Method for preparing epoxide

An epoxide and organic peroxide technology, applied in chemical instruments and methods, chemical/physical processes, organic chemistry, etc., can solve the problems of poor mass transfer effect, low catalyst activity, high production cost, and reduce manufacturing costs. , The effect of high catalyst activity and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

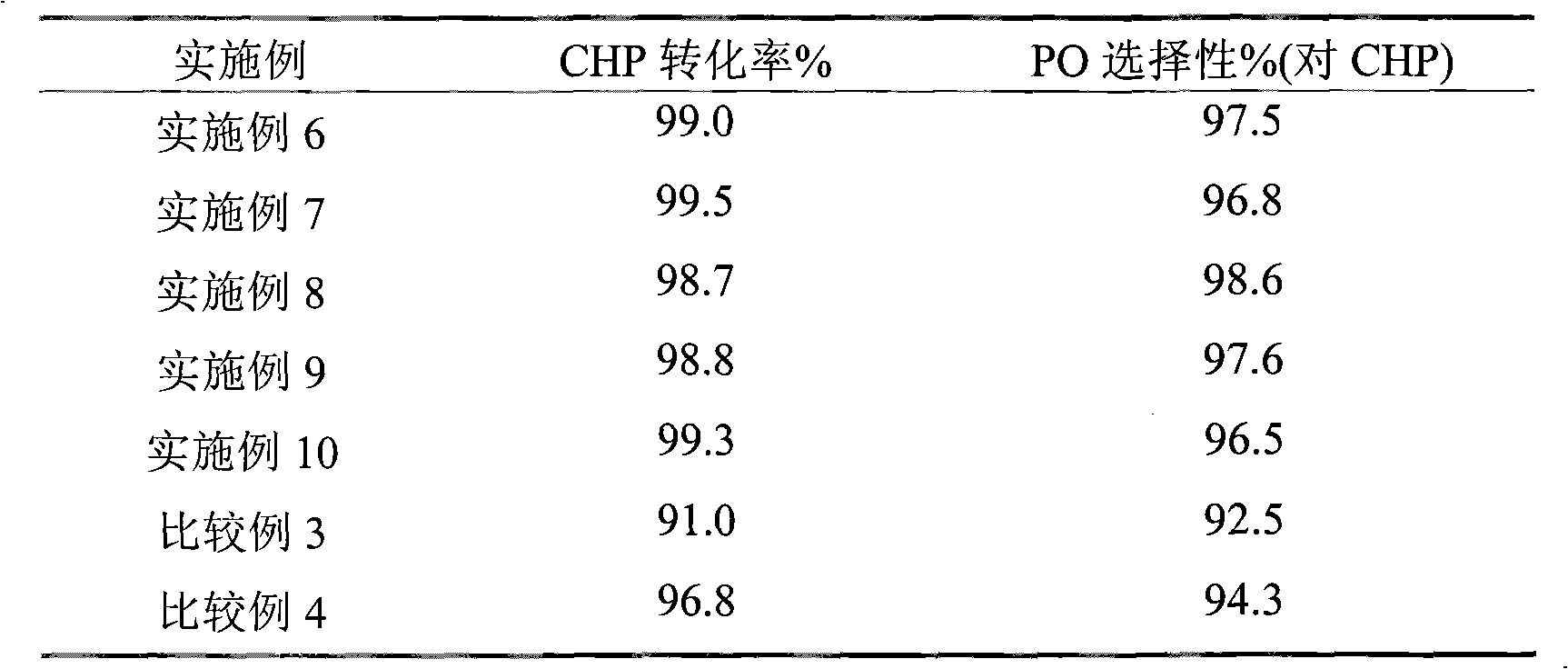

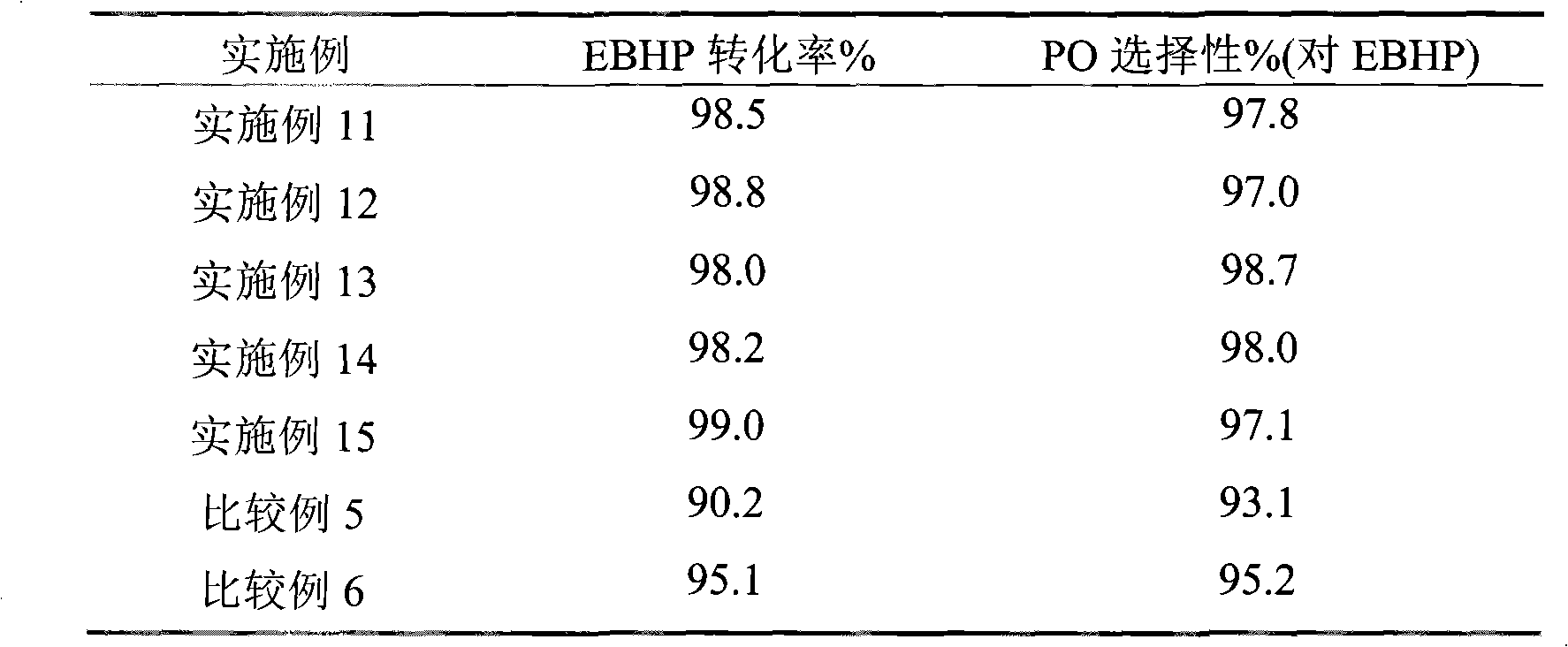

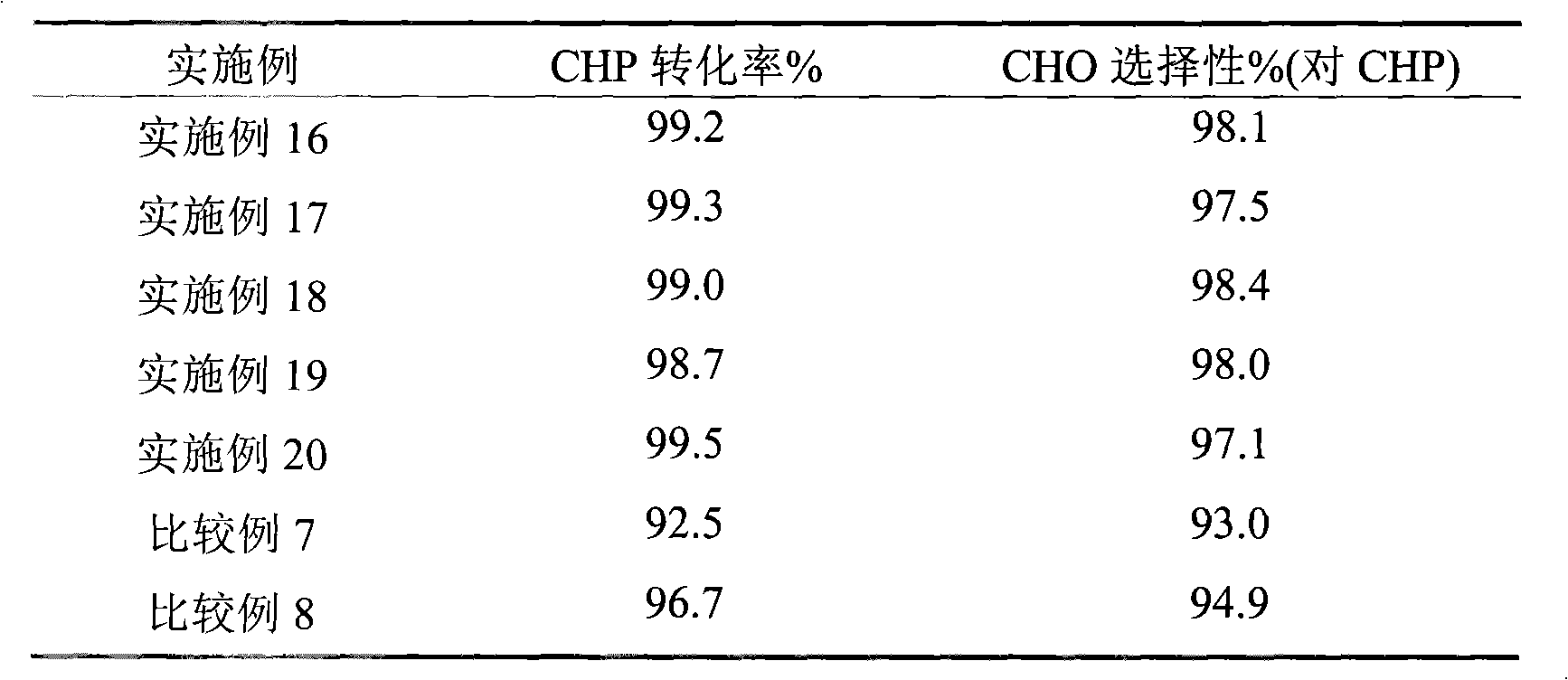

Examples

Embodiment 1

[0021] With stirring at room temperature, 10 g of hexadecylamine and 5 g of dodecylamine were added to 80 ml of H 2 O. In a mixed solution of 60 milliliters of ethanol and 5 milliliters (1M) of hydrochloric acid, stir until the solution is one phase. 65.0 g of ethyl orthosilicate dissolved in 30 ml of ethanol was added to the above mixed solution, stirred for 30 minutes and then crystallized for 24 hours. The resulting solid was filtered and washed with water to remove residual Cl - . The washed solid was dried at 110° C. for 12 hours, and then calcined at 600° C. for 4 hours to obtain HMS with a hexagonal mesoporous structure.

[0022] Press the powder sample prepared above into tablets (forming pressure is 20MPa), crush and sieve, take 10.0 grams of 20-40 mesh particles and put them into a quartz tube reactor, and dry them at 120°C for 2 hours under a nitrogen atmosphere. Raise the temperature to 300°C and dissolve 1.2 g of TiCl with nitrogen 4Saturated steam is brought ...

Embodiment 2

[0024] except TiCl 4 The amount is except 1.5 grams, and all the other conditions are identical with [embodiment 1]. The prepared Ti-HMS catalyst has a specific surface area of 800 m 2 / g, the pore volume is 0.85 cm 3 / g, the average pore diameter is

Embodiment 3

[0026] except TiCl 4 The amount is except 0.9 gram, and all the other conditions are identical with [Example 1]. The prepared Ti-HMS catalyst has a specific surface area of 850 m 2 / g, the pore volume is 0.9 cm 3 / g, the average pore diameter is

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com