Preparation method of small grain ZSM-35 molecular sieve

A technology of ZSM-35 and molecular sieve, which is applied in the direction of molecular sieves and alkali exchange compounds, chemical instruments and methods, crystalline aluminosilicate zeolites, etc. It can solve the problems of not being able to obtain molecular sieve products in a simple way, environmental impact, and increased production costs. , to achieve good catalytic stability, uniform particle size and small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

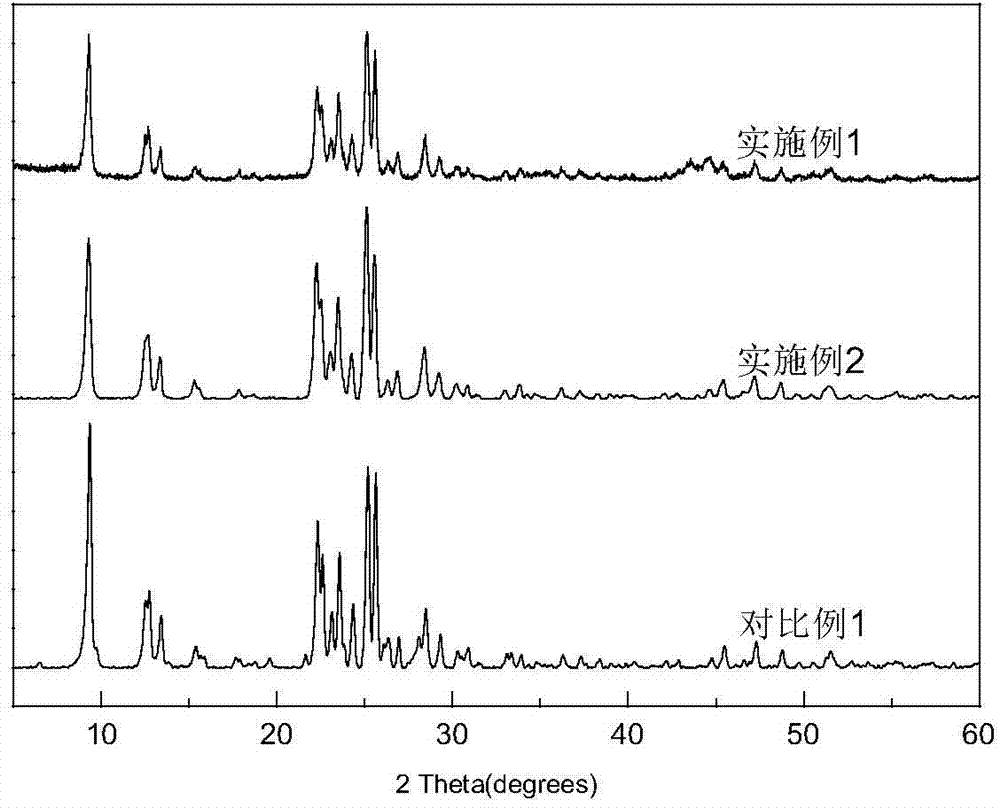

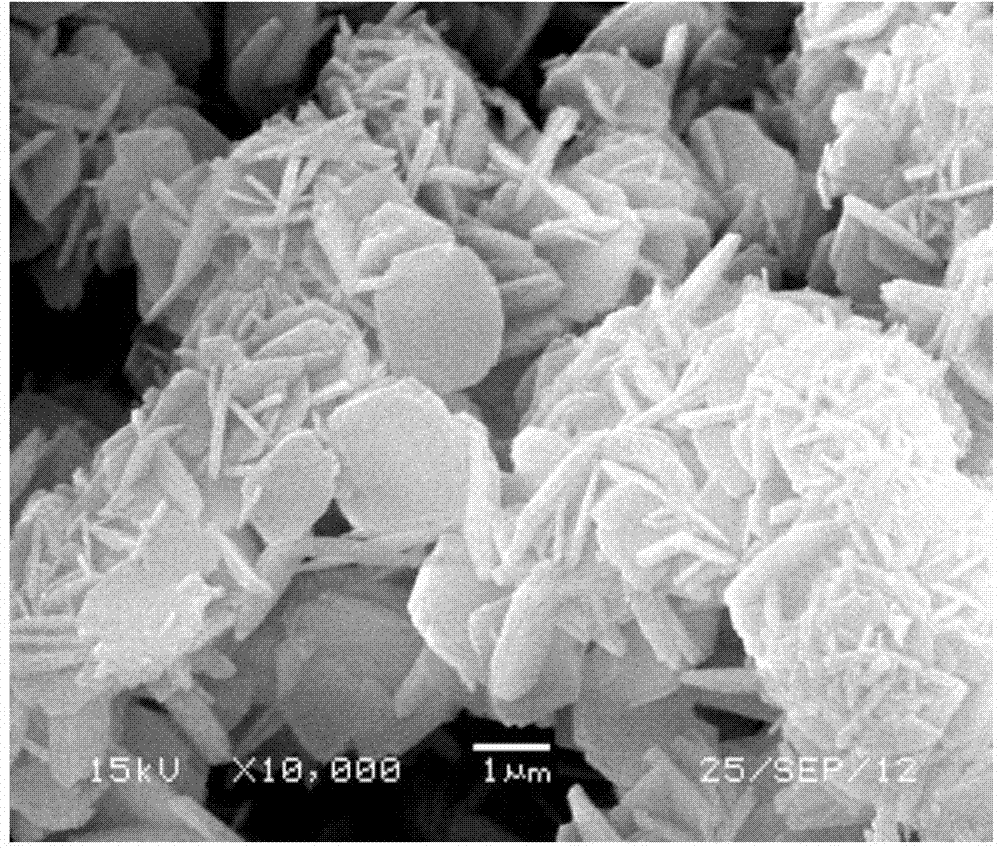

Embodiment 1

[0032] Weigh 0.27g of sodium hydroxide (produced by Shenyang Xinxing Reagent Factory, analytically pure solid sodium hydroxide) and add it to 30.44g of deionized water, stir until completely dissolved, then add 1.65g of sodium aluminate (Zibo Zhoucun Tongjie Chemical Industry Co., Ltd. Ltd. Production, Al 2 o 3 Mass content is 40%), make it dissolve completely under stirring state, stand-by as solution A; Then, 9.15g templating agent ethylenediamine (produced by Quanrui Reagent Factory, analytically pure) is added to 27.06g silica sol (Qingdao ocean Produced by Chemical Co., Ltd., SiO 2 Mass content is 25%), mix uniformly, as solution B; under stirring state, solution B is slowly added dropwise in solution A, continue to stir for 30 minutes, obtain colloidal solution; The molar ratio of each component in this colloidal solution is: SiO 2 / Al 2 o 3 =18.5, R / SiO 2 =0.81, OH - / SiO 2 =0.06,H 2 O / SiO 2 =10; Add 0.1g of ZSM-35 molecular sieve powder with a particle size o...

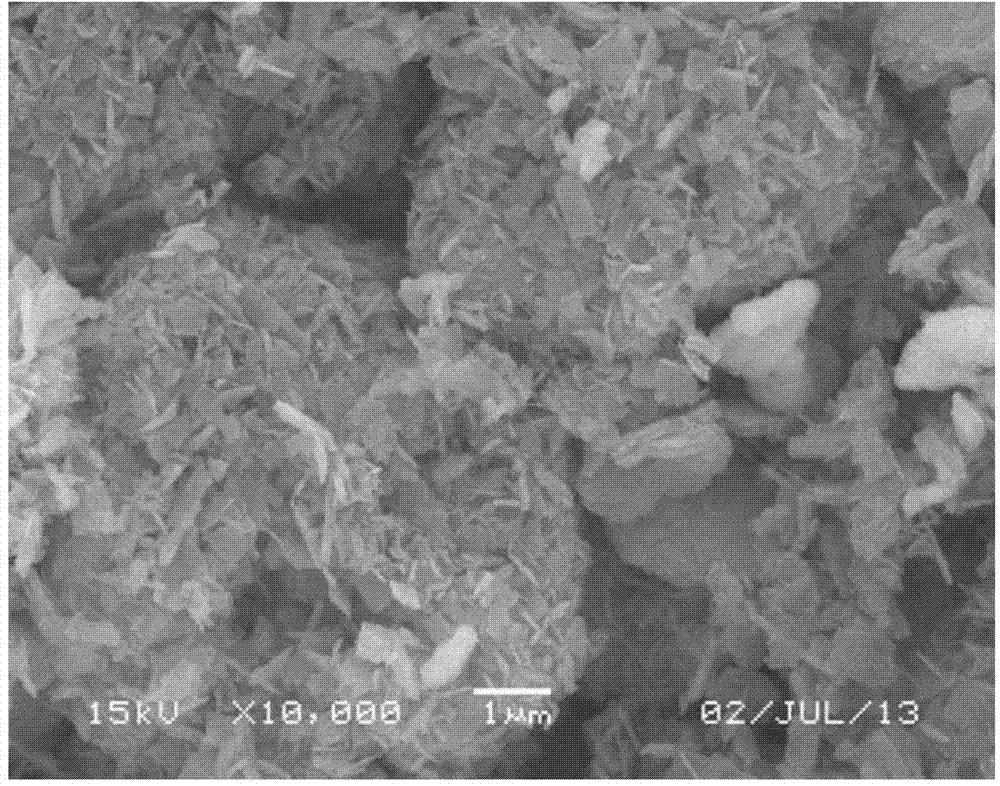

Embodiment 2

[0034] Weigh 0.27g of sodium hydroxide (produced by Shenyang Xinxing Reagent Factory, analytically pure solid sodium hydroxide) and add it to 53.9g of deionized water, stir until completely dissolved, then add 1.65g of sodium aluminate (Zibo Zhoucun Tongjie Chemical Co., Ltd. Produced by the company, Al 2 o 3 Mass content is 40%), make it dissolve completely under stirring state, stand-by as solution A; Then, 9.15g ethylenediamine (produced by Quanrui Reagent Factory, analytically pure) is added to 27.06g silica sol (Qingdao Ocean Chemical Co., Ltd. Produced by the company, SiO 2 Mass content is 25%), mix uniformly, as solution B; Under stirring state, solution B is slowly added dropwise in solution A, continue to stir for 0.5 hour, obtain colloidal solution; The molar ratio of each component in this colloidal solution is: SiO 2 / Al 2 o 3 =18.5, R / SiO 2 =0.81, OH - / SiO 2 =0.06,H 2 O / SiO 2 =26. The colloidal solution was crystallized in a high-pressure crystallizati...

Embodiment 3

[0036] In Example 2, only the heating process of crystallization was changed, from room temperature to 80°C at a rate of 1°C / min, kept for 10 hours, then heated to 180°C at a rate of 4°C / min, and crystallized for 20 hours, other The condition remains unchanged, and the ZSM-35 molecular sieve is obtained, the grain size of which is about 1-3 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com