Laser electrical arc complex welding method for intensifying current magnetohydrodynamics effect

A magnetohydrodynamic, laser arc technology, applied in laser welding equipment, arc welding equipment, welding equipment and other directions, can solve the problems of poor gap adaptability, narrow weld seam, etc., to improve surface forming, weld surface forming improvement, The effect of gap adaptation improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

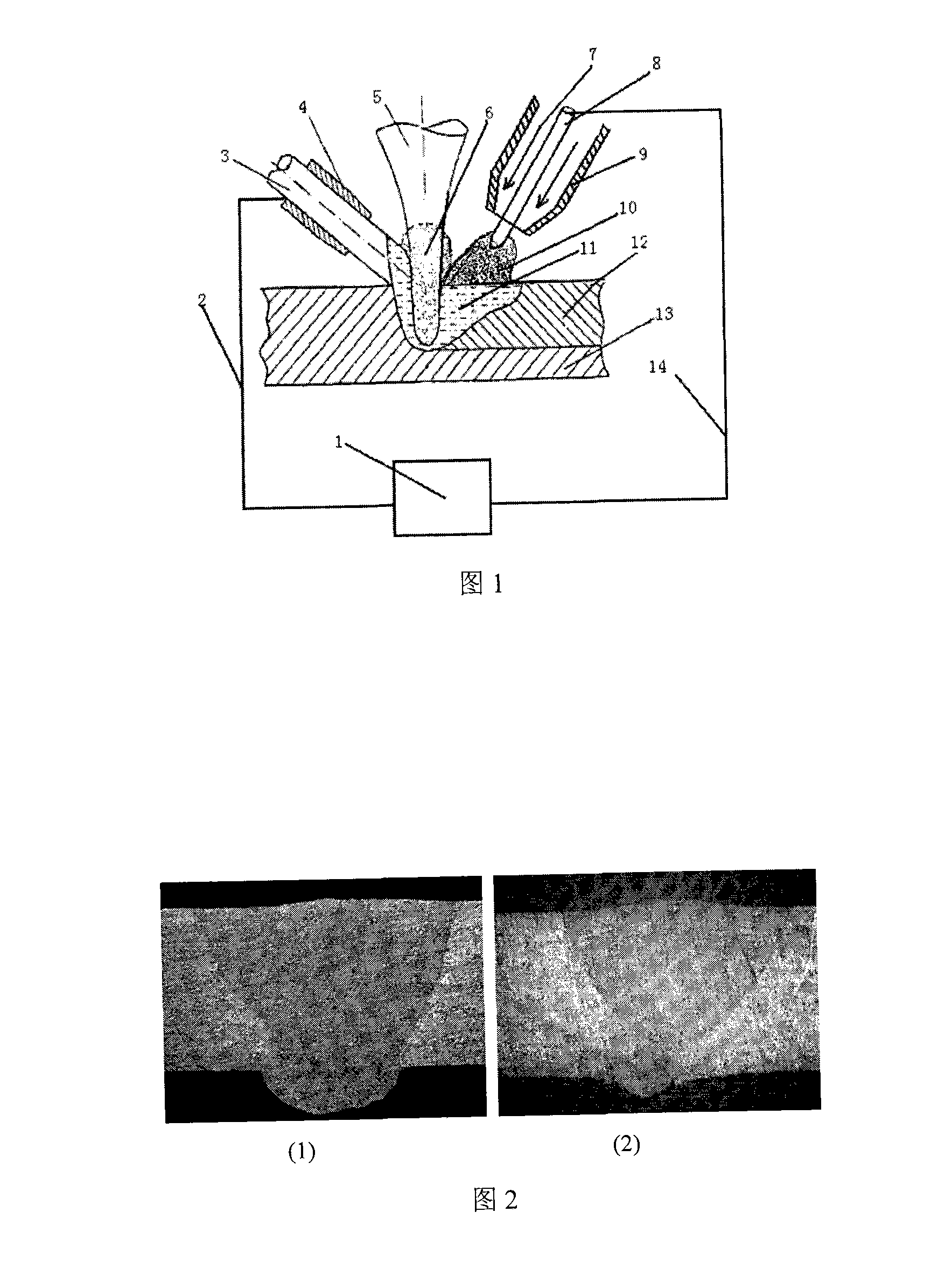

[0016] Referring to accompanying drawing 1 for the technical solution of this embodiment, a laser-arc coordinated arrangement is adopted, and a filler wire 3 is added at the same time. An electric arc 10 is placed behind the laser beam 5, wherein the electric arc 10 can be a TIG arc or a plasma arc.

[0017] The filler wire 3 is fed in from the front of the molten pool 11 , and the welding current flows from the welding wire 3 through the molten pool 11 and the arc 10 to form a current loop. Most of its current flows through the molten pool, generating electromagnetic force in the molten pool.

[0018] During welding, the two poles of the welding power source 1 are respectively connected to the tungsten pole 8 and the welding wire 3, and most of the welding current flows through the welding pool 11 through the welding wire 3, which strengthens the magnetohydrodynamic effect of the arc current. Since the electromagnetic force is proportional to the square of the current densit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com