High tenacity halogen-free flame-retardant glass fiber reinforced polycarbonate composition

A polycarbonate and composition technology, applied in the field of polymer composite materials, can solve the problems of increasing the sensitivity of the material to notched impact, difficulty in meeting the requirements of flame retardant properties, failure of key electronic and electrical components, etc., and improving mechanical properties. , Improve dimensional stability, maintain the effect of rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

[0027] Using bisphenol A polycarbonate as the base material, flame retardant, compound toughening agent, coupling agent and various processing aids, the above components except glass fiber are mixed in a high-speed mixer 2— 3 minutes, and then extruded pellets at 250-260°C, adding glass fibers during the extrusion process, and after drying, injection molded into standard samples for performance testing.

[0028] See Table 1 for each component and parts by weight (kg) in Examples 1, 2, and 3.

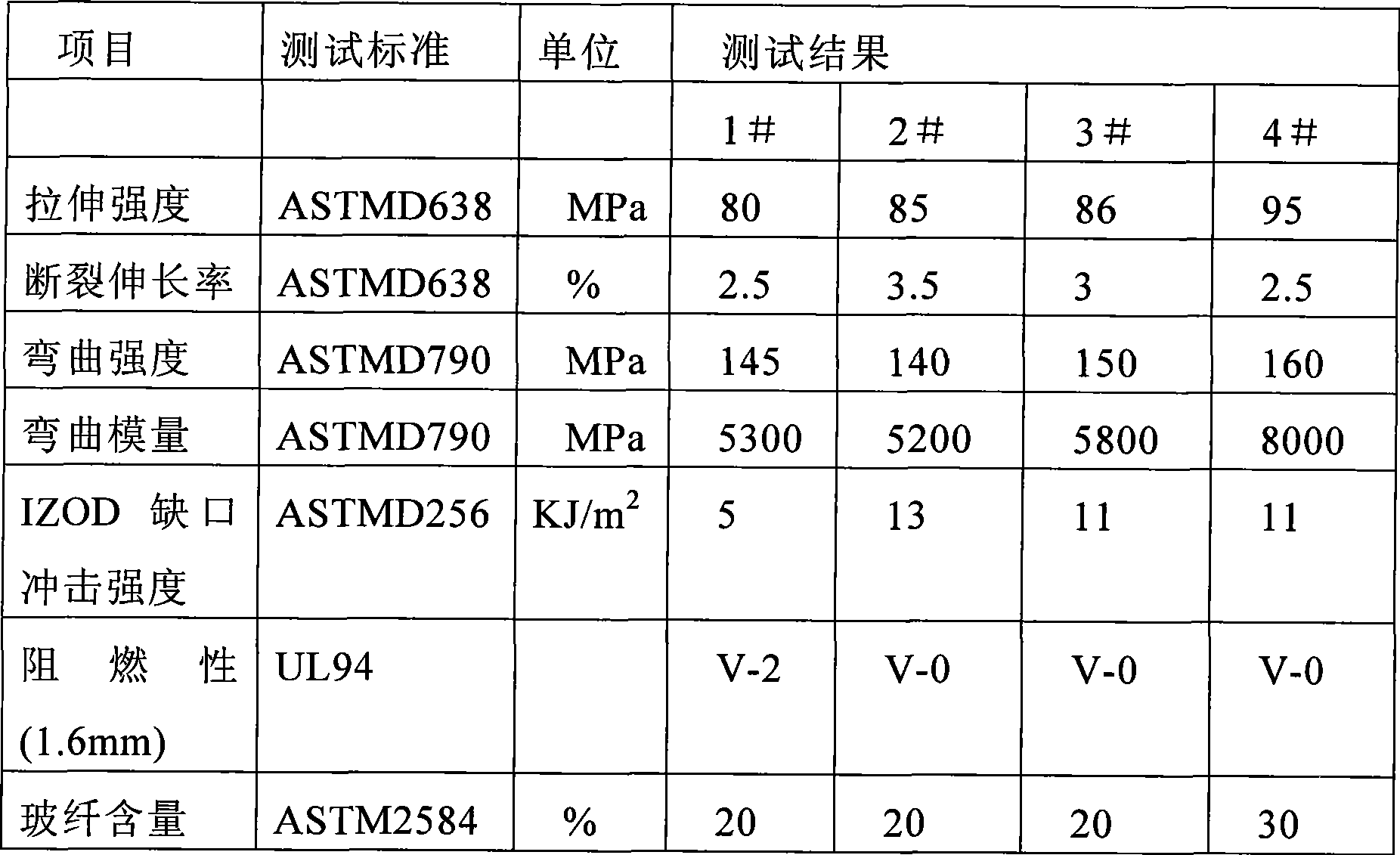

[0029] The prepared resin was injection-molded into test specimens according to the standard size, and the physical properties in the examples were tested according to the ASTM standard, and the performance results are shown in Table 2.

[0030] Table 1

[0031] 1# comparative example 2# embodiment 1 3# embodiment 2 4# embodiment 3 PC 800 640 590 490 E-glass fiber 200 200 200 300 MBS 60 60 60 SMA 60 60 KH550 6 6 6 6 P...

Embodiment 4

[0037] A high-toughness halogen-free flame-retardant glass fiber reinforced polycarbonate composition, the composition includes the following components and content (kg): bisphenol A polycarbonate 300; alkali-free glass fiber 100; methyl methacrylate— Styrene-butadiene copolymer (MBS) 30; silicone oil 10; nano-layered silicate earth 10; 1 part by weight of antioxidant 1076;

Embodiment 5

[0039] A high-toughness halogen-free flame-retardant glass fiber reinforced polycarbonate composition, the composition includes the following components and content (kg): bisphenol A polycarbonate 800; alkali-free glass fiber 400; styrene-maleic anhydride Copolymer (SMA) 150; polysiloxane 100; nano silicon dioxide 150; 10 parts by weight of antioxidant 1076; 15 parts by weight of antioxidant 168; titanate coupling agent 15; lubricant and toner 20.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com