Preparation method of total-silicon molecular sieve Silicalite-1 having high hydrogen bond silicon hydroxyl content

A high-hydrogen-bonding silanol and all-silicon molecular sieve technology, which is applied in molecular sieves and base-exchange compounds, chemical instruments and methods, and inorganic chemistry, can solve problems such as high toxicity, long crystallization time, and expensive templates, and achieve High hydrothermal stability, short crystallization time, and low-cost raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Under stirring conditions, the following two solutions were prepared:

[0052] Mixture I: 17.5 g of silica sol (40% SiO 2 , 60%H 2 O, the same below), 1.77g tetrapropylammonium bromide (99%), 16.5g deionized add in the beaker and mix well;

[0053] Mixture II: 2.2mol / L sodium hydroxide homogeneous solution;

[0054] Under constant stirring, the mixture II was slowly added to the mixture I, and stirred for 2 h to obtain a gel with a mass ratio of SiO 2 :N:H 2 O=1:0.06:20, adjust the pH of the gel to 8.5. Among them, with SiO 2 Calculate the number of moles of silicon source, and calculate the number of moles of template agent with N element, the same below. It was transferred to a reaction kettle with a polytetrafluoroethylene lining, sealed and placed in an oven for hydrothermal synthesis, first at 90 °C for 6 hours, and then heated to 165 °C for 14 hours. After the reaction kettle was cooled, the solid was separated from the mother liquor, the solid was washed w...

Embodiment 2

[0058] Under stirring conditions, the following two working solutions were prepared:

[0059] Solution I: add 25g of silica sol, 3.55g of tetrapropylammonium bromide, and 26.5g of deionization into a beaker and mix well;

[0060] Solution II: 2.2mol / L sodium hydroxide homogeneous solution;

[0061] Under constant stirring, solution II was slowly added to solution I and stirred for 4 h. The molar ratio of the initial gel is SiO 2 :N:H 2 O=1:0.08:20, adjust the gel pH to 8.0. The crystallization conditions, washing, drying, roasting and other processes are the same as those in Example 1, and the original powder of molecular sieve Silicalite-1 is prepared. The obtained molecular sieve Silicalite-1 original powder is treated with an ammonium nitrate solution, and the treatment process is shown in Example 1, and finally a hydrogen-type all-silicon molecular sieve is obtained.

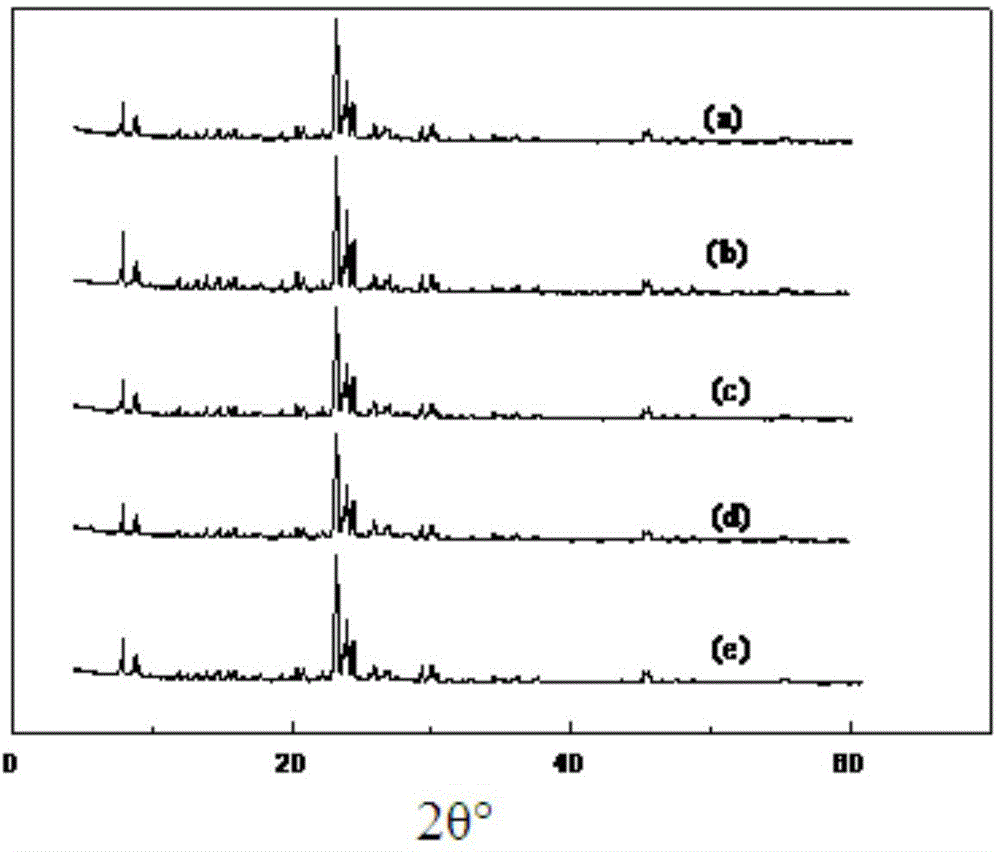

[0062] The final product powder was analyzed by X-ray diffraction ( figure 1 (b)), the relative cry...

Embodiment 3

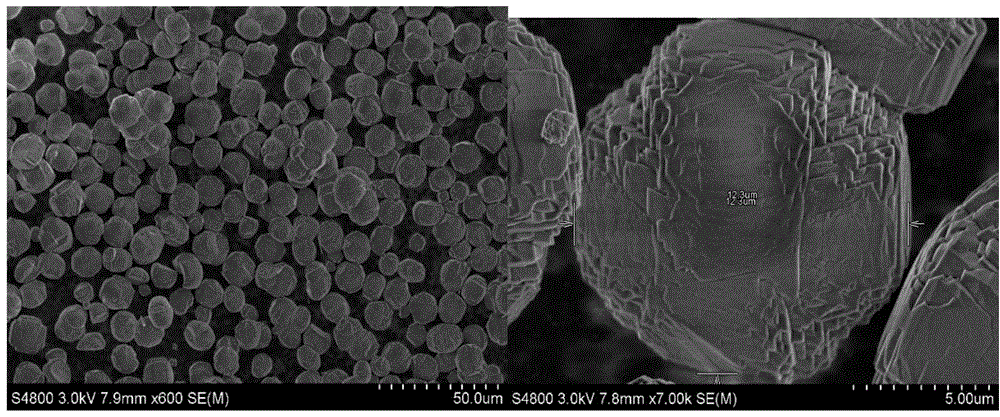

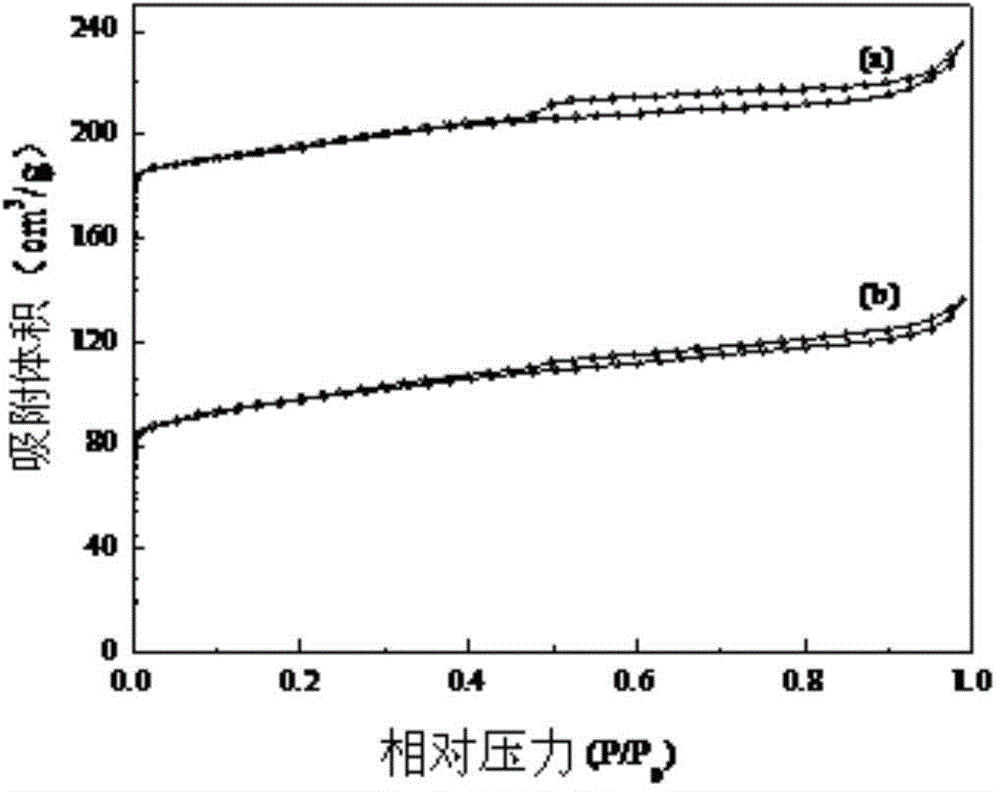

[0064] The raw materials, composition and technological process of the present embodiment are the same as those in Example 2, the difference is that the temperature is kept constant at 70 °C for 10 h, then the temperature is increased at 150 °C and the constant temperature is continued for 20 h, and the final product powder is analyzed by X-ray diffraction ( figure 1 (c)), the relative crystallinity is 101.2%, and its grain size is 200 nm. Its specific surface is 373.8m measured by low temperature nitrogen adsorption and desorption 2 / g, the total pore volume is 0.362cm 3 / g, mesoporous pore volume 0.161cm 3 / g. Infrared detection ( Figure 5 (b)), the relative content of silanols in the molecular sieve is 0.84, 3550cm -1 The peak area at 3740cm -1 The ratio of peak areas at 22:10.7. via NH 3 -TPD detection, the molecular sieve acid content is 0.24mmol / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com