Preparation method of composite high-gloss film imitating metal drawing

A technology of imitating metal and wire drawing, which is applied in the field of preparation of metal imitation wire drawing composite high-gloss film, which can solve the problems of low interface bonding strength and difficulty in passing main performance inspections, and achieve soft visual effects, excellent anti-glare performance, and excellent anti-scratch performance damage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

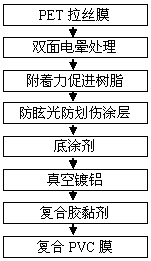

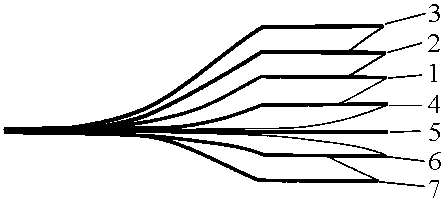

[0029] refer to figure 1 and figure 2 As shown, the present invention includes the following process steps.

[0030] A PET wire drawing film 1 with wire drawing stripes on the surface is selected as the base film, with a thickness of 25±1 μm. The surface corona treatment of the PET wire drawing film is carried out by a film corona machine, and the arc discharge power of the film corona machine is set to 7000w to prevent the film from being broken down by the transitional corona and improve the surface tension coefficient of the film. After corona treatment, the surface tension coefficient is 52mN / m, which is conducive to improving the adhesion fastness of various coatings to PET wire drawing film. Use a coating machine to coat the surface of the PET wire drawing film with no wire drawing pattern adhesion promotion resin layer 2. The adhesion promotion resin has a non-volatile component content of 15%, a viscosity of 100 mPa s under standard conditions, and a coating speed ...

Embodiment 2

[0032] Use a coating machine to coat the surface of the PET wire drawing film 1 without the wire drawing pattern with an adhesion promotion resin layer 2. The adhesion promotion resin has a non-volatile component content of 10%, a viscosity of 85 mPa·s under standard conditions, and a coating speed of 60 m / min. , coating machine oven baking temperature 95 ℃, baking time 6s, glue amount 7g / m 2 , After winding, the aging temperature is 55°C, and the aging time is 48h. Anti-glare and anti-scratch coating 3 is coated on the surface of the adhesion promotion resin layer 2 by dimple coating method, the non-volatile component content of the UV photocurable resin containing anti-glare particles is 40%, and the viscosity is 160 mPa·s under standard conditions , coating speed 40m / min, coating machine oven baking temperature 110°C, baking time 13s, UV lamp ultraviolet radiation energy 400mj / cm 2 , the irradiation time is 2.0s, and the thickness of the anti-glare and anti-scratch coating...

Embodiment 3

[0034] The anti-glare and anti-scratch coating 3 is coated on the surface of the adhesion promotion resin layer by the dimple coating method. The non-volatile component content of the UV light-curable resin containing anti-glare particles is 55%, and the viscosity is 240 mPa·s under standard conditions. Coating speed 40m / min, coating machine oven baking temperature 120°C, baking time 13s, UV lamp ultraviolet radiation energy 380mj / cm 2 , the irradiation time is 2.0s, and the thickness of the anti-glare and anti-scratch coating is 4 μm. Anti-glare particles are SiO 2 Microparticles with a particle size of 4±1 μm. The UV light-curable resin is mixed with polyurethane acrylate resin, silicone acrylate resin and polyester acrylate resin in a mass ratio of 50:25:25wt%. Vacuum aluminum plating on the surface of the primer layer with a winding high vacuum coating machine to form a vacuum aluminum coating layer 5, and the vacuum degree of the coating machine is 6*10 -3 Pa, coating c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com