Method for constructing beam plate supporting system having post-cast strip

A technology of support system and construction method, which is applied in the fields of formwork/formwork/work frame, on-site preparation of building components, construction, etc., can solve the problems of roof cracking, roof cantilever, failure to return to the roof in advance or in time, etc. Achieve the effect of ensuring structural safety, avoiding duplication of work, obvious economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

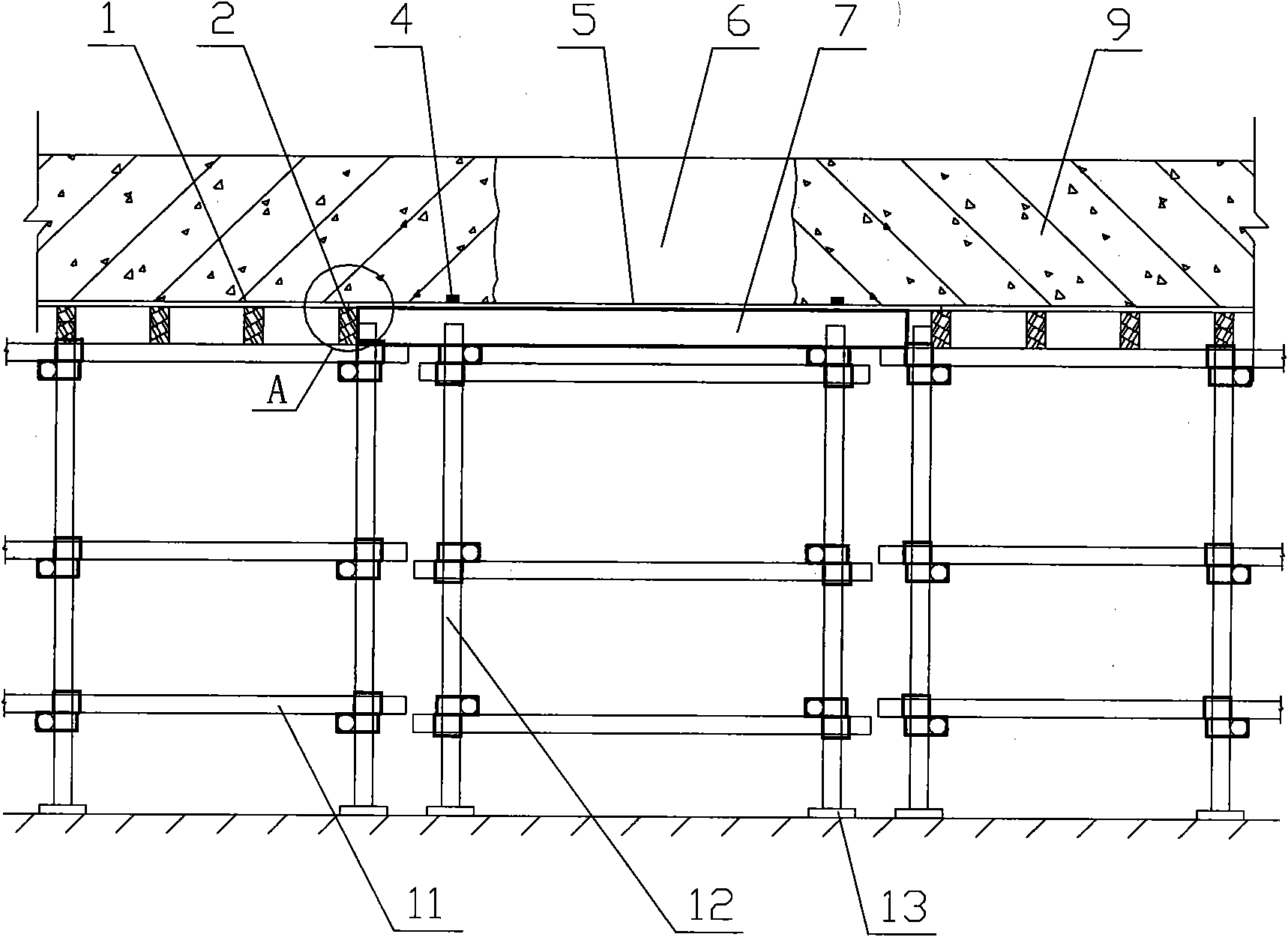

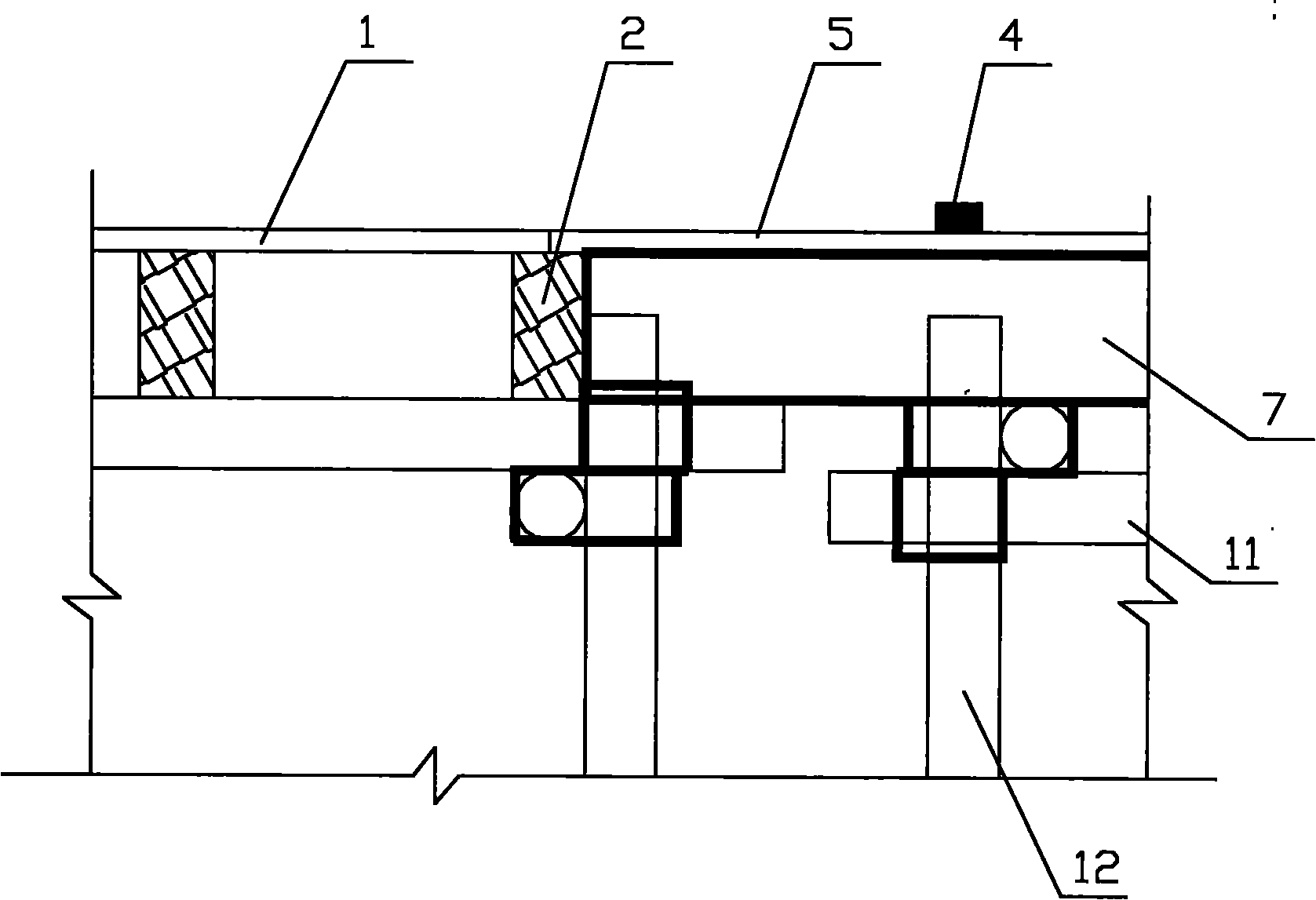

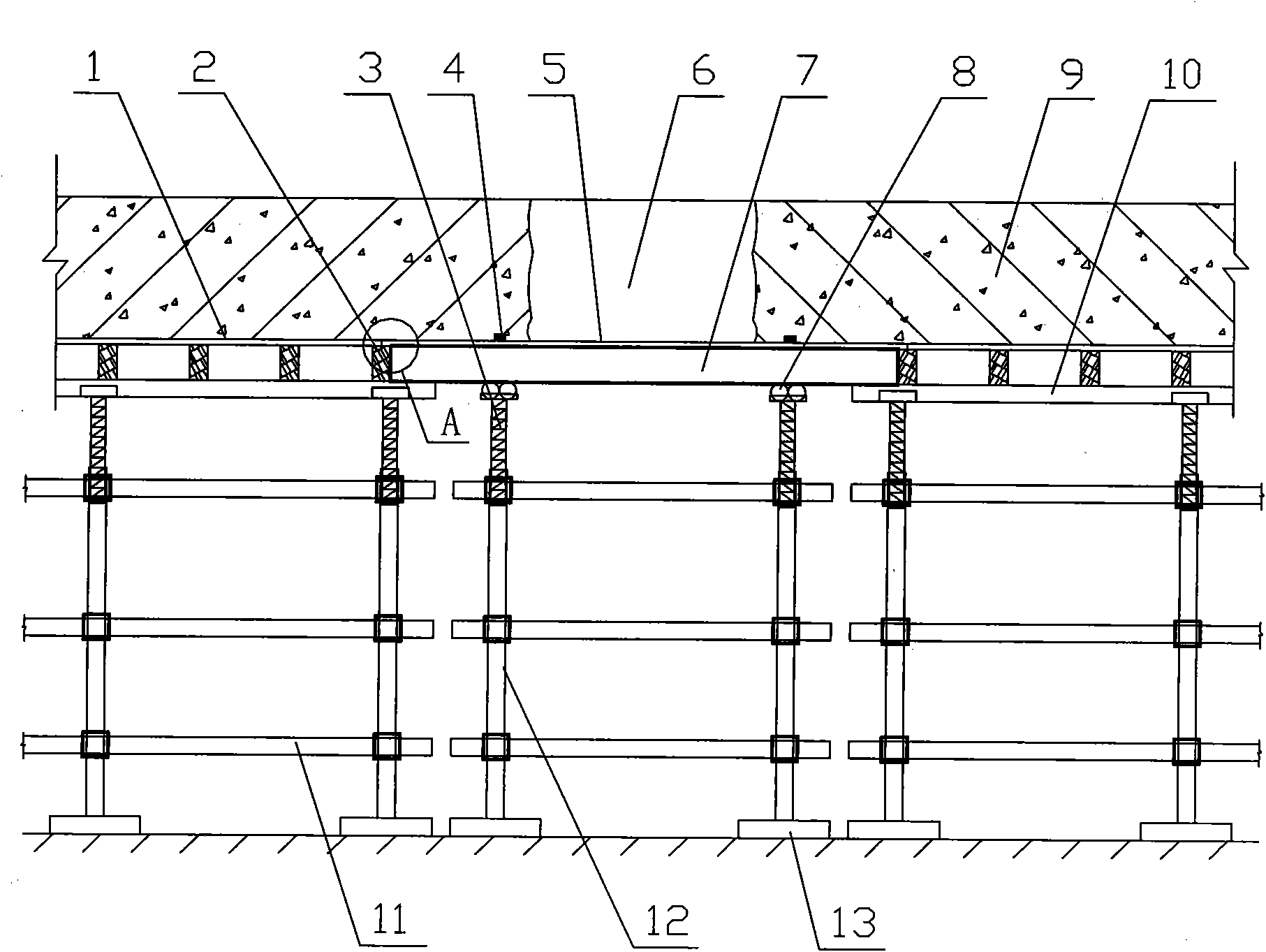

[0017] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0018] see Figure 1 to Figure 5 , the direction described in the text is figure 1 with Figure 4 prevail.

[0019] A roof construction method with post-pouring tape, the method comprises the following steps:

[0020] (1) Set up the roof support system:

[0021] 1) Set up the vertical pole 12 and the horizontal pole 11 to form a support frame body, wherein the support frame body at the post-casting belt part forms a separate system, and a backing plate 13 is provided at the bottom of each vertical pole 12;

[0022] 2) Laying longitudinal sub-keels 2 on the horizontal rods 11 of the supporting frame body on both sides of the post-casting belt 6;

[0023] 3) Install the formwork 5 of the post-casting belt on the transverse sub-keel 7 first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com