Modified ABS resin for 3D printing as well as preparation method of modified ABS resin

An ABS resin, 3D printing technology, applied in the field of polymer material synthesis and preparation, can solve the problems of unfavorable 3D printing technology promotion and application, can not guarantee the accuracy of 3D printing products, limit the use of ABS resin, etc., to ensure the quality of 3D printing products , The effect of preventing edge warping and improving fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Weigh 55kg of ABS resin and modified nano-CaCO in proportion 3 5kg of particles, 20kg of SAN resin, and 20kg of fiber-reinforced ABS resin pellets were mixed uniformly by a high-speed mixer and then added to a twin-screw extruder for melt blending modification. pellets or wire drawing, and winding to obtain the modified ABS resin for 3D printing of the present invention.

Embodiment 2

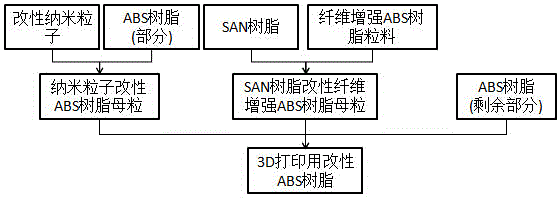

[0020] In order to make the various components of the modified ABS resin for 3D printing blend uniformly, the system is more stable. The following preferred preparation method can be adopted for preparation. figure 1 It is a schematic flow diagram of the preferred preparation method of inorganic modified ABS resin for 3D printing of the present invention, as figure 1 As shown, take 5kg out of 55kg ABS resin and modify nano-CaCO 3 5 kg of particles are uniformly compounded by a high-speed mixer, dried in vacuum at 90°C for 2-4 hours, and then added to a twin-screw extruder. The temperature of each heating section is 185-205°C. After extrusion and granulation, nano-CaCO 3 Modified ABS resin masterbatch; Take 20kg of SAN resin and 20kg of fiber-reinforced ABS resin pellets and mix them uniformly through a high-speed mixer. After vacuum drying at 90°C for 2 hours, add them to a twin-screw extruder. The temperature of each heating section is 185~205 ℃, obtained SAN resin modified...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com