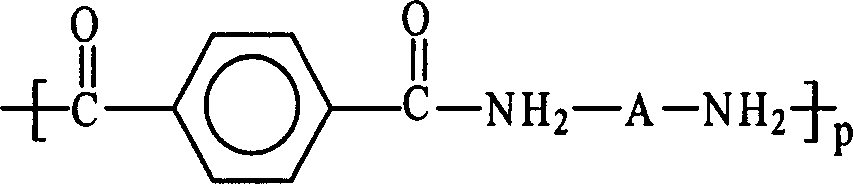

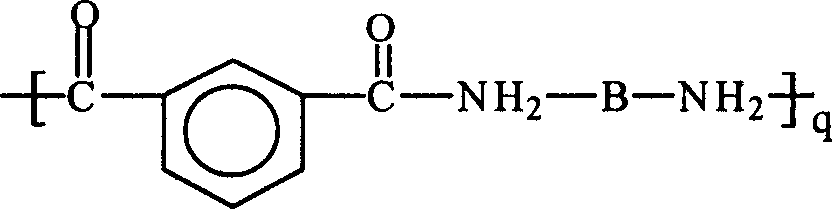

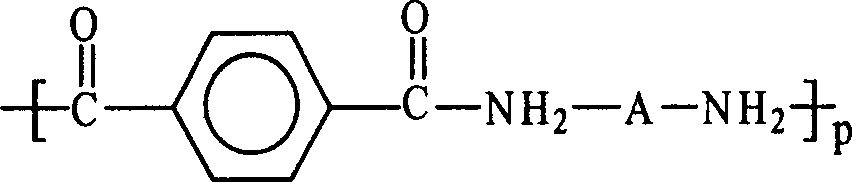

High-toughness semi-aromatic nylon and its preparation method

A semi-aromatic nylon, high-toughness technology, applied in the field of toughened semi-aromatic nylon and its preparation, can solve problems such as unsatisfactory toughness, overcome poor impact resistance, improve toughness, and excellent impact resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Mix 1014 grams of nylon 10T salt, 380 grams of nylon 10I salt, 1400 grams of deionized water, 30 grams of silicone oil, 5 grams of NaH 2 PO 2 and 72 grams of PA1212 resin into a 5-liter steel reactor. First evacuated, then passed 0.2MPa nitrogen, and started to heat up. When the pressure rises to 3.2Mpa, start holding pressure. When the temperature rises to 290-300°C, the pressure is reduced. When the temperature rises to 320°C, the temperature is kept at a constant temperature and normal pressure for 30 minutes, and then the material is discharged from the reaction kettle. The thermal and mechanical properties of the resin are as follows:

[0035] Melting point: (Tm) 305°C Tensile strength: 41.2MPa Elongation at break: 4.2%

[0036] Flexural modulus: 3019Mpa Izod notched impact strength: 58J / m

[0037] Heat distortion temperature: 124℃.

Embodiment 2

[0039] 1014 grams of nylon 9T salt, 380 grams of nylon 9I salt, 1400 grams of deionized water, 30 grams of silicone oil and 115 grams of PA1212 resin were added to a 5-liter steel reaction kettle. The specific operation process is the same as that of Example 1. The thermal and mechanical properties of the resin are as follows:

[0040] Melting point: (Tm) 300°C Tensile strength: 67.6MPa Elongation at break: 6%

[0041] Flexural modulus: 2910Mpa Izod notched impact strength: 88J / m

[0042] Heat distortion temperature: 114℃.

Embodiment 3

[0044] 1014 grams of nylon 9T salt, 380 grams of nylon 9I salt, 42 grams of caprolactam, 1400 grams of deionized water, and 144 grams of PA1010 resin were added to a 5-liter steel reactor. The specific operation process is the same as that of Example 1. The thermal and mechanical properties of the resin are as follows:

[0045] Melting point: (Tm) 295°C Tensile strength: 91.2MPa Elongation at break: 6.4%

[0046] Flexural modulus: 2830Mpa Izod notched impact strength: 110J / m

[0047] Heat distortion temperature: 110℃.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com