Sb-Si3N4 thin film material for phase change memory and preparation method thereof

A phase-change memory, sb-si3n4 technology, applied in the direction of electrical components, etc., can solve the problems of poor thermal stability of thin-film amorphous state, high power, high current of phase-change memory, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

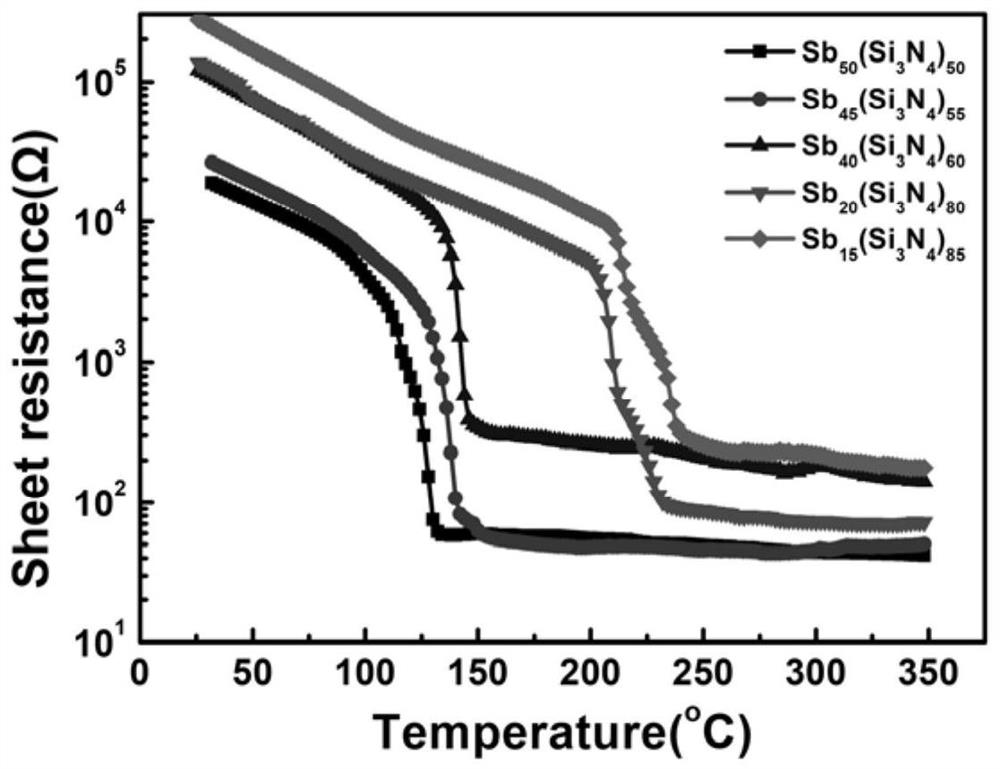

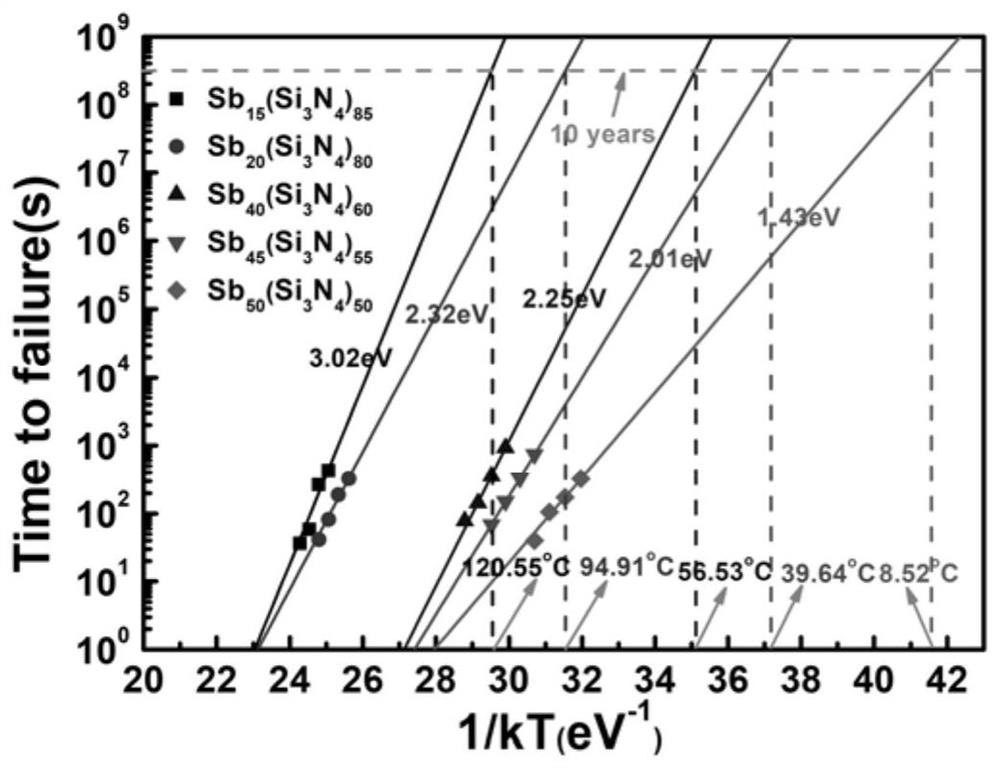

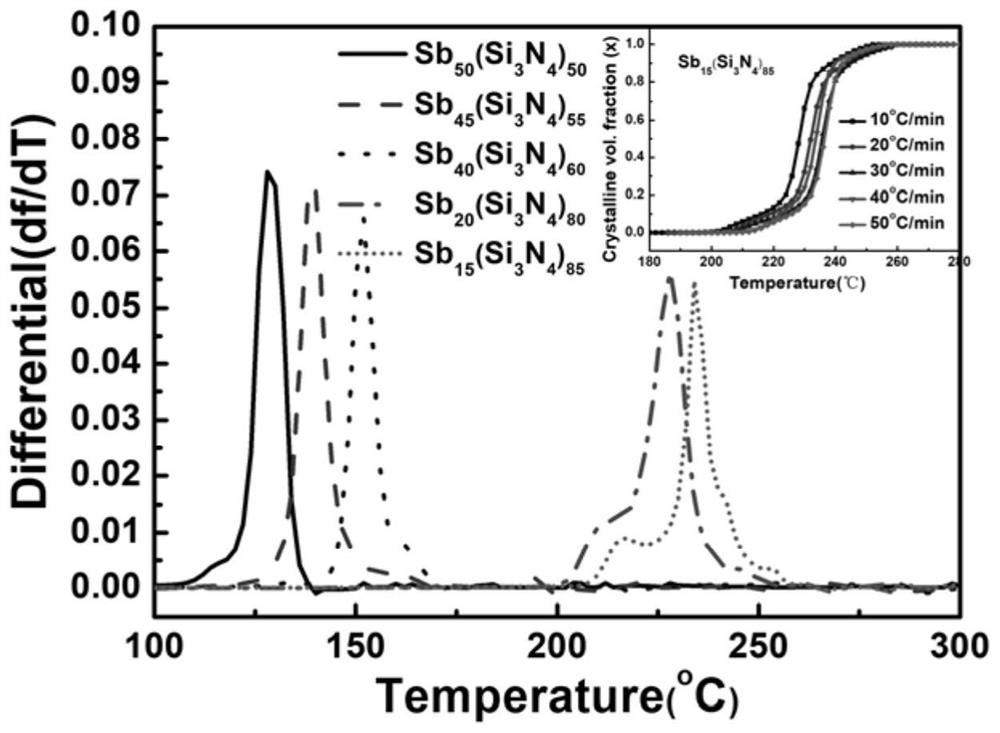

[0031] A kind of Sb-Si for phase change memory 3 N 4 Thin film material, its chemical structure is Sb x (Si 3 N 4 ) 100-x , where the atomic percentage of Sb is 15≤x≤50, the crystallization temperature of the material is between 110 and 210°C, and the amorphous resistance is 10 4 ~10 6 Ω, crystalline resistance 10 1 ~10 3 Ω. Its preparation method is: using high-purity round blocks of Sb and Si 3 N 4 The material is used as the target material, using a magnetron sputtering device, double targets are sputtered at the same time, high-purity argon is introduced as the working gas, and quartz wafers or silicon wafers are used as the substrate material for surface area deposition. The specific steps are as follows:

[0032] (1) Si 3 N 4 The round target and the back of the Sb round target are completely attached to a circular copper sheet with the same diameter as the target. The thickness of the copper sheet is about 1mm to obtain a magnetron sputtering coating target;...

Embodiment 1

[0038] A kind of Sb-Si for phase change memory 3 N 4 Thin film, its preparation method is as follows:

[0039] (1) Using Si 3 N 4 Simultaneous sputtering coating with Sb double target: Install the Sb target in the magnetron DC sputtering target, and the Si 3 N 4 The target is installed in the magnetron radio frequency sputtering target; vacuumize the sputtering chamber, when the vacuum degree in the sputtering chamber reaches 6×10 -4 Pa, fill the chamber with high-purity argon gas, the flow rate of argon gas is 50.0ml / min, until the initiation pressure required for sputtering is 0.3Pa in the chamber; turn on the radio frequency power supply, and after the initiation is stable, adjust the position where Sb is located. DC sputtering target power is 10W, Si 3 N 4 The magnetron radio frequency sputtering power where the target is located is 60W. After the power is stable, turn on the substrate turntable and set the rotation rate to 5rpm, open the baffle under the substrate,...

Embodiment 2

[0043] Same as Example 1, the difference is that the power of the DC sputtering target where the Sb is located is still 10W, and the Si 3 N 4 The RF power of the RF target is adjusted to 50W.

[0044] The Sb-Si prepared in above-mentioned embodiment 2 3 N 4 The film composition is measured by X-ray Energy Spectroscopy (EDS), and the film thickness is measured by a step meter. The test results are: the film composition is (Sb) 20 (Si 3 N 4 ) 80 , film thickness is 150nm. The corresponding crystallization temperature of the film is 200°C, and the amorphous resistance is 1.4×10 5 Ω, the crystalline resistance is 1×10 2 Ω; 10-year data retention temperature has been tested to be 94.91°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Crystallization temperature | aaaaa | aaaaa |

| Crystallization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com