Manufacturing process for plugging conductive holes of circuit board with resin

A technology of resin plugging and manufacturing process, which is applied in the direction of electrical connection formation of printing components, etc., can solve the problems of difficult air bubbles and difficult to polish clean, and achieve the effect of solving the easy generation of air bubbles, facilitating the polishing process, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

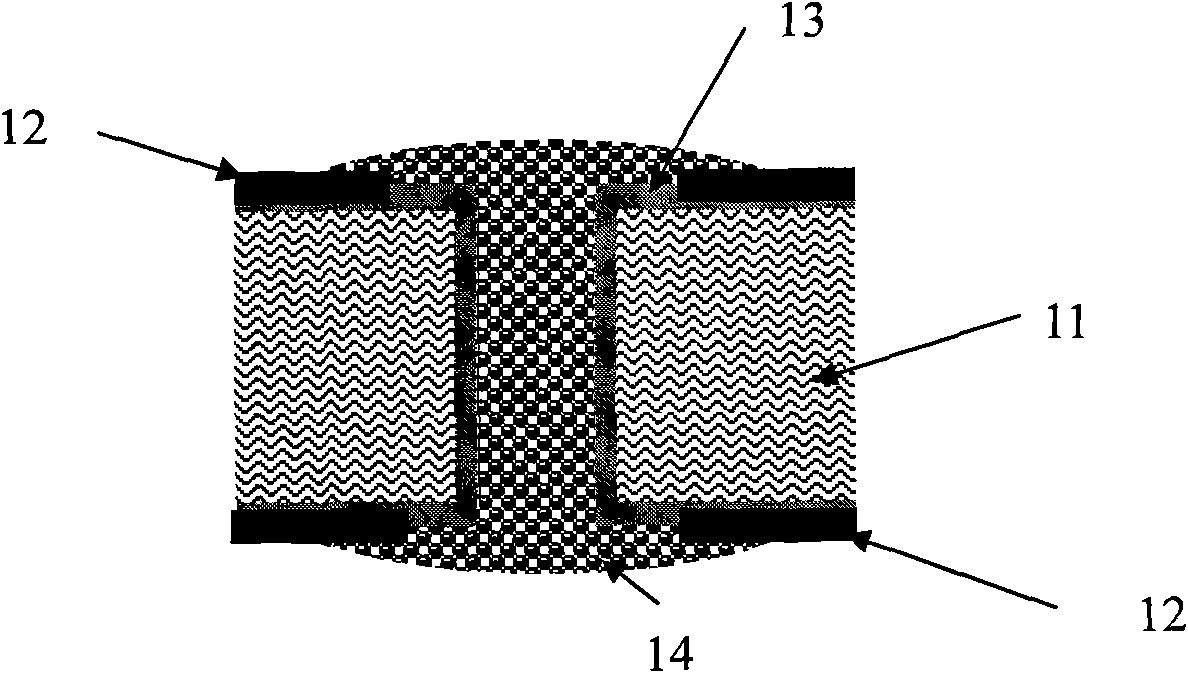

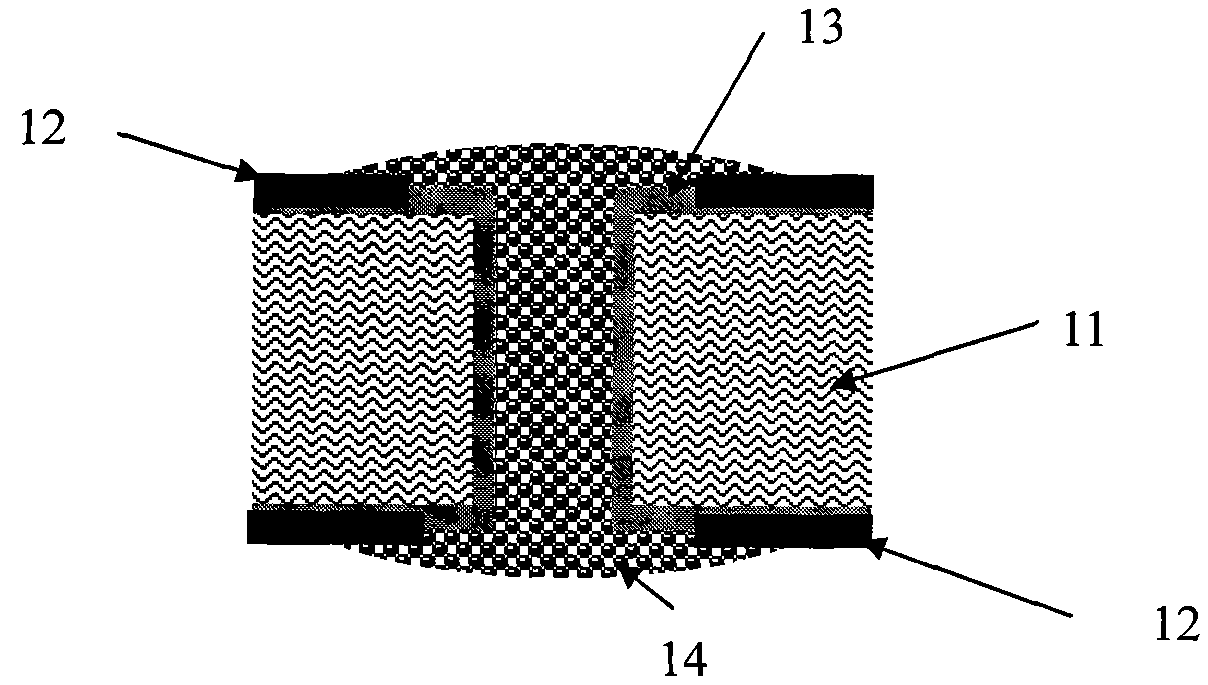

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0023] figure 1 For the circuit board in the process of resin filling through the manufacturing process of resin plugging the conductive holes of the circuit board described in this embodiment, in the figure, 11 is the circuit board substrate, 12 is the dry film, 13 is the window opening, and 14 is the Filled with epoxy resin. Resin filling is carried out through the manufacturing process of resin plugging the conductive holes of the circuit board described in this embodiment. The specific process is as follows:

[0024] Perform copper sinking treatment on the circuit board substrate with conductive holes, and perform electroplating treatment on the substrate plate with copper sinking treatment; perform window opening treatment on the conductive holes of the circuit board substrate after electroplating, and the window opening is set ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com