High-rise long-span door type truss integral lifting device and construction method thereof

An overall lifting and large-span technology, applied in lifting devices, building maintenance, construction, etc., can solve problems such as unguaranteed safety and economy, many auxiliary measures, and temporary reinforcement of anchor points, etc., to save labor and time by taking measures , the amount of measures is small, and the effect of ensuring construction safety and structural safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

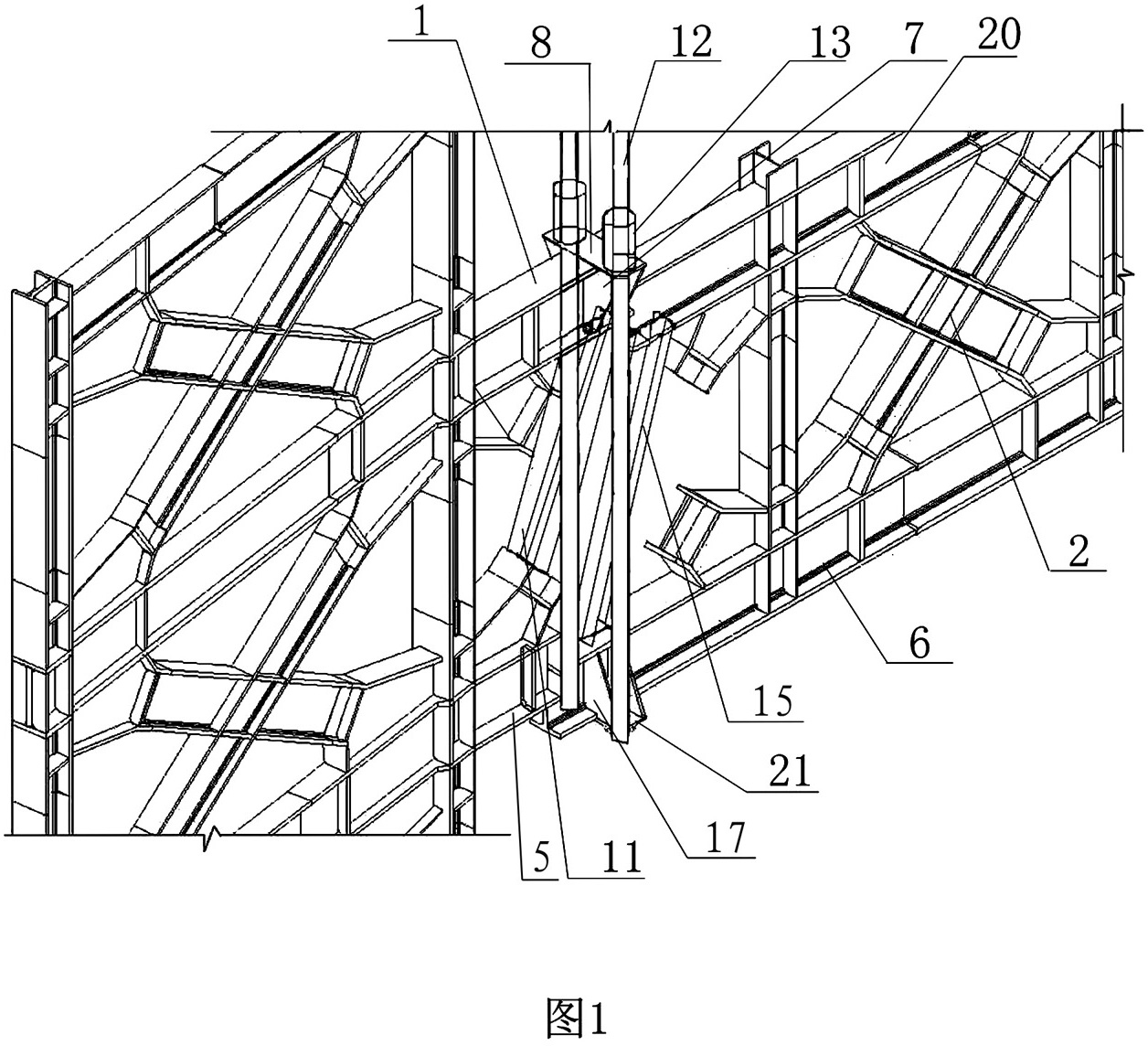

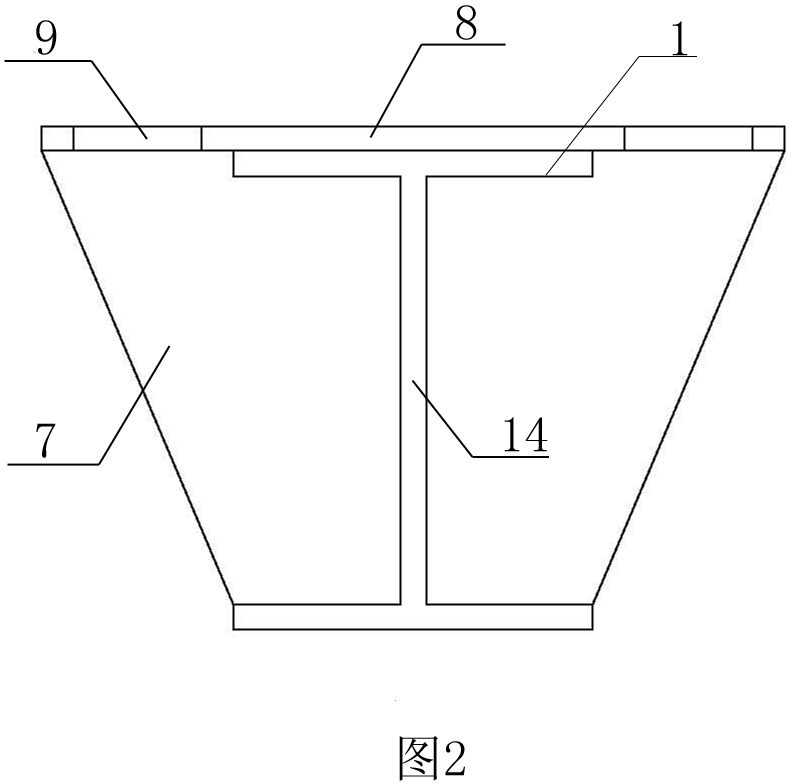

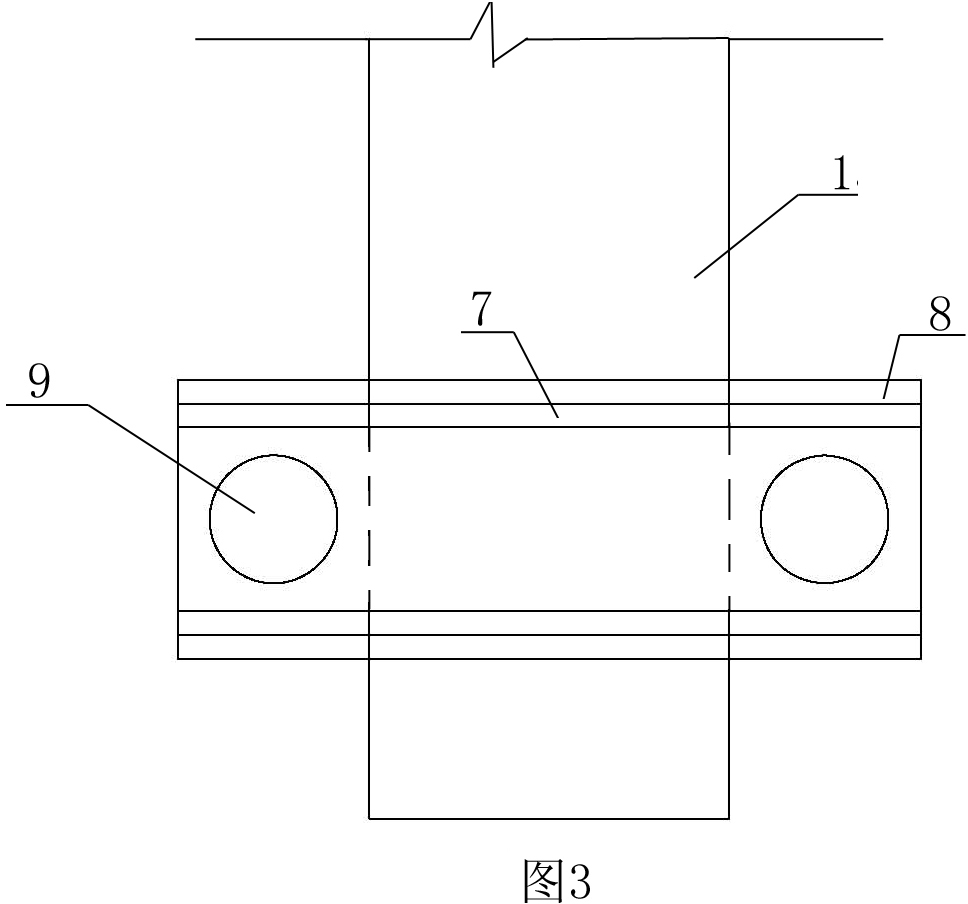

[0041] Examples see Figure 1 to Figure 5 As shown, a high-rise large-span portal truss overall lifting device includes a through-hole jack 13, a steel strand 12 and an anchoring structure, and the anchoring structure is composed of an upper anchoring structure 3 and an upper anchoring structure fixed on the truss corbels in place. It consists of a lower anchoring structure 4 fixed on the lifted truss 2, and the through-hole jack 13 is fixed on the upper anchoring structure 3, symmetrical to both sides of the upper corbel 1 of the truss in place, the through-hole jack 13 and The steel strand 12 will be lifted by the lifting truss 2 as a whole to be flush with the upper corbel 1 of the truss already in place.

[0042] see Figure 7 , the upper anchoring structure 3 is connected into one by two upper reinforced diagonal supports 11, the upper corbel anchorage seat and the lower corbel anchorage seat 19, and the upper corbel anchorage seat is welded on the top surface of the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com