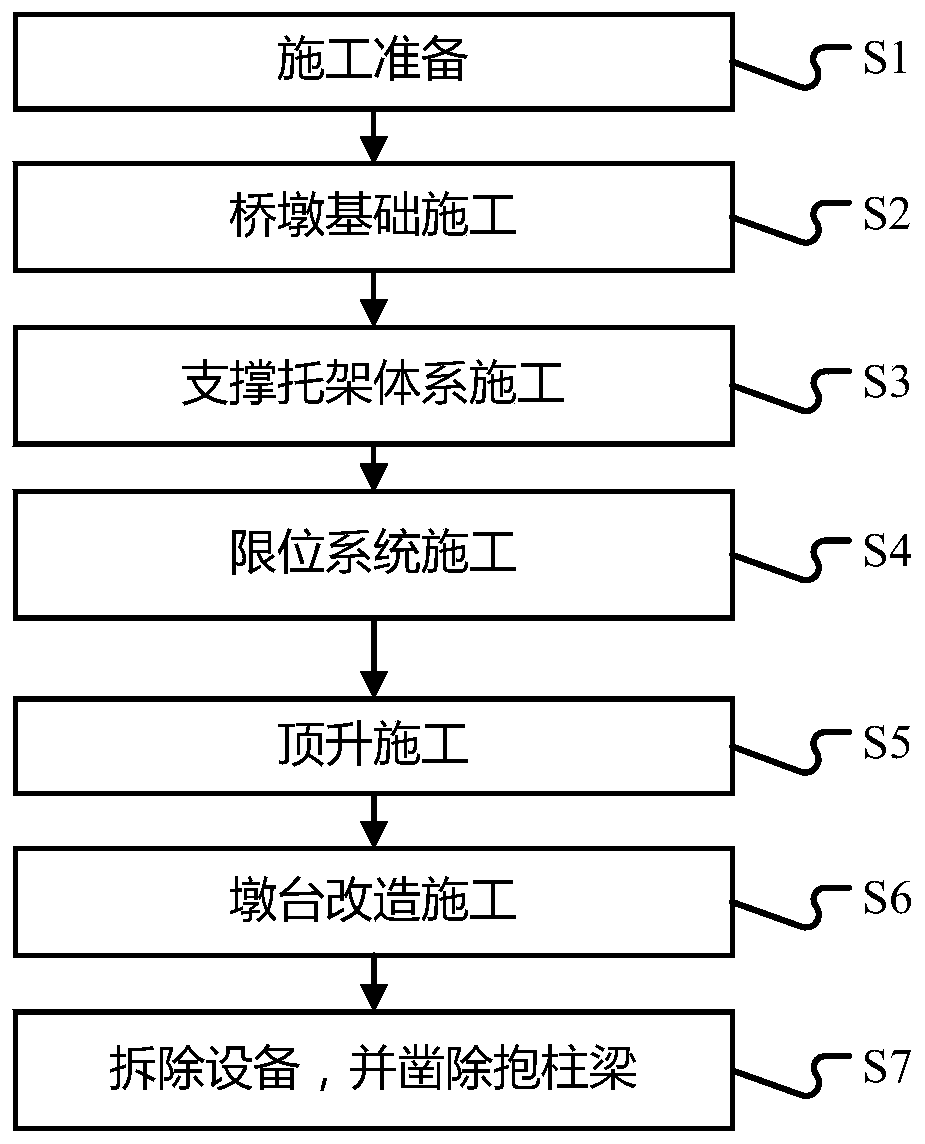

Integral synchronous jacking transformation method of overpass railway flyover

A technology of synchronous jacking and overpass, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of long construction period, large safety risks and protection pressure of railway traffic, and minimum electrified catenary erection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

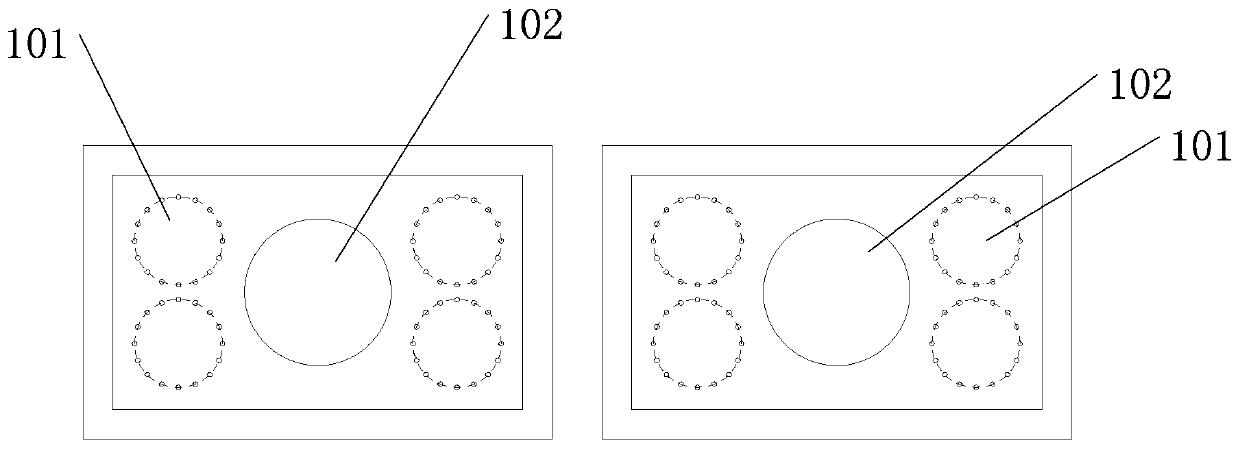

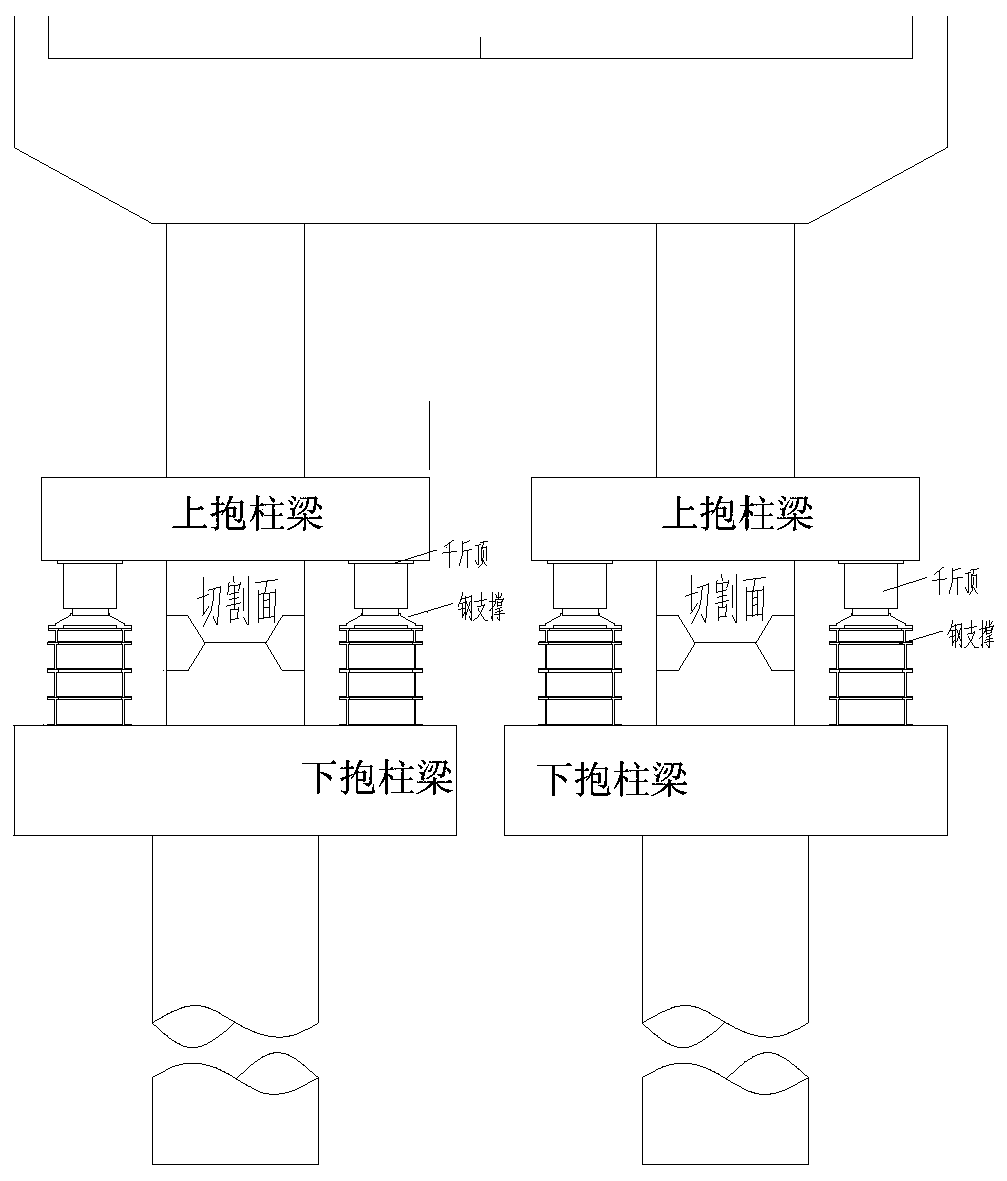

Method used

Image

Examples

Embodiment Construction

[0127] In order to make the purpose, features, and advantages of the present invention more obvious and understandable, specific embodiments and drawings will be used to clearly and completely describe the technical solutions protected by the present invention. Obviously, the implementation described below The examples are only a part of the embodiments of the present invention, not all the embodiments. Based on the embodiments in this patent, all other embodiments obtained by those of ordinary skill in the art without creative work shall fall within the scope of protection of this patent.

[0128] The terminology used herein is only for describing specific embodiments, and is not intended to limit the expression in this document. As used herein, the singular forms "a", "an" and "the" are intended to include plural forms unless the context clearly dictates otherwise. It should also be understood that when used in this specification, the term "comprising" refers to the existence ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com