Filling-type thermal-conducting electric-insulating polyphenyl thioether and polyamide blended alloy and preparation method thereof

A polyphenylene sulfide, heat conduction and insulation technology, applied in the field of polyphenylene sulfide/polyamide blend alloy, can solve the problems of unfavorable polymer processing, increased processing viscosity, machine wear, etc., and achieve excellent mechanical properties and processing performance , Notched impact strength is improved, and the effect of prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

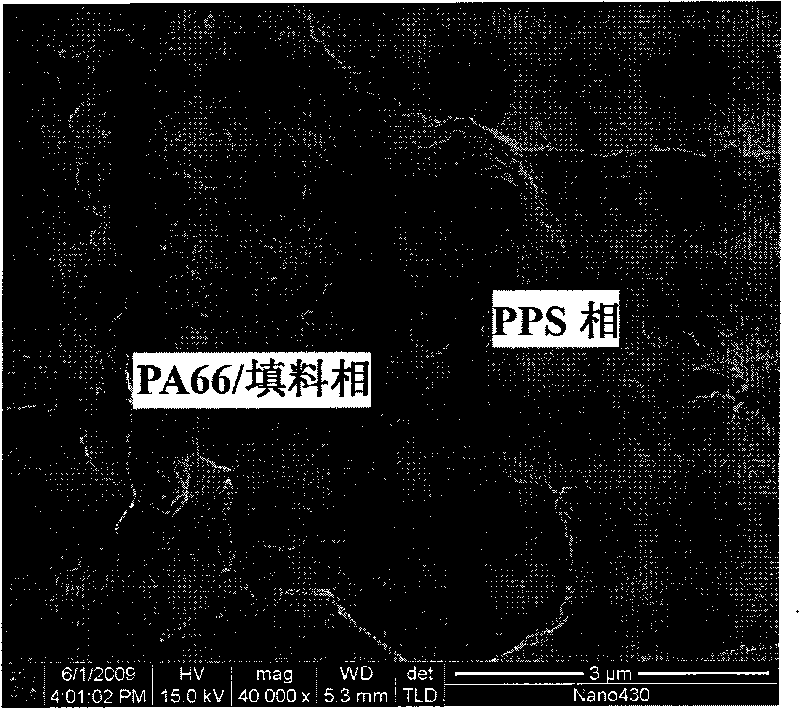

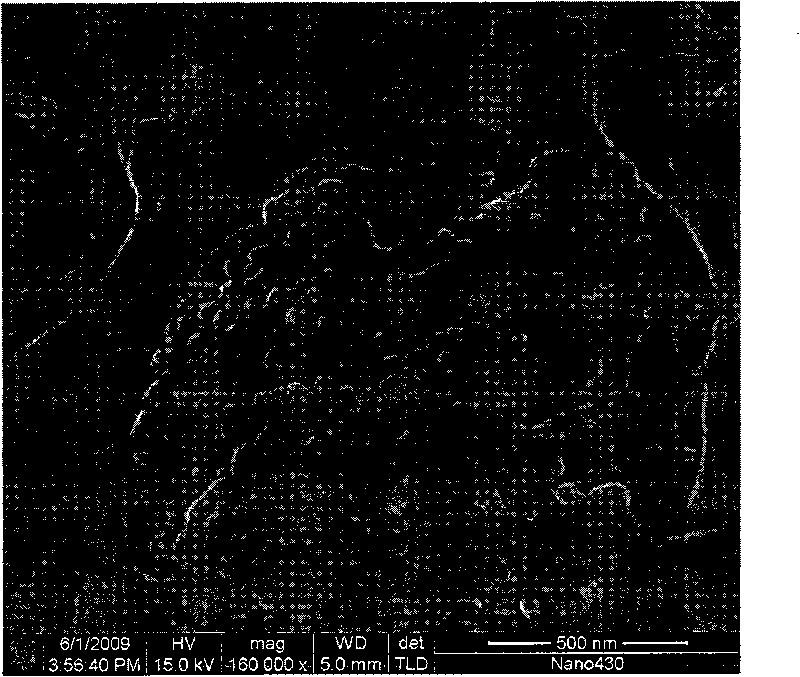

Image

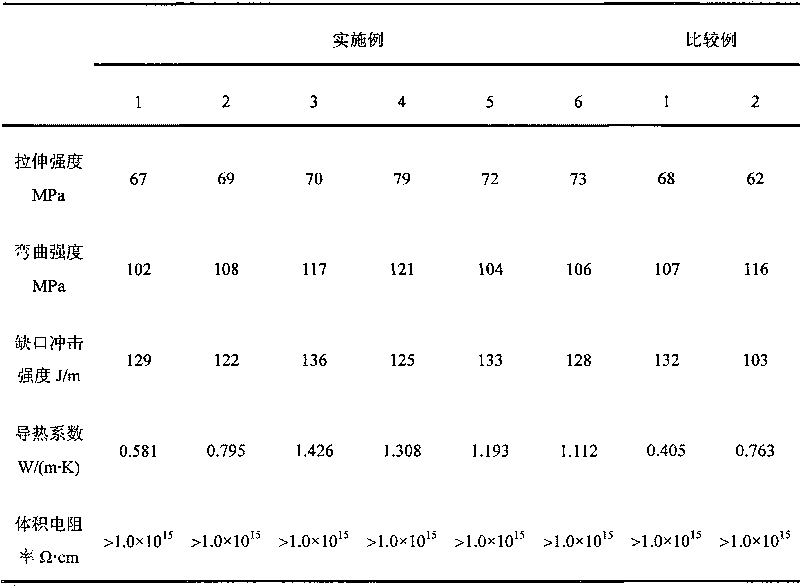

Examples

Embodiment 1

[0030] 300g of nano-Al with an average particle size of 70nm and a thermal conductivity of 42W / (m·K) 2 o 3 , 20g of silane coupling agent KH560 pretreated by hydrolysis and 1L of petroleum ether were mixed, then ultrasonically dispersed for 30min (40kHz), heated to reflux for 12h and then extracted with ethanol for 12h. Vacuum drying at 80°C for 24 hours; the dried modified Al 2 o 3 , 350g PA66, 3g antioxidant (3052FF / P-EPQ) and 3g lubricant (PTES) are dispersed and mixed by a high-speed mixer, and then extruded by a twin-screw extruder to obtain a heat-conducting masterbatch. Section 270°C, homogenization section 275°C; then mix the thermally conductive masterbatch, 350g polyphenylene sulfide, 3g antioxidant (3052FF / P-EPQ) and 3g lubricant (PTES) in a high-speed mixer and perform secondary extrusion For granulation, the temperature of each zone of the twin-screw extruder used was 250-282 °C to prepare a filled thermally conductive insulating polyphenylene sulfide / polyamide...

Embodiment 2

[0032] 350g of nano-Al with an average particle size of 70nm and a thermal conductivity of 42W / (m·K) 2 o 3, 25g of silane coupling agent KH560 pretreated by hydrolysis and 1L of petroleum ether were mixed, then ultrasonically dispersed for 30min (40kHz), heated to reflux for 12h and extracted with ethanol for 12h. Vacuum drying at 80°C for 24 hours; the dried modified Al 2 o 3 , 325g PA66, 3g antioxidant (3052FF / P-EPQ) and 3g lubricant (PTES) are dispersed and mixed by a high-speed mixer, and then extruded by a twin-screw extruder to obtain a heat-conducting masterbatch. Section 270°C, homogenization section 275°C; then mix thermally conductive masterbatch, 325g polyphenylene sulfide, 3g antioxidant (3052FF / P-EPQ) and 3g lubricant (PTES) in a high-speed mixer and perform secondary extrusion For granulation, the temperature of each zone of the twin-screw extruder used was 250-282 °C to prepare a filled thermally conductive insulating polyphenylene sulfide / polyamide blend all...

Embodiment 3

[0034] Mix 400g of AlN with an average particle size of μm and a thermal conductivity of 320W / (m K), 10g of hydrolyzed pretreated silane coupling agent KH570, and 1L of petroleum ether, then ultrasonically disperse for 30min (40kHz), heat and reflux for 12h, and ethanol Extraction 12h. Vacuum drying at 80°C for 24 hours; After the dried modified AlN, 300g PA66, 3g antioxidant (3052FF / P-EPQ) and 3g lubricant (PTES) were dispersed and mixed by a high-speed mixer, extruded by a twin-screw extruder The heat-conducting masterbatch is obtained, wherein the feeding section is 170°C, the melting section is 270°C, and the homogenizing section is 275°C; then the heat-conducting masterbatch, 300g polyphenylene sulfide, 3g antioxidant (3052FF / P-EPQ) and 3g lubricant (PTES) is mixed by a high-speed mixer for secondary extrusion and granulation. The temperature of each zone of the twin-screw extruder used is 250-282°C to obtain a filled thermally conductive insulating polyphenylene sulfide / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com