Method for synthesizing MCM-22 molecular sieve

A molecular sieve and compound technology, applied in the field of synthesis of MCM-22 molecular sieve, can solve the problems affecting the performance of molecular sieve, and achieve the effects of high product yield, short crystallization time, high product purity and crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

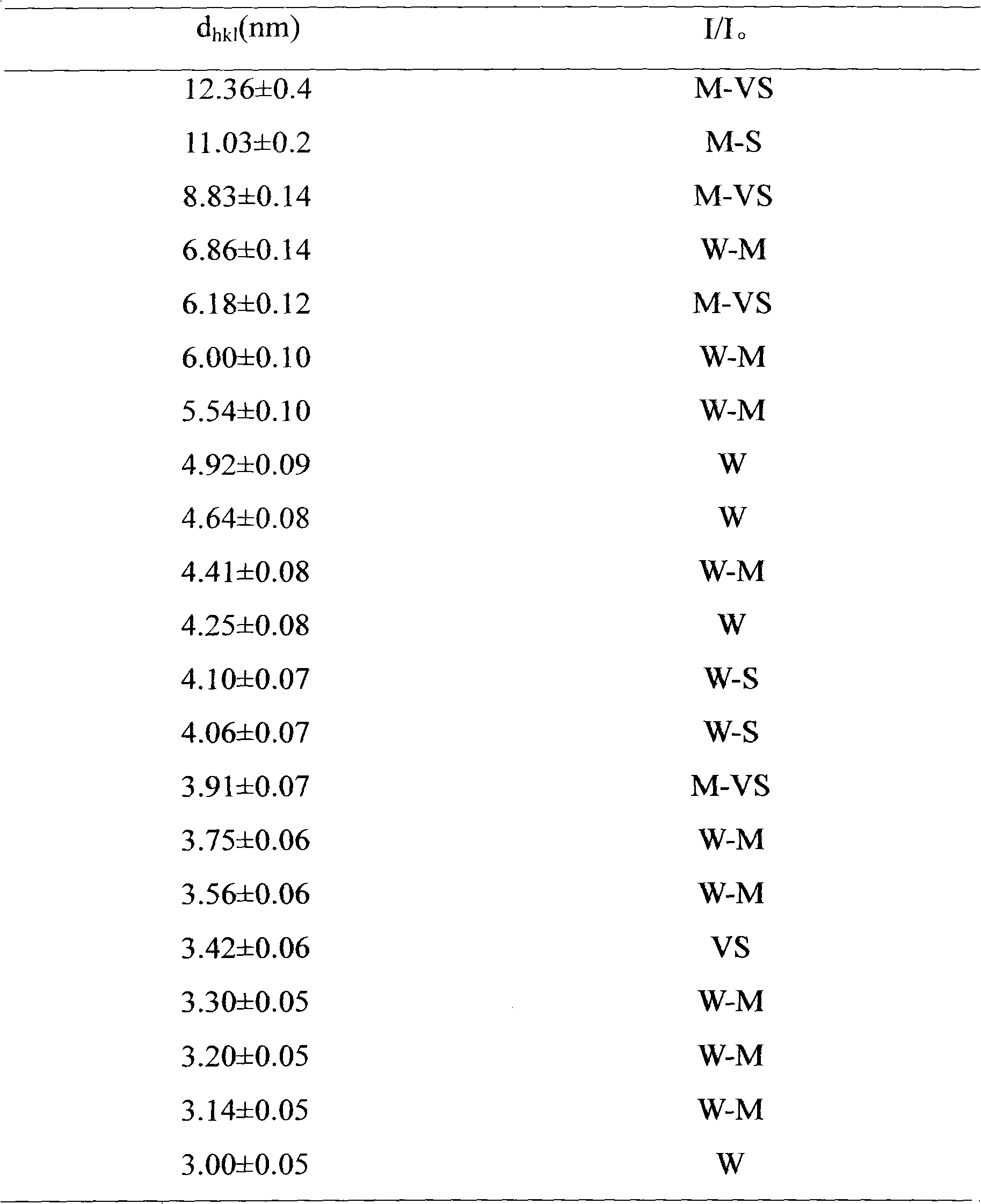

[0045] 0.71g NaAlO 2 Mix evenly with 3.18g of sodium hydroxide solution in a 100ml stainless steel reaction kettle, add 5.5g of silica gel, 69.7g of deionized water and 3.16g of HMI into the kettle in sequence while stirring, and finally add 0.275g of NaF. After continuing to stir for 10 minutes, the reaction vessel was sealed and crystallized at 110° C. for 60 h. After cooling, centrifuge the solid from the mother liquor, wash the solid with deionized water to pH 8-9, and air-dry the sample at 100°C for 8 hours to obtain the raw powder of molecular sieve, which is analyzed by X-ray diffraction (XRD) after roasting at 550°C for 4 hours It is determined that its crystal phase is MCM-22, and its relative crystallinity is 100%. Its XRD spectrum data are shown in Table 4.

Embodiment 2

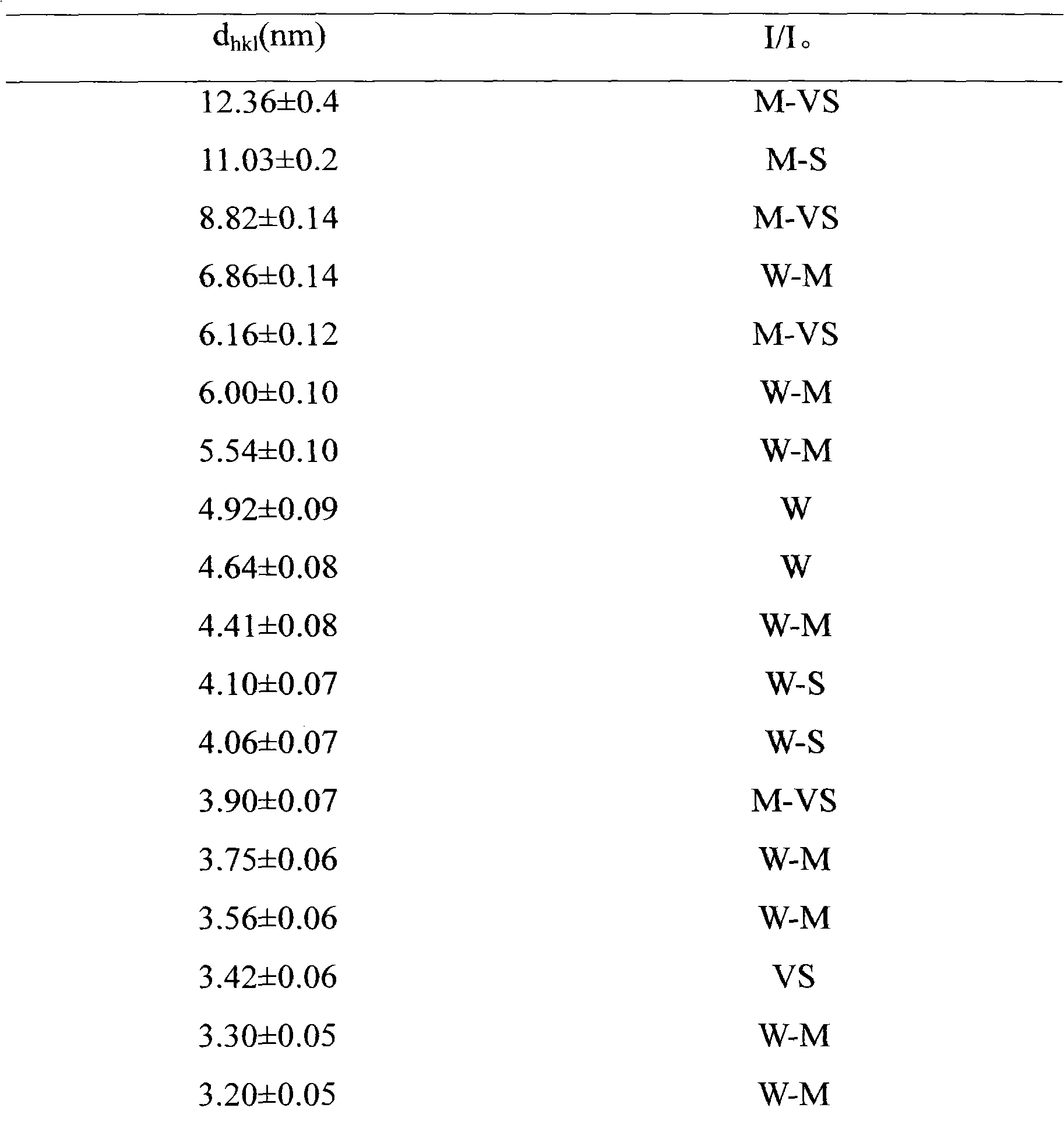

[0047] 0.284g NaAlO 2 Mix evenly with 6.01g of sodium hydroxide solution in a 100ml stainless steel reaction kettle, add 5.5g of silica gel, 59.3g of deionized water, 3.00g of HMI and 1.50g of CHA into the kettle in sequence while stirring, and finally add 0.55g of NaCl. After continuing to stir for 10 minutes, the reaction vessel was sealed and crystallized at 120° C. for 15 hours. After cooling, centrifuge the solid from the mother liquor, wash the solid with deionized water to pH 8-9, and air-dry the sample at 100°C for 8 hours to obtain the raw powder of molecular sieve, which is analyzed by X-ray diffraction (XRD) after roasting at 550°C for 4 hours It is determined that its crystal phase is MCM-22, and its relative crystallinity is 99%. Its XRD spectrum data are shown in Table 5.

Embodiment 3

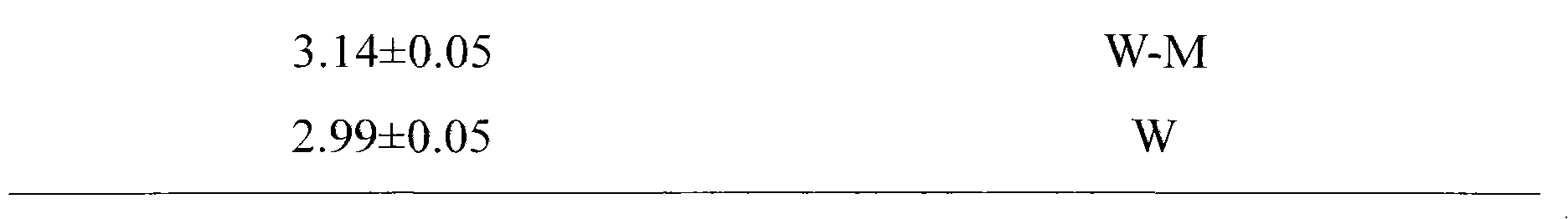

[0049] 0.284g NaAlO 2 Mix evenly with 6.01g of sodium hydroxide solution in a 100ml stainless steel reaction kettle, add 5.5g of silica gel, 59.3g of deionized water, 3.00g of HMI and 1.50g of CHA into the kettle in sequence, and finally add 1.1g of CHCl 3 . After continuing to stir for 10 minutes, the reaction vessel was sealed and crystallized at 130° C. for 20 h. After cooling, centrifuge the solid from the mother liquor, wash the solid with deionized water to pH 8-9, and air-dry the sample at 100°C for 8 hours to obtain the raw powder of molecular sieve, which is analyzed by X-ray diffraction (XRD) after roasting at 550°C for 4 hours It is determined that its crystal phase is MCM-22, and its relative crystallinity is 100%. Its XRD spectrum data are shown in Table 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com