Polypropylene Composite

A composite material, polypropylene technology, applied in the field of polypropylene composite materials, can solve the problems of poor creep resistance and low mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

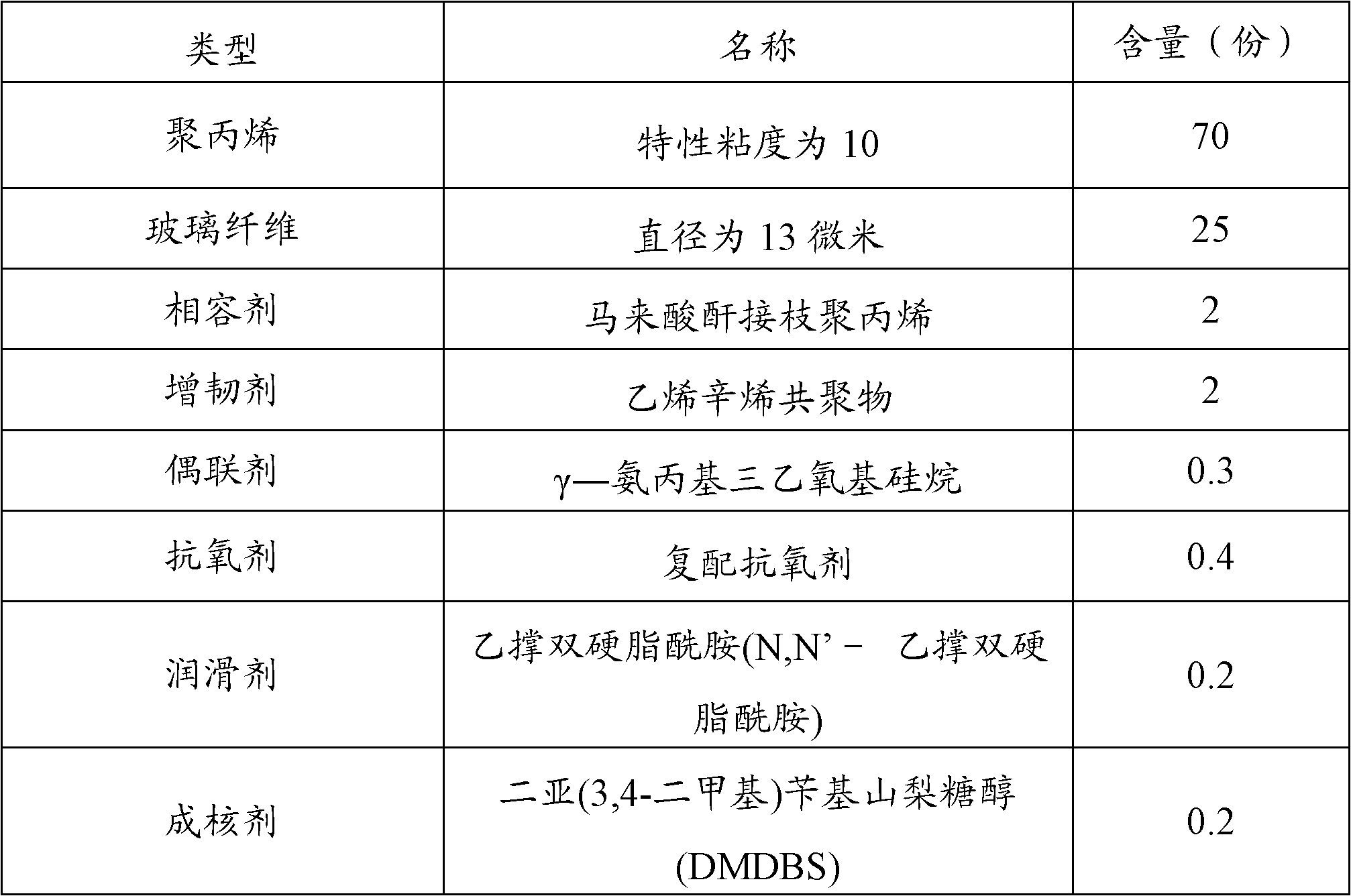

[0028] Prepare materials according to the group distribution ratio in the following table:

[0029]

[0030] Weigh each component according to the data in the above table, mix them uniformly, extrude and granulate, and obtain the polypropylene composite material. In this embodiment, the polypropylene, toughening agent, compatibilizer and coupling agent are mixed in a high-speed mixer for 5 minutes, then antioxidant, lubricant and nucleating agent are added and mixed for 5 minutes, after adding glass fiber A twin-screw extruder is used for extrusion, the screw speed is 450r / min, and the temperature of each zone of the extruder is between 175°C and 210°C.

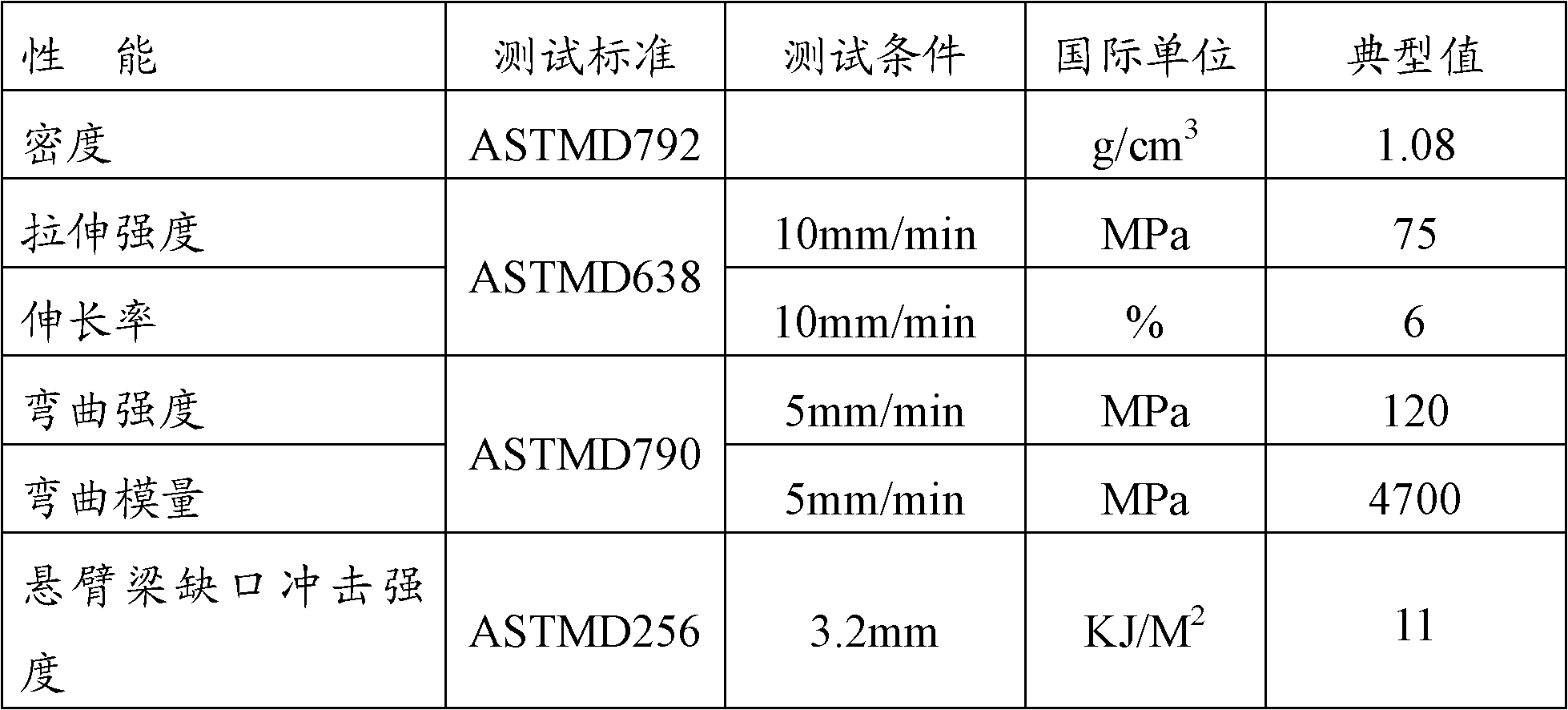

[0031] Performance test results:

[0032]

[0033] The cylinder made of the above-mentioned polypropylene material is tested according to the NSF / ANSI 44-2007 standard. When the burst pressure rises to 3.0Mpa, the lower cover of the cylinder will not break, and when the burst pressure rises to 3.5Mpa, the lower cover o...

Embodiment 2

[0035] Prepare materials according to the group distribution ratio in the following table:

[0036]

[0037]

[0038] Weigh each component according to the data in the above table, mix them uniformly, extrude and granulate, and obtain the polypropylene composite material. In this embodiment, the polypropylene, toughening agent, compatibilizer and coupling agent are mixed in a high-speed mixer for 5 minutes, then antioxidant, lubricant and nucleating agent are added and mixed for 5 minutes, after adding glass fiber A twin-screw extruder is used for extrusion, the screw speed is 450, and the temperature of each zone of the extruder is between 175°C and 210°C.

[0039] Performance test results:

[0040]

[0041] The cylinder made of the above-mentioned polypropylene material is tested according to the NSF / ANSI 44-2007 standard. When the burst pressure rises to 3.0Mpa, the lower cover of the cylinder will not break, and when the burst pressure rises to 3.5Mpa, the lower ...

Embodiment 3

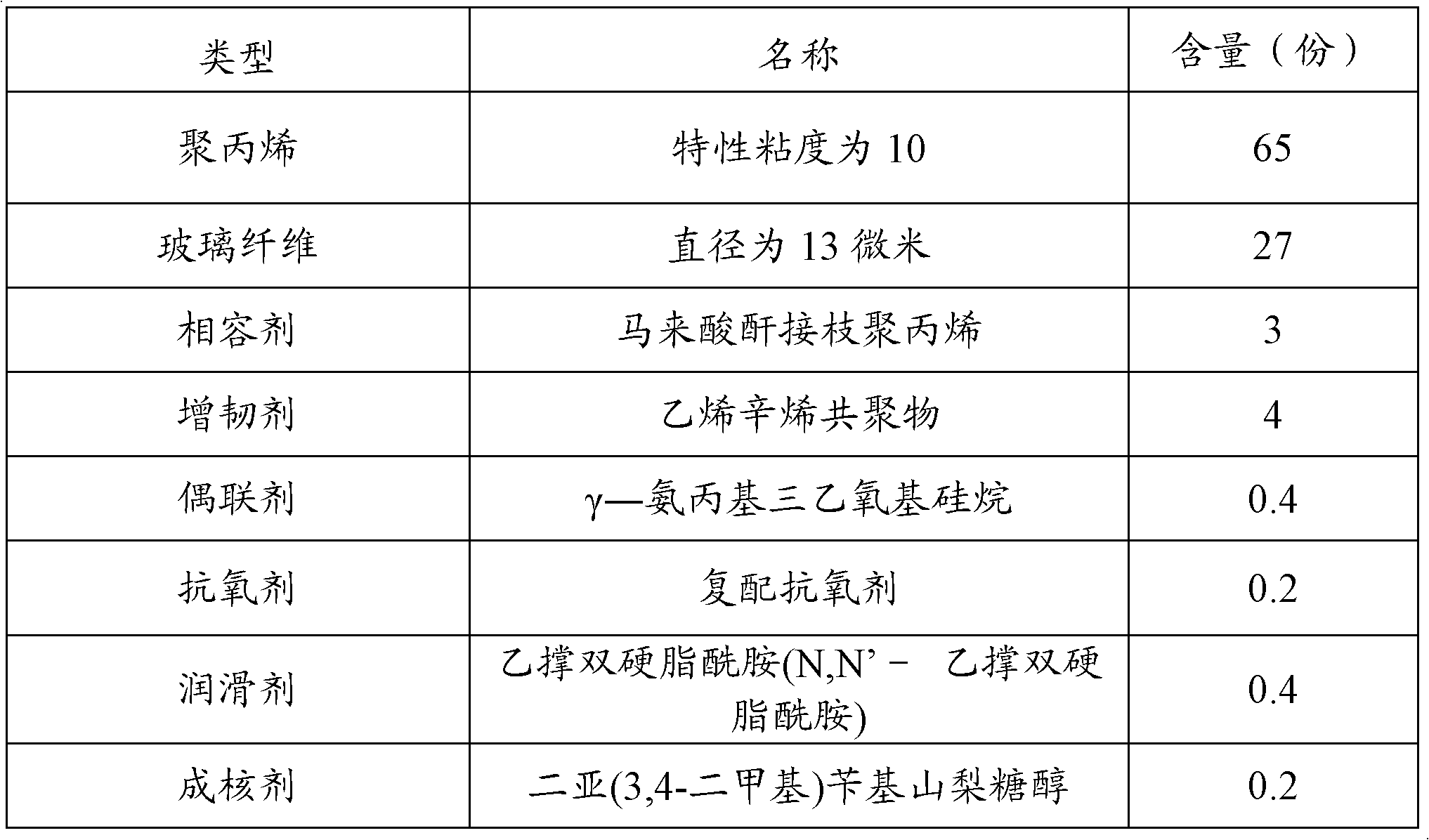

[0043] Prepare materials according to the group distribution ratio in the following table:

[0044]

[0045]

[0046] Weigh each component according to the data in the above table, mix them uniformly, extrude and granulate, and obtain the polypropylene composite material. In this embodiment, the polypropylene, toughening agent, compatibilizer and coupling agent are mixed in a high-speed mixer for 5 minutes, then antioxidant, lubricant and nucleating agent are added and mixed for 5 minutes, after adding glass fiber A twin-screw extruder is used for extrusion, the screw speed is 450r / min, and the temperature of each zone of the extruder is between 175°C and 210°C.

[0047] Performance test results:

[0048]

[0049] The cylinder made of the above-mentioned polypropylene material is tested according to the NSF / ANSI 44-2007 standard. When the burst pressure rises to 3.0Mpa, the lower cover of the cylinder will not break, and when the burst pressure rises to 3.5Mpa, the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com