Winding device and winding machine

A winding device and winding machine technology, which is applied in winding capacitor machines, coil manufacturing, winding resistance elements, etc., can solve the problems of not meeting production needs, low efficiency, waste of human resources, etc., and achieve improvement Efficiency, uniform number of winding turns, and good market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

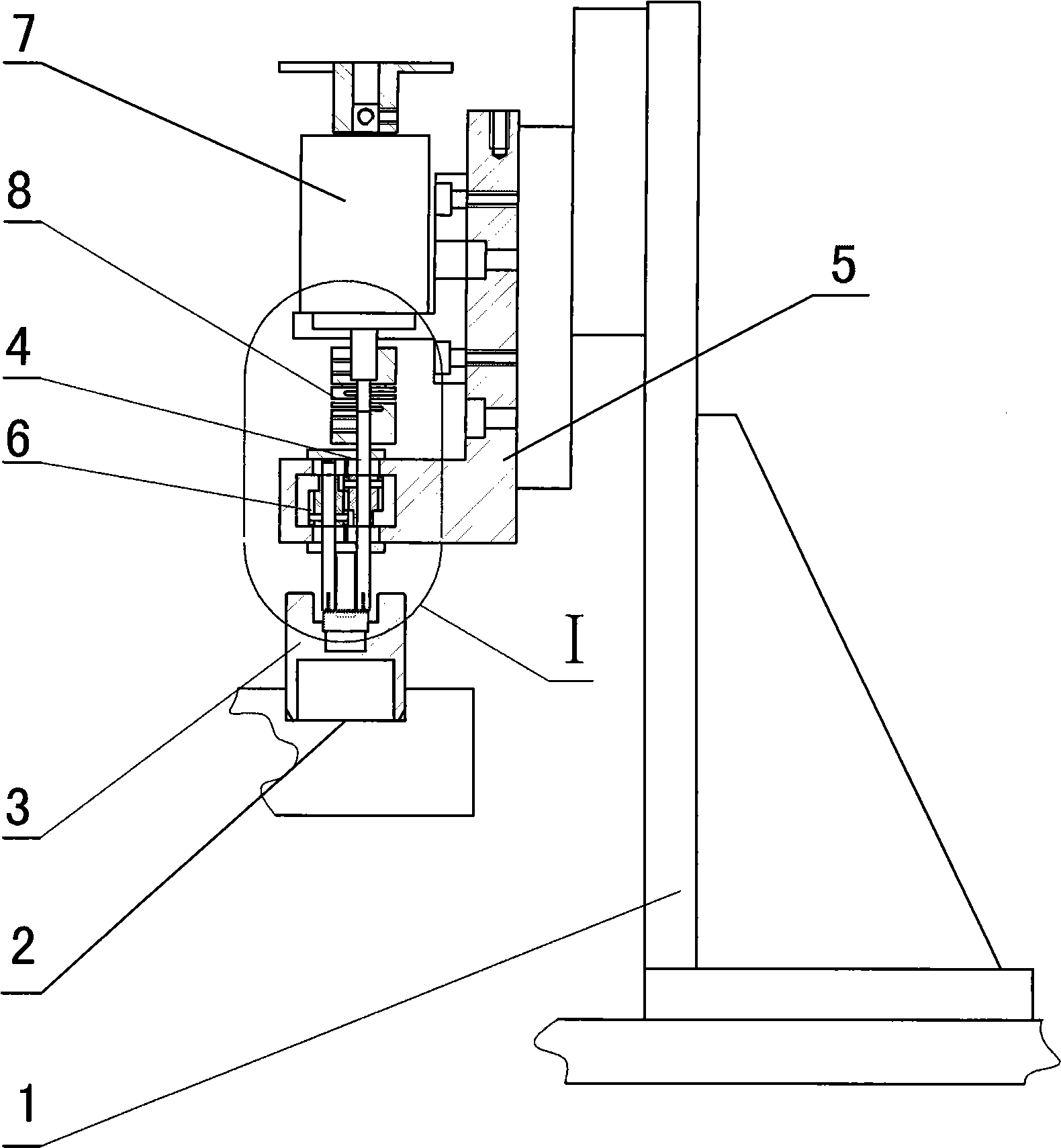

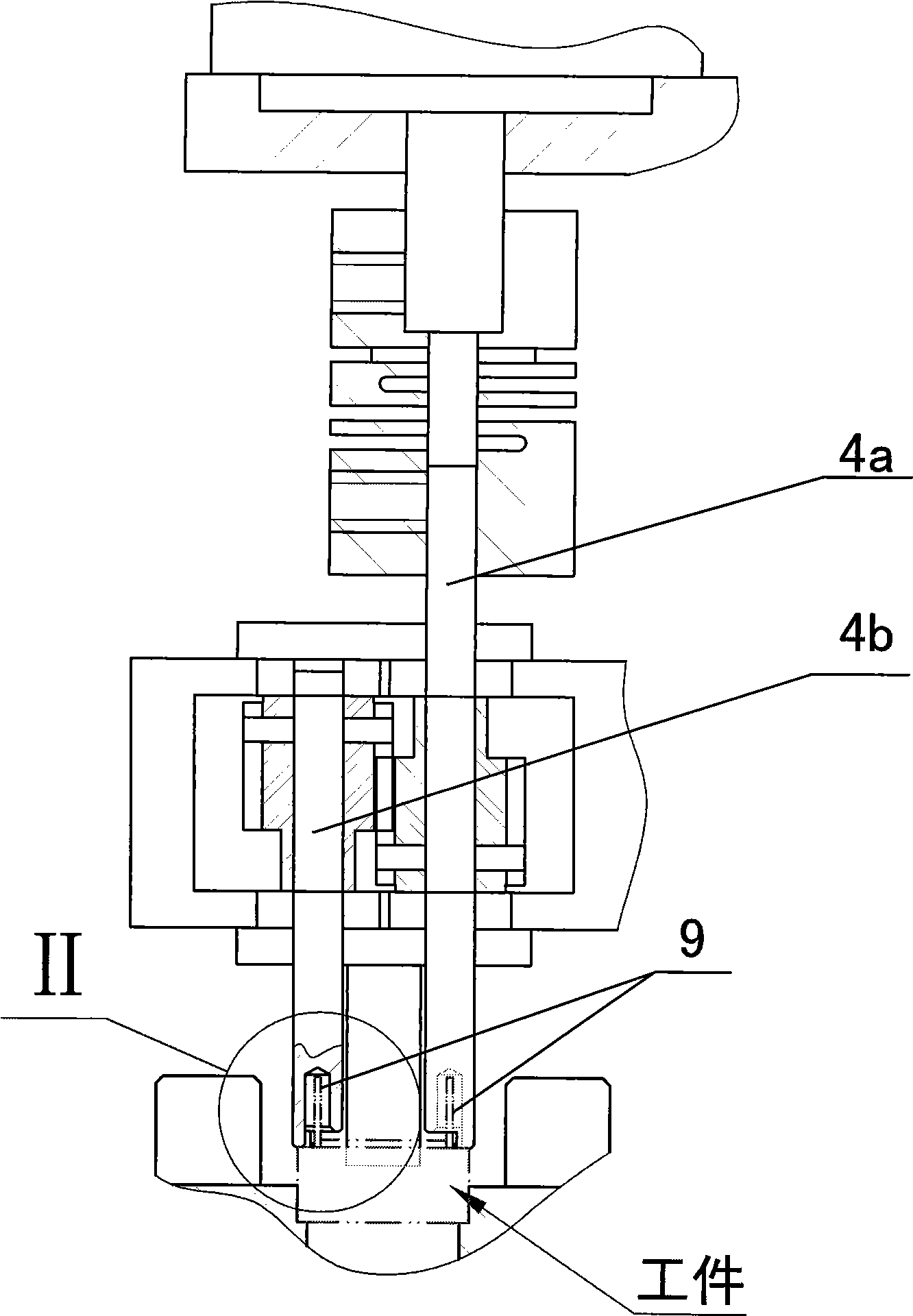

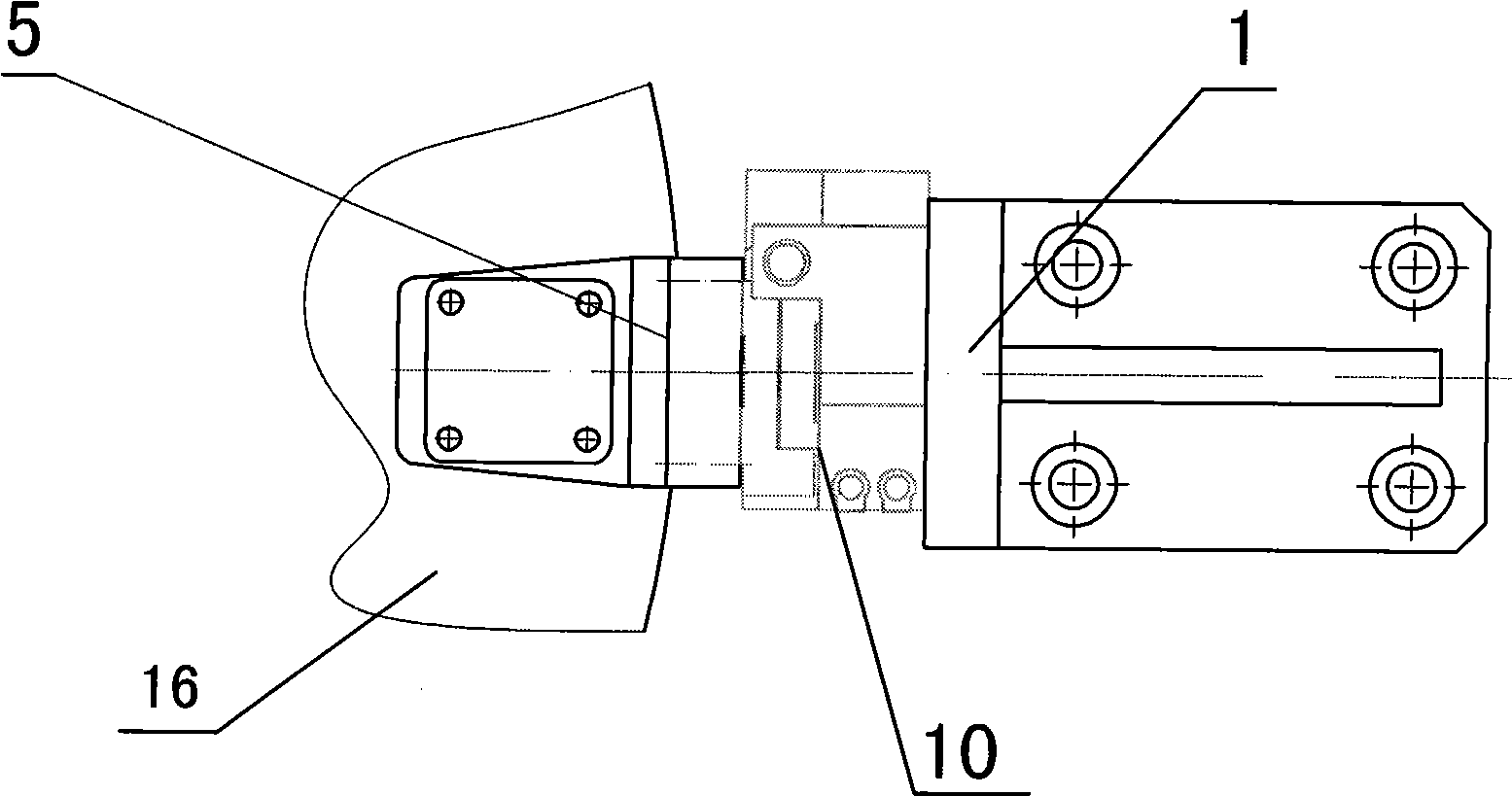

[0018] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 As shown, the present invention discloses a winding device for winding wire legs of electronic components such as resistors, capacitors, and inductors, including a winding seat bracket 1, a winding shaft seat 5, a motor 7, a coupling 8 and a winding shaft 4. The motor 7 is installed on the upper part of the winding shaft seat 5, and a sliding table guide rail 10 is provided on the winding seat support 1, and the winding shaft seat 5 is driven by another motor, along the sliding table guide rail 10 Up and down displacement movement relative to the bobbin holder support 1; the bobbin 4 includes a long bobbin 4a and a short bobbin 4b, the upper end of the long bobbin 4a is connected to the output shaft of the motor 7 through a coupling 8, and the lower end and the short winding shaft 4b through gear 6 transmission, under the drive of the motor 7, the long winding shaft 4a and the short winding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com