Synthetic method of Ti-beta molecular sieve

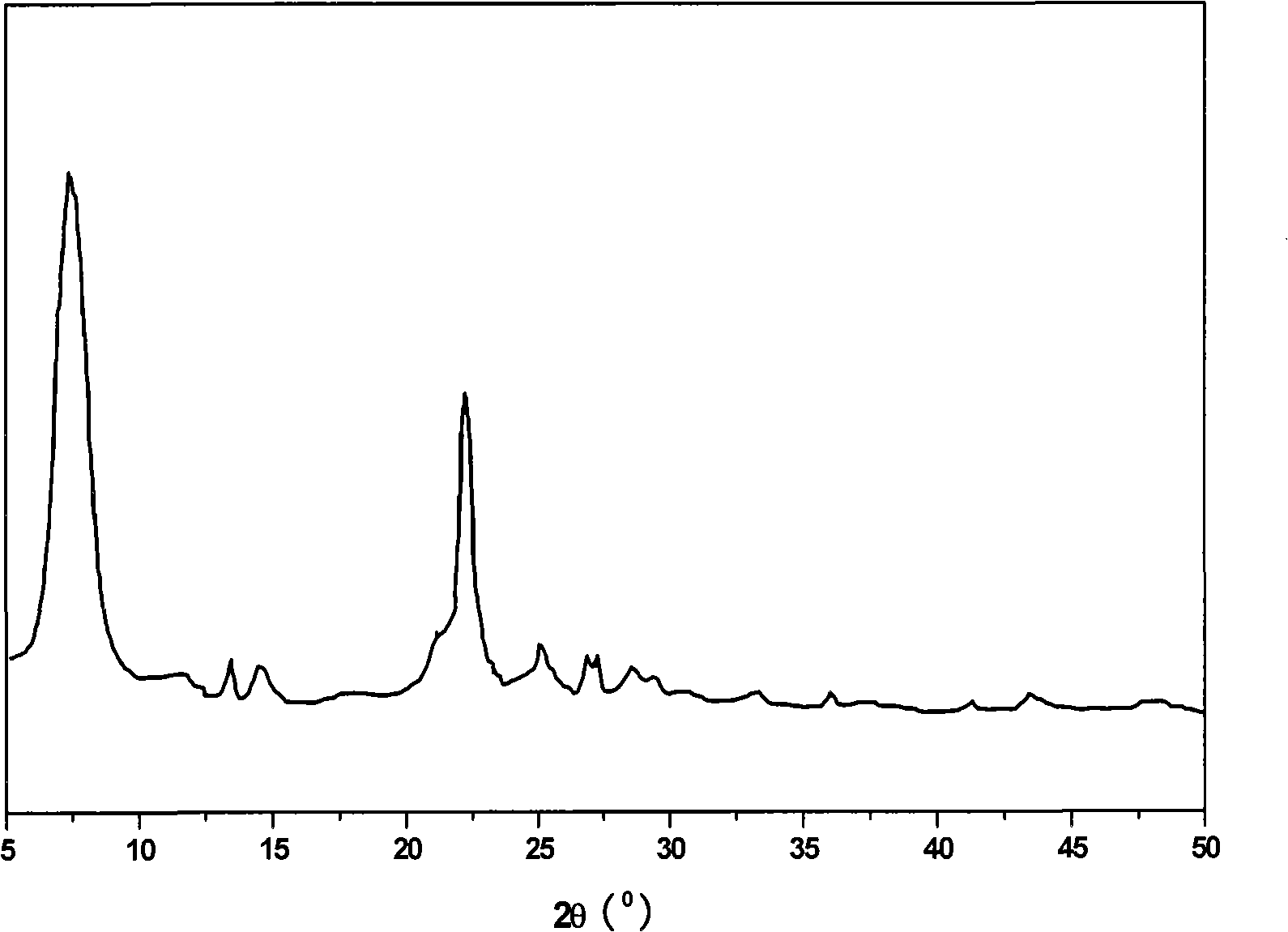

A technology of β molecular sieve and synthesis method, which is applied in the direction of crystalline aluminosilicate zeolite, etc., can solve the problems of molecular diffusion of unfavorable reactants, large amount of template agent, large grain size of Ti-β molecular sieve, etc., and achieve simple process flow and relative The effect of high crystallinity and high thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] (1) According to SiO 2 :TiO 2 : Alcohol=1:0.0125:4.0 molar ratio Mix ethyl silicate, tetrabutyl titanate and tert-butanol evenly, and then slowly add NaOH solution dropwise to it under the condition of constant stirring, so that the molar ratio in the system For: SiO 2 :TiO 2 :Na 2 O:H 2 O=1:0.0125:0.026:6.5, and after reacting at room temperature, the mixture solution was roasted at 700°C for 3 hours, and then the sample obtained after roasting was ground into small particles, washed, filtered, and dried to obtain Ti's two-dimensional layered hydrodistalite;

[0046] (2) According to SiO 2 : templating agent: water = 1: 0.5: 6.0 molar ratio will be hydrodistalite (with SiO 2 ), the template agent TEAF was mixed with water and then crystallized at 140°C for 4 days to synthesize Ti-β molecular sieve;

[0047] (3) The titanium silicon molecular sieve raw powder obtained in step (2) and the acetic acid solution of 4mol / l are prepared into a reaction mixture accordi...

Embodiment 2

[0051] (1) According to SiO 2 :TiO 2 : Alcohol=1:0.033:4.0 molar ratio Mix ethyl silicate, tetrabutyl titanate and tert-butanol evenly, and then slowly add NaOH solution dropwise therein under constant stirring, so that the molar ratio in the system For: SiO 2 :TiO 2 :Na 2 O:H 2 O=1:0.033:0.052:13.5, and after reacting at room temperature, the mixture solution was roasted at 650°C for 5 hours, and then the sample obtained after roasting was ground into small particles, washed, filtered, and dried to obtain Ti's two-dimensional layered hydrodistalite;

[0052] (2) According to SiO 2 :TEAOH:(NH 4 ) 2 SiF 6 : Water = 1: 0.95: 0.317: 8.0 molar ratio will be hydrodisoblastite (as SiO 2 meter), templating agent (TEAOH and (NH 4 ) 2 SiF 6 ) mixed with water and crystallized at 120°C for 7 days to synthesize Ti-β molecular sieve;

[0053] (3) The titanium silicon molecular sieve raw powder obtained in step (2) and 8mol / L citric acid solution are prepared in a weight rati...

Embodiment 3

[0057] (1) According to SiO 2 :TiO 2 : Alcohol = 1:0.017:6.0 molar ratio Mix ethyl silicate, tetrabutyl titanate and tert-butanol evenly, and then slowly add NaOH solution dropwise under constant stirring, so that the molar ratio in the system For: SiO 2 :TiO 2 :Na 2 O:H 2 O=1:0.017:0.037:10.5, and after reacting at room temperature, the mixture solution was roasted at 750°C for 3 hours, and then the sample obtained after roasting was ground into small particles, washed, filtered, and dried to obtain Ti's two-dimensional layered hydrodistalite;

[0058] (2) According to SiO 2 :TEAOH:HF:Water=1:0.1:0.15:2.0

[0059] The molar ratio of hydrodistalite (as SiO 2 ), templating agents (TEAOH and HF) were mixed with water and then dynamically crystallized at 170°C for 2 days to synthesize Ti-β molecular sieves;

[0060] (3) The titanium-silicon molecular sieve raw powder obtained in step (2) and 6mol / L nitric acid solution were prepared in a weight ratio of 1:15 to prepare a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com