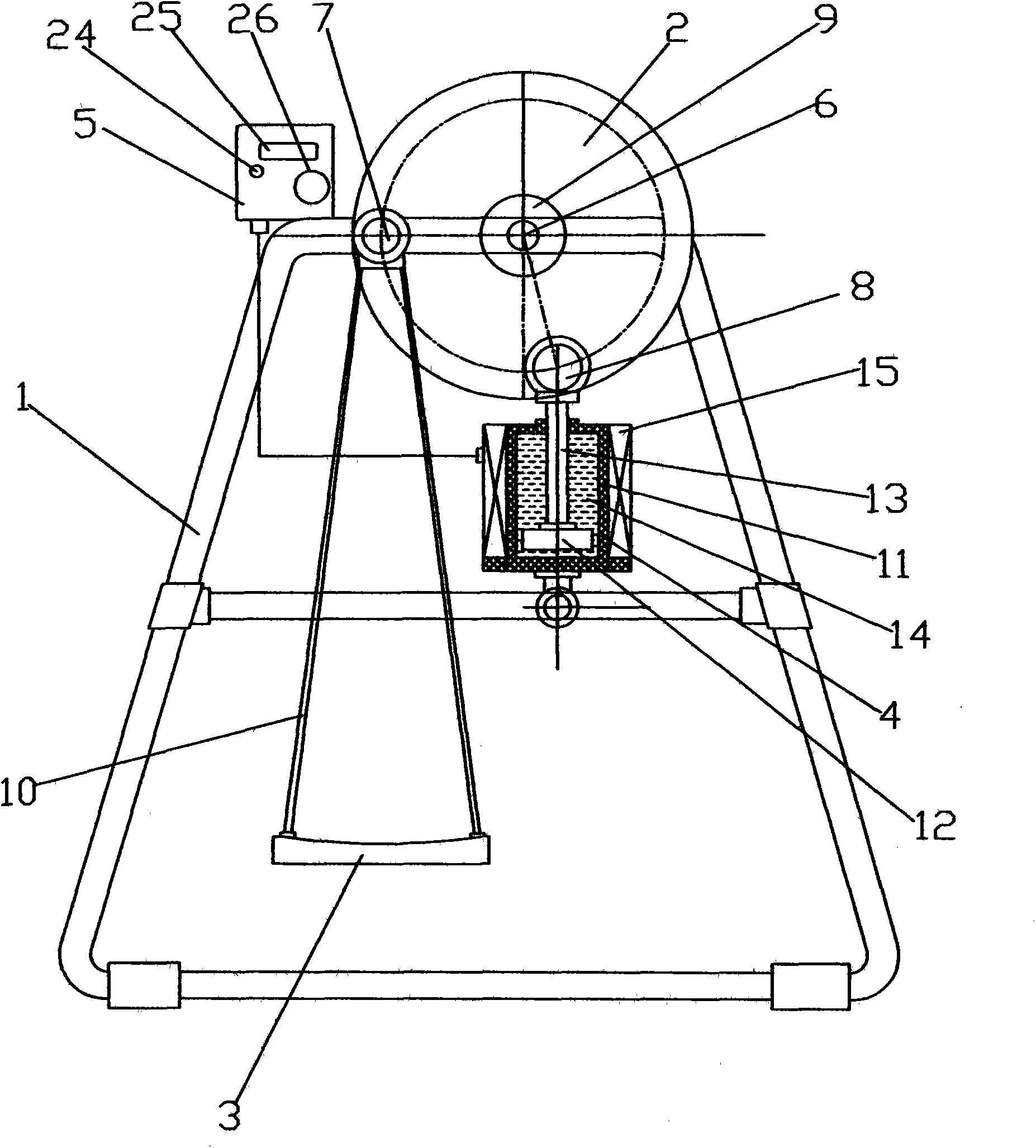

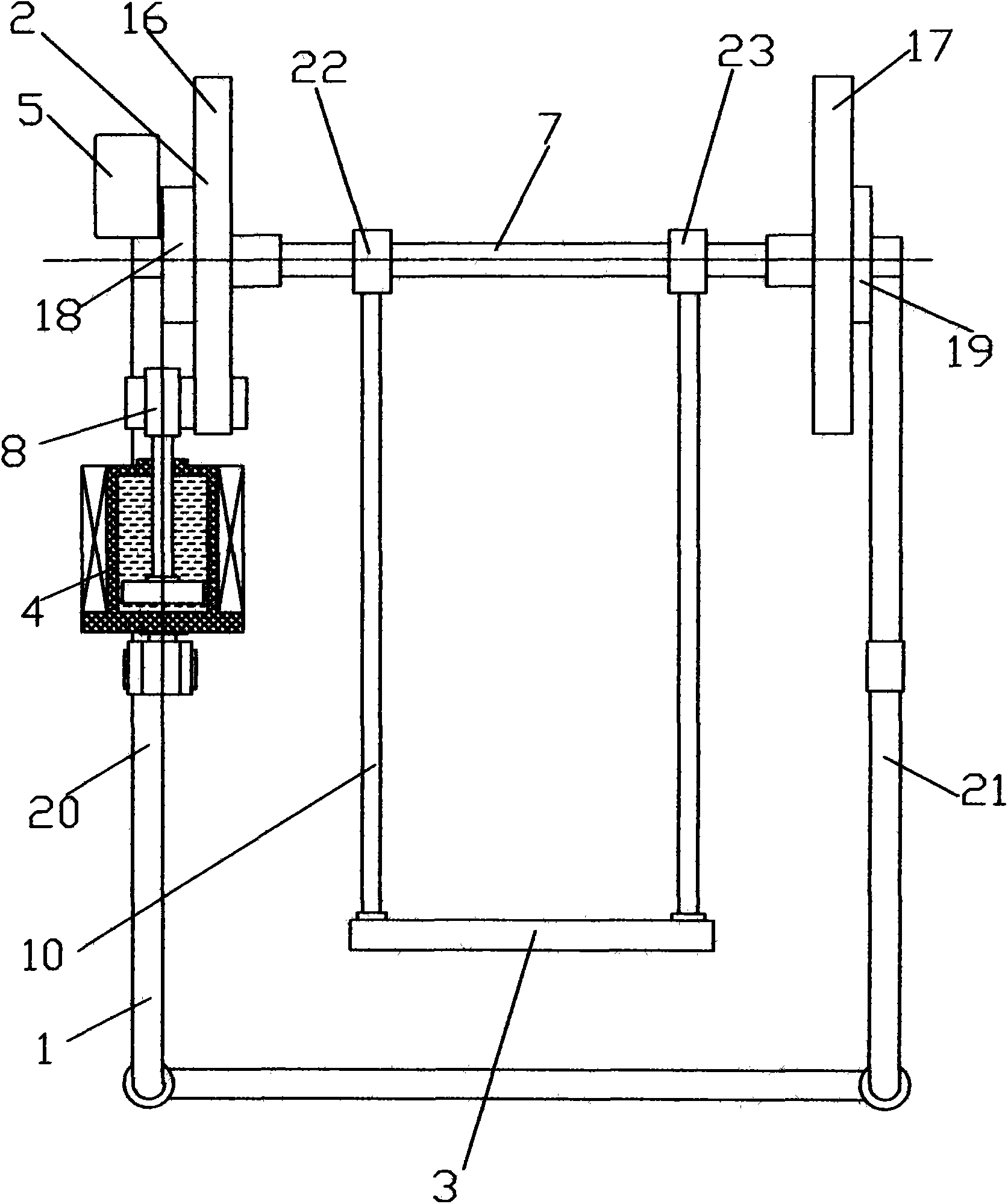

Swing

A swing comprises a support, a balance wheel, a swing plate, a magnetohydrodynamic device and a controller. The balance wheel is provided with a central shaft, a swing eccentric shaft and a swinging eccentric shaft, the swing eccentric shaft and the swinging eccentric shaft are arranged at different positions of the balance wheel, and the central shaft of the balance wheel is connected with a bearing block of the support in a movable fit manner; the magnetohydrodynamic device comprises a cylinder, a piston, a piston rod, magnetic fluid and an electromagnetic coil, the piston and the magnetic fluid are arranged in a cavity of the cylinder, the cylinder is hinged to the support, and the piston rod is hinged to the swinging eccentric shaft. The swing has the advantages that the piston and the piston rod ascend and descend in the magnetic fluid according to rhythm of music for children under the control of the controller, the piston rod drives the balance wheel to swing along with the rhythm of the music for the children, and the balance wheel and the swing eccentric shaft drive the swing plate to swing according to the rhythm of the music for the children, so that the children, particularly babies, on the swing can swing along with the music for the children, and the swing playing interestingness is improved.

Owner:郑运婷

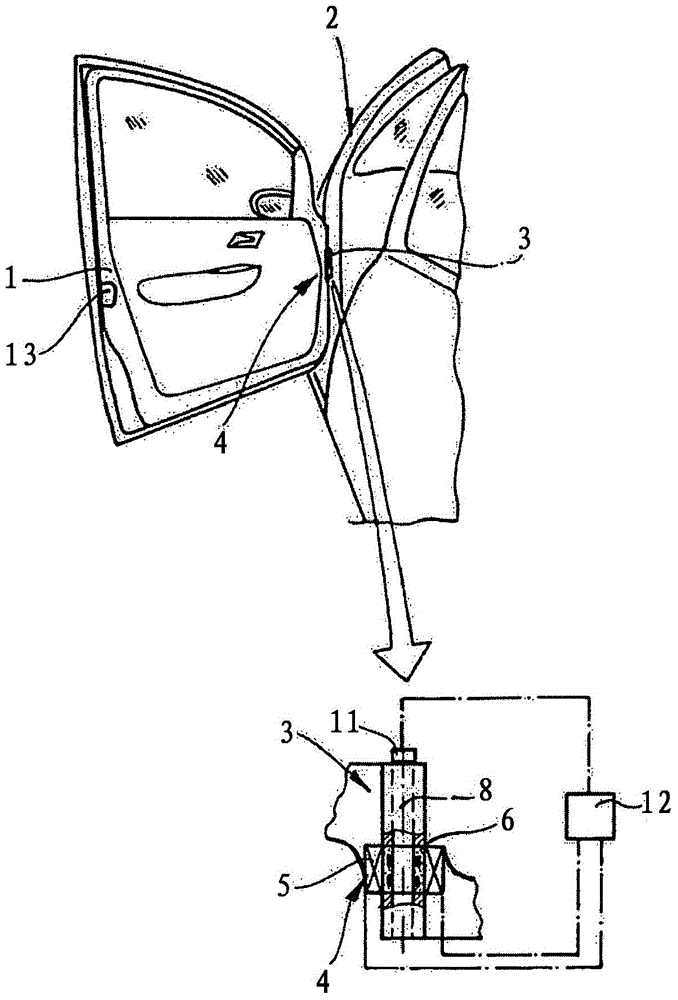

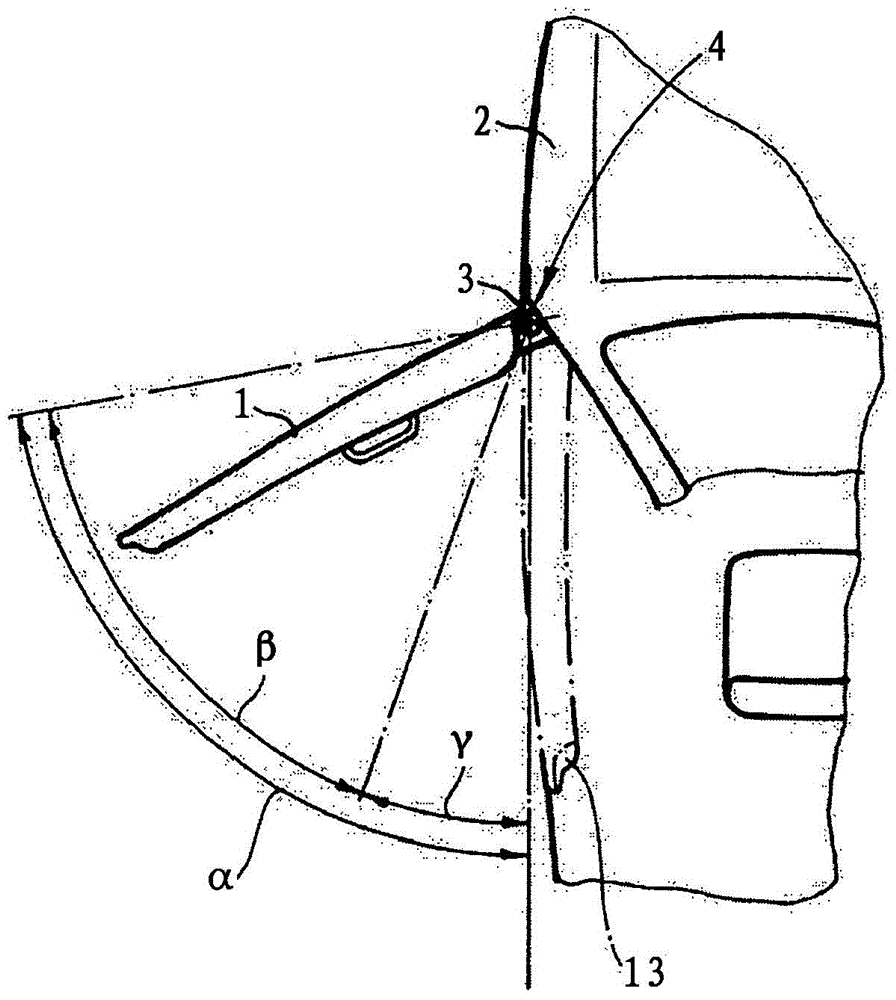

Motor vehicle door

ActiveCN104981581AAchieve dampingImplementation driveBuilding braking devicesWing accessoriesMotor vehicle partMagneto hydrodynamic

The invention relates to a motor vehicle door comprising a door leaf (1) with a drive, a magnetic device (4) as a component of the drive, and at least one sensor (11) which is associated with the door leaf (1). According to the invention, said magnetic device (4) also comprises a magnetorheological element (7) and / or a magnetohydrodynamic element which can be actuated by at least one magnet (5).

Owner:KIEKERT AG

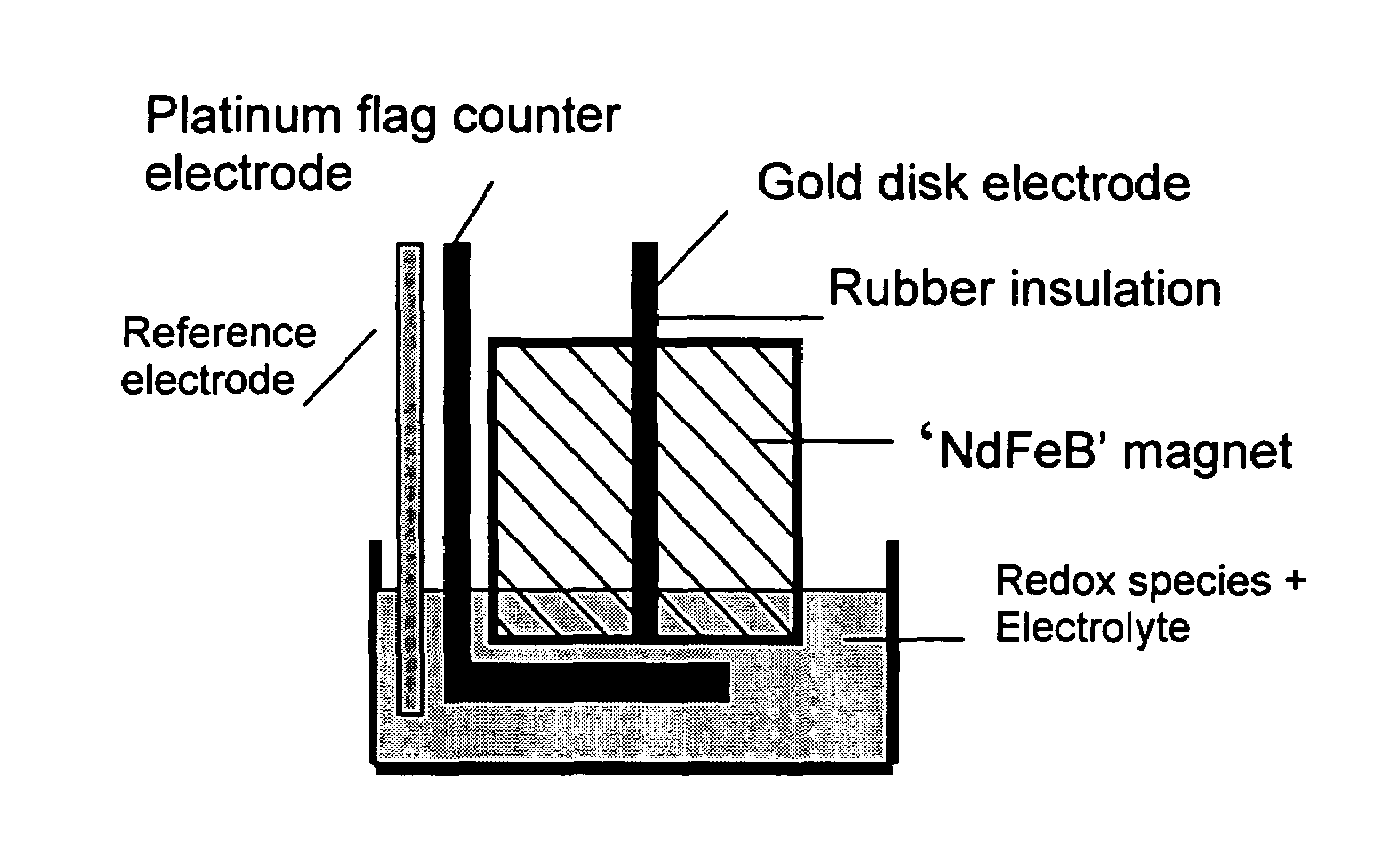

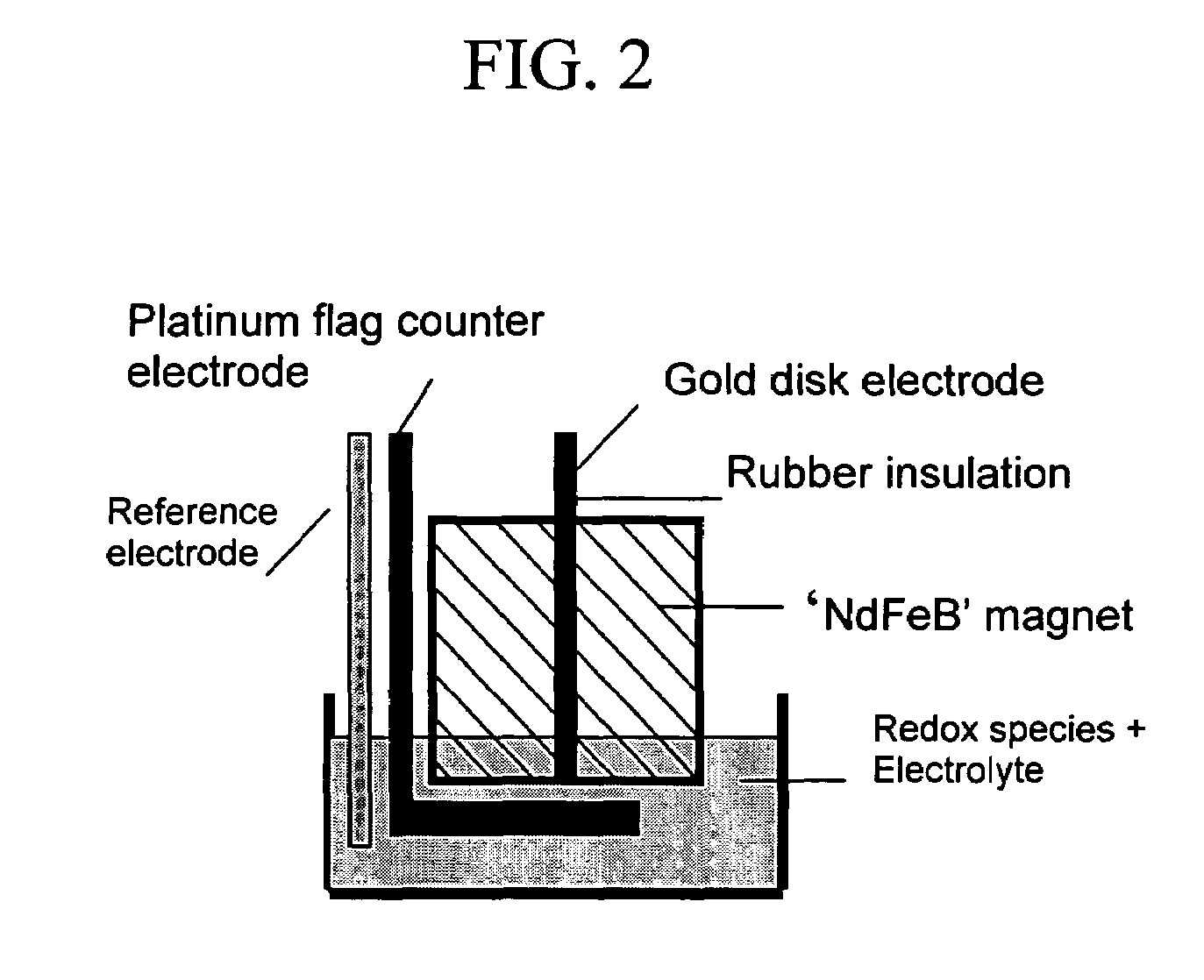

Electrochemistry using permanent magnets with electrodes embedded therein

InactiveUS7572355B1Well mixedLow voltage requirementRotary stirring mixersTransportation and packagingHigh-Throughput Screening MethodsLab-on-a-chip

Devices and methods of enhancing mass transport proximate a surface of an electrode immersed in a liquid are disclosed. One aspect of the device comprises an electrode embedded in a sintered or bonded magnetic material. The device is contacted with a solvent containing a redox material dissolved therein. An external voltage or current is applied to the electrode, which external voltage or current is sufficient to enhance mass transport proximate the surface of the electrode. Magnetic field effects can be effectively applied to the microstirring of fluids in conjunction with microelectrochemical systems in a lab-on-a-chip format. Suitable applications include bioassays, drug discovery, and high throughput screening, and other applications where magnetohydrodynamics can enhance chemical detection and / or reagent mixing, which otherwise rely on diffusional processes.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ARKANSAS

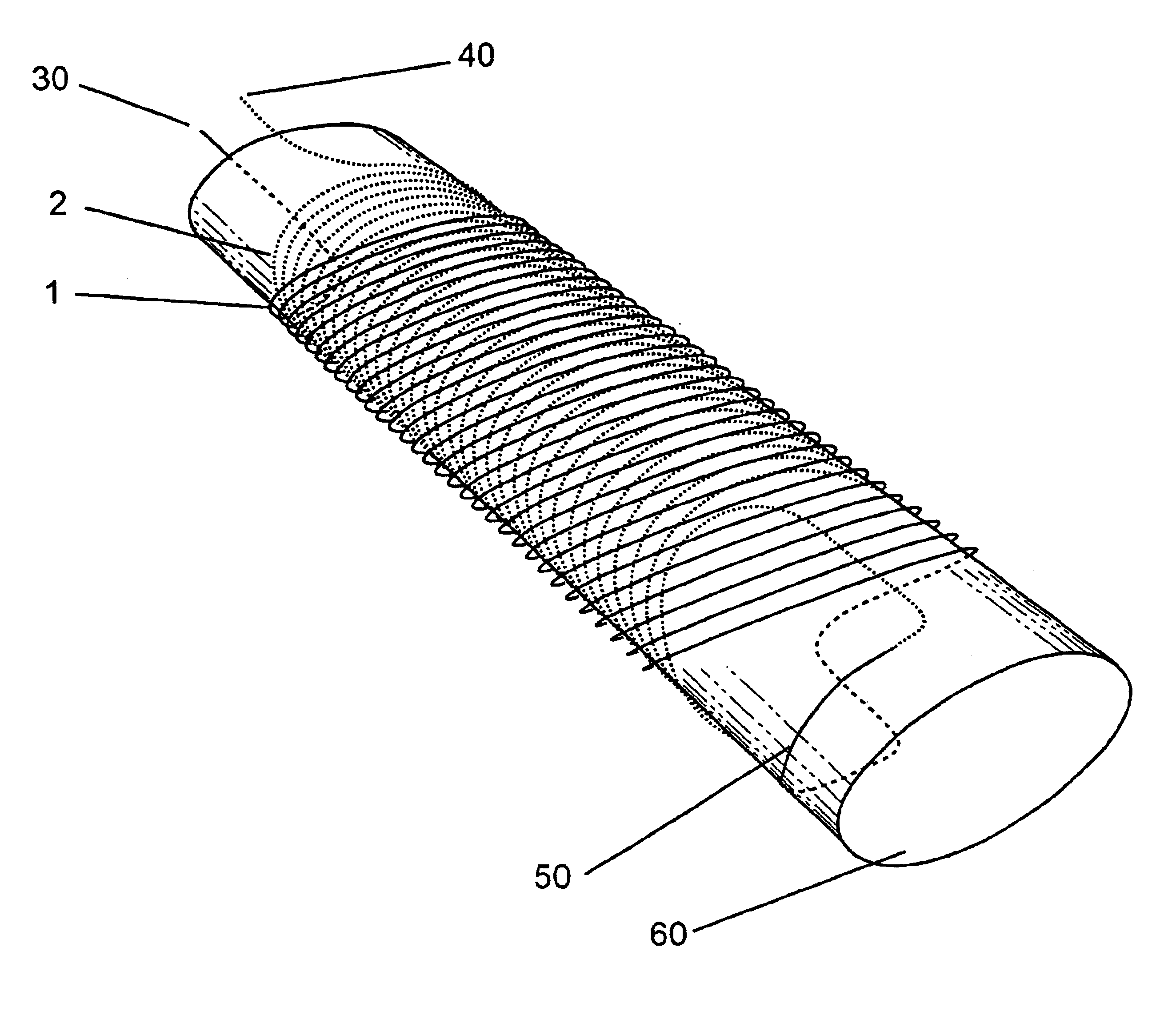

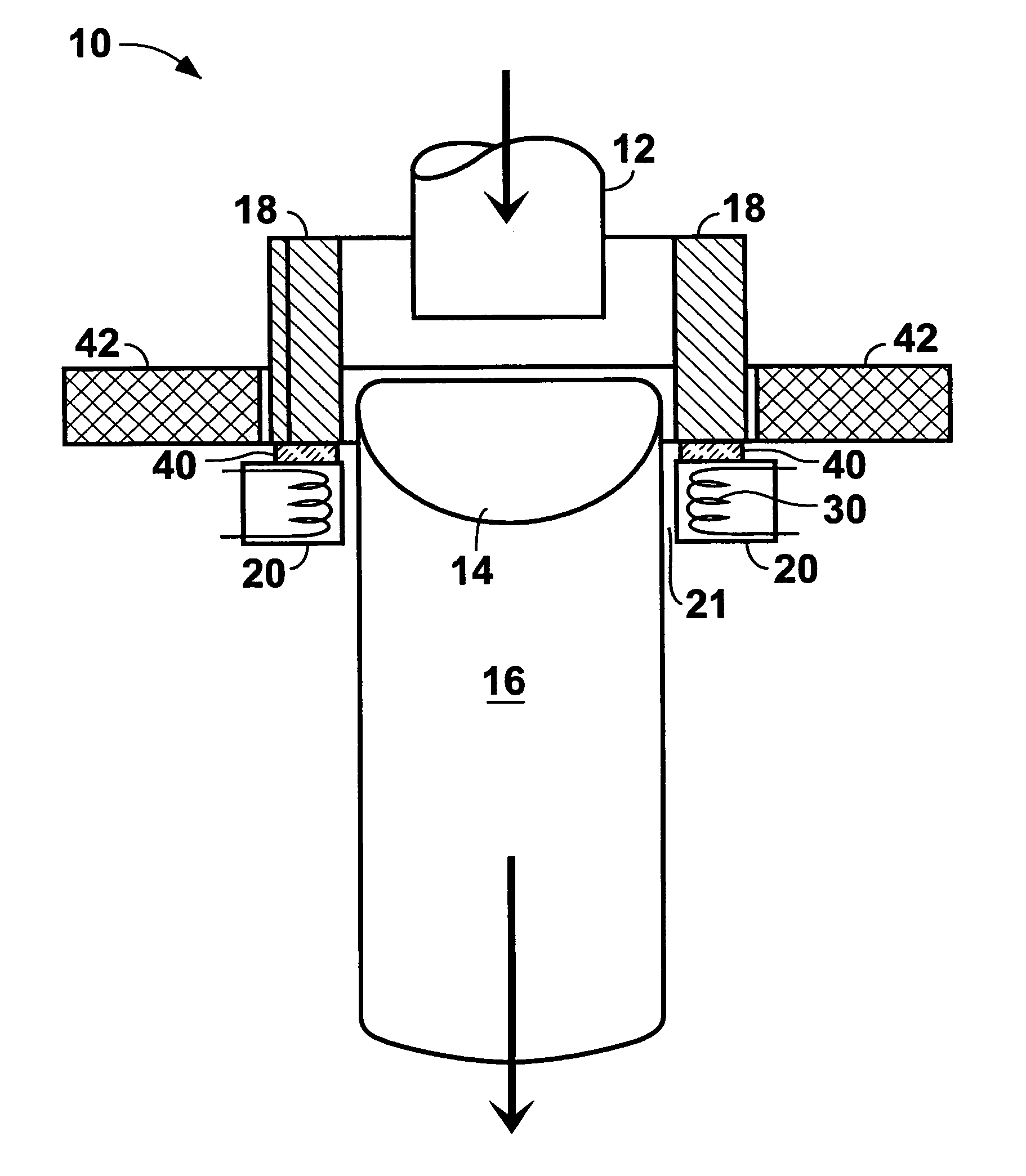

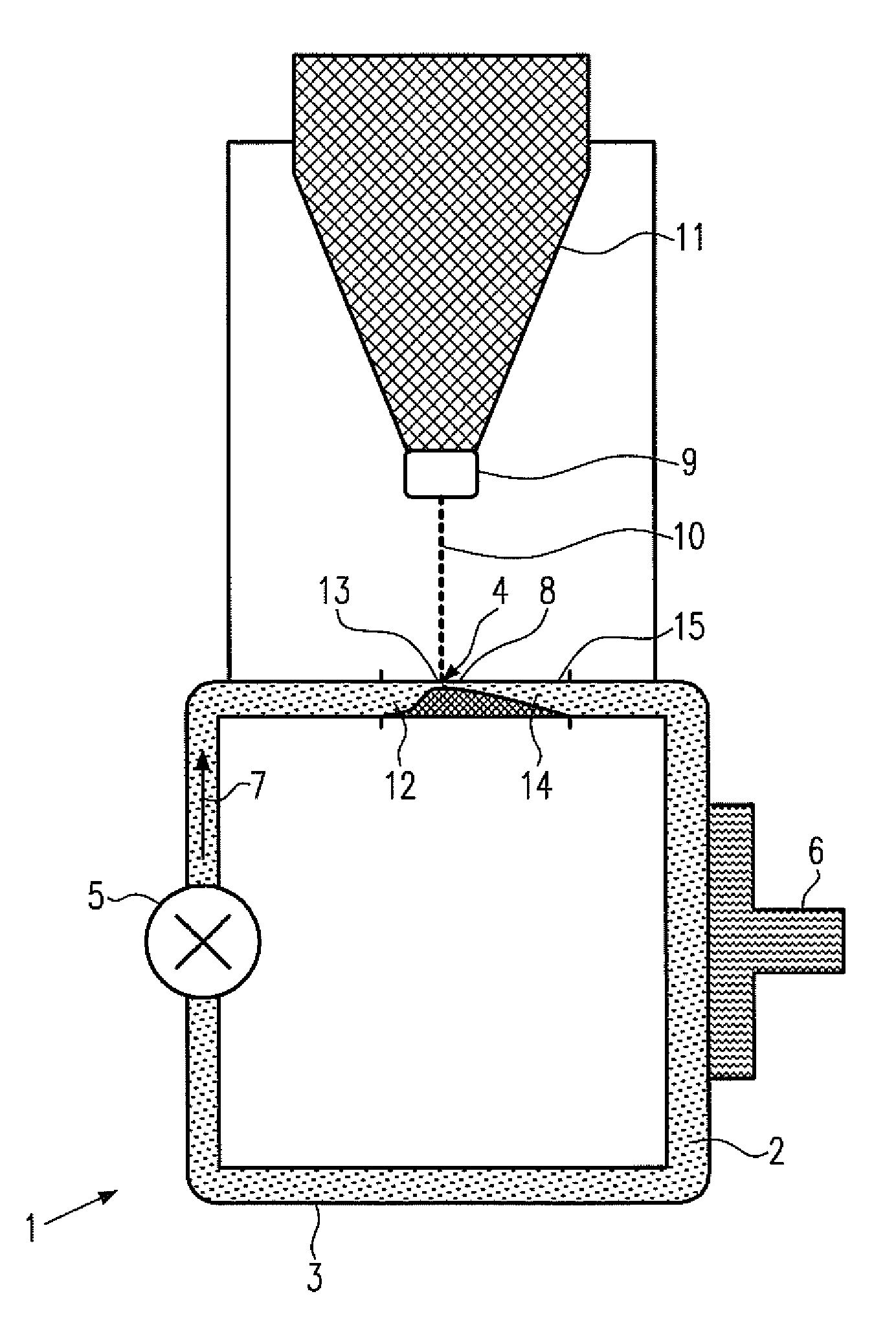

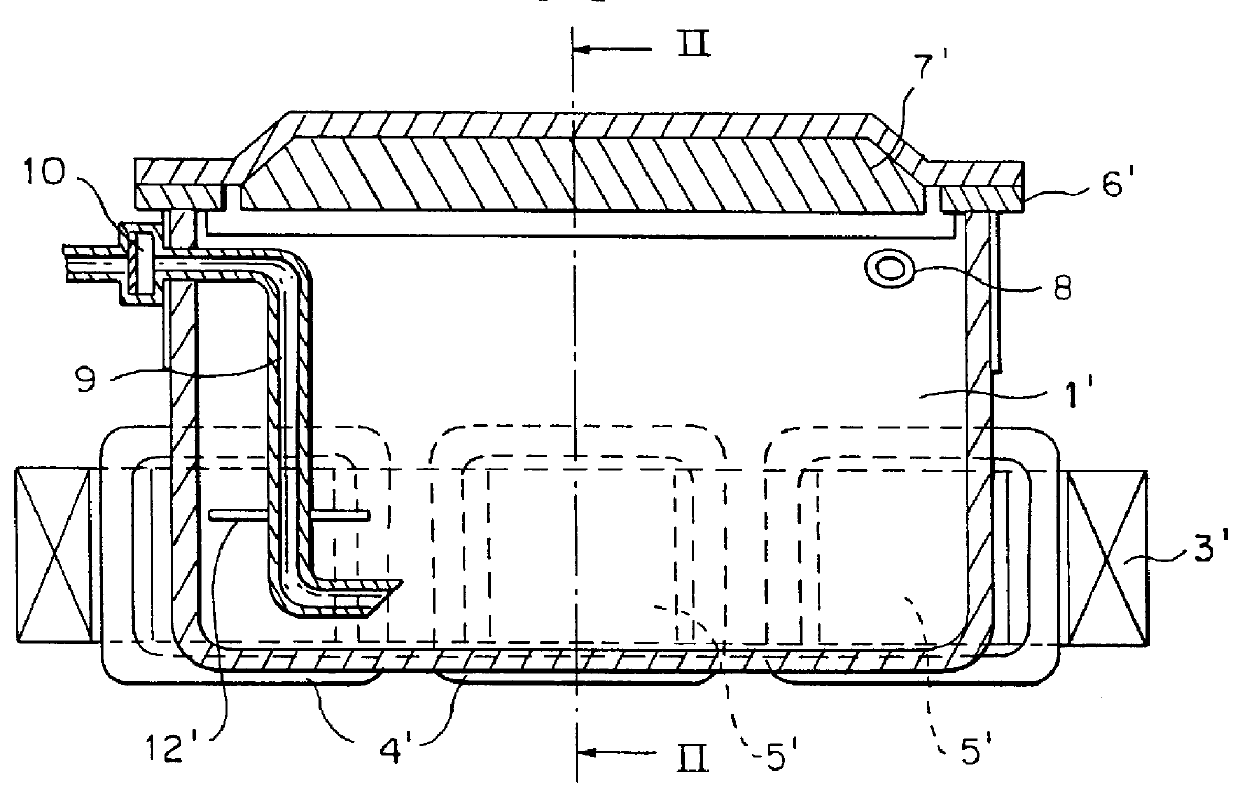

X-ray emitter, liquid-metal anode for an x-ray source and method for operating a magnetohydrodynamic pump for the same

InactiveUS7412032B2Improve matchIncrease rotation speedX-ray tube electrodesDynamo-electric machinesMagneto hydrodynamicX-ray

The invention relates to a method for operating a magnetohydrodynamic pump 5 for a liquid-metal anode 1 of an X-ray source.It is provided according to the invention that it can be operated in at least two modes, wherein the first mode is a thawing mode in which the liquid metal 2 is melted in a line 3 of the liquid-metal anode 1, the second mode is an operating mode in which the liquid metal 2 is pumped through the line 3 and X-ray beams are produced. In addition, the invention relates to a liquid-metal anode 1 for an X-ray source with a liquid metal 2 which is located in a line 3, wherein an anode module 15 is inserted into the line 3 in the region of focus 4, with a pump 5 for circulating the liquid metal 2 in the line 3 and with a cooling system 6 for the liquid metal 2. According to the invention, such a liquid-metal anode 1 has a magnetohydrodynamic pump 5 as described above.

Owner:MORPHO DETECTION INC

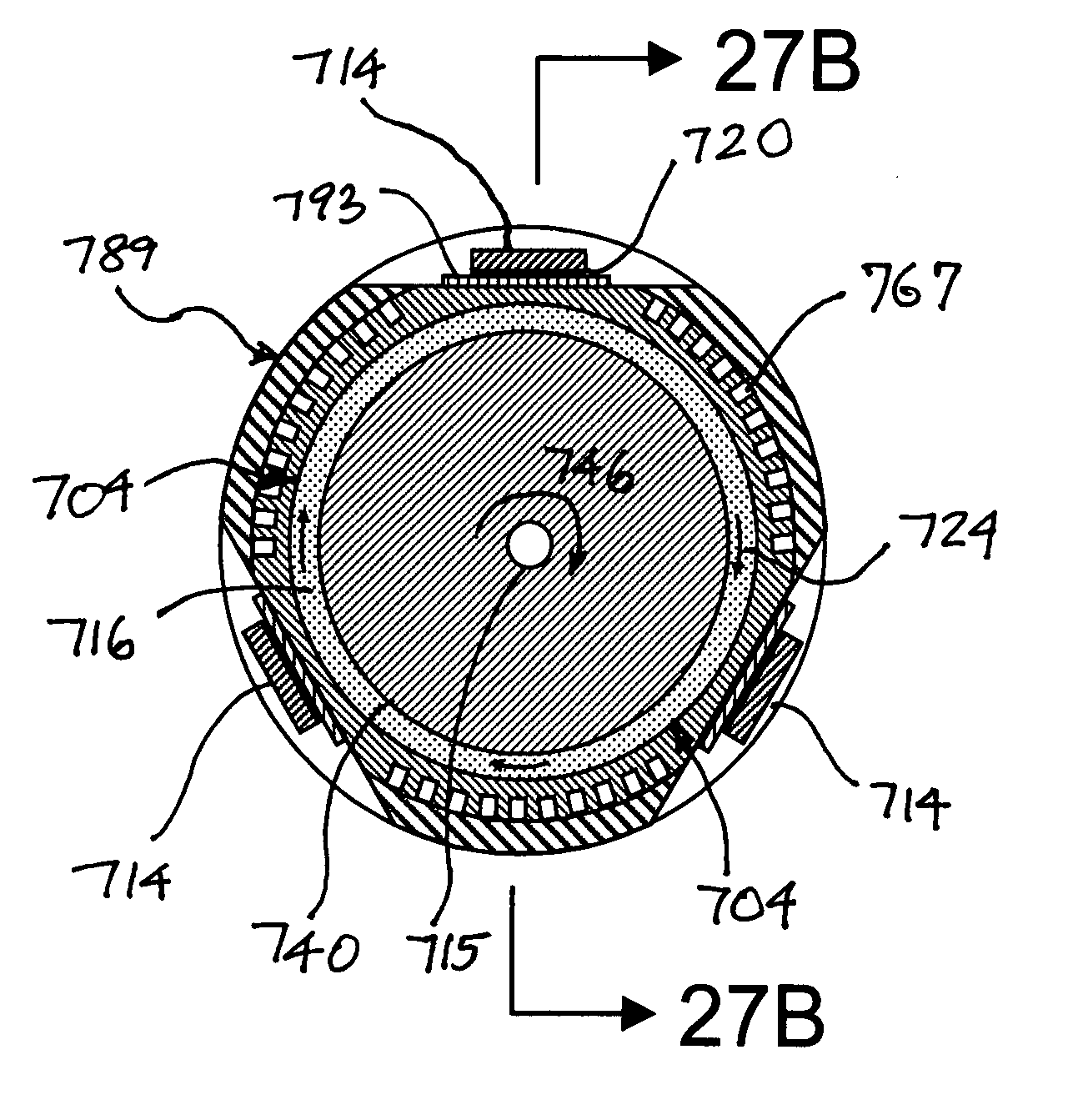

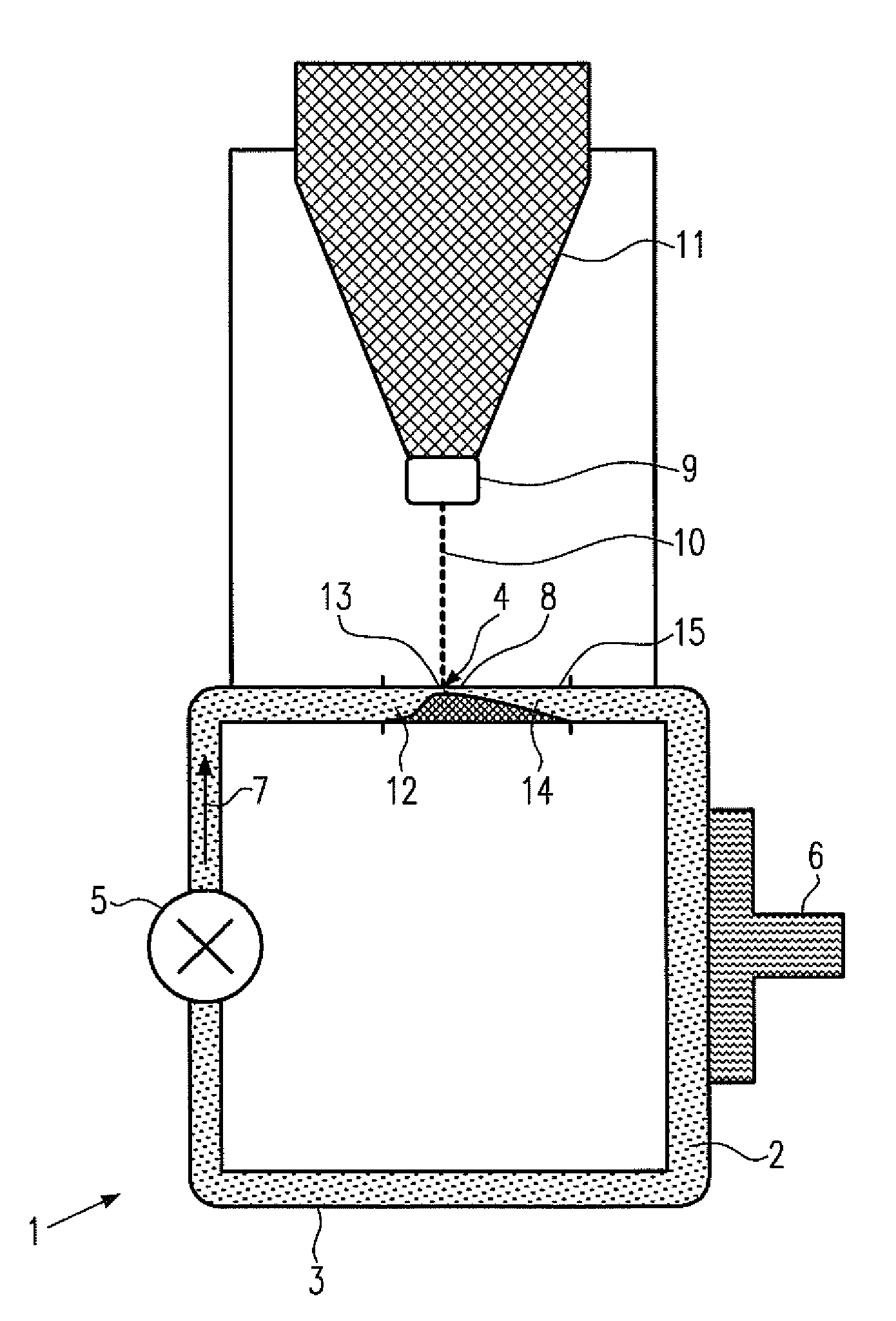

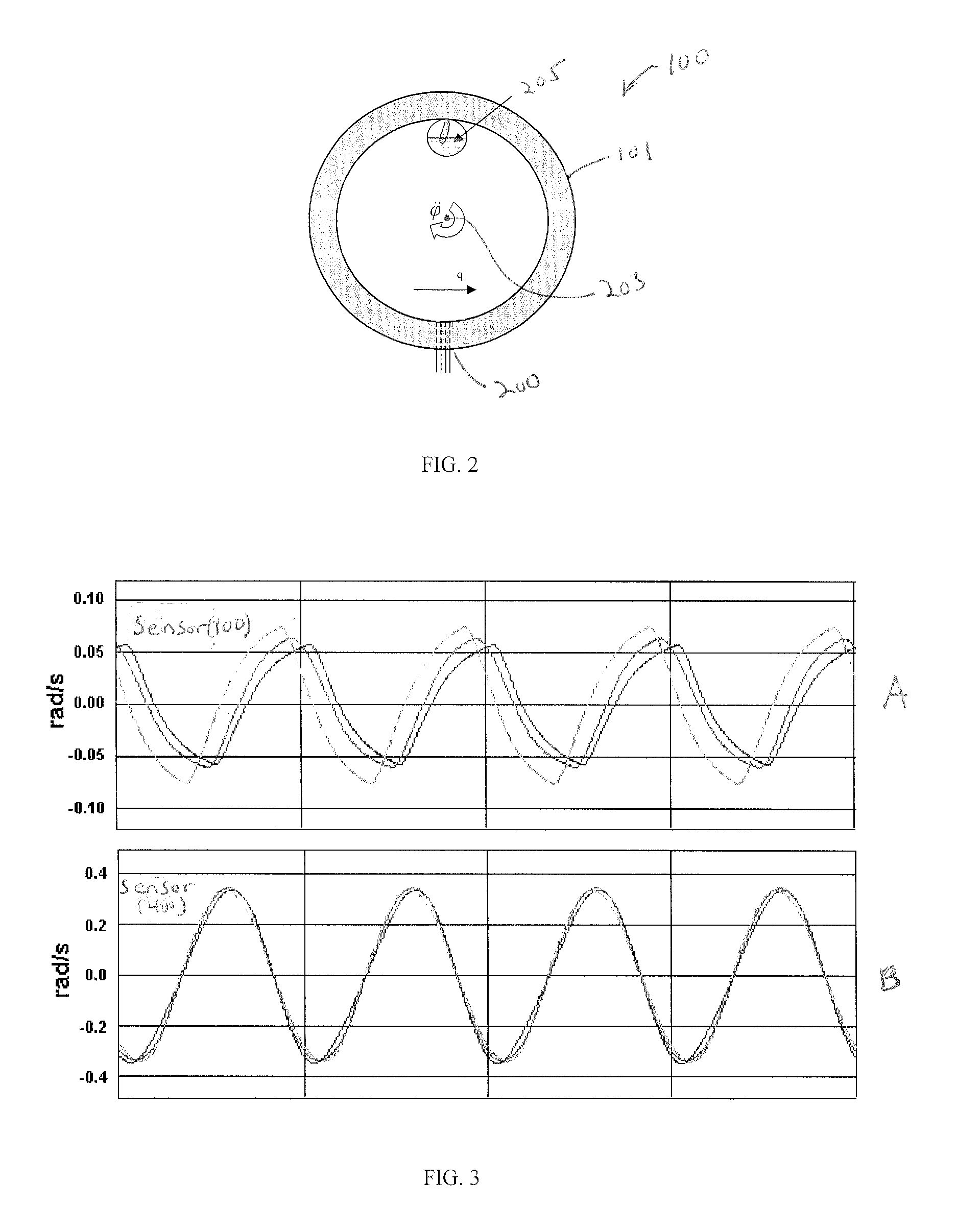

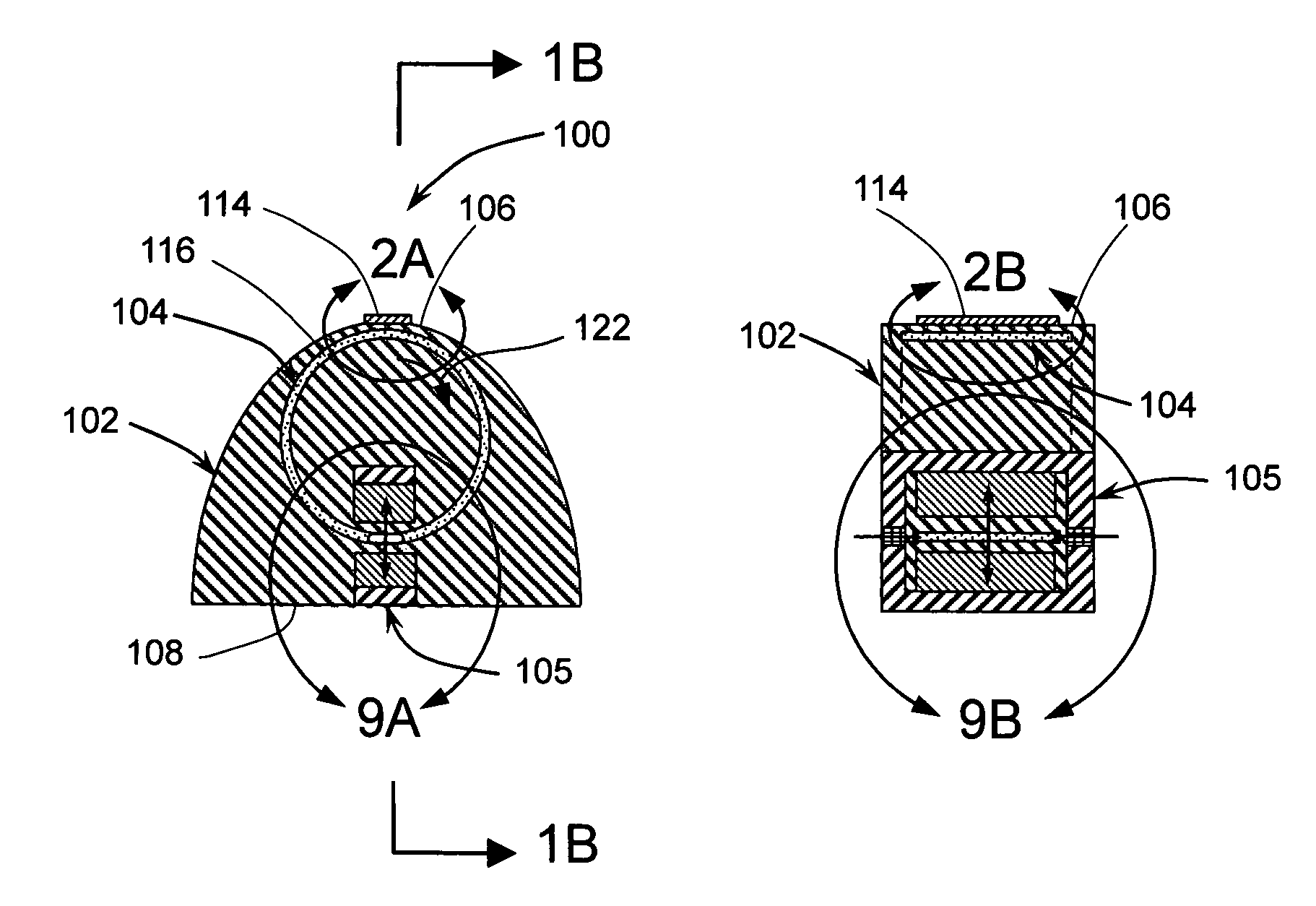

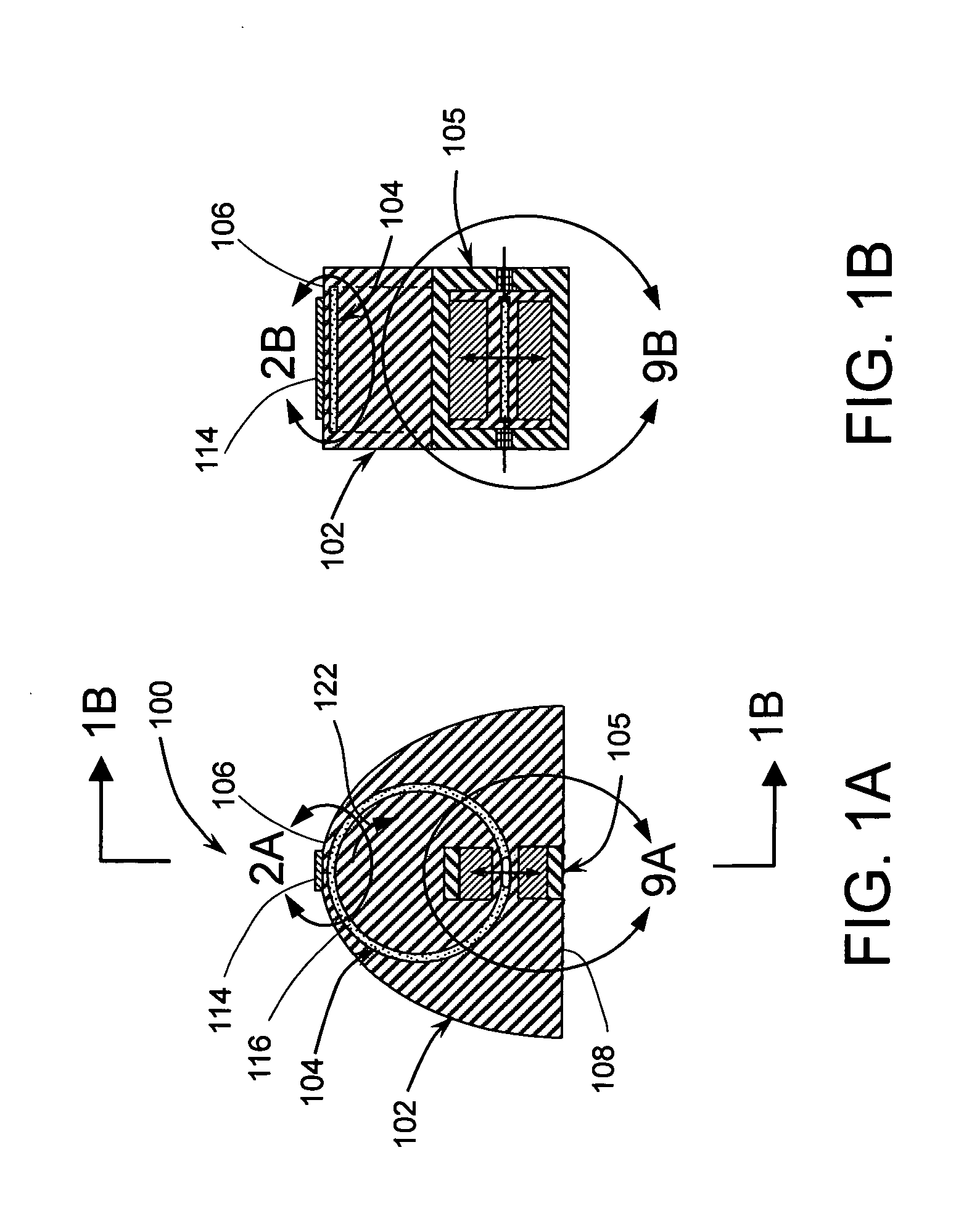

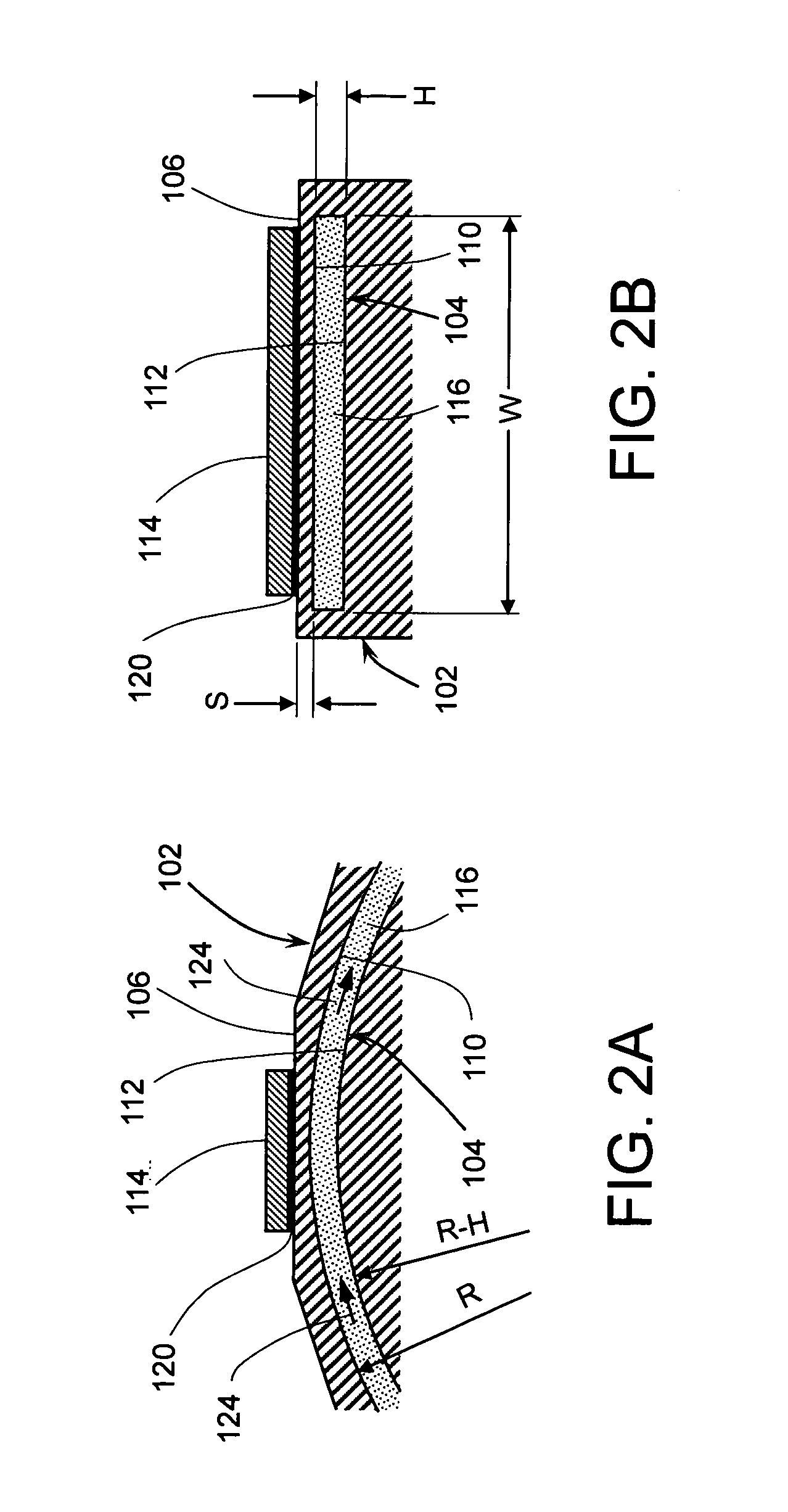

Rotational electrochemical seismometer using magnetohydrodynamic technology and related methods

InactiveUS9300409B1Seismic signal receiversTransmission monitoringMagneto hydrodynamicElectrochemistry

Systems and methods are provided for an electrochemical rotational sensor suitable for use in seismic applications that includes a magnetohydrodynamic (MHD) calibrator. The systems and methods allow for a rotational sensor to utilize a smaller toroid electrolyte channel and to be calibrated in a bandpass range of 100 seconds or 100 Hz.

Owner:LEUGOUD ALEXANDRA

Thermal interface device

InactiveUS20110180238A1High removal rateLittle powerSemiconductor/solid-state device detailsSolid-state devicesMagnetic tension forceLiquid metal

The invention is for an apparatus and method for removal of waste heat from heat-generating components including high-power solid-state analog electronics such as being developed for hybrid-electric vehicles, solid-state digital electronics, light-emitting diodes for solid-state lighting, semiconductor laser diodes, photo-voltaic cells, anodes for x-ray tubes, and solids-state laser crystals. Liquid coolant is flowed in one or more closed channels having a substantially constant radius of curvature. Suitable coolants include electrically conductive liquids (including liquid metals) and ferrofluids. The former may be flowed by magneto-hydrodynamic effect or by electromagnetic induction. The latter may be flowed by magnetic forces. Alternatively, an arbitrary liquid coolant may be used and flowed by an impeller operated by electromagnetic induction or by magnetic forces. The coolant may be flowed at very high velocity to produce very high heat transfer rates and allow for heat removal at very high flux.

Owner:VETROVEC JAN

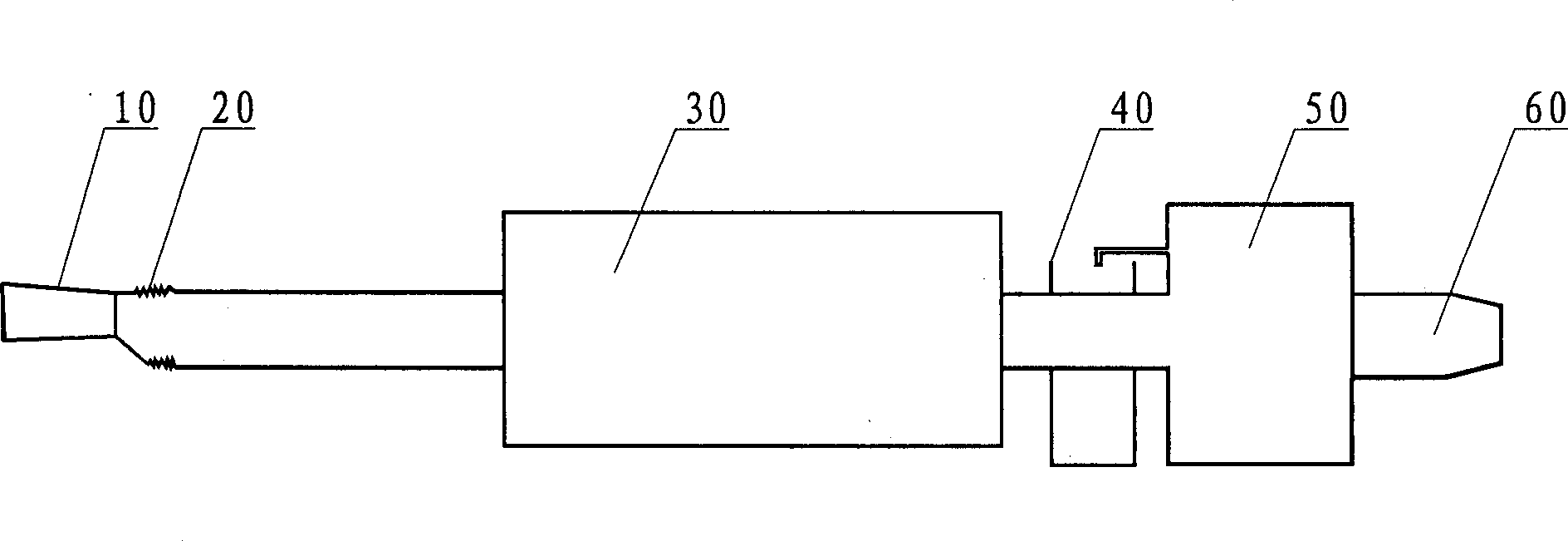

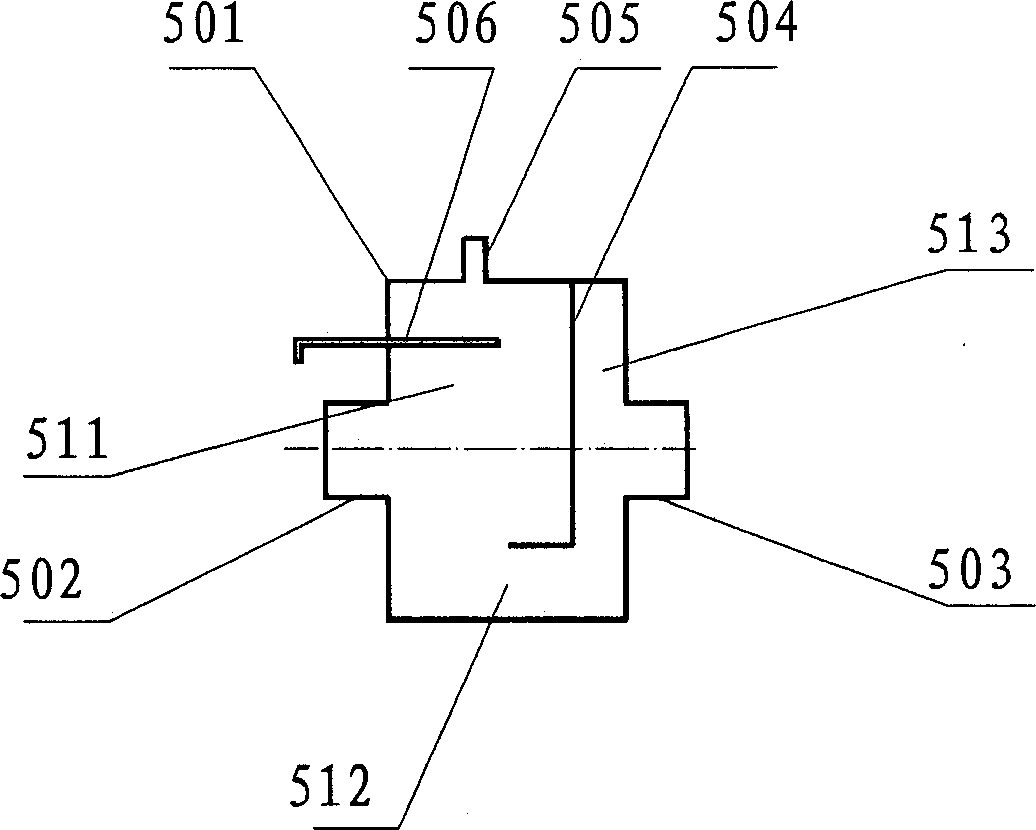

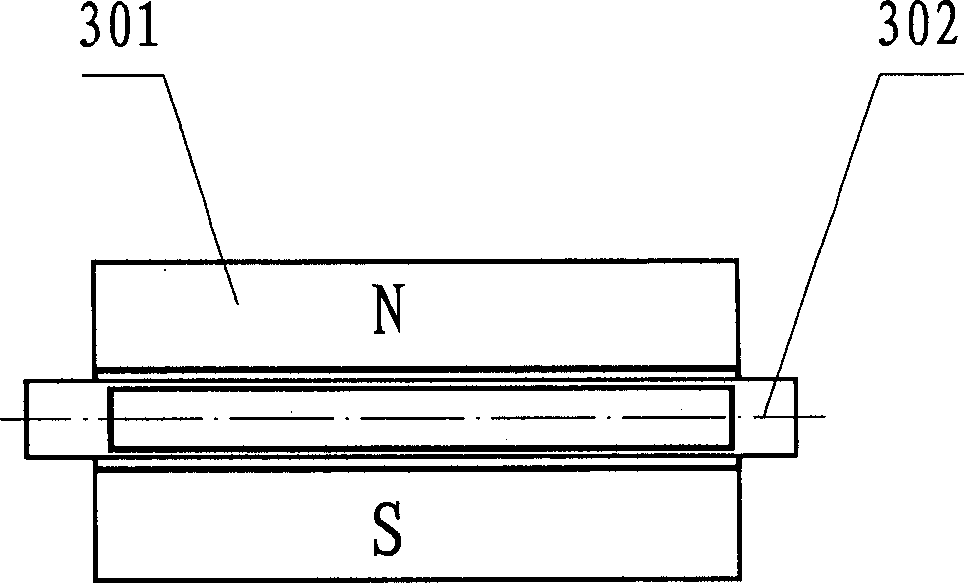

Method and apparatus for recovering float oil on sea by magnetic fluid power

InactiveCN1483898AReduce flow rateFatty/oily/floating substances removal devicesWater cleaningRecovery methodFuel tank

The present invention relates to a method for recovering floating oil on sea and its equipment. Said invention utilizes the magnetic fluid power produced by magnetic fluid propulsion device to suck oil contaminated sea water from front end, and the oil contaminated sea water is pressurized and accelerated in the magnetic fluid channel then fed into the oil-water separation chamber, the floating oil is centralized in the upper portion, and discharged into the oil-recovered tank, and the deoiled water can be ejected from tail portion. Said equipment includes water inlet, guide section, magnetic fluid propulsion device, oil-water separator, oil-recovered tank and tail ejeclor nozzle.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

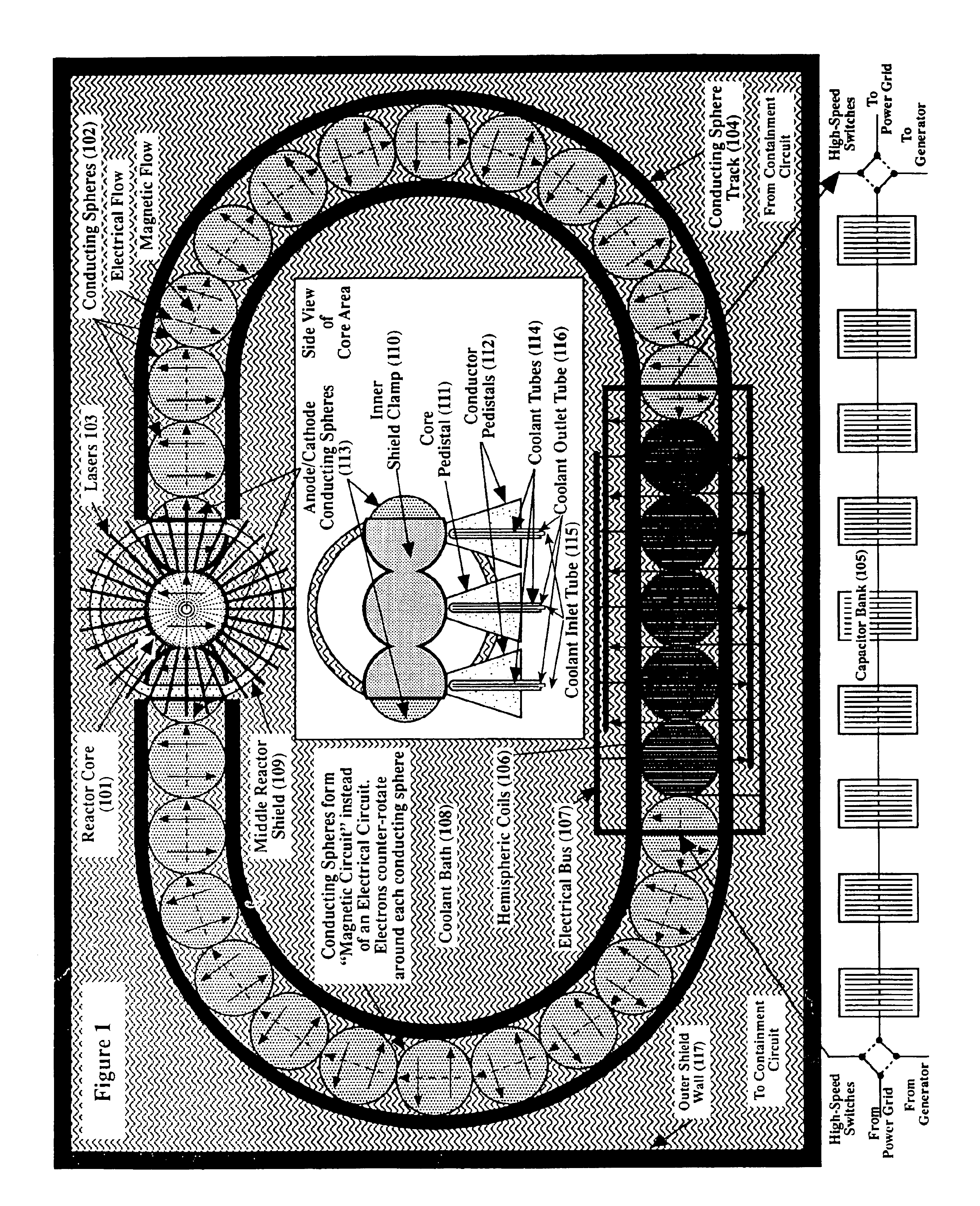

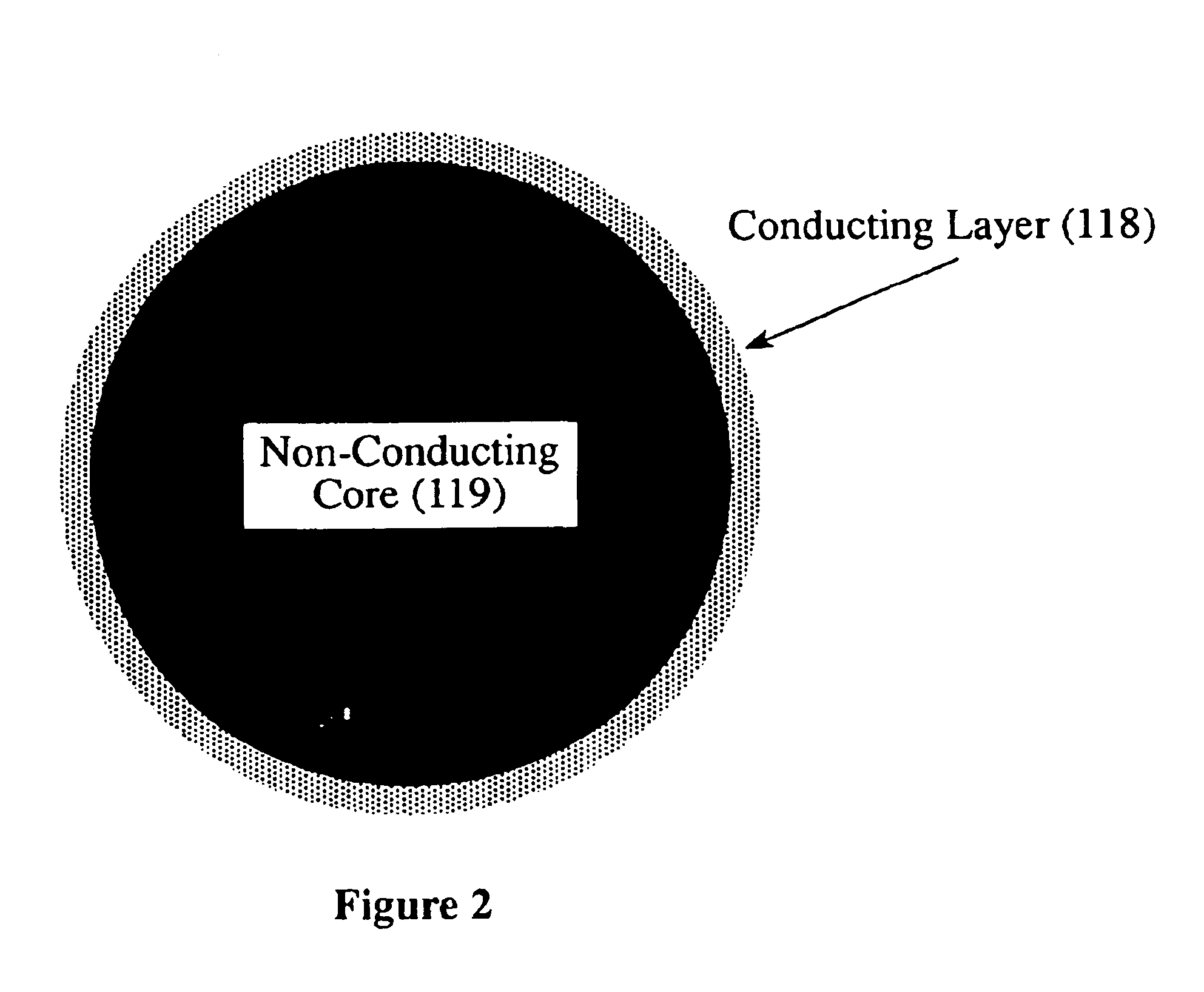

Nuclear fusion reactor incorporating spherical electromagnetic fields to contain and extract energy

InactiveUS6888434B2Clean harmonicLow costNuclear energy generationPermanent magnetsElectricityMagnetic current

A nuclear fusion reactor system includes a reactor core containing nuclear fusionable material and a plurality of conducting spheres arranged adjacent each other with at least two of said conducting spheres adjacent the reactor core. The reactor core and the conducting spheres form a electro / magnetic circuit such that fusion of fusionable material in the reactor core establishes an electro / magnetic flow around the electro / magnetic circuit. Preferably, a spherical electromagnetic confinement field is initiated around the reactor core such that fusion of the nuclear fusionable material generates a plasma which interacts with the spherical electromagnetic confinement field in a magnethydrodynamic manner. Preferably, electrical energy is inductively extracted in response to the electro / magnetic flow through a coil arrangement located around at least one of the conducting spheres.

Owner:NORDBERG JOHN T

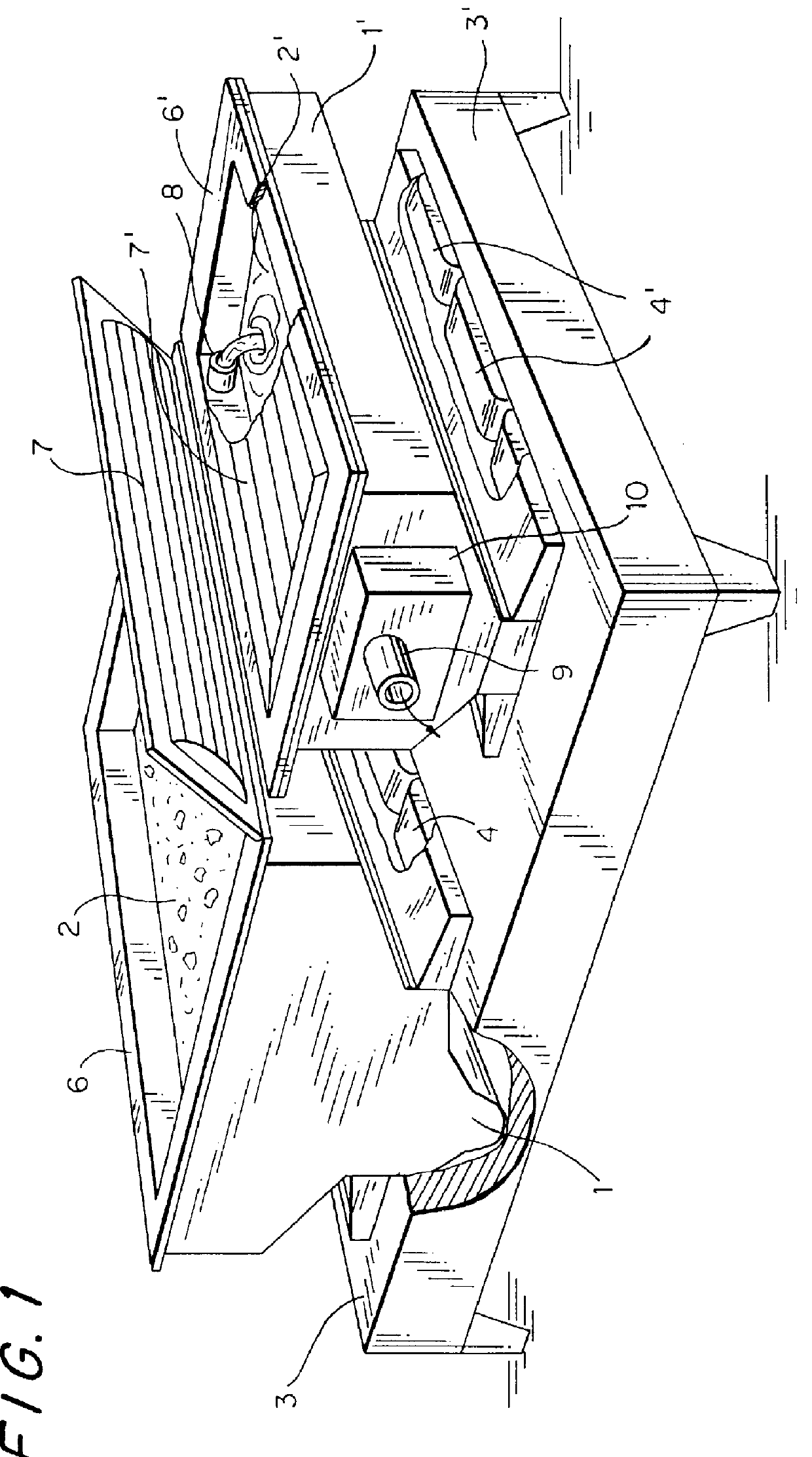

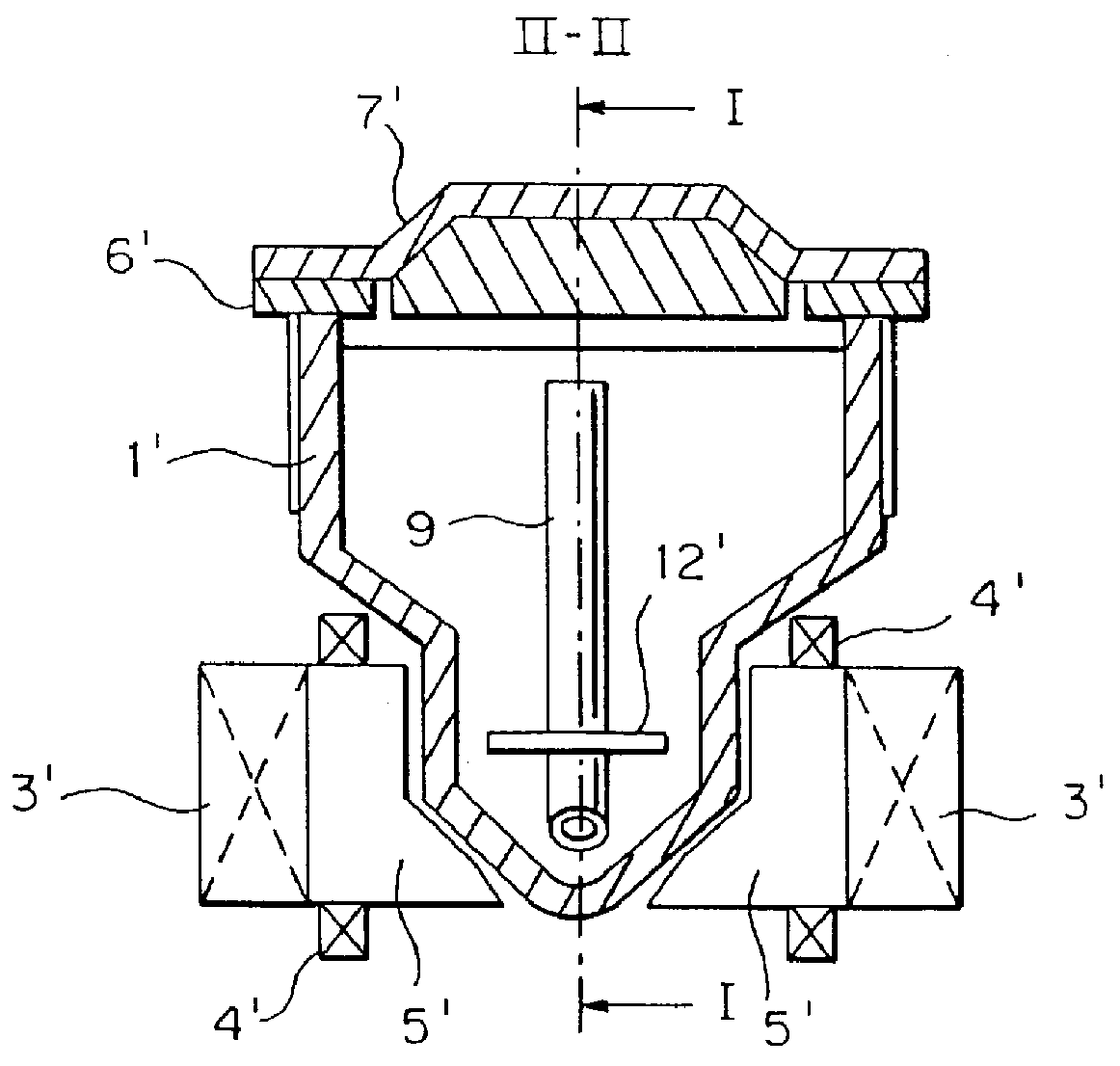

Apparatus for the process of melting and purification of aluminum, copper, brass, lead and bronze alloys

InactiveUS6010552AReduce riskReduced effectivenessTransportation and packagingMixersFiltrationElectromagnetic induction

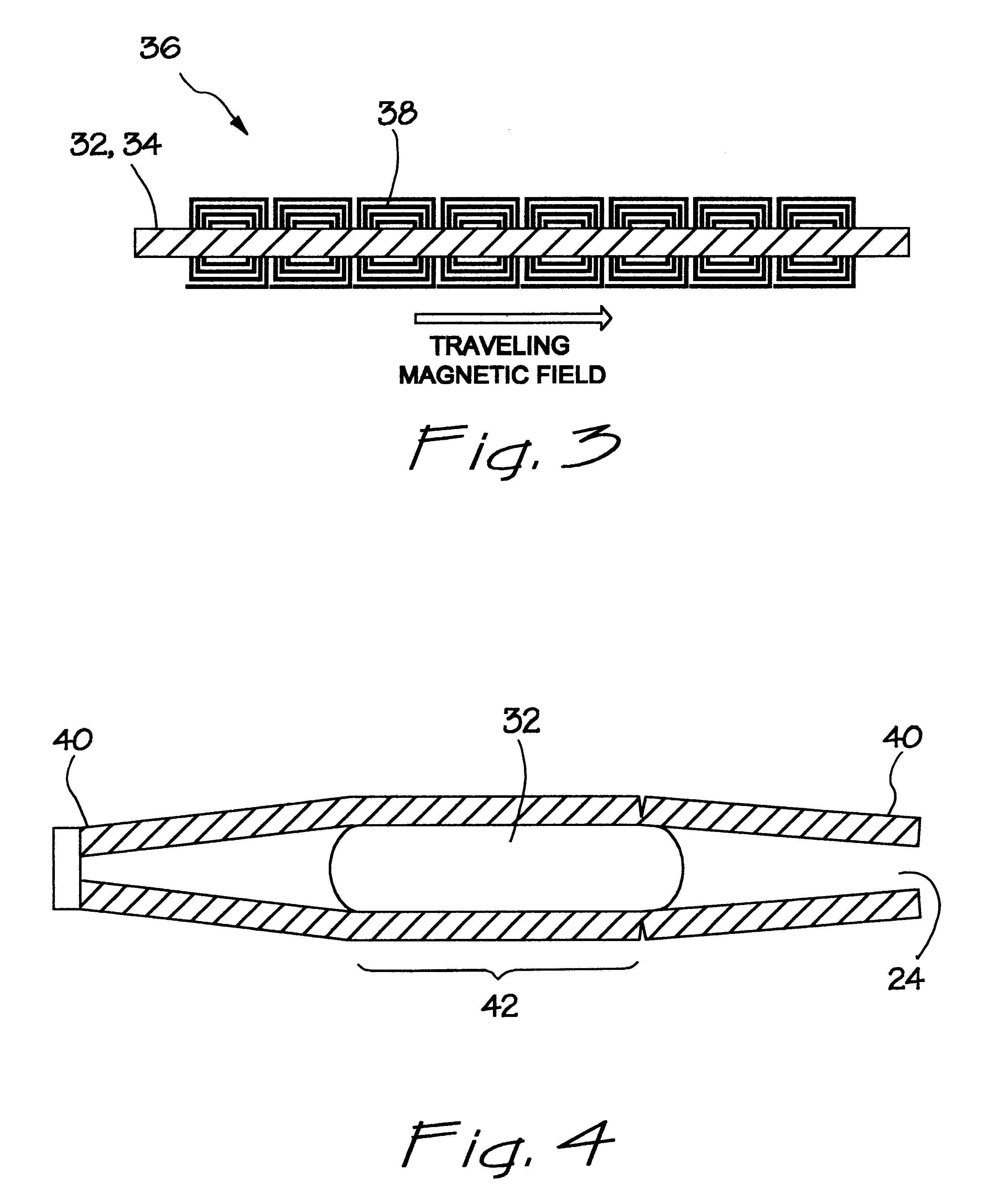

The present apparatus is comprised by two magnetic induction sets, one for melting of the raw material and the second for purification of molten metal; each set comprises a pot or crucible (1, 1'), an electromagnetic device, a filter (11) and a power supply; each crucible (1, 1') is surrounded in the lower part by a hollow permanent magnet (3, 3') in which three pairs of electromagnets facing each other are arranged; the process consists of the following stages: a) charging of metallic raw material inside a crucible (1); b) electromagnetic induction heating to melt the metallic raw material (2) inside crucible (1) through a three-phase magnetic system creating a horizontal travelling or pules magnetic field which builds a turbulent flux inside the melt (2'); c) whirling stirring of melt (2') by electromagnetic induction and purification of it via extraction of hydrogen and of non-electroconductive inclusions by coagulation of them in agglomerates; d) discharging of purified melt (2') by a magneto-hydrodynamic pump effect for the next treatment or technological actions such as the continuous or periodical casting through a filter for the mechanical filtration of the agglomerates.

Owner:S E TRI

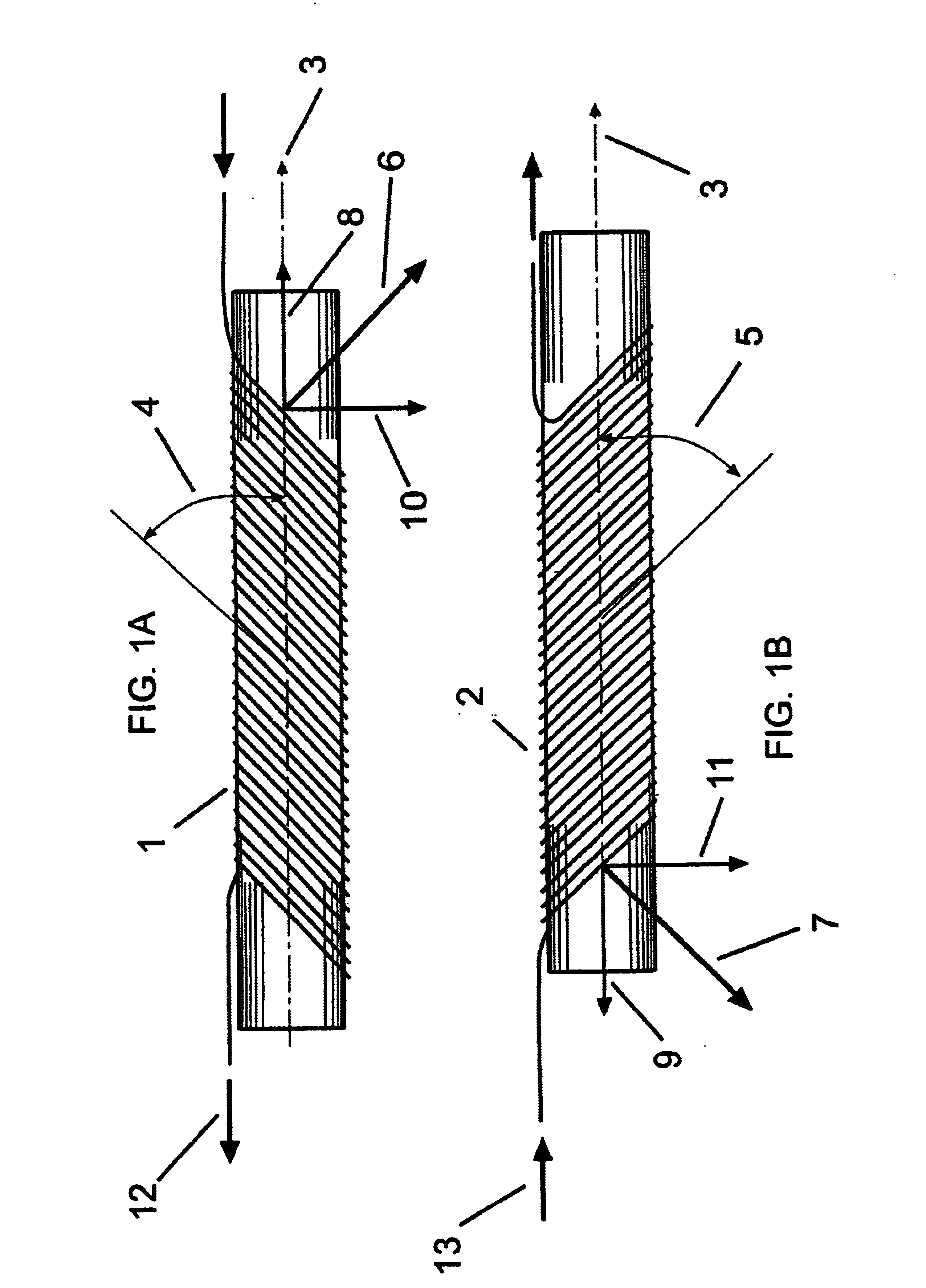

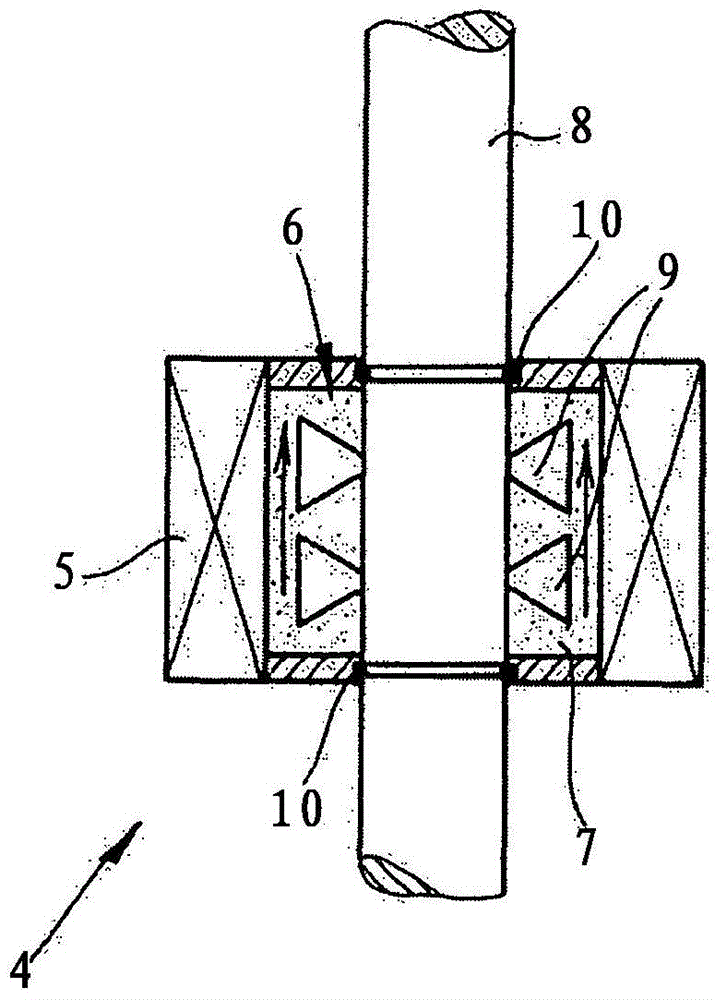

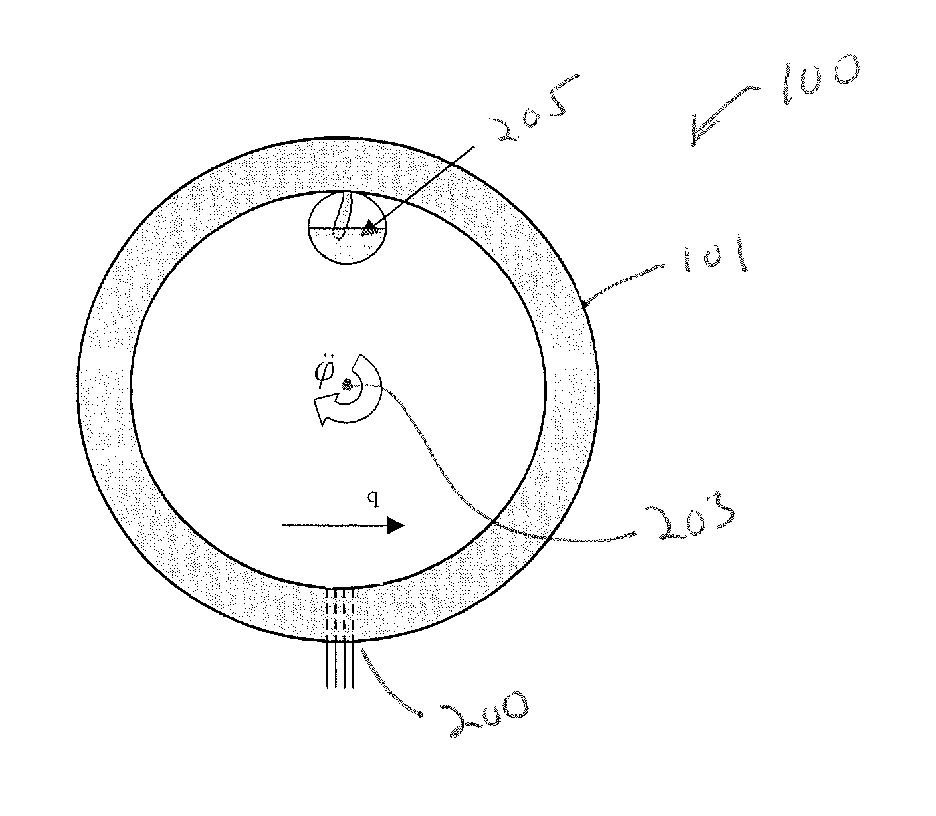

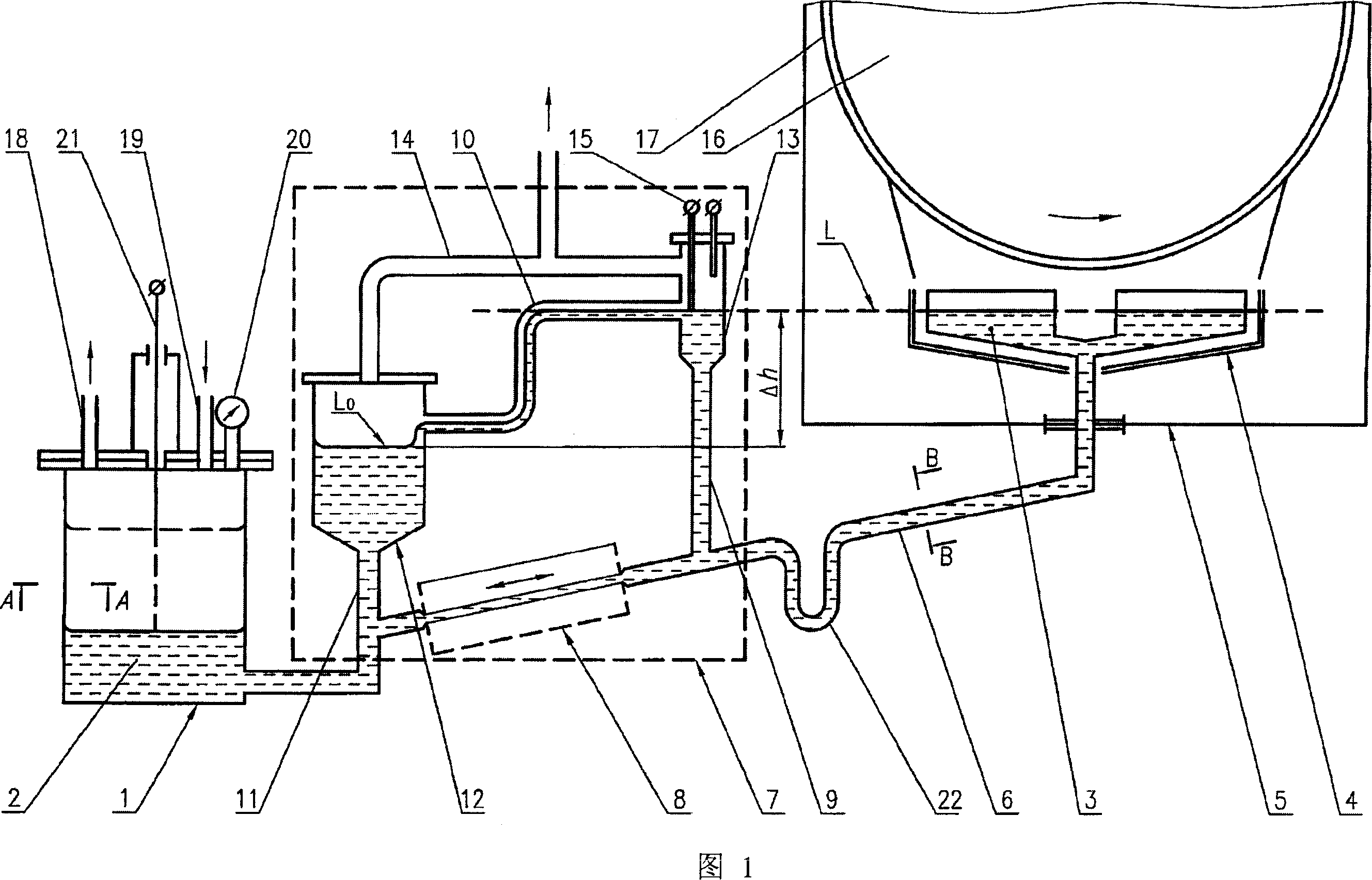

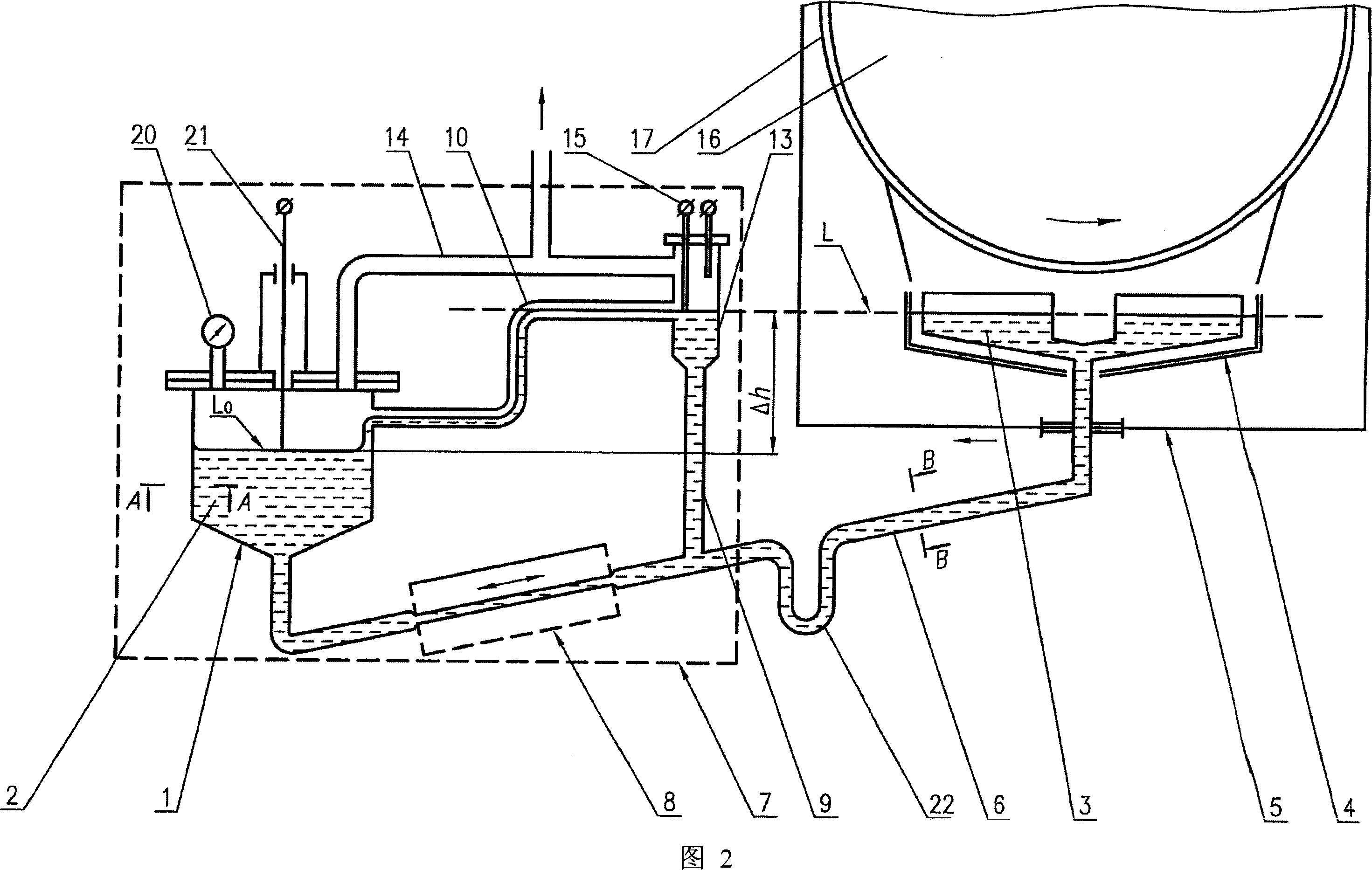

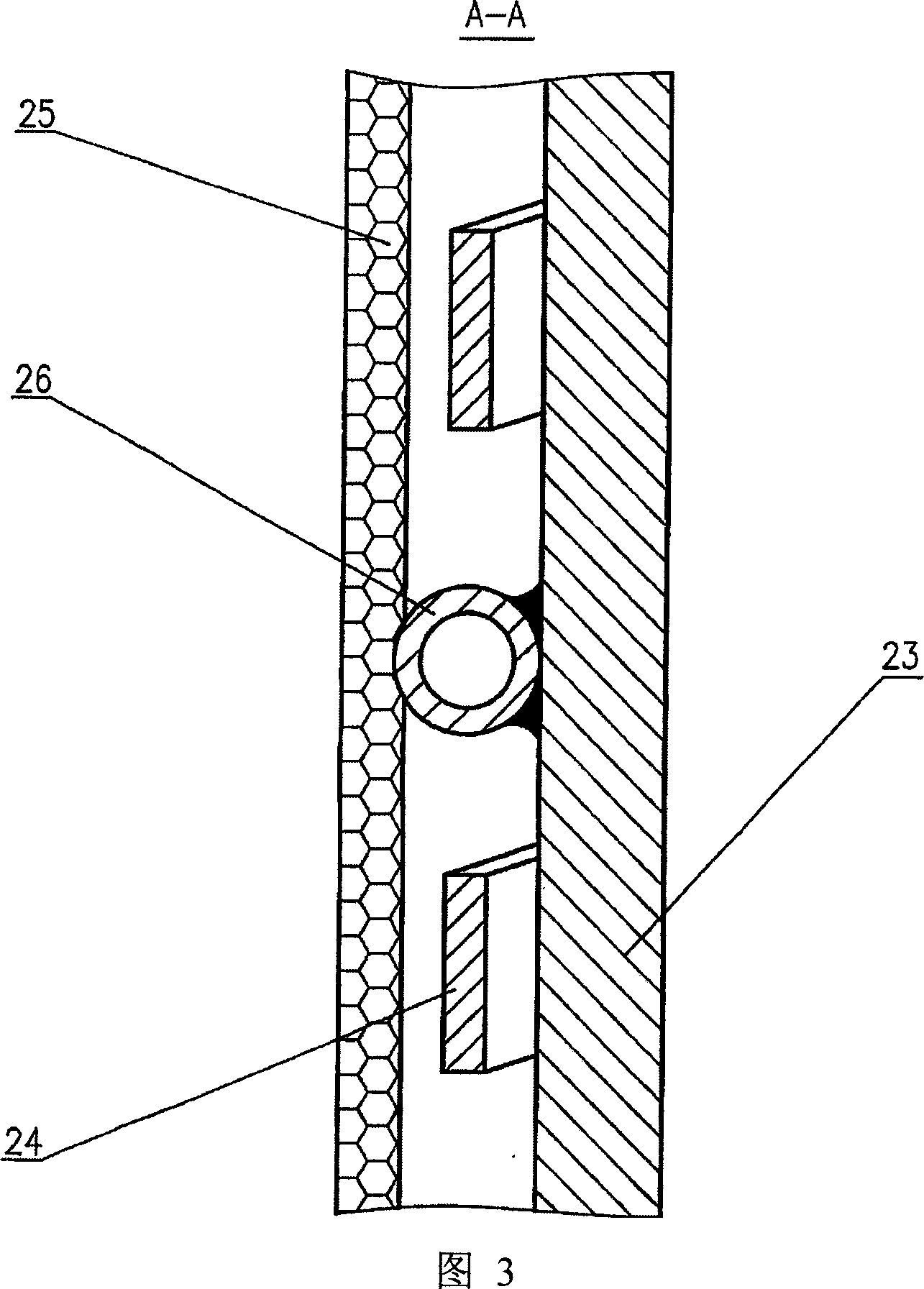

Method and apparatus for vacuum deposition by vaporizing metals and metal alloys

The invention relates to a method and device for vacuum deposition by thermal evaporation of metals and alloys. The offered device (figure 1) contains a melting crucible (1) with molten material (liquid metal) (2), one or several crucibles (3) of evaporation device (4) in a vacuum chamber (5), a heated liquid-metal pipe (6), connecting the said melting crucible to the said evaporation crucibles through a magnetohydrodynamic (MHD) circuit (7) of static melt pressure. The circuit (7) is provided with an MHD pump (8) and incorporates the liquid-metal pipe (6) sectors, which are adjacent to the MHD pump, heated liquid-metal pipes (9, 10) and (11), a heated reservoir (13), connected to the liquid-metal pipe (6) sector before the MHD pipe through the liquid-metal pipe (11) and to an expander (12), installed in the said pipe (9), through the liquid-metal pipe (10). Spaces above the melt in the expander and reservoir are interlinked with a pipe (14), connected to a vacuum pumping system (not shown). Two electrical sensors (15) of the melt level L are installed in the expander. The melt level L in the expander and in the evaporator is delta h high relative the melt level L0 in the MHD circuit reservoir, i.e. the MHD pump should provide pressure delta h. The present technical solution allows increasing the stability of metals and alloys evaporation in long-run processes and thus increasing the productivity. The solution may be used for the deposition of various functional coatings in electronics, metallurgy, mechanical engineering. It is possible to evaporate zinc, magnesium, cadmium, lithium, zinc-magnesium alloy with this method.

Owner:SIDRABE

Method and apparatus for treating articles during formation

A method of making an article includes forming a molten material by melting at least a portion of a mass of a metal and an alloy. The method further includes forming the article by solidifying at least a portion of the molten material within a mold, and contacting the article with plasma during formation of the article. A method for making an article also is disclosed wherein a molten material is formed by melting at least a portion of a mass of one of a metal and an alloy, the molten material is collected within a mold, and at least a portion of the molten material is magnetohydrodynamically stirred within the mold.

Owner:ATI PROPERTIES

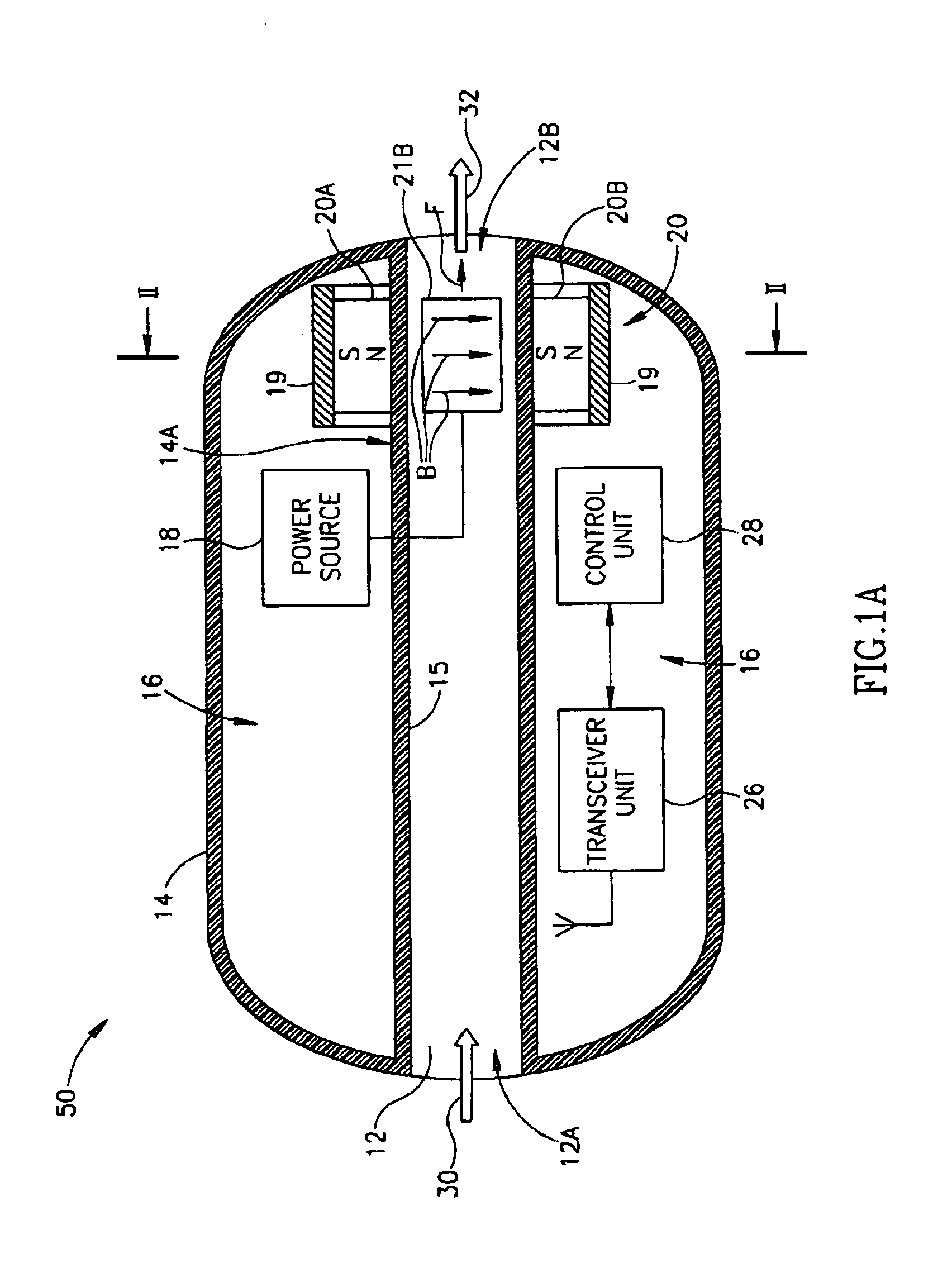

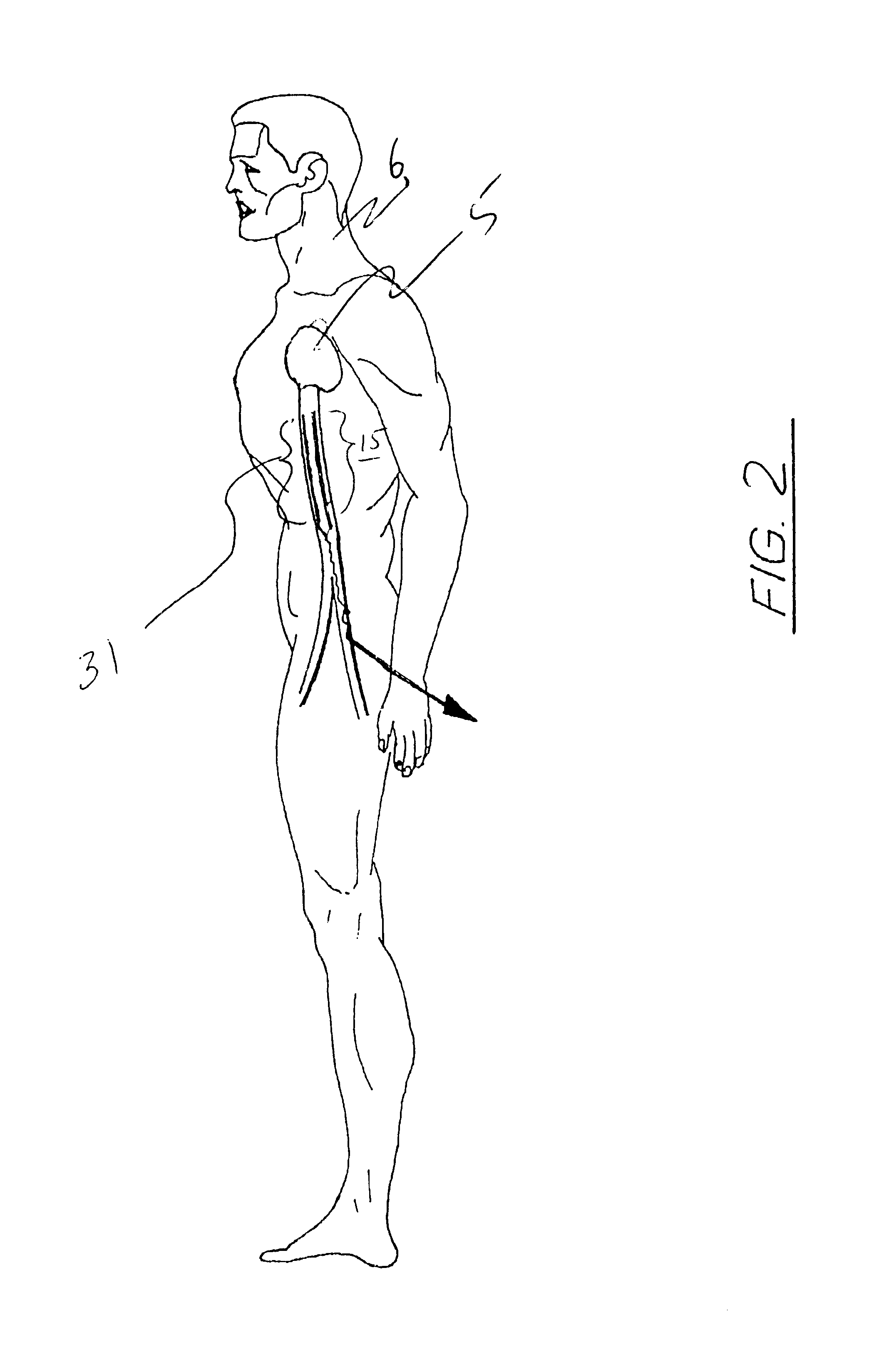

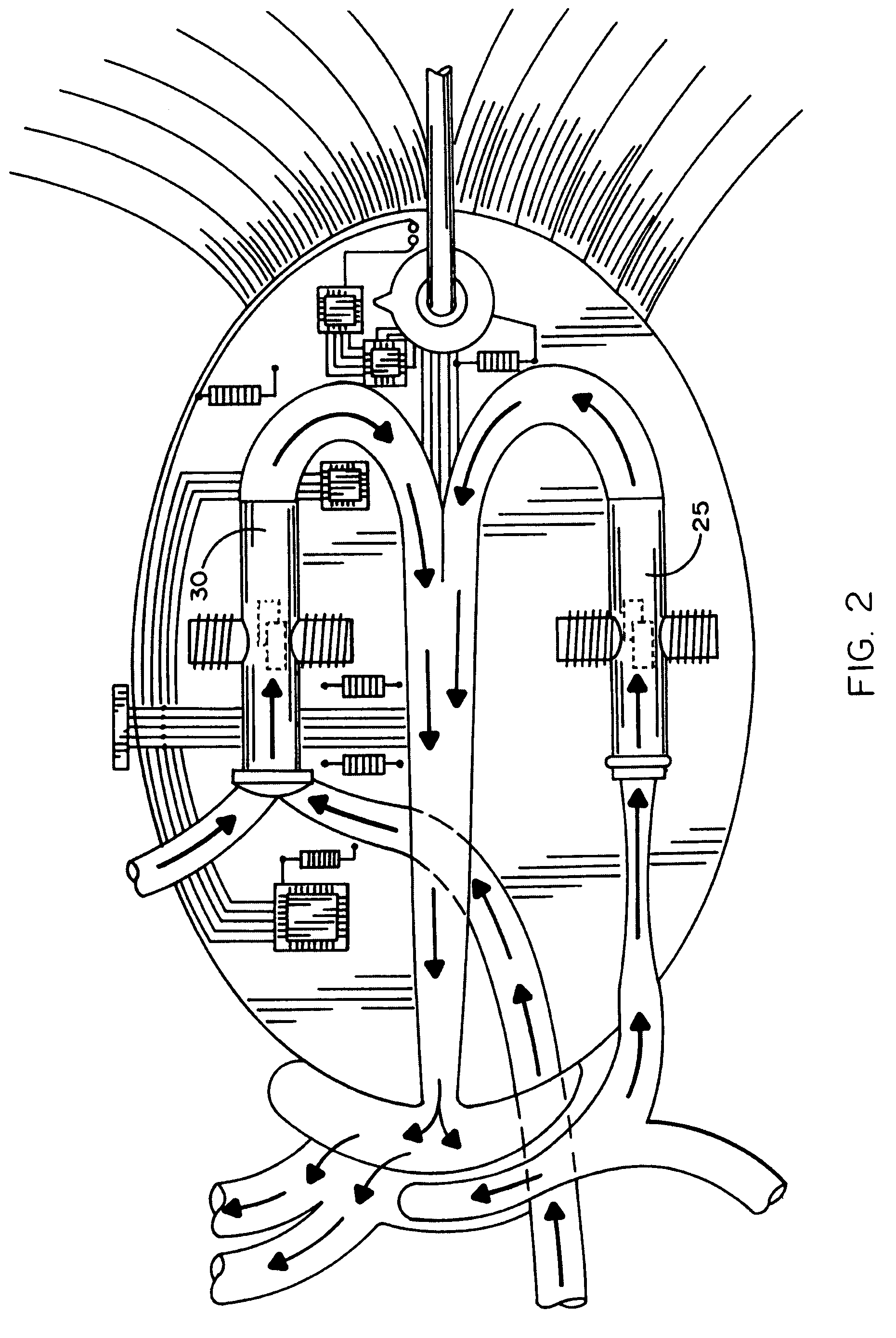

Artificial heart using magnetohydrodynamic propulsionh

InactiveUS7303581B2Highly preventive effectReduce weightControl devicesMedical devicesCardiac cycleOxygen

An implantable artificial heart apparatus which has no moving parts. It employs the technology of magnetohydrodynamics (MHD) to induce flow of human blood. An MHD propulsion unit is a device which applies magnetic and electric fields to blood to propel the conductive fluid through the body's circulatory system. Electricity is passed through the blood via electrodes at the same junction where the blood is exposed to the magnetic field. Charged ions that move from anode to cathode create their own corresponding magnetic fields which are either attracted or repelled by the externally applied magnetic field. The result is propulsion in a uniform direction with the moving ions, in effect, dragging fluid molecules with them. A single MHD propulsion unit performs the combined functions of the atrium and the ventricle of the human heart. Two MHD propulsion units are required to perform the full cardiac cycle of the heart, one to pump unoxygenated blood through the lungs and one to pump oxygenated blood through the body's circulatory system.

Owner:PERALTA EDUARDO J

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com