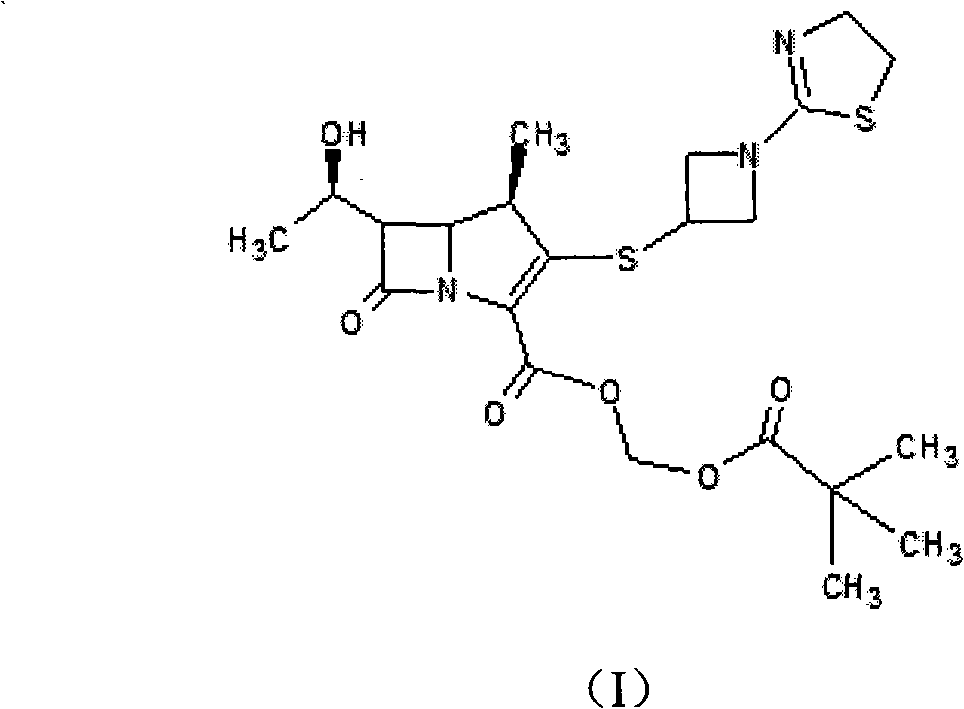

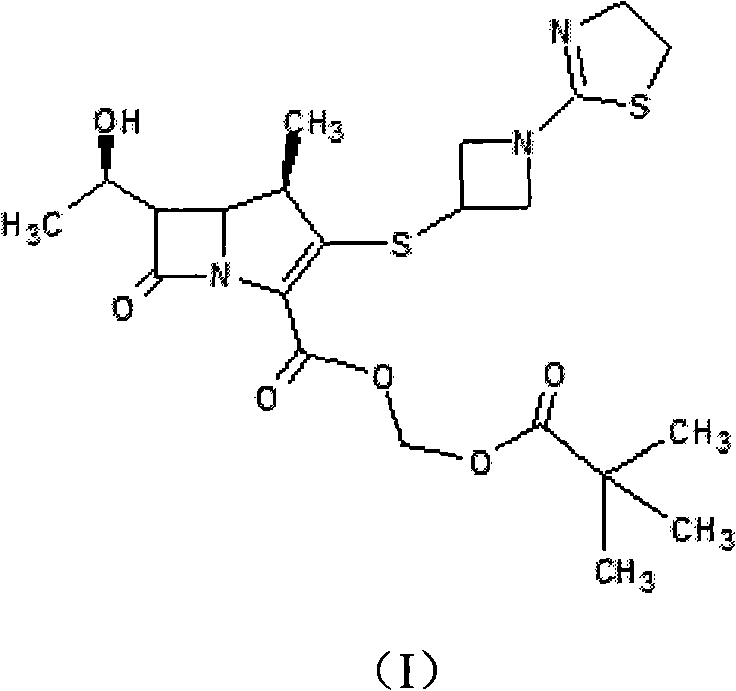

A kind of recrystallization refining method of tipipenem ester

A technology of tipipenem pivoxil and a refining method, which is applied in the field of refining the raw material drug tipipenem pivoxil, can solve the problems of low recrystallization yield, slow crystallization, and long melting range of the product, and achieve recrystallization High yield, short crystallization time and short melting range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The preparation of embodiment 1 formula (I) compound crude product

[0019] Add 70g of tipipenem tetrahydrate, 70g of TEBAC (triethylbenzyl ammonium chloride), 40g of diisopropylethylamine, and 250ml of DMF (dimethylformamide) into the 1000ml reaction bottle, stir to dissolve, Under the protection of nitrogen, 50ml of chloromethyl pivalate was added dropwise, and the temperature was kept at 45°C for 5 hours to react. After completion, the reaction solution was cooled to room temperature, 200 ml of ethyl acetate and 200 ml of water were added, the pH value was adjusted to 4.0±0.1 with 1N citric acid, the liquids were separated, the aqueous phase was washed three times with 200 ml of ethyl acetate, and the organic phase was discarded. The pH value of the aqueous phase was adjusted to 7.6 ± 0.1 with potassium carbonate solution. Extract three times with 200ml ethyl acetate, combine the organic layers, wash three times with 200ml saturated NaCl solution. The organic phase...

Embodiment 2

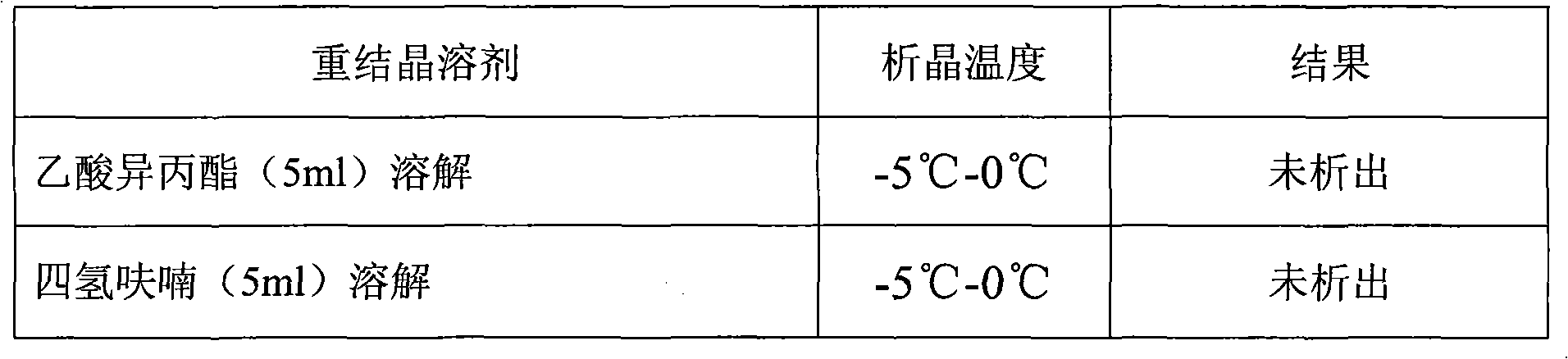

[0020] The recrystallization purification of embodiment 2 formula (I) compound crude product

[0021] The recrystallization method is as follows: dissolve 50 g of the crude product in acetone, add isopropyl ether dropwise, stir while adding dropwise, continue to stir and crystallize for a period of time after the dropwise addition, filter under reduced pressure to obtain a white solid, and vacuum drum the solid at 50°C Wind dry. The specific process conditions and test results are shown in the table below:

[0022] volume of acetone

Crystallization temperature

Crystallization time

Rotating speed

yield

HPLC purity

50ml

50ml

0℃

5 hours

10rpm

75.3%

140~142℃

99.90%

100ml

200ml

20℃

2 hours

20rpm

82.8%

140~142℃

99.96%

100ml

300ml

20℃

0.5 hours

40rpm

76.6%

140~141℃

9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com