Method and apparatus for vacuum deposition by vaporizing metals and metal alloys

A technology of vacuum deposition and evaporation of metals, which is applied in vacuum evaporation plating, metal material coating technology, ion implantation plating, etc., and can solve the problems such as the decline of coating quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

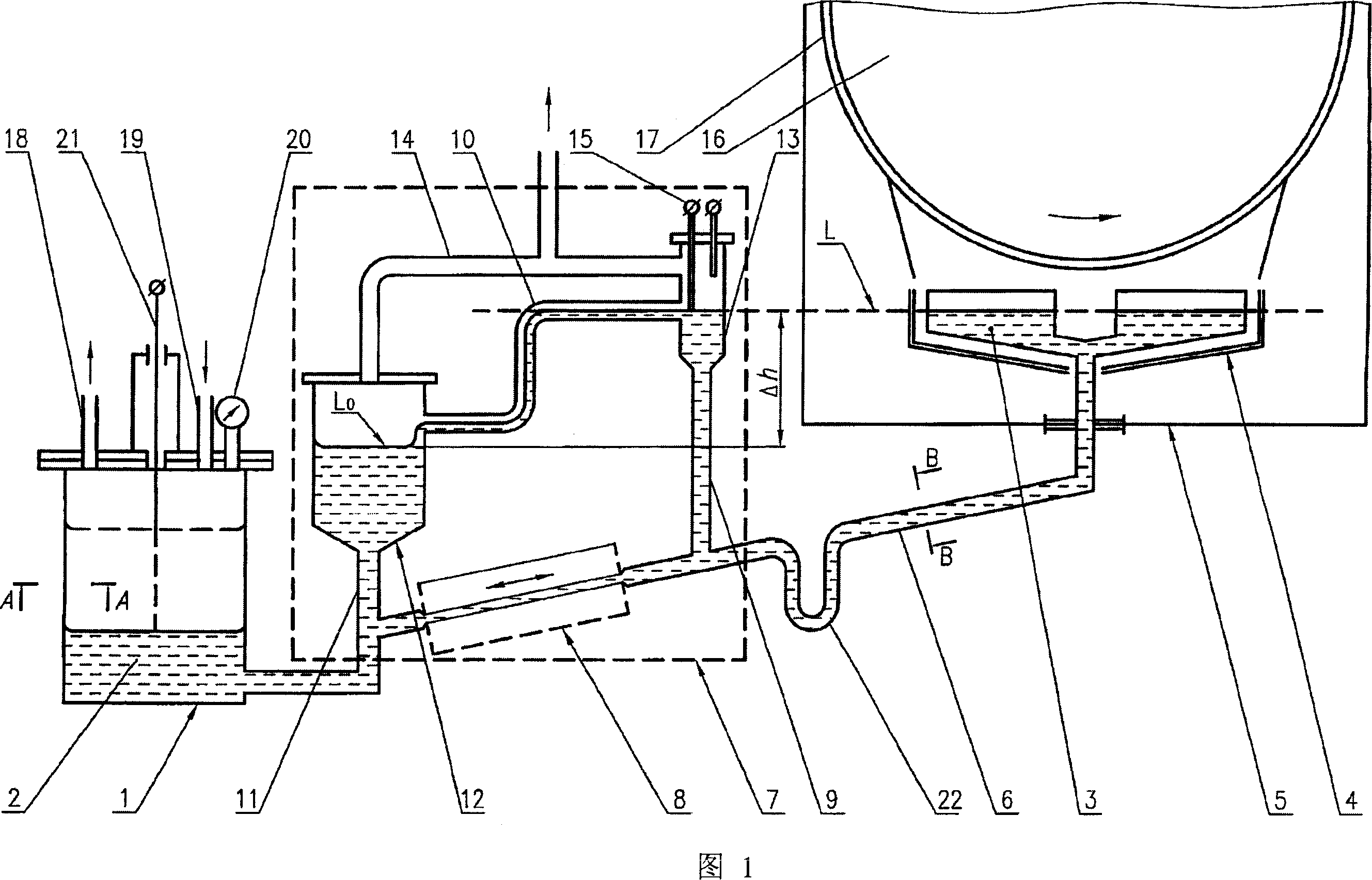

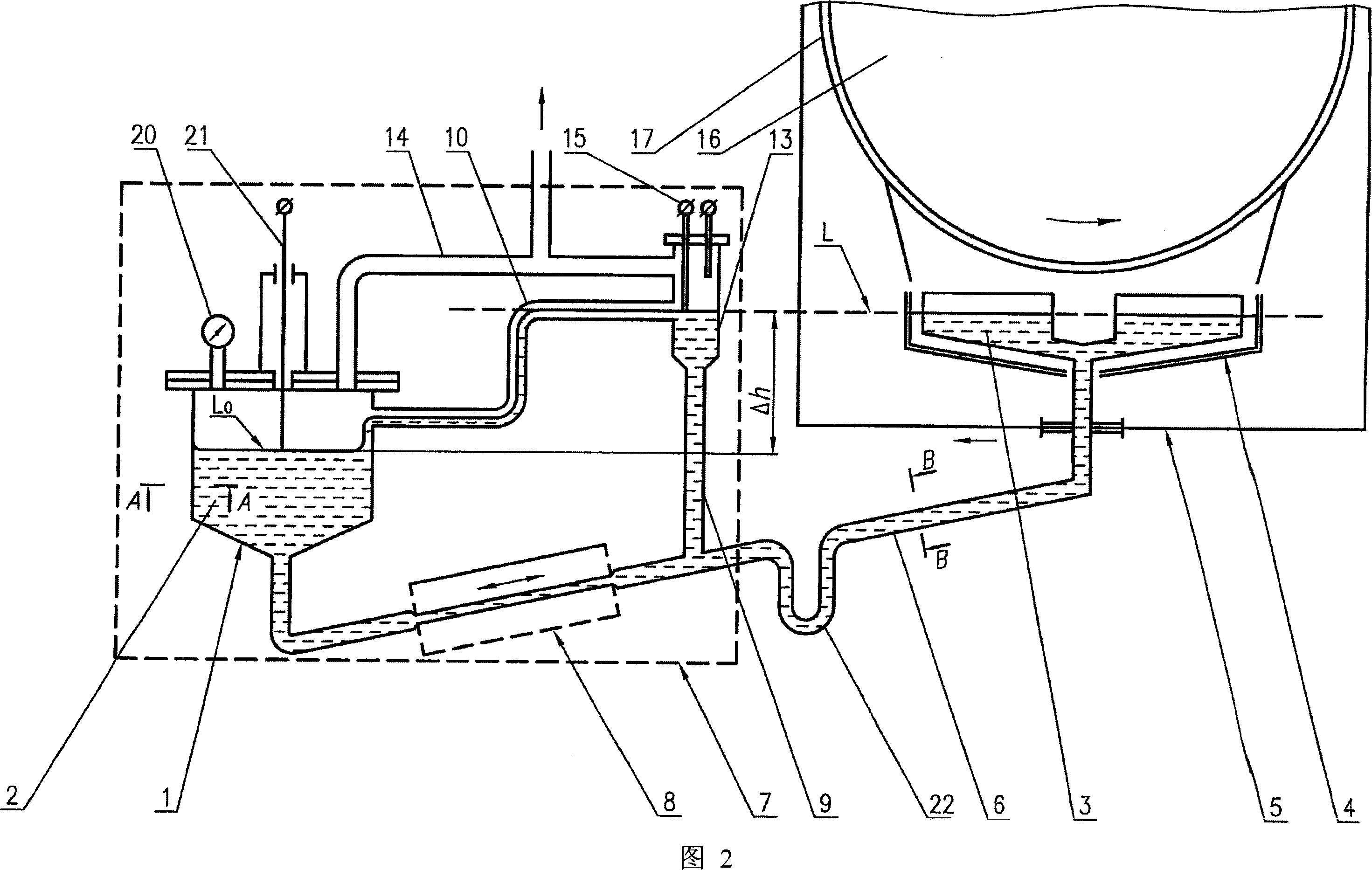

[0025] The apparatus of the invention comprises a melting crucible 1, a vacuum chamber 5, a hot liquid metal conduit 6 and an MHD circuit 7 with static melting pressure. Wherein, there is a molten material (liquid metal) 2 to be evaporated in the melting crucible 1, and the evaporation device 4 in the vacuum chamber 5 has one or more crucibles 3, and the hot liquid metal pipeline 6 passes the molten material (liquid metal) 2 through the MHD circuit 7. A crucible is connected to the evaporation crucible.

[0026] The MHD circuit 7 has the MHD pump 8 and includes a part of the liquid metal conduit 6 adjacent to the MHD pump, the liquid metal conduits 9 , 10 and 11 , the heating reservoir 12 . The heating reservoir 12 is connected to the part before the MHD pump in the liquid metal pipeline 6 through the liquid metal pipeline 11 , and is connected to an expansion tank 13 installed in the pipeline 9 through the liquid metal pipeline 10 . The liquid reservoir 12 and the space abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com