Graphene modified PA6 composite and preparation method thereof

A technology of graphene modification and composite materials, which is applied in the field of highly dispersed modified graphene/PA6 composite materials and its preparation, can solve the problems of low strength, large amount of addition, and poor compatibility of PA6, so as to reduce water absorption, The effect of improving the notched impact strength and improving the mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

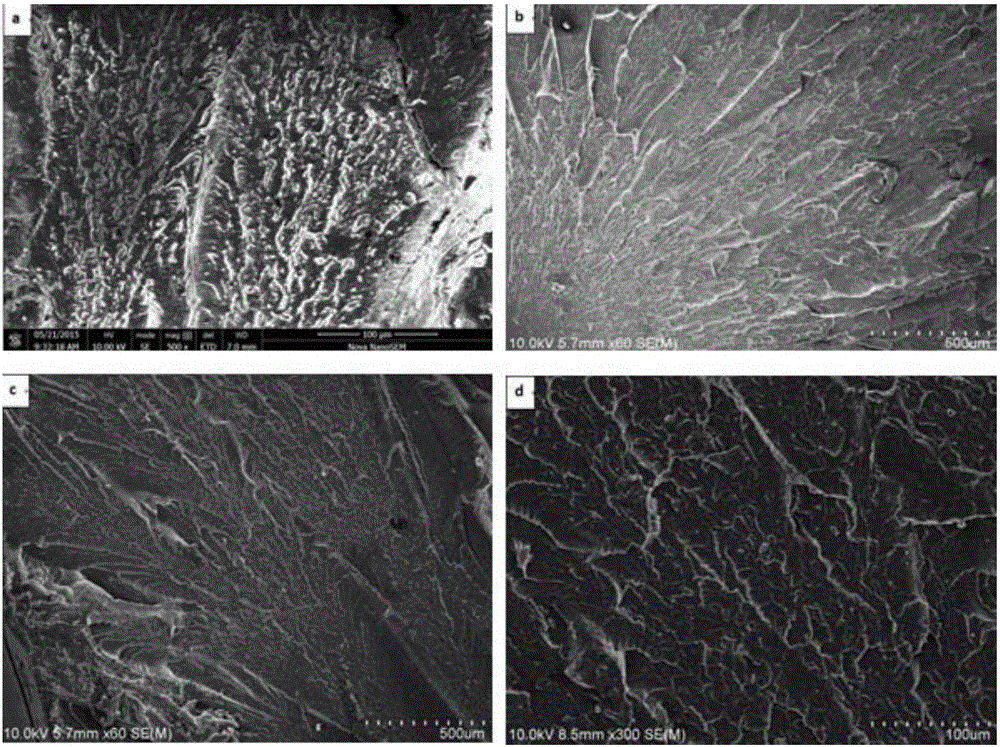

Image

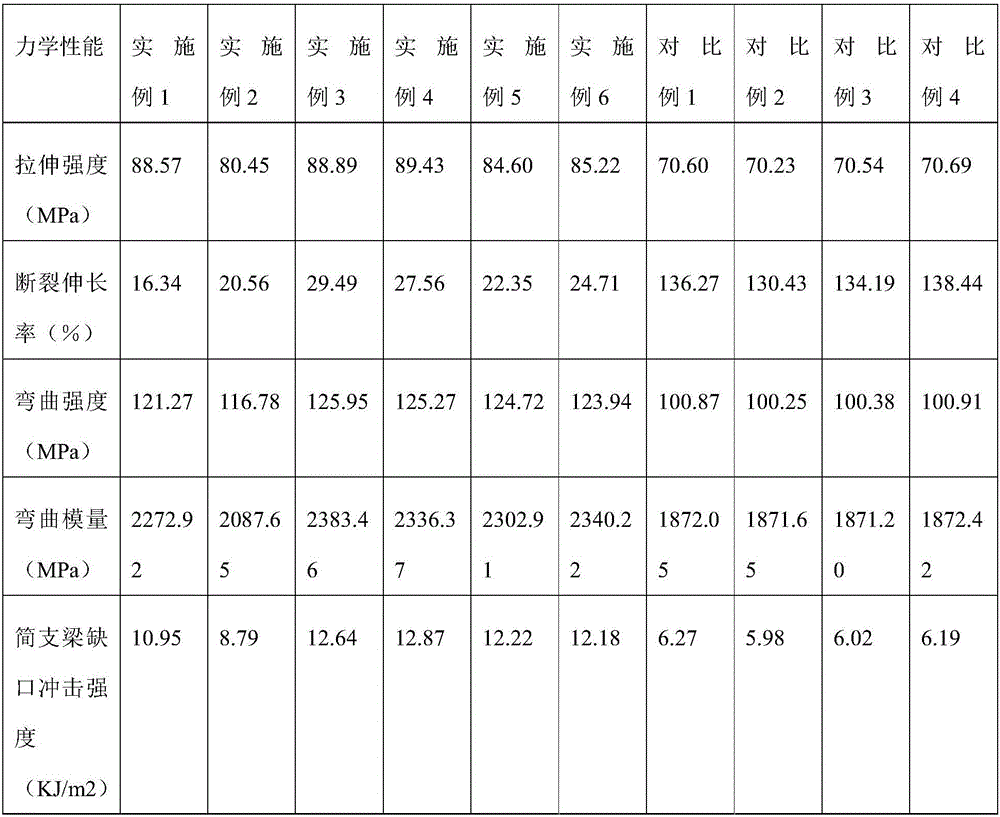

Examples

Embodiment 1

[0045] 1) Weigh 5g of graphene and mix it with 25g of silane coupling agent KH550, pour into 10L of ethanol solvent, add 2.5g of polymer dispersant in advance in the ethanol solvent, put the above graphene solution at a temperature of 45°C, stirring at a speed of Under the condition of 400rpm, react for 4 hours, wash the obtained modified graphene, place it in a vacuum drying oven, and dry it at 50°C until the solvent evaporates completely to obtain modified graphene, which is ready for use.

[0046] 2) Take 2 g of the modified graphene prepared in step 1), configure it into a 1 mg / ml formic acid solution, disperse it ultrasonically for 45 minutes, weigh 500 g of PA6 resin, and add it to the above modified graphene solution, at 25 ° C, 400 rpm The PA6 is heated and dissolved completely, dried, and pulverized to obtain a modified graphene / PA6 powder, which is ready for use.

[0047] 3) The modified graphene / PA6 powder obtained in step 2) is mixed with PA6 resin 9500g, compatibi...

Embodiment 2

[0049] 1) Take 8g graphene oxide by weighing and mix with 800g cetyltrimethylammonium bromide, pour into 20L water solvent, add 2.5g polymer type dispersant in advance in water solvent, put above-mentioned graphene oxide solution in The temperature was 80°C, the stirring speed was 500rpm, and the reaction was carried out for 8 hours to obtain modified graphene oxide. After washing, it was placed in a vacuum drying oven, and dried at 100°C until the water evaporated completely, and it was ready for use.

[0050] 2) Take 6g of the modified graphene oxide prepared in step 1) and configure it into a 1mg / ml mixed solution of ethanol and formic acid, disperse it ultrasonically for 60min, weigh 800g of PA6 resin, add it to the above-mentioned modified graphene oxide solution, and heat it at 40°C , under the condition of 600rpm, PA6 is heated and dissolved completely, dried, and pulverized to obtain modified graphene oxide / PA6 powder, which is ready for use.

[0051] 3) The modified g...

Embodiment 3

[0053] 1) Mix 10g of graphene with 50g of silane coupling agent KH550, pour into 10L of ethanol and water solvent, add 2g of polymer dispersant in advance in ethanol and water solvent, and put the graphene solution above at a temperature of 45°C , under the condition of a stirring speed of 800rpm, reacted for 4 hours, washed the obtained modified graphene, placed in a vacuum drying oven, and dried at 50°C until the solvent evaporated completely, ready for use.

[0054] 2) Take 15g of the modified graphene obtained in step 1) and configure it into a 1mg / ml formic acid solution, ultrasonically disperse it for 45min, weigh 500g of PA6 resin, add it to the modified graphene solution, and heat the PA6 at 25°C and 600rpm Dissolve completely, dry, and pulverize to obtain modified graphene / PA6 powder, which is ready for use.

[0055] 3) Take by weighing 10g graphene oxide and mix with 100g cetyltrimethylammonium bromide, pour into 10L of water solvent, add 2g polymer type dispersant i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com