Propelled hydraulic cable carrying crane

A cable-loaded crane and self-propelled technology, which is applied in the direction of cable cranes, load hanging components, cranes, etc., can solve the problems of extended construction period and increased cost, and achieve the effects of high safety, fast walking speed and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The structure of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

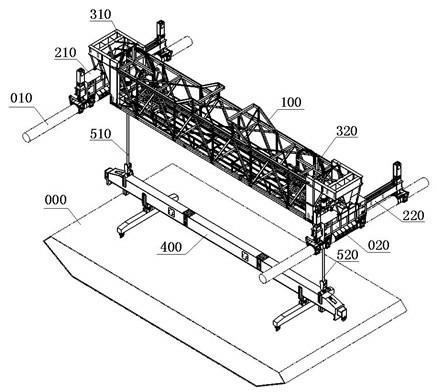

[0018] Such as figure 1 As shown, the present invention is mainly composed of the main truss 100, two sets of walking self-propelled systems 210 and 220 installed at the two ends of the main truss, two sets of hydraulic lifting systems 310 and 320 installed on the main truss, and a mechanical part composed of a pole beam 400 and Composition of power system and control system. In the figure, 010 and 020 are the main cables erected in parallel, and 000 is the steel box girder to be hoisted. The walking system 210 and 220 are supported on the main cable, and the main truss is hinged with the two walking systems, so that the whole machine can move on the main cable through the walking system.

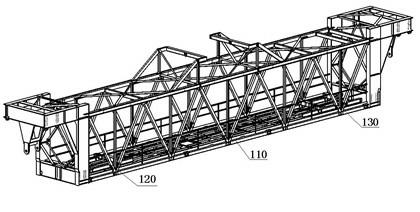

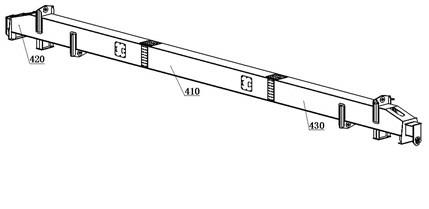

[0019] Both the main truss and the pole beam adopt a variable length structure, figure 2 As shown: the main truss 100 is composed of the middle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com