Slope-variable proportional alternate jacking construction method for continuous beam bridges

A construction method and jacking technology, applied in bridges, bridge maintenance, bridge reinforcement and other directions, can solve problems such as the compression of the bracket system of the steel support block, the unsafe hidden danger of the jacking system, etc., to ensure the safety of the structure. , to ensure the effect of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

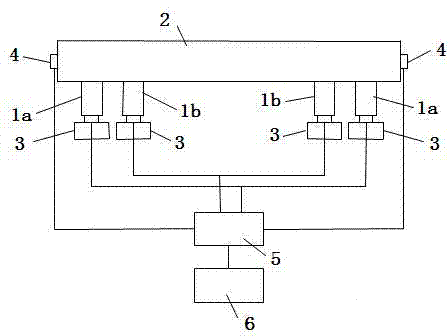

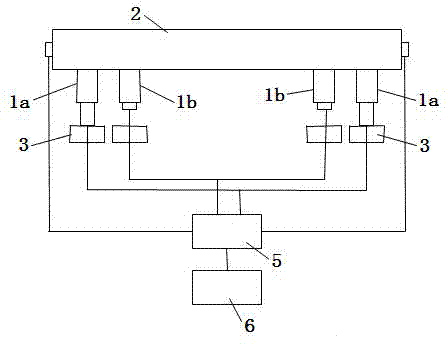

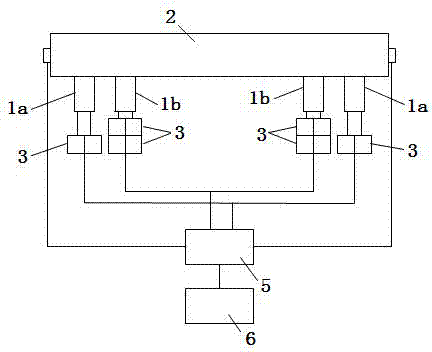

[0030] Such as Figure 1 to Figure 5 As shown, a continuous girder bridge slope-changing ratio alternate jacking construction method includes the following steps:

[0031] (1) Install the distribution beam at the bottom of the bridge structure 2 to be lifted. The distribution beam is located at the front and back of the pier and inside the abutment. Two sets of jacks are installed at the bottom of the distribution beam, namely the first set of jacks 1a and the second set of jacks 1b, and There are 4 jacks in each group, so that the piston of the jack is set downward, and a steel support pad 3 of equal height is placed at the lower end of the piston. The steel support pad 3 is a steel pipe with flanges welded at both ends. The first steel support The lower end is connected to the pier cap through pre-embedded implanted anchor bolts;

[0032] (2) C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com