Double-micropore SAPO (silicoaluminophosphate)-34/SAPO-18 composite molecular sieve, and preparation method and application thereof

A technology of SAPO-34 and SAPO-18, applied in the direction of molecular sieve and alkali exchange of phosphate, can solve the problem of catalyst deactivation, and achieve the effect of high synthesis efficiency, optimized performance and short crystallization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

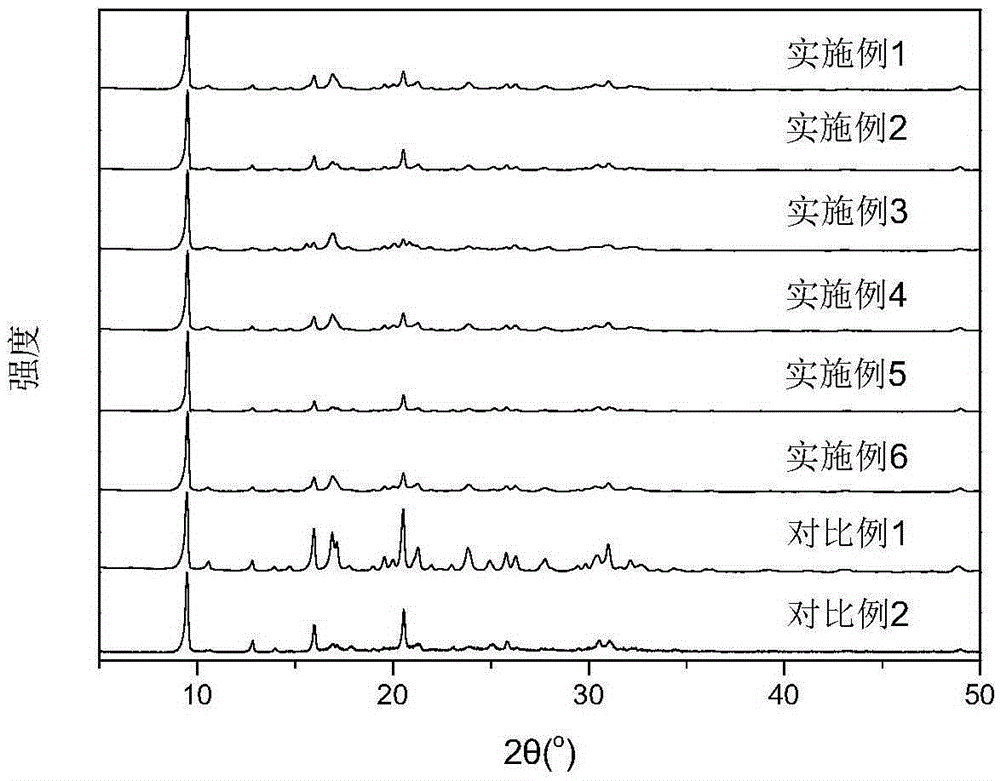

Image

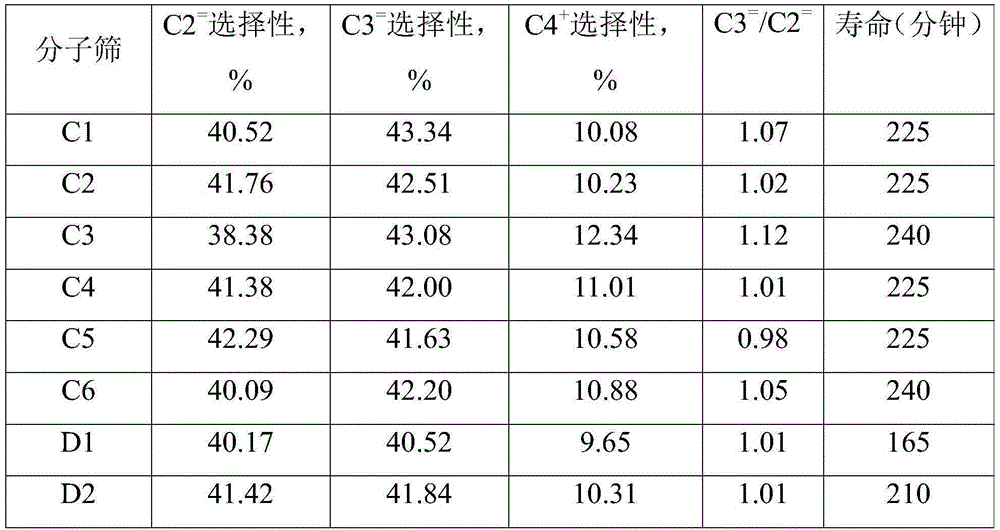

Examples

Embodiment 1

[0049] 1) 8.22g of pseudo-boehmite (alumina content 62% by weight, the same below), 11.53g of phosphoric acid (concentration of 85% by weight) and 38.88g of deionized water were mixed and stirred respectively, and after vigorous stirring for 1 hour, solidified dropwise Content is 40% by weight of silica sol 2.25g, after stirring evenly, add templating agent triethylamine (TEA) 10.12g, continue to stir for 2h, room temperature 20 ℃ aging 2h; The material molar ratio of each component in the obtained raw material mixture A is : 2TEA:0.3SiO 2 :Al 2 o 3 :P 2 o 5 :50H 2 O. Put the above-mentioned gel raw material mixture A into a reaction kettle with a polytetrafluoroethylene lining, and conduct hydrothermal pre-crystallization at 200°C for 10 hours to obtain pre-crystallization solution S1;

[0050] The pseudo-boehmite (aluminum oxide content 62% by weight, hereinafter the same) of 8.22g, 11.53g phosphoric acid (concentration 85% by weight) and 35.05g deionized water were mi...

Embodiment 2

[0053] 1) 8.22g of pseudo-boehmite, 11.53g of phosphoric acid (concentration: 85% by weight) and 6.84g of deionized water were mixed and stirred respectively, and after vigorous stirring for 1 hour, 4.50g of silica sol with a solid content of 40% by weight was added dropwise, After stirring evenly, 55.24 g of an aqueous solution of tetraethylammonium hydroxide (TEAOH) with a concentration of 20% by weight was added, stirring was continued for 2 h, and aging was performed at room temperature at 20° C. for 2 h. The molar ratio of each component in the obtained raw material mixture A is: 1.5TEAOH:0.6SiO 2 :Al 2 o 3 :P 2 o 5 :65H 2 O. Put the above-mentioned gel raw material mixture A into a reaction kettle with a polytetrafluoroethylene liner, and conduct hydrothermal pre-crystallization at 200°C for 6 hours to obtain pre-crystallization solution S1;

[0054] 8.22g of pseudo-boehmite, 10.37g of phosphoric acid (concentration 85% by weight) and 39.95g of deionized water were...

Embodiment 3

[0057] 1) 8.22g of pseudo-boehmite, 11.53g of phosphoric acid (concentration: 85% by weight) and 42.93g of deionized water were mixed and stirred respectively, and after vigorous stirring for 1 hour, 4.5g of silica sol with a solid content of 40% by weight was added dropwise, After stirring evenly, 10.12 g of template triethylamine (TEA) was added, stirring was continued for 2 h, and aging was performed at room temperature at 20° C. for 2 h. The molar ratio of each component in the resulting raw material mixture A is: 2TEA:0.6SiO 2 :Al 2 o 3 :P 2 o 5 :55H 2 O. Put the above-mentioned gel raw material mixture A into a reaction kettle with a polytetrafluoroethylene lining, and conduct hydrothermal pre-crystallization at 200°C for 10 hours to obtain pre-crystallization solution S1;

[0058]8.22g of pseudo-boehmite, 10.37g of phosphoric acid (concentration 85% by weight) and 48.95g of deionized water were mixed and stirred respectively, and after vigorous stirring for 1 hour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com