Preparation method of titanium-silicate molecular sieve having large particle size

A technology of titanium-silicon molecular sieve and large particle size, which is applied in molecular sieves and alkali exchange compounds, chemical instruments and methods, crystalline aluminosilicate zeolites, etc., and can solve the problems of separation and recovery of difficult products of small particle size titanium-silicon molecular sieves, etc. Achieve the effects of simple operation, easy process control, and short crystallization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

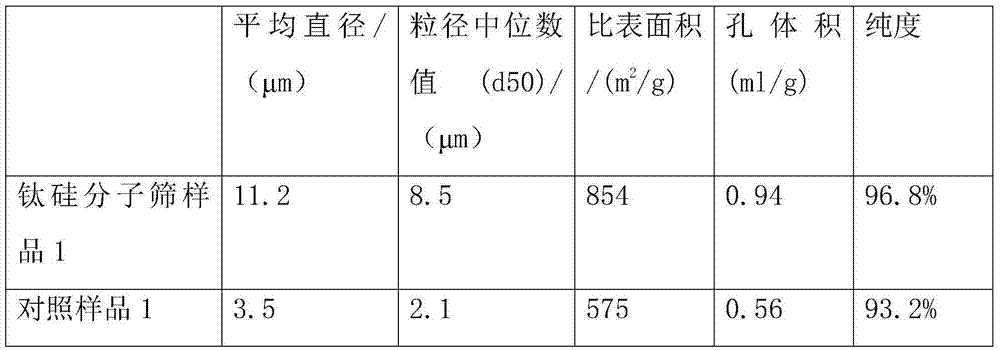

Examples

preparation example Construction

[0034] The invention provides a preparation method of a large-diameter titanium-silicon molecular sieve, which is characterized in that it comprises the following preparation process:

[0035] (1) Preparation of the mixed solution:

[0036] At room temperature, slowly add the organic template aqueous solution to the inorganic silicon source. After the addition, stir for 0.5-2 hours to obtain the initial mixed solution; then add the inorganic titanium source to the initial mixed solution. After the addition, fully stir for 0.5-2 hours. 5h to obtain a mixed solution; the molar ratio of inorganic silicon source, inorganic titanium source, organic template and water in the mixed solution is 1:(0.013~0.025):(0.025~0.2):(30~60), wherein the inorganic silicon source SiO 2 In terms of inorganic titanium source as TiO 2 Wherein, the preferred molar ratio of inorganic silicon source, inorganic titanium source, organic templating agent and water in the mixed solution is 1: (0.015~0.02)...

preparation example 1

[0047] Slowly add tetrapropyl ammonium hydroxide aqueous solution to 12.1g silica sol (SiO 2 content is 30%), after stirring for 30 minutes, slowly add titanium trichloride solution, and stir for 1 hour to obtain a mixed solution. Wherein the molar ratio of silica sol, titanium trichloride, tetrapropylammonium hydroxide and water in the mixed solution is 1:0.018:0.1:40.

Embodiment 1

[0051] At a mixing temperature of 60°C, first slowly add tetrapropylammonium hydroxide aqueous solution to 6.8g of tetraethyl silicate, stir well for 1 hour to obtain component A; then add isopropanol to tetraethyl titanate After mixing evenly, component B is obtained; slowly add component B to component A, and after fully stirring for 30 minutes, the preparation solution is obtained. In the preparation solution, tetraethyl silicate, tetraethyl titanate, tetrapropyl The molar ratio of ammonium hydroxide, isopropanol and water is 1:0.02:0.2:1.0:30.

[0052] The preparation solution was added into a sealed reaction kettle, and the preparation solution was hydrothermally crystallized at a crystallization temperature of 170°C and a crystallization time of 4 days; then the preparation solution was filtered to obtain the first filter cake, and the first filter cake was washed to Neutral, and vacuum-dry the first filter cake at 120°C for 10 hours to obtain a crystalline material;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com