High-glowing-filament high-CTI (comparative tracking index) super-tough flame-retardant PBT/PC (polybutylene terephthalate/polycarbonate) alloy material and preparation method thereof

A high-glow wire and alloy material technology, applied in the field of modified plastic alloys, can solve the problems of low glow wire temperature and poor toughness, achieve high flame retardancy, overcome poor leakage resistance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

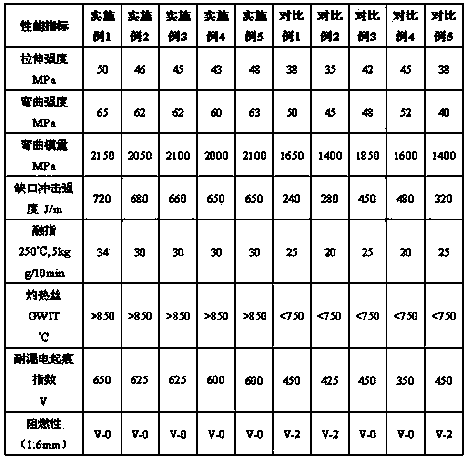

Examples

Embodiment 1

[0027] Embodiment 1 Preparation of PBT / PC alloy material of the present invention (1)

[0028] a) Prepare raw materials according to the following parts by weight: 59 parts of polybutylene terephthalate PBT, 15 parts of polycarbonate PC, 10 parts of compound toughening agent, 13 parts of brominated flame retardant, phosphorus nitrogen flame retardant 6 parts of additives, 3 parts of inorganic flame retardant synergists, 0.3 parts of transesterification inhibitors, 0.3 parts of anti-dripping agent PTFE, 0.5 parts of lubricants, and 0.5 parts of antioxidants;

[0029] Wherein, the composite toughening agent is composed of: 5 parts of ethylene-methyl acrylate-glycidyl methacrylate terpolymer, 5 parts of ethylene-butyl acrylate-glycidyl methacrylate terpolymer The brominated flame retardant consists of: decabromodiphenylethane; the phosphorus nitrogen flame retardant consists of: 2 parts of trihexyl phosphate, 4 parts of melamine; the inorganic flame retardant synergistic The ag...

Embodiment 2

[0031] Example 2 Preparation of PBT / PC alloy material of the present invention (two)

[0032] a) Prepare raw materials according to the following parts by weight: 15 parts of polybutylene terephthalate PBT, 25 parts of polycarbonate PC, 15 parts of compound toughening agent, 20 parts of brominated flame retardant, phosphorus nitrogen flame retardant 3 parts of agent, 5 parts of inorganic flame retardant synergist, 0.1 part of transesterification inhibitor, 0.5 part of anti-dripping agent PTFE, 0.1 part of lubricant, and 0.1 part of antioxidant.

[0033] Wherein, the composite toughening agent is composed of: 10 parts of ethylene-methyl acrylate-glycidyl methacrylate terpolymer, 5 parts of ethylene-butyl acrylate-glycidyl methacrylate terpolymer The brominated flame retardant consists of: 10 parts of decabromodiphenylethane, 10 parts of brominated epoxy; the phosphorus nitrogen flame retardant consists of: 2 parts of sodium phosphinate, 1 part of melamine ; The inorganic fla...

Embodiment 3

[0035] Example 3 Preparation of PBT / PC alloy material of the present invention (3)

[0036]a) Prepare raw materials according to the following parts by weight: 70 parts of polybutylene terephthalate PBT, 10 parts of polycarbonate PC, 25 parts of compound toughening agent, 5 parts of brominated flame retardant, phosphorus nitrogen flame retardant 10 parts of additives, 2 parts of inorganic flame retardant synergists, 0.5 parts of transesterification inhibitors, 0.1 parts of anti-dripping agent PTFE, 0.3 parts of lubricants, and 0.3 parts of antioxidants.

[0037] Wherein, the composite toughening agent is composed of: 10 parts of ethylene-methyl acrylate-glycidyl methacrylate terpolymer, 15 parts of ethylene-butyl acrylate-glycidyl methacrylate terpolymer The brominated flame retardant consists of: decabromodiphenylethane; the phosphorus nitrogen flame retardant consists of: 4 parts of trihexyl phosphate, 6 parts of melamine; the inorganic flame retardant synergistic The age...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com