A kind of polypropylene composition and preparation method thereof

A polypropylene composition and polypropylene technology, applied in the field of polypropylene composition and its preparation, to achieve the effects of fast crystallization speed, cost reduction, high melting point and crystallization temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0139] 1) Preparation of polypropylene raw material

[0140] A, the preparation of main catalyst:

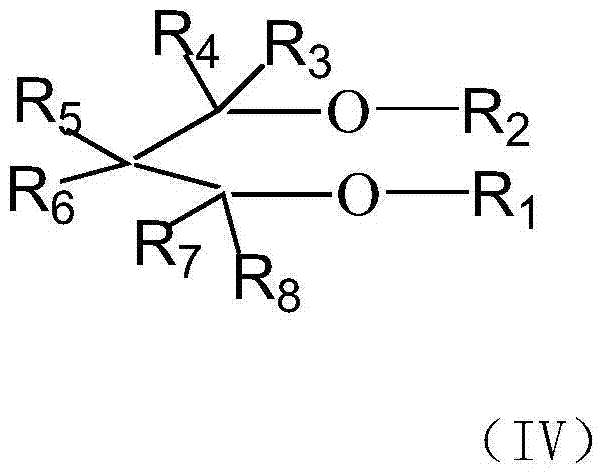

[0141]After the 16L pressure-resistant reactor with a stirrer was fully replaced with nitrogen, 10L ethanol, 300mL 2‐ethylhexanol, 11.2g iodine, 8g magnesium chloride and 640g magnesium powder were added to the reactor. While stirring, the temperature of the system was raised to 75° C. for reflux reaction until no more hydrogen gas was discharged. Stop the reaction, wash with 3L of ethanol, filter and dry to obtain dialkoxymagnesium carrier of spherical particles. The resulting dialkoxymagnesium carrier has a D50 of 30.2 μm, a span value of 0.81, and an m value of 0.015. Take 650g of the above-mentioned dialkoxymagnesium carrier, 3250mL of toluene and 65mL of 2-isopropyl-2-isoamyl-1,3-dimethoxypropane to prepare a suspension. In a 16L pressure-resistant reaction kettle that has been repeatedly replaced with high-purity nitrogen, add 2600mL of toluene and 3900mL of titanium te...

Embodiment 2

[0157] 1) Preparation of polypropylene raw material

[0158] A. raw material (same as embodiment 1)

[0159] B. Test device (same as embodiment 1)

[0160] C. Test conditions

[0161] Step (1) Pre-polymerization: Reaction pressure is 2.5MPa, reaction temperature is 10°C, reaction time is 12 minutes; main catalyst and triethylaluminum feeding amount are 0.4g / hour and 0.058mol / hour respectively; propylene feeding amount It is 10 kg / hour, and the prepolymerization ratio is 65 grams of polymer / gram of catalyst.

[0162] Step (2) gas phase polymerization: reaction temperature is 91°C, reaction pressure is 2.3MPa, reaction time is 60 minutes; propylene feed rate is 30 kg / hour; hydrogen feed rate is 0.4 g / hour; The propylene molar ratio was 0.008.

[0163] D. Test results

[0164] The continuous test was carried out for 48 hours according to the above conditions, and the operation of the device was stable. The polymer obtained by the reaction was analyzed and tested, and the res...

Embodiment 3

[0171] 1) Preparation of polypropylene raw material

[0172] A. raw material (same as embodiment 1)

[0173] B. Test device (same as embodiment 1)

[0174] C. Test conditions

[0175] Step (1) pre-polymerization: reaction pressure 2.5MPa, reaction temperature 10°C, reaction time 12 minutes; main catalyst, triethylaluminum, dicyclopentyldimethoxysilane DCPDMS (commonly known as D-Donor) feed The amount is 1.1g / hour, 0.051mol / hour, 0.0082mol / hour respectively; Al / Si (mol / mol)=6.2; The feed rate of propylene is 10 kg / hour, and the prepolymerization ratio is 90 grams of polymer / gram of catalyst .

[0176] Step (2) gas phase polymerization: reaction temperature is 98°C, reaction pressure is 2.3MPa, reaction time is 60 minutes; feed rate of propylene is 30 kg / hour; feed rate of hydrogen is 0.6 g / hour; The propylene molar ratio was 0.012.

[0177] D. Test results

[0178] The continuous test was carried out for 48 hours according to the above conditions, and the operation of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| crystallization temperature | aaaaa | aaaaa |

| crystallization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com