Patents

Literature

130 results about "SSZ-13" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

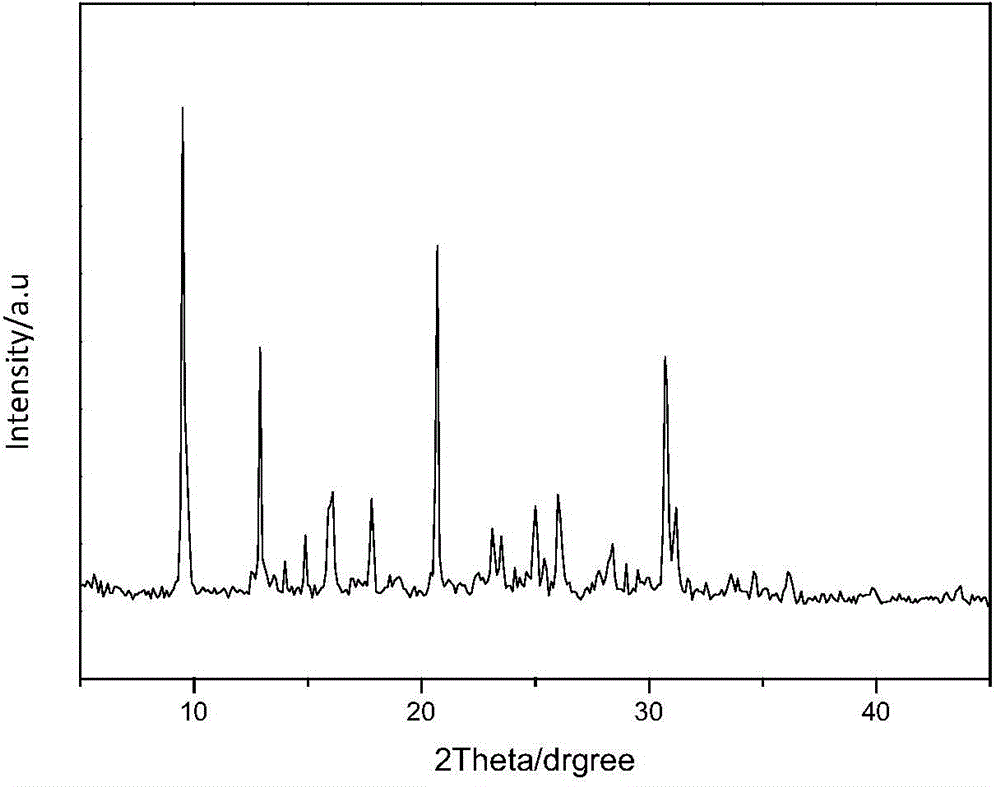

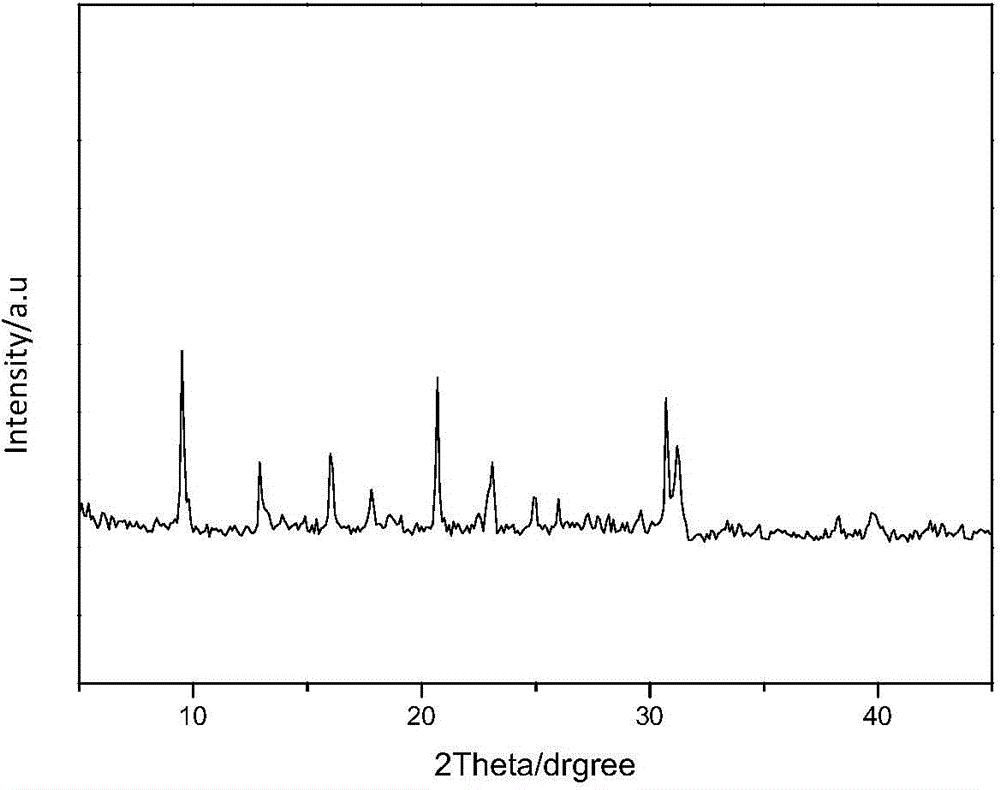

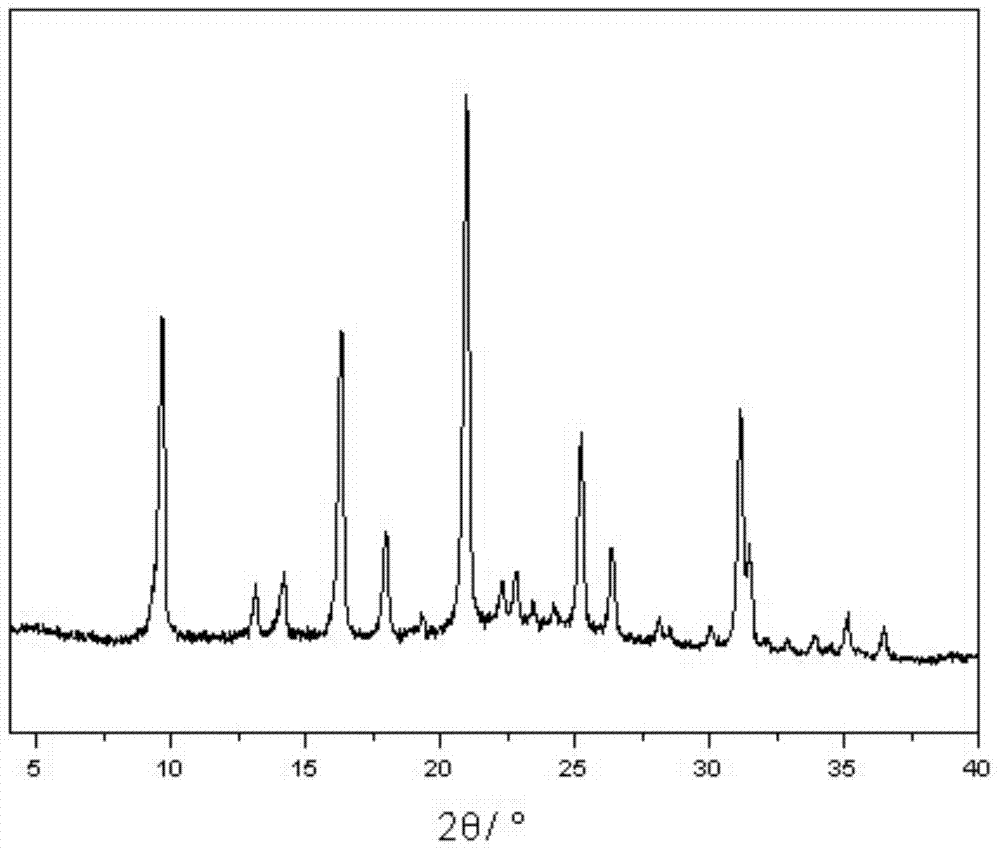

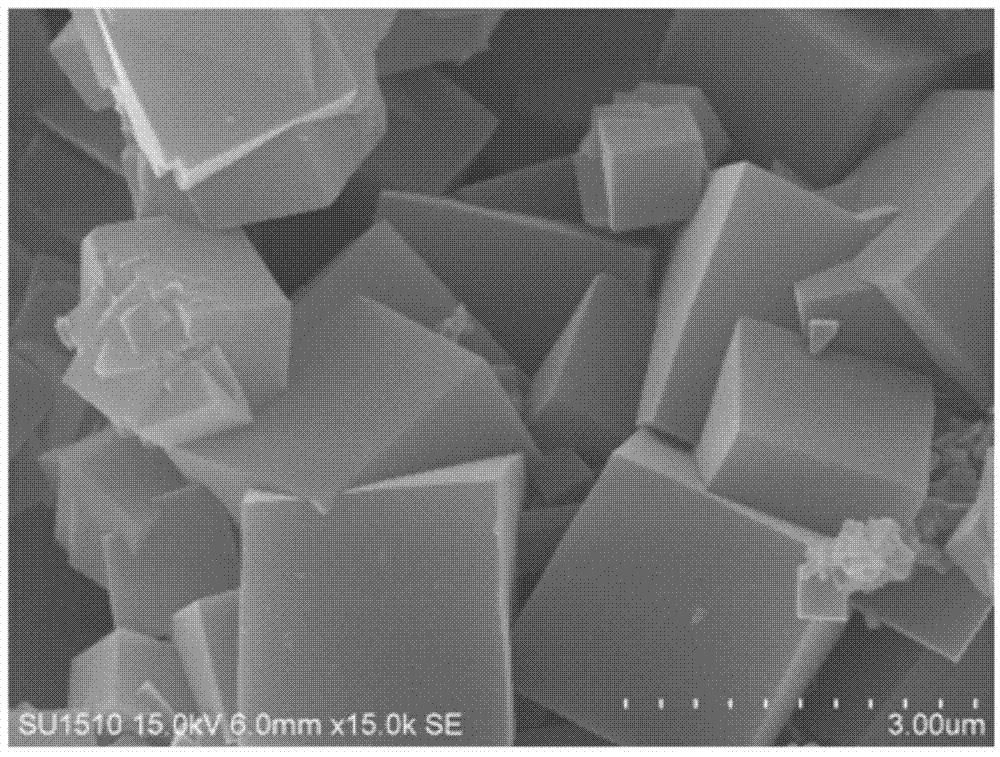

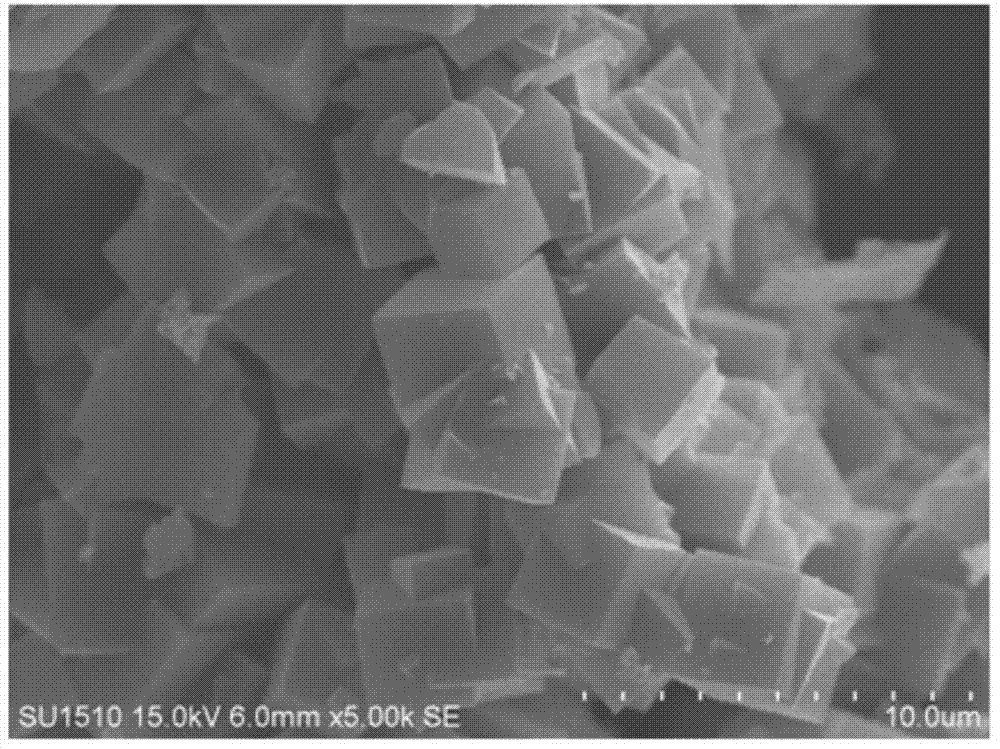

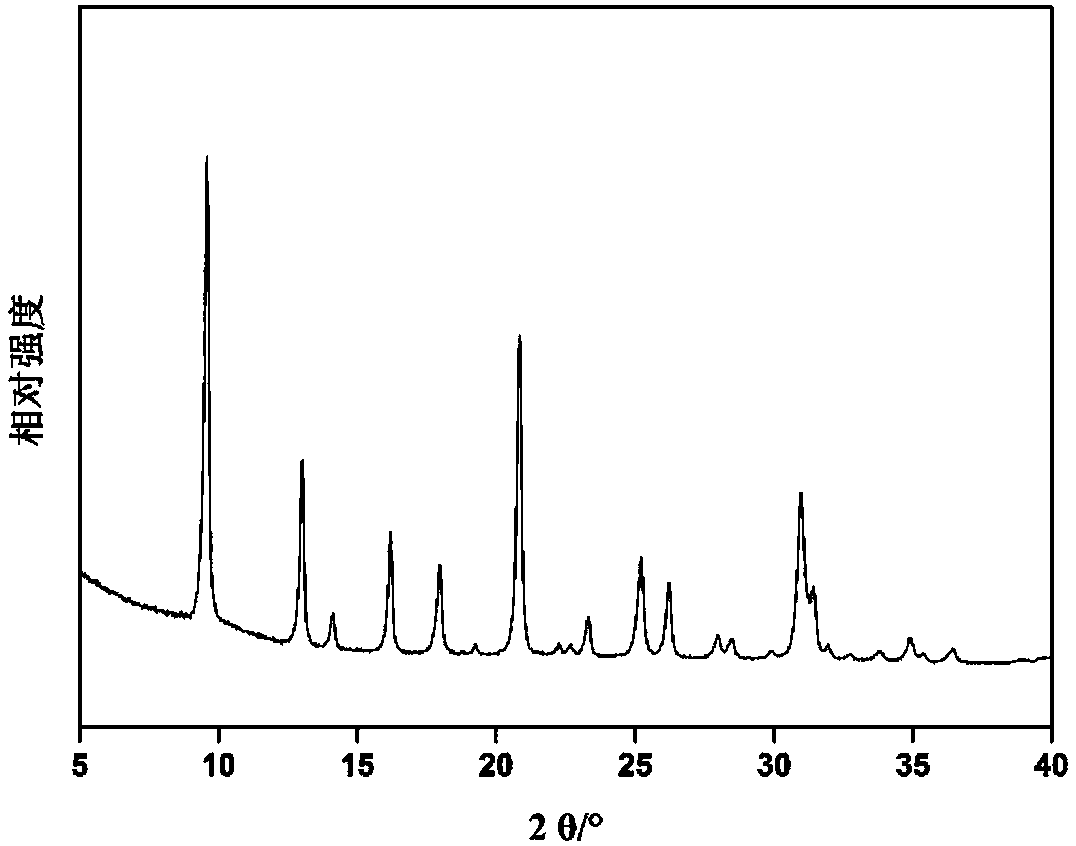

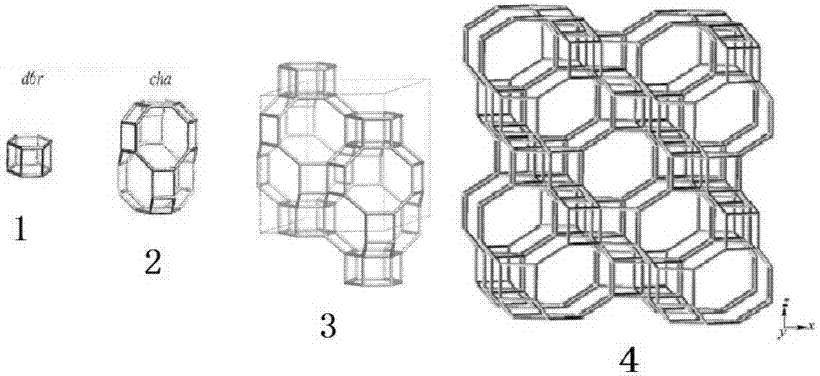

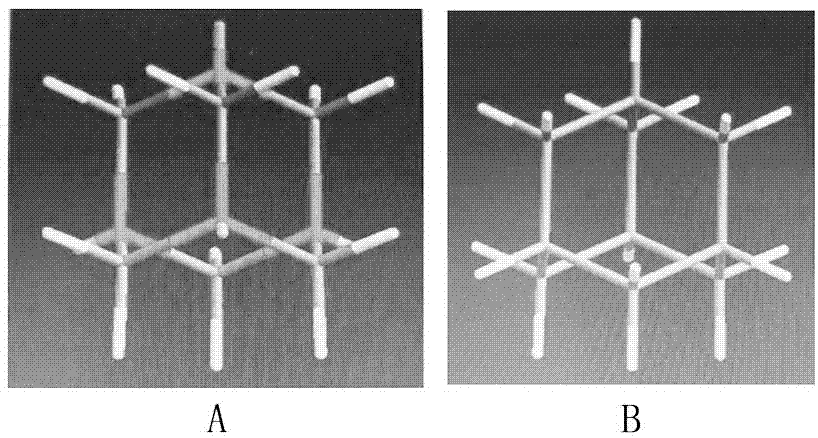

SSZ-13 (framework type code CHA) is an aluminosilicate zeolite mineral possessing 0.38 × 0.38 nm micropores. It belongs to the ABC-6 family of zeolites as well as offretite, cancrinite, erionite and other related minerals. The framework topology is the same as that of chabazite but SSZ-13 has high-silica composition with Si/Al > 5 which leads to low cation exchange capacity. The typical chemical formula of the unit cell can be described as QₓNayAl2.4Si33.6O₇₂•zH₂O (1.4 < x <27)(0.7 < y < 4.3)(1 < z <7), where Q is N,N,N-1-trimethyladamantammonium. The material was patented by Chevron research Company in 1985, and has a potential use as a solid catalyst for the methanol-to-olefins (MTO) process and the selective catalytic reduction (SCR) of NOx.

Mixed matrix membrane with mesoporous particles and methods for making and using the same

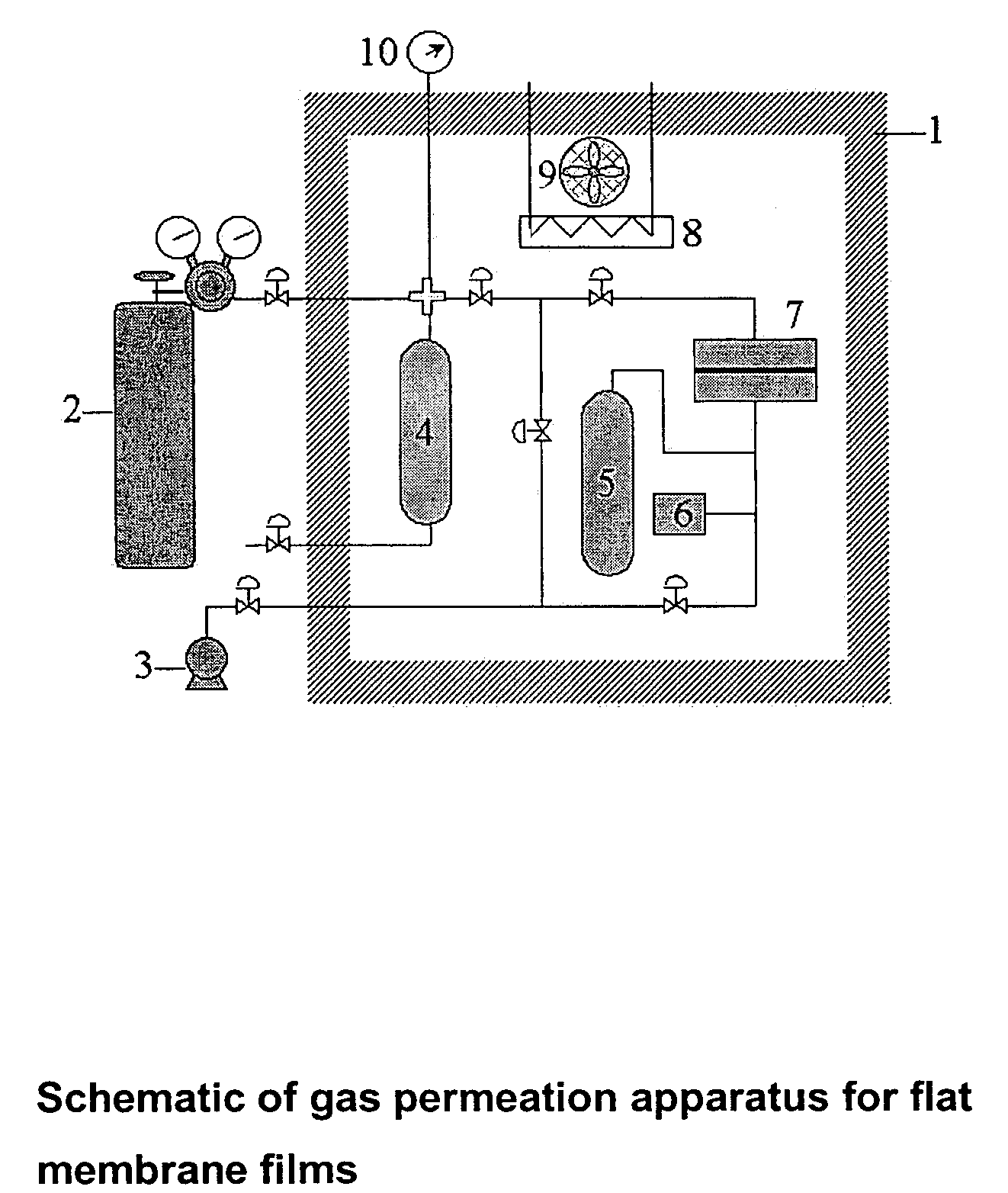

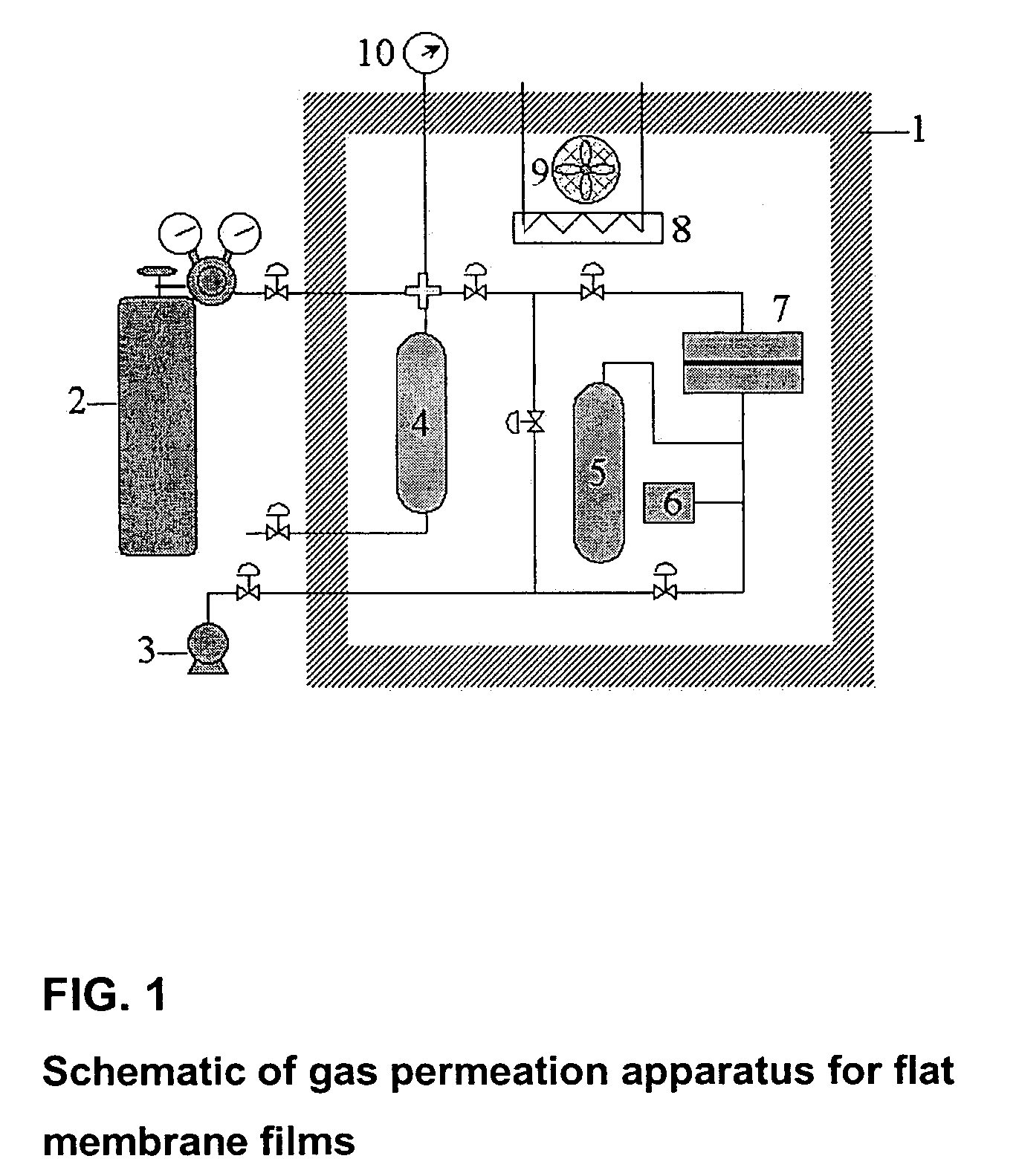

InactiveUS20060107830A1More productivity per unit costImprove the level ofSemi-permeable membranesIsotope separationPorous particleMembrane configuration

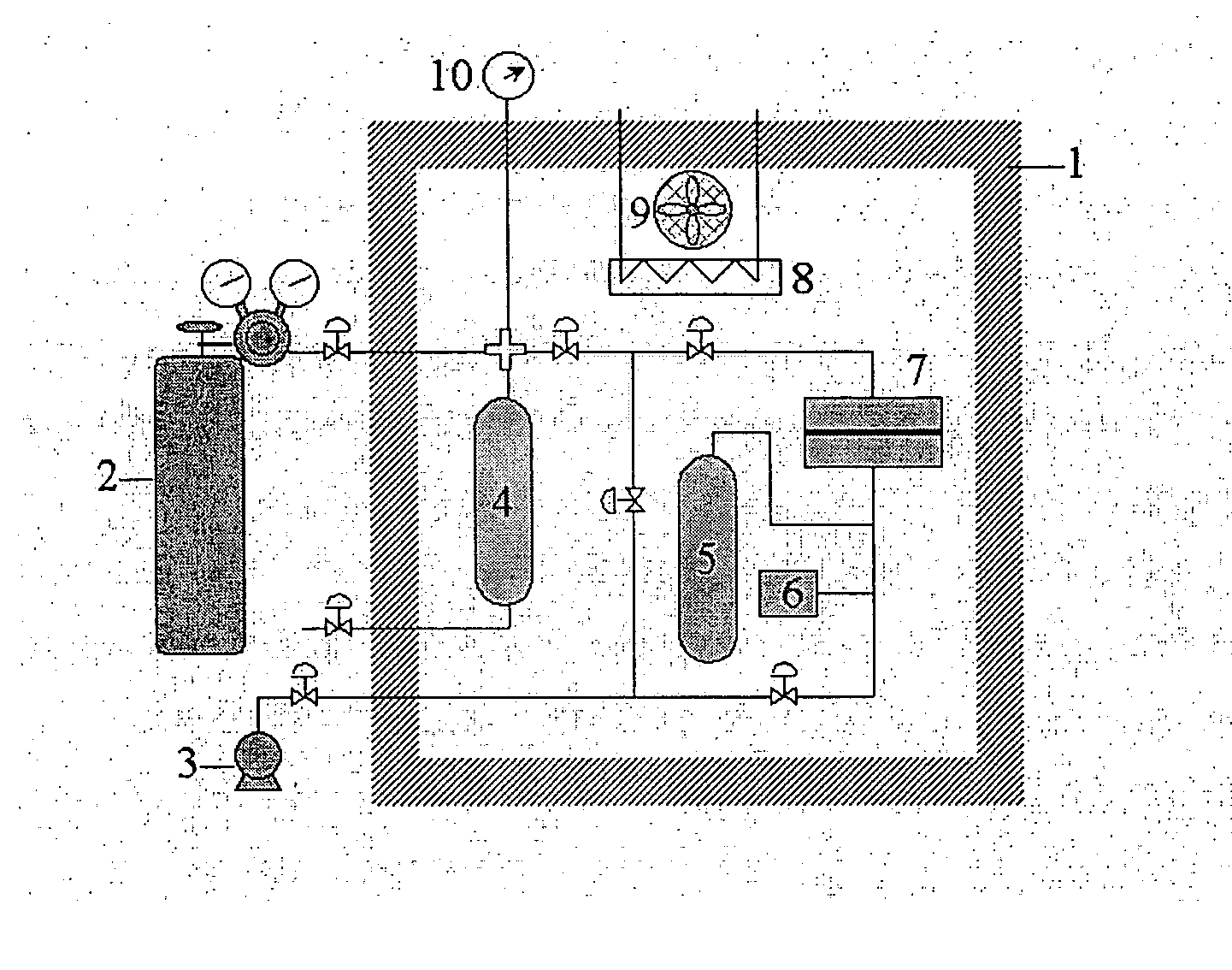

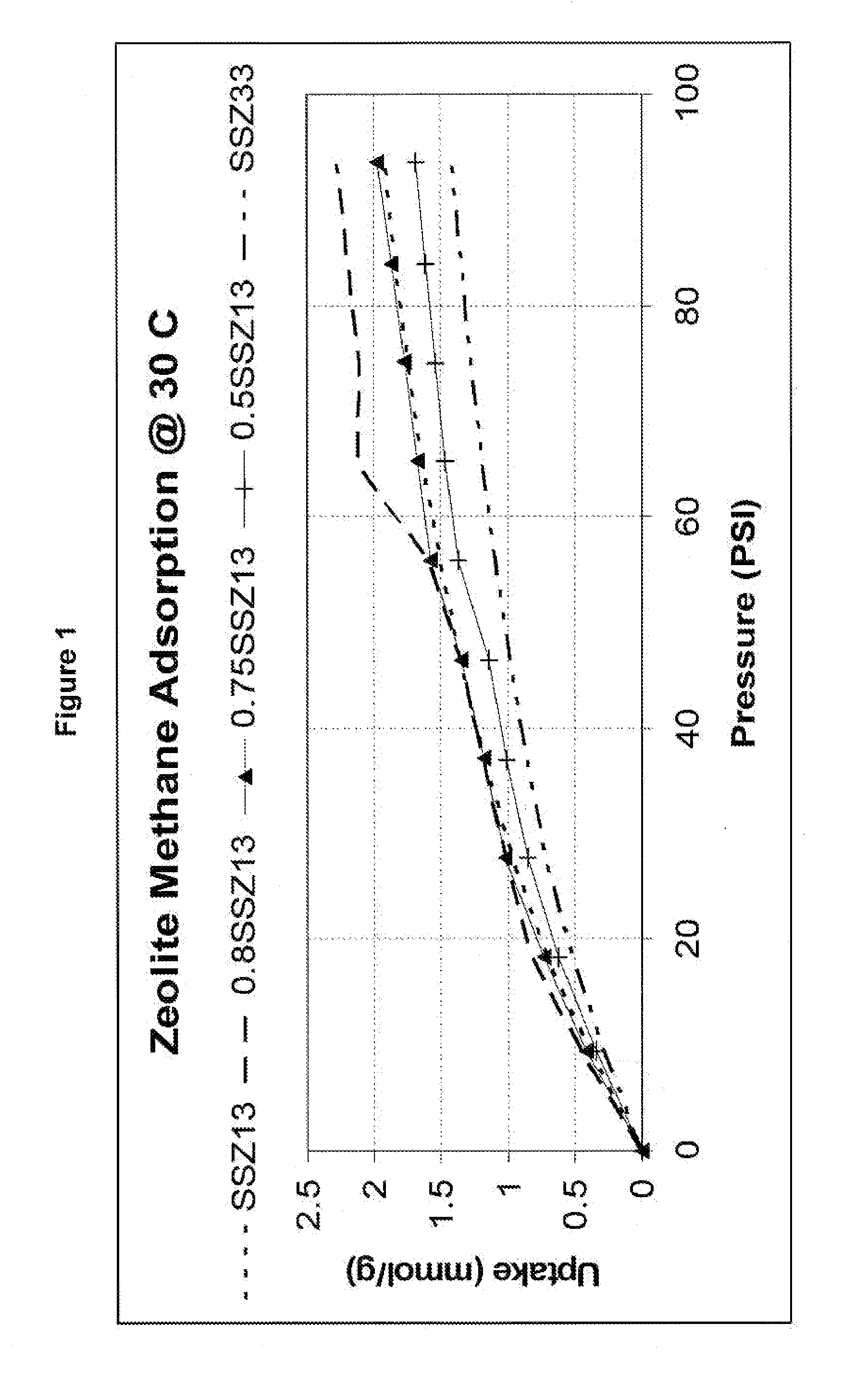

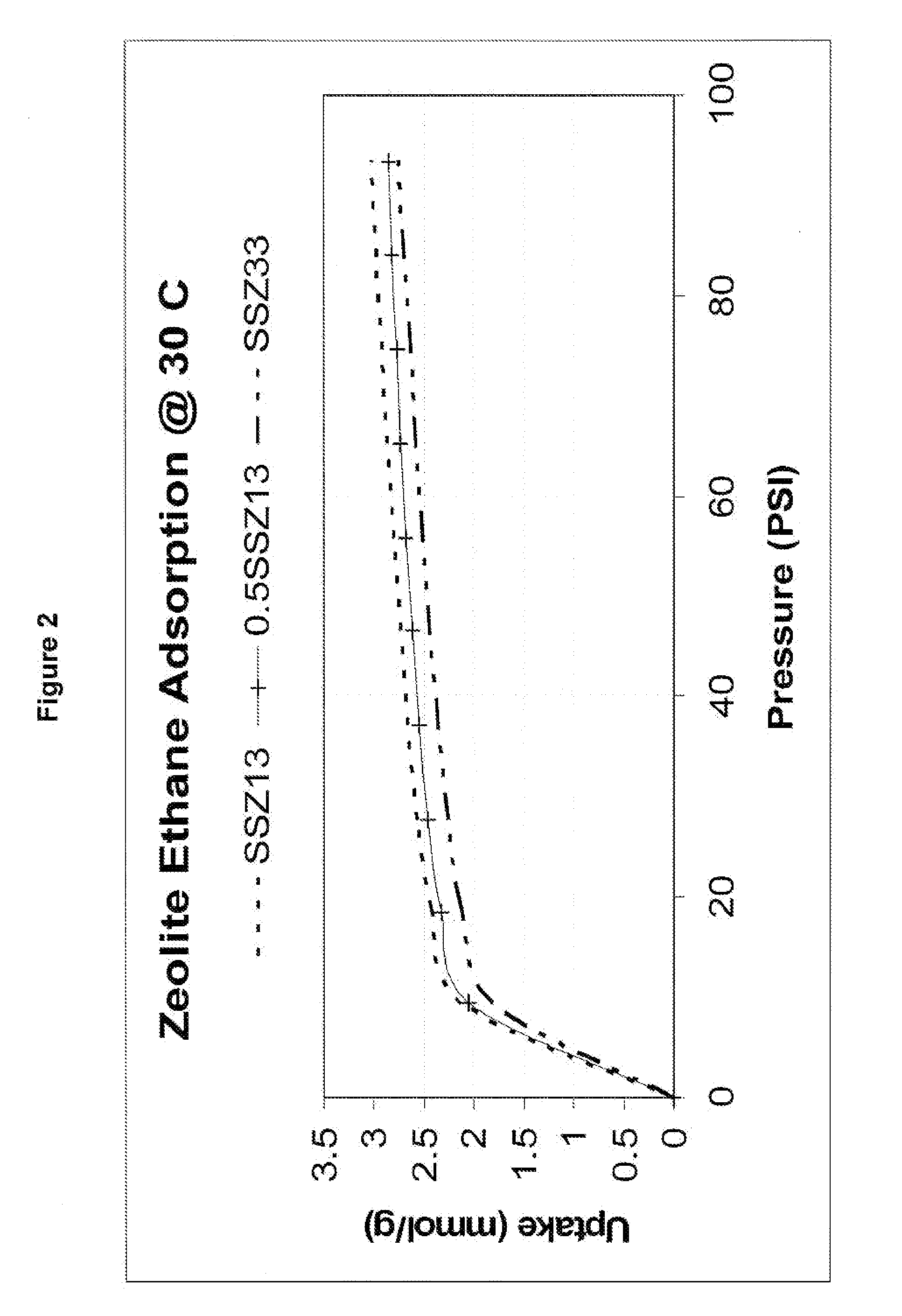

A mixed matrix membrane for separating gas components from a mixture of gas components is disclosed. The membrane comprises a continuous phase polymer with inorganic porous particles, preferably molecular sieves, interspersed in the polymer. The polymer has a CO2 / CH4 selectivity of at least 20 and the porous particles have a mesoporosity of at least 0.1 cc STP / g. The mixed matrix membrane exhibits an increase in permeability of least 30% with any decrease in selectivity being no more than 10% relative to a membrane made of the neat polymer. The porous particles may include, but are not limited to, molecular sieves such as CVX-7 and SSZ-13, and / or other molecular sieves having the required mesoporosity. A method for making the mixed matrix membrane is also described. Further, a method is disclosed for separating gas components from a mixture of gas components using the mixed matrix membrane with mesoporous particles.

Owner:CHEVROU USA INC

Molecular sieve based catalyst used for low-temperature SCR denitration and its preparation method

InactiveCN103599813AHigh low temperature activityGood choiceMolecular sieve catalystsDispersed particle separationSulfurNitrogen oxide

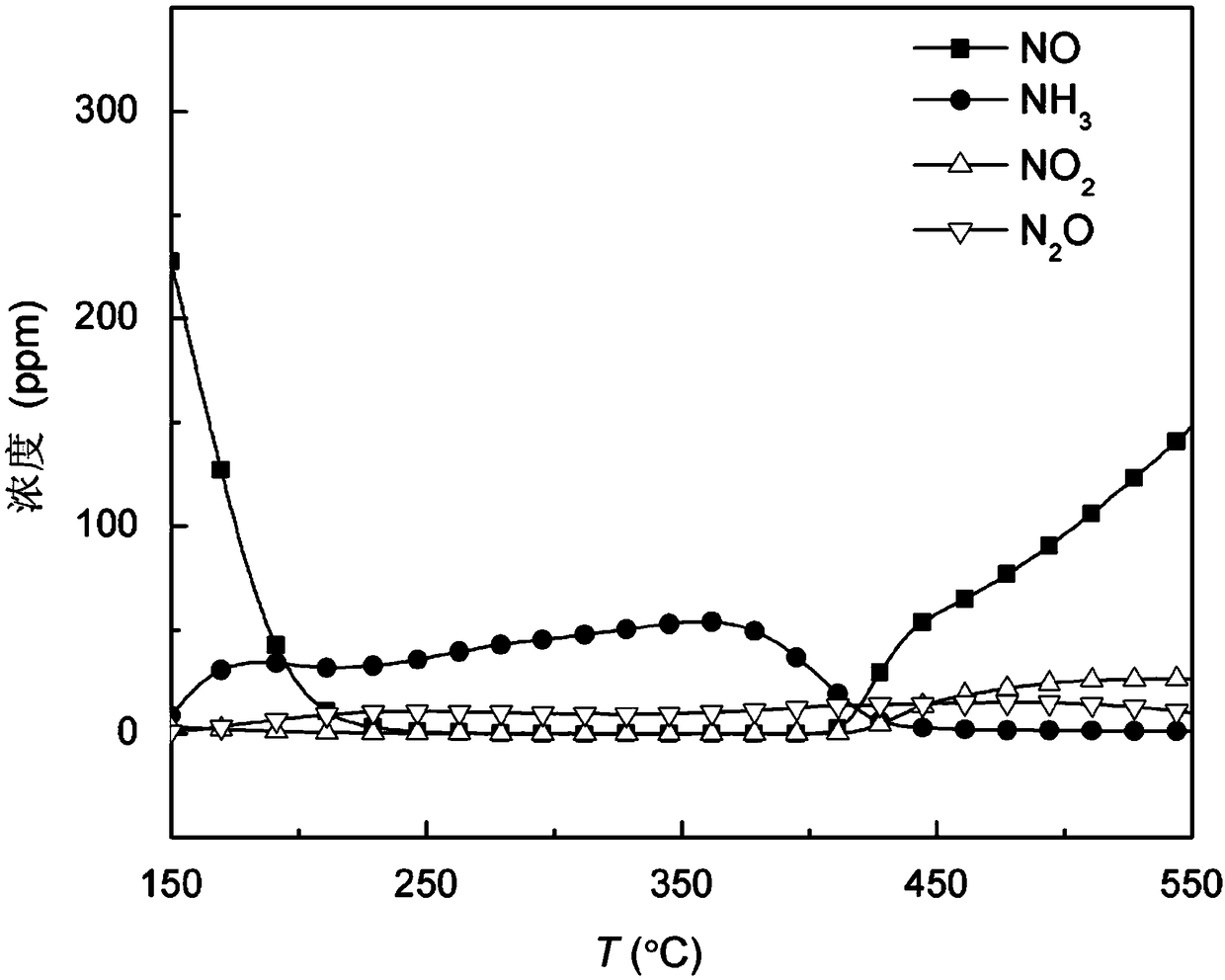

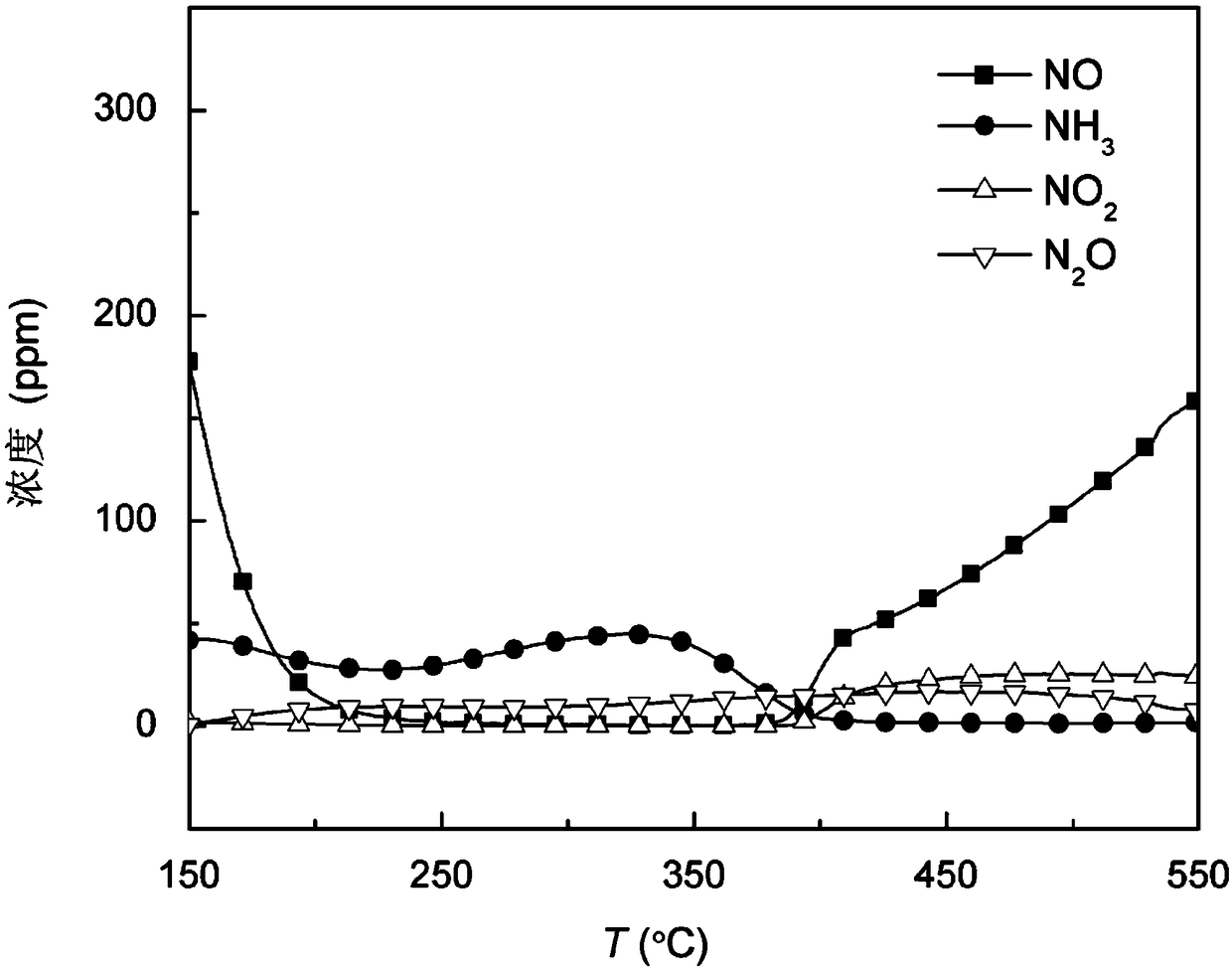

The invention relates to a low-temperature denitration SCR (selective catalytic reduction) catalyst, which includes a Cu modified molecular sieve carrier and one or more oxides of Ce, Zr, and Mn. The employed carrier is a Cu-SSZ-13 molecular sieve that is synthesized by a cheap template route and then undergoes modification. The catalyst provided by the invention has a nitrogen oxide removal rate up to 62-100% in the range of 100-250DEG C, and the low-temperature catalyst involved in the invention has good sulfur-resisting capacity.

Owner:BEIJING UNIV OF CHEM TECH

Treatment of cold start engine exhaust

ActiveUS20080159936A1Emission reductionAluminium compoundsOrganic chemistryInternal combustion engineMole ratio

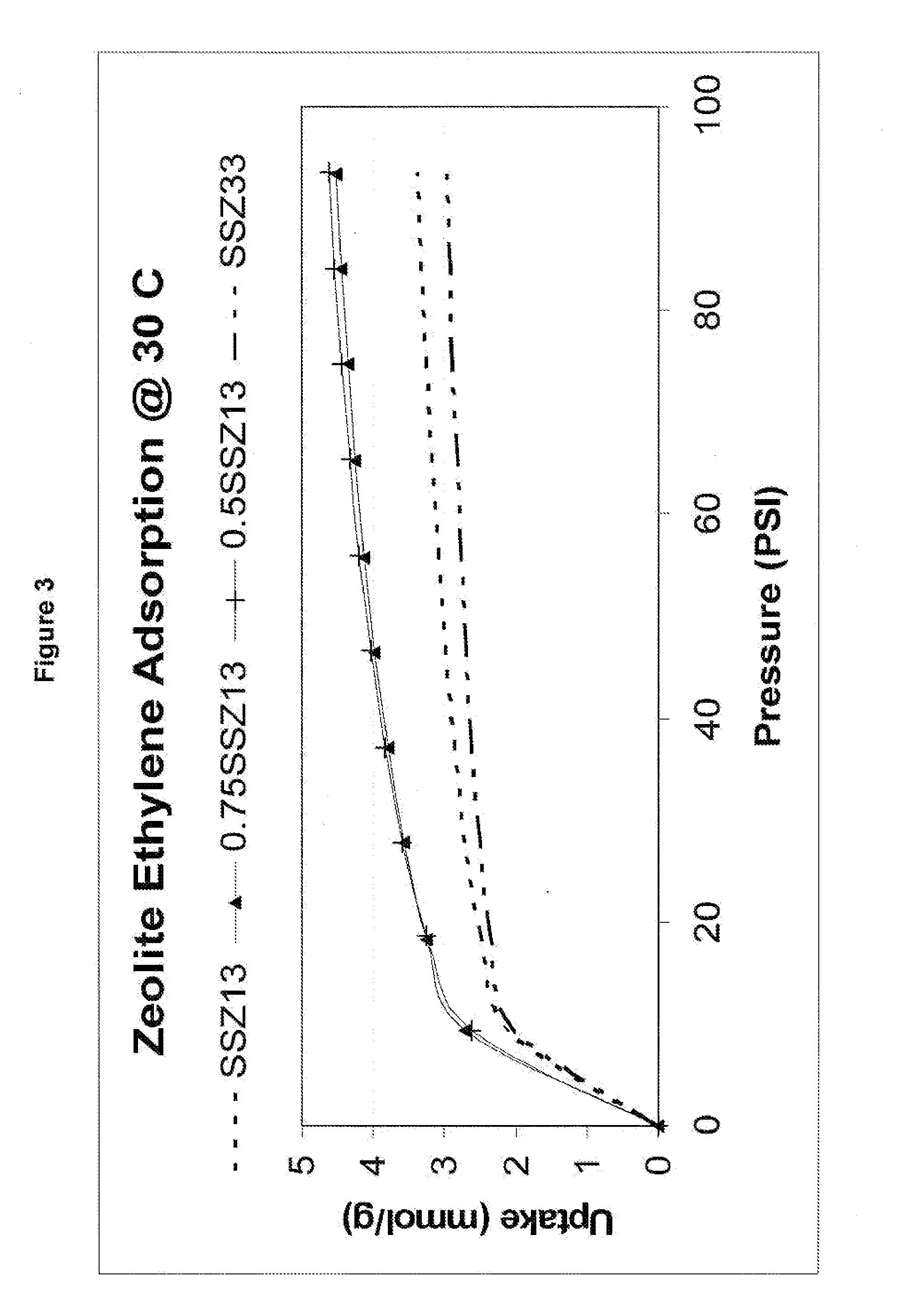

The present invention relates to a process for reducing cold start emissions in an exhaust gas stream (such as from an internal combustion engine) by contacting the exhaust stream with a combination of molecular sieves comprising (1) a small pore crystalline molecular sieve or mixture of molecular sieves having pores no larger than 8 membered rings selected from the group consisting of SSZ-13, SSZ-16, SSZ-36, SSZ-39, SSZ-50, SSZ-52 and SSZ-73 molecular sieve and having a mole ratio at least 10 of (a) an oxide of a first tetravalent element to (b) an oxide of a trivalent element, pentavalent element, second tetravalent element which is different from said first tetravalent element or mixture thereof and (2) a medium-large pore crystalline molecular sieve having pores at least as large as 10 membered rings selected from the group consisting of SSZ-26, SSZ-33, SSZ-64, zeolite Beta, CIT-1, CIT-6 and ITQ-4 and having a mole ratio of at least 10 of (a) an oxide of a first tetravalent element to (b) an oxide of a trivalent element, pentavalent element, second tetravalent element which is different from said first tetravalent element or mixture thereof.

Owner:CHEVROU USA INC

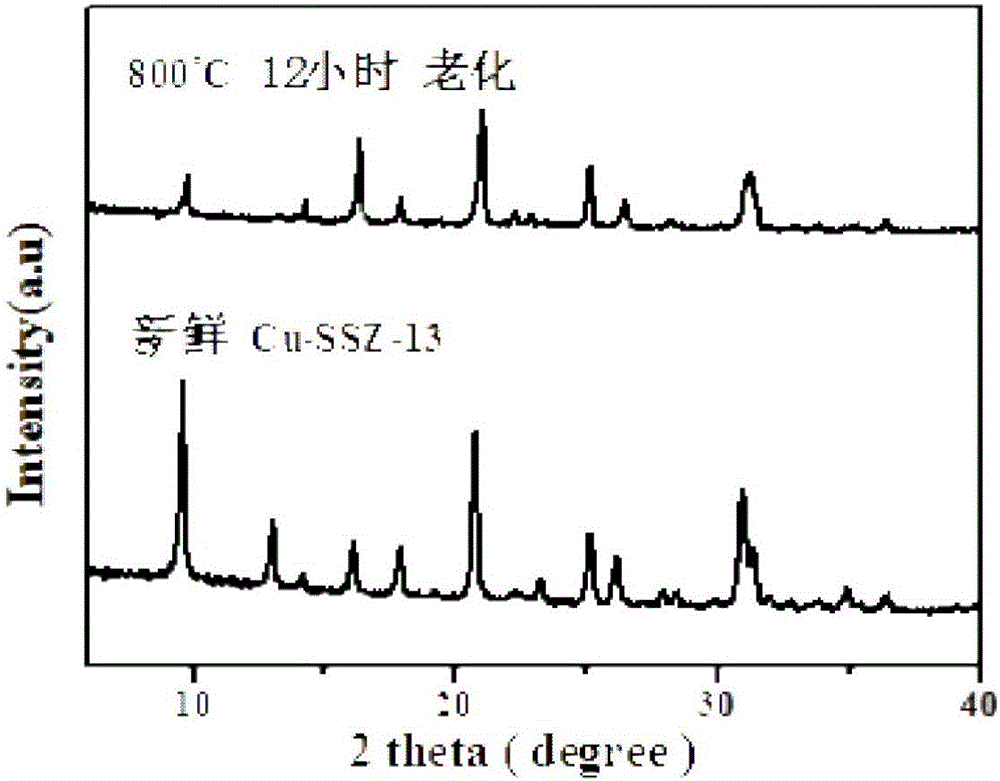

Cu-SSZ-13 catalyst, and preparation method and application thereof

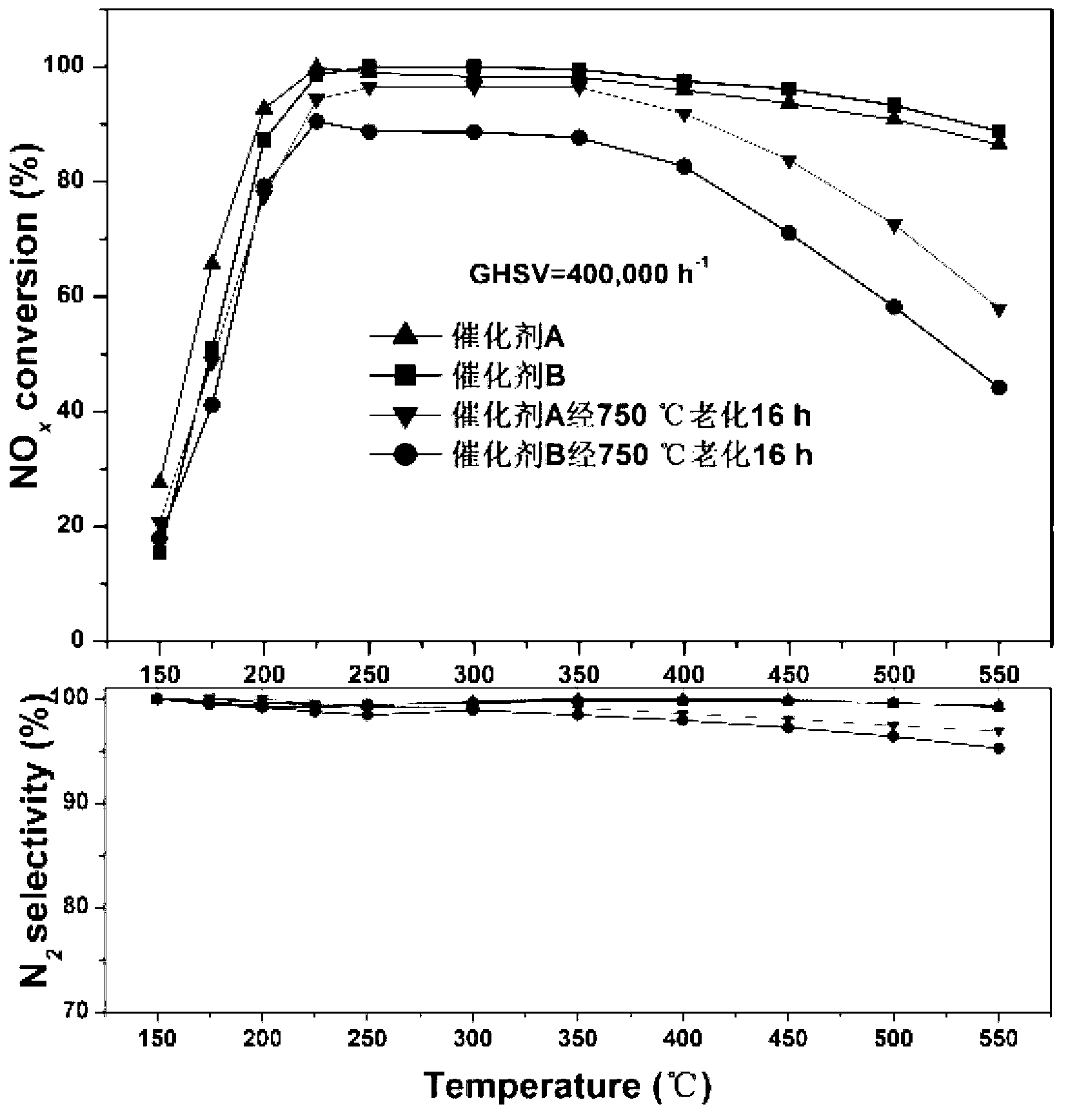

ActiveCN103157505ASolve pollutionImprove activity stabilityMolecular sieve catalystsDispersed particle separationAfter treatmentSynthesis methods

The invention discloses a method for preparing a Cu-SSZ-13 catalyst through an in-situ synthesis method. A Cu-SSZ-13 molecular sieve sample is prepared by taking acid as an exchange reagent and treating through an in-situ synthesis method. Compared with the currently used ammonium nitrate ion exchange method, the after treatment method for the Cu-SSZ-13 molecular sieve prepared through an in-situ synthesis method is more environment-friendly and effective; the activity of the prepared catalyst is higher; and the hydrothermal stability is better. According to the method, the silica-alumina ratio of the molecular sieve structure is increased while the catalyst having high catalytic activity is obtained; and the obtained Cu-SSZ-13 catalyst has excellent hydrothermal stability, wide temperature window and excellent N2 selectivity, and is very applicable to purification of tail gas from diesel cars.

Owner:江西中科鸿虔新材料有限公司

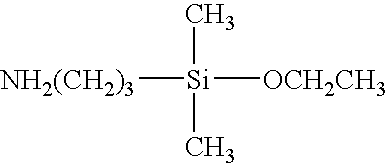

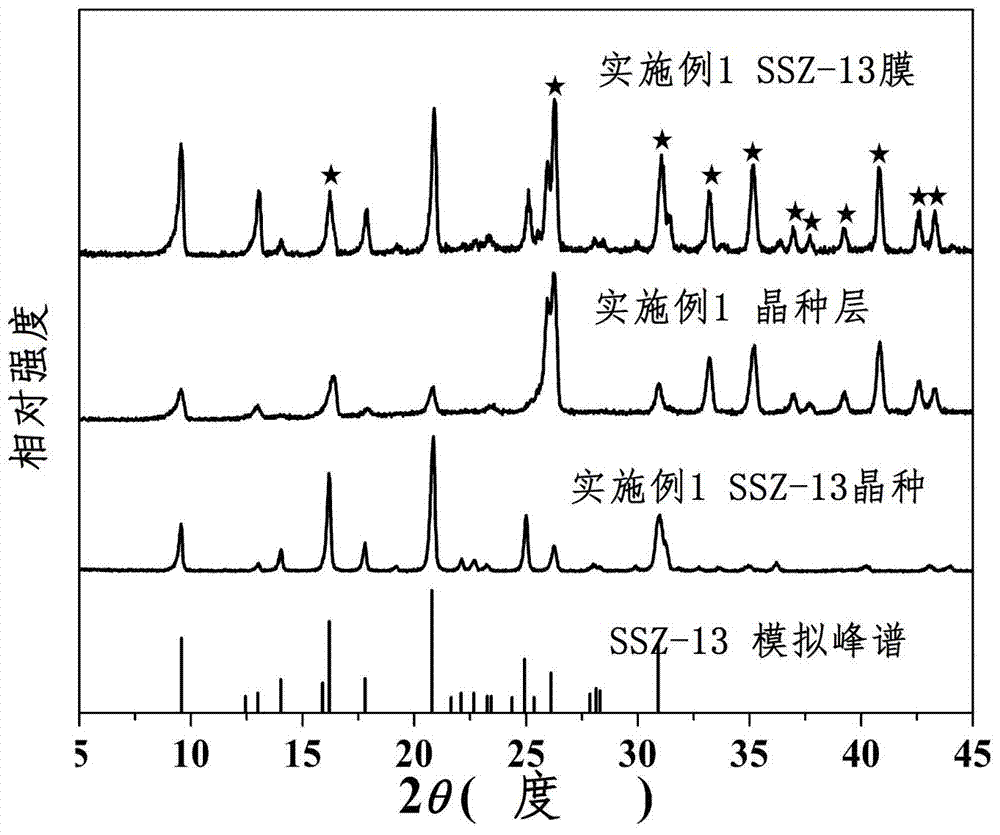

High silicon CHA type SSZ-13 zeolite membrane preparation method

The invention relates to a high silicon CHA type SSZ-13 zeolite membrane preparation method, which is characterized that a SSZ-13 zeolite membrane with high performance is prepared on a porous ceramics support body by employing multiple templates combination, and a dual-template is employed for inducing the compact zeolite membrane on the surface of the porous support body. The membrane has the characteristics of high chemical stability and water vapour resistance, and is suitable for separating inorganic gas such as hydrogen or carbon dioxide or nitrogen from low carbon hydrocarbon, and is also suitable for separating C1-C3 low carbon hydrocarbon such as ethane / ethane.

Owner:NANJING UNIV OF TECH

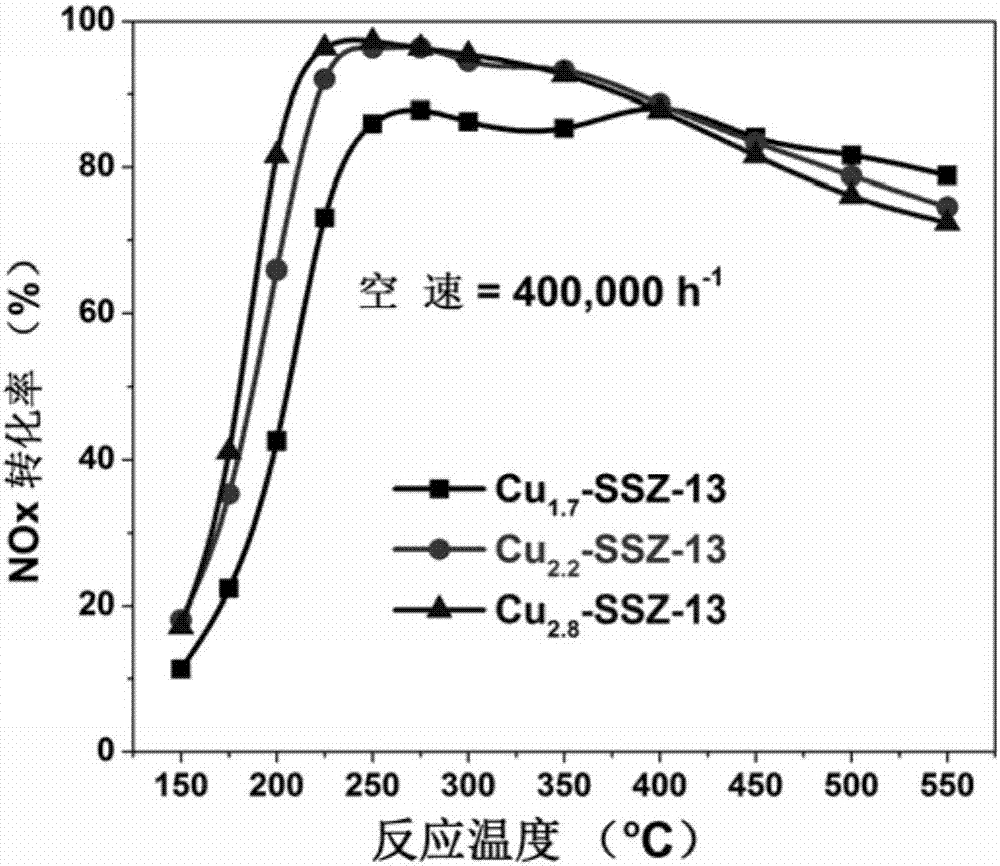

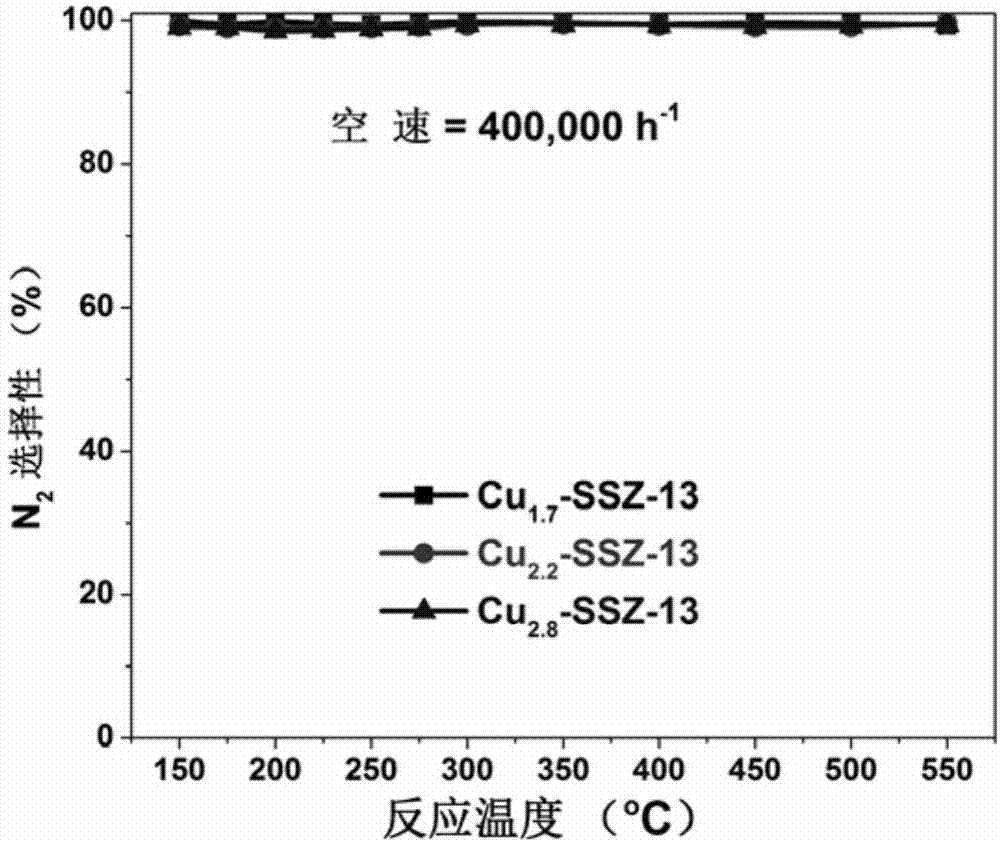

Preparation method and application of Cu-SSZ-13 catalyst

InactiveCN107115888AHigh catalytic activityExcellent resistance to high airspeedGas treatmentMolecular sieve catalystsIon exchangeCopper nitrate

The invention provides a preparation method and application of a Cu-SSZ-13 catalyst. The preparation method comprises the following steps: 1) putting raw materials including a silicon source, an aluminum source, a template agent and seed crystals into a mortar, and grinding to form a uniform mixture; 2) feeding the mixture into a reaction kettle and crystallizing; after cooling, washing and drying, roasting to obtain an Na-SSZ-13 molecular sieve carrier; 3) preparing an ammonium nitrate solution, and adding into the Na-SSZ-13 molecular sieve carrier; after carrying out ion exchange, filtering, washing and drying to obtain an NH4-SSZ-13 molecular sieve; 4) preparing a copper nitrate solution and adding into the NH4-SSZ-13 molecular sieve; after carrying out ion exchange, filtering, drying and roasting to obtain the Cu-SSZ-13 catalyst. The Cu-SSZ-13 catalyst prepared by the preparation method has excellent NH3-SCR (Selective Catalytic Reduction) catalytic activity, N2 selectivity, hydrothermal stability, and H2O and SO2 positioning resisting properties, and is applicable to purification of tail gas of diesel vehicles.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

One-pot method for the synthesis of cu-ssz-13, the compound obtained by the method and use thereof

Process for the direct synthesis of Cu-SSZ-13 from a synthesis mixture comprising water, at least one silicon source, at least one Al source, at least one Cu source, at least one polyamine for complexing with Cu, and a single organic structure directing agent. A Cu containing molecular sieve having the framework structure of SSZ-13, obtainable by the process and use of the Cu containing molecular sieve.

Owner:UMICORE AG & CO KG

Method for preparing H-SSZ-13 molecular sieve

ActiveCN108059172AEliminates the ion exchange stepImprove solubilityInternal combustion piston enginesMolecular sieve catalystsHydrogenSolvent

The invention relates to a method for preparing an H-SSZ-13 molecular sieve and belongs to the field of hydrogen molecular sieve catalyzed synthesis. The method comprises the following steps: a) uniformly stirring and mixing a silicon source, an aluminum source, a template agent and water; b) uniformly mixing the silicon source, the aluminum source, the template agent, a cosolvent and water to form initial gel, adding a guiding agent solution, and crystallizing after being uniformly stirred; and c) separating, washing, drying and calcining the product after crystallization completion, therebyobtaining the H-SSZ-13 molecular sieve. According to the method disclosed by the invention, due to use of the guiding agent solution and the aided template agent, the effects of reducing usage of an expensive template agent and shortening the crystallization time are achieved, so that the production cost is greatly reduced.

Owner:SHANDONG QILU HUAXIN HIGH TECH

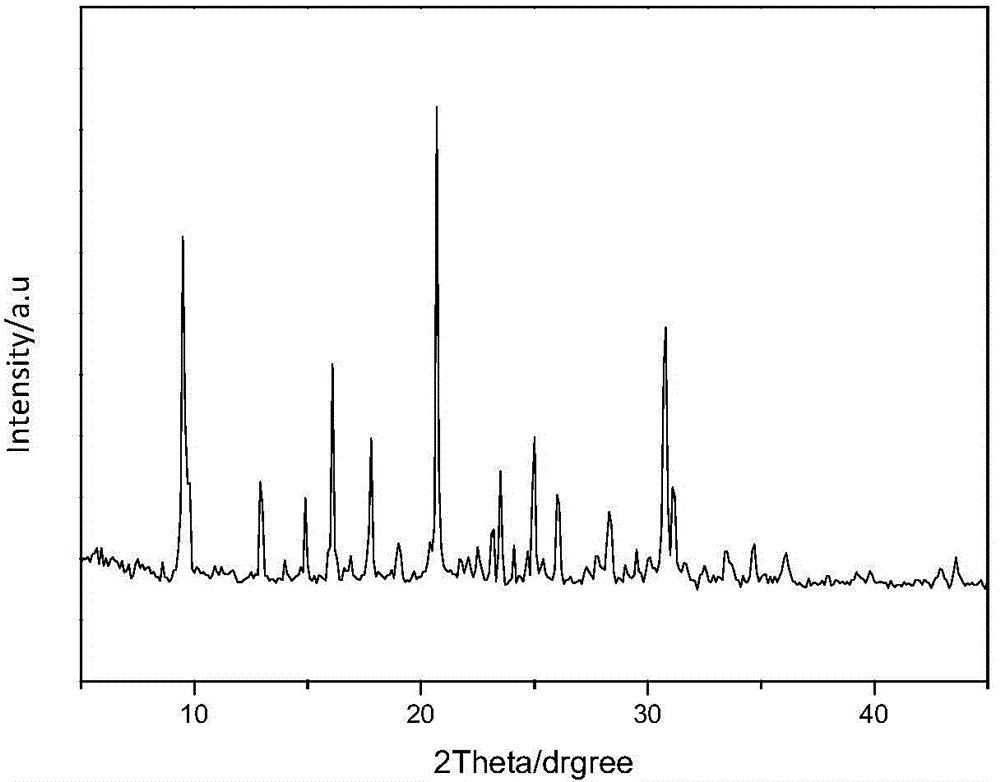

Synthesis method of SSZ-13 molecular sieve

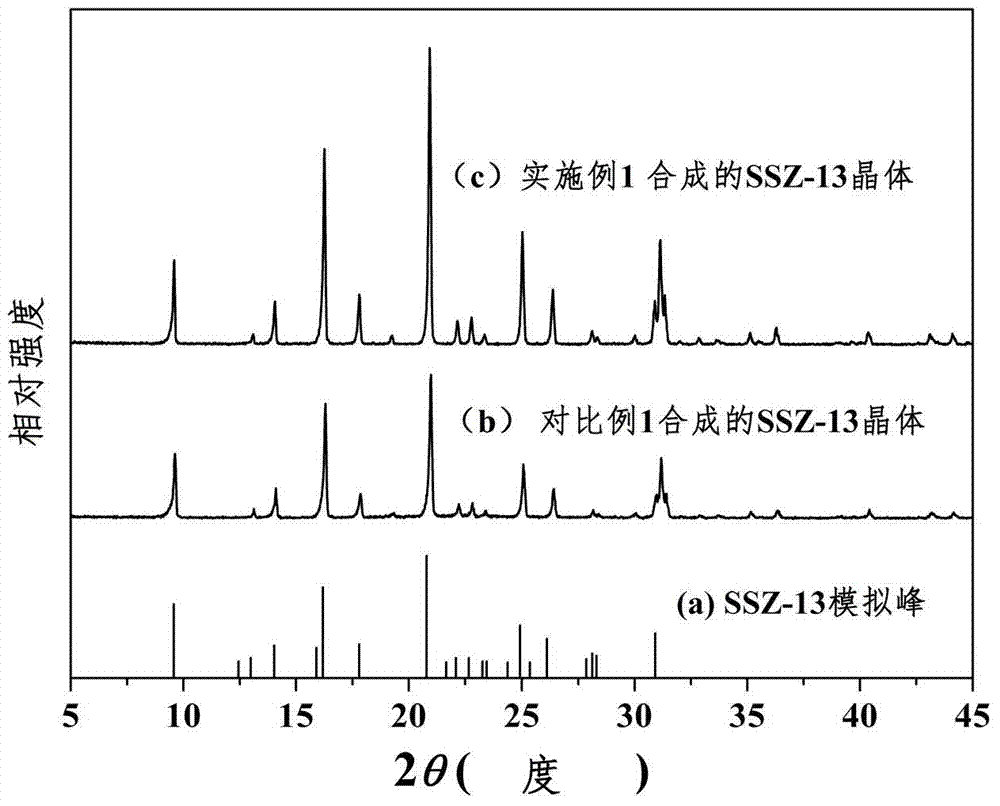

ActiveCN106629761ASynthetic Method AdvantagesReduce usageCrystalline aluminosilicate zeolites1-adamantanamineSynthesis methods

The invention provides a synthesis method of an SSZ-13 molecular sieve. A USY molecular sieve or Beta molecular sieve with adsorbed N,N,N-trimethyl-1-adamantanamine cations is used as a structure guide agent to synthesize the SSZ-13 molecular sieve together with an aluminum source, a silicon source, an alkali source, water and mixed seeds, thereby greatly reducing the consumption of the expensive template N,N,N-trimethyl-1-adamantanamine cations in the traditional method, and obviously lowering the cost for synthesizing the SSZ-13 molecular sieve. The method can enhance the crystallization rate of the SSZ-13 molecular sieve and shorten the required crystallization time, and thus, is more beneficial to industrial production. The SSZ-13 molecular sieve synthesized by the method has high crystallinity and favorable hydrothermal stability; and the synthesized SSZ-13 molecular sieve can be used as an MTO (Methanol To Olefins) catalyst and can also be used as an automobile tail gas treatment catalyst support.

Owner:SHANGHAI NOVEL CHEM TECH

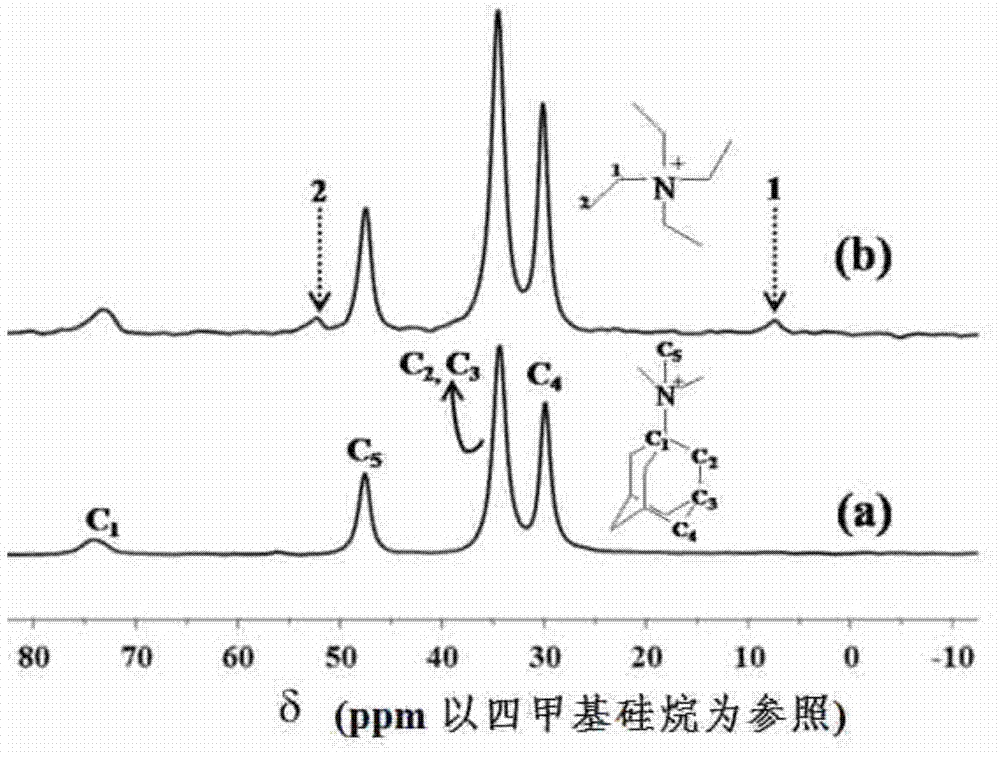

Method for synthesizing CHA molecular sieve by using tetraethyl ammonium hydroxide as templating agent

InactiveCN105236440AReduce pollutionHigh catalytic activityCrystalline aluminosilicate zeolitesFiltrationRoom temperature

The present invention discloses a method for synthesizing a CHA molecular sieve by using tetraethyl ammonium hydroxide as a templating agent. The method comprises: mixing a templating agent tetraethyl ammonium hydroxide (TEA) and NaOH, melting into an appropriate amount of water to obtain a mixed solution, adding a USY molecular sieve as a silicon source and an aluminum source to the mixed solution, continuously stirring until obtaining a homogeneous gel, transferring the gel to an autoclave, crystallizing for a certain time at a certain temperature, cooling at a room temperature after completing the crystallizing, recovering the solid phase product through filtration, washing with deionized water, drying, and calcining at a temperature of 580 DEG C in air so as to obtain the SSZ-13 molecular sieve. According to the present invention, the used templating agent has advantages of low price and environment pollution reducing; and the Cu-based small pore molecular sieve catalyst having the CHA structure obtained through the further preparation has characteristics of excellent NH3-SCR activity, extremely high solid phase yield and substantially-reduced production cost, and is suitable for the large-scale promotion application of Cu-SSZ-13.

Owner:TIANJIN UNIV

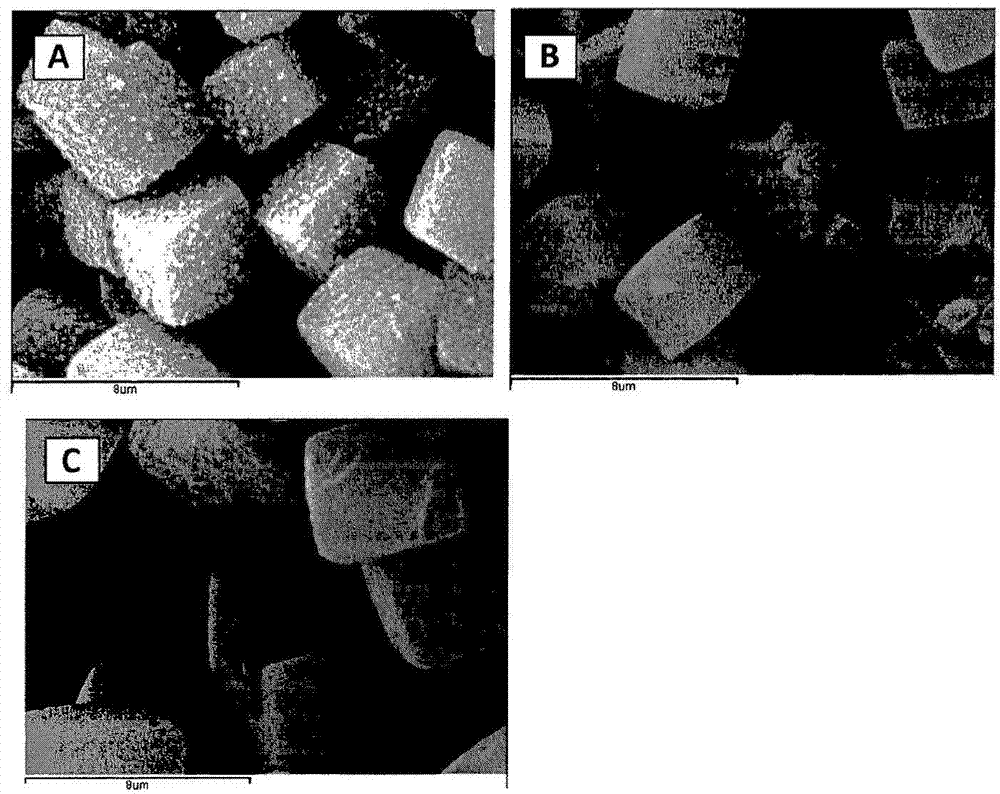

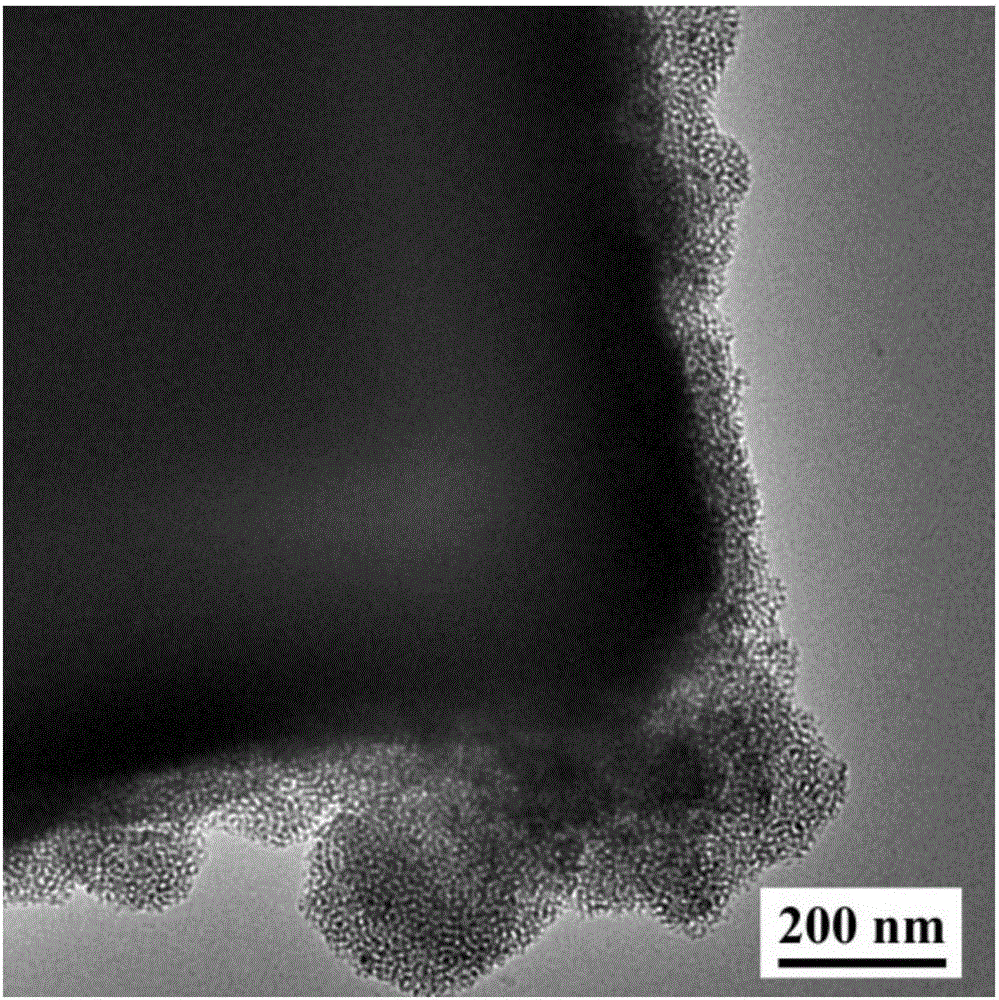

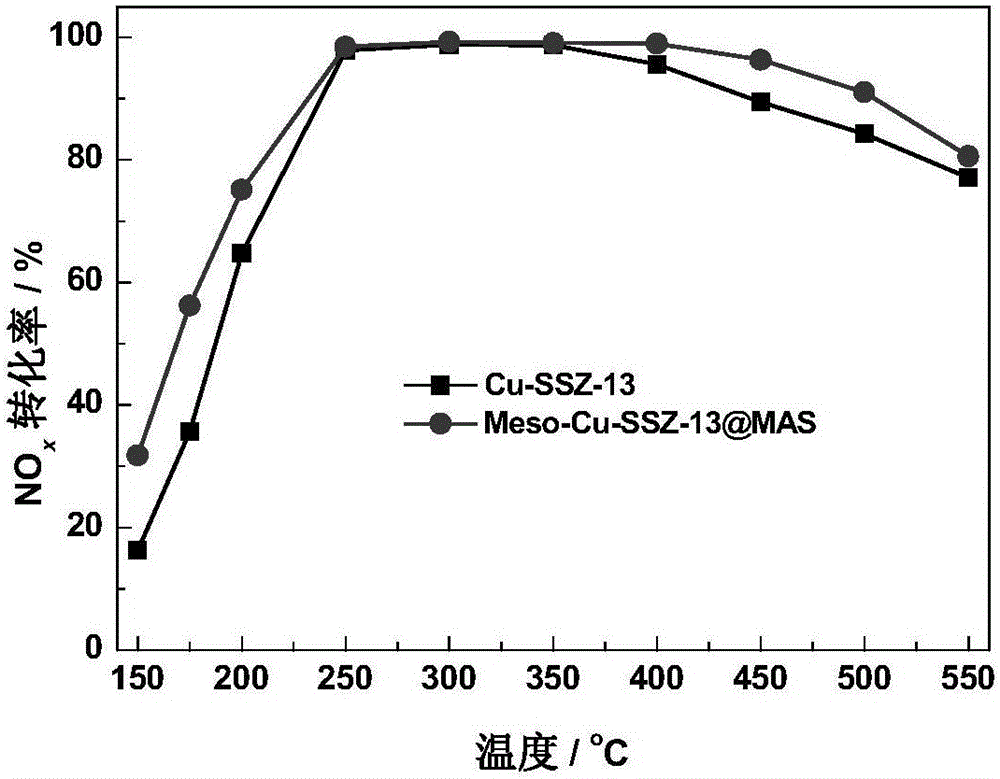

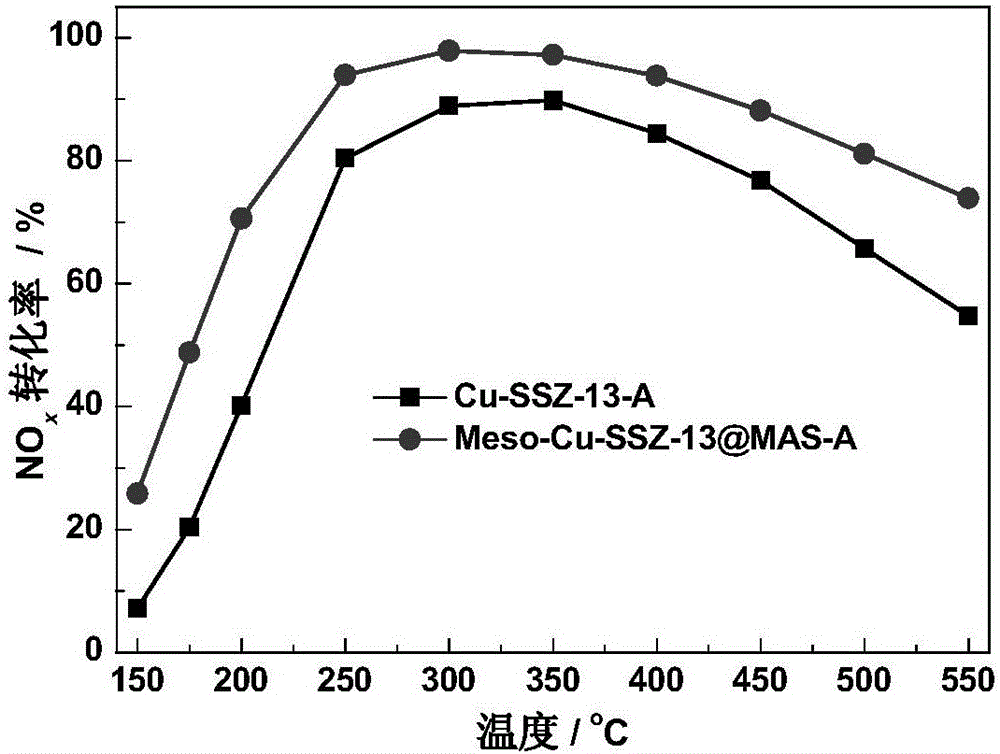

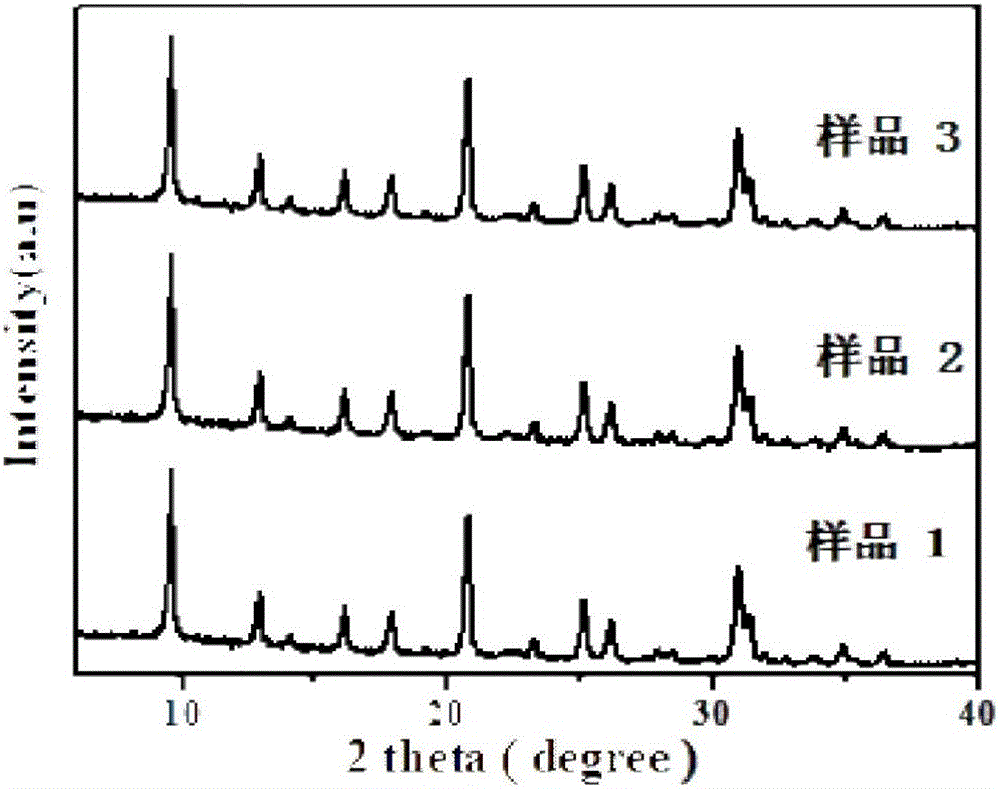

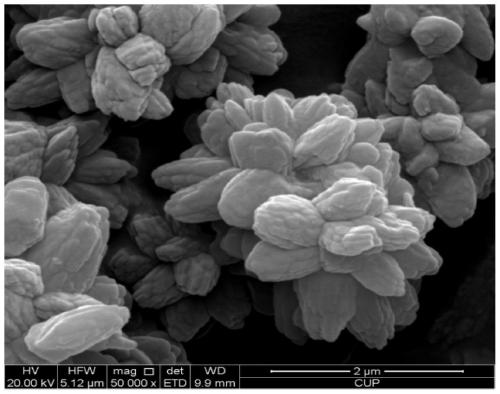

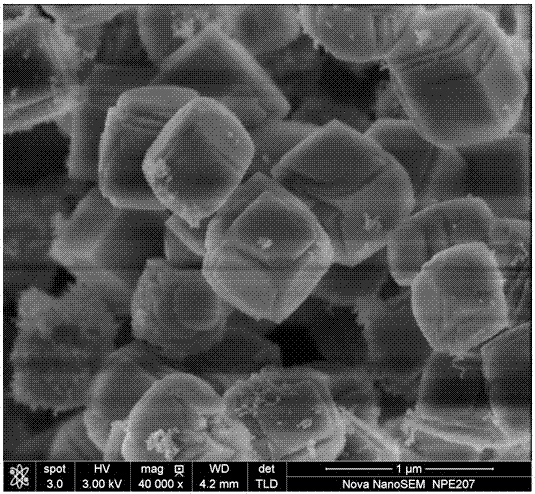

Cu-SSZ-13 molecular sieve based catalyst adopting core-shell structure as well as preparation and application of catalyst

InactiveCN105944753AImprove activity stabilityHigh hydrothermal stabilityGas treatmentMolecular sieve catalystsWorking temperatureIon exchange

The invention relates to a Cu-SSZ-13 molecular sieve based catalyst adopting a core-shell structure as well as preparation and an application of the catalyst and belongs to the technical field of purification treatment of nitric oxide in the technical field of environmental protection. An SSZ-13 molecular sieve is taken as a carrier and subjected to desilicication treatment with NaOH solutions with different concentrations, and a mesoporous structure is introduced to the molecular sieve; then, a mesoporous template agent is added to a turbid liquid containing the mesoporous molecular sieve, and an aluminosilicate shell adopting a mesoporous structure is self-assembled on the surface of the molecular sieve; finally, the corresponding catalyst is prepared with an ion exchange method. The working temperature window of the catalyst is widened, the hydrothermal stability and the hydrocarbon toxicosis resisting capability of the catalyst are improved, and the catalyst has good actual application prospect; in a motor vehicle exhaust component simulation experiment, the removal efficiency of NOx is 90% or higher; the removal efficiency of NOx is 80% or higher after the catalyst is subjected to hydrothermal ageing for 24 h at the temperature of 750 DEG C; ; the removal efficiency of NOx is 80% or higher in the presence of propylene.

Owner:TSINGHUA UNIV

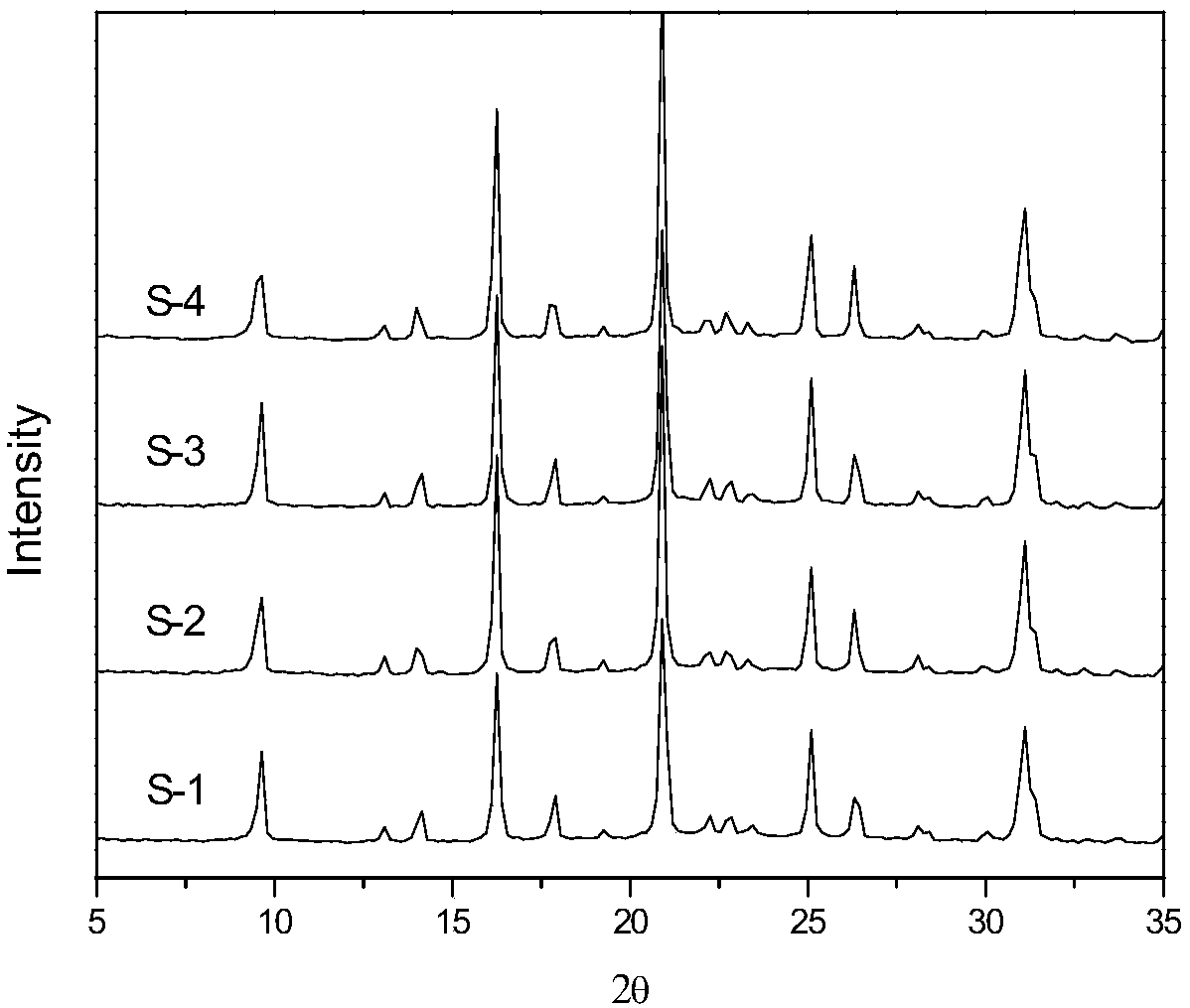

Method for synthesizing SSZ-13 molecular sieve by double-template agent in one step and application of SSZ-13 molecular sieve

InactiveCN106745034AHigh crystallinityHigh yieldMolecular sieve catalystsCrystalline aluminosilicate zeolitesSelective reductionCrystallization

The invention provides a method for synthesizing an SSZ-13 molecular sieve by a double-template agent in one step. The method takes N,N,N-trimethyl adamantanamine (TMADa<+>) and choline chloride as the double-template agent and the SSZ-13 molecular sieve with a high crystallization degree and a pure phase is obtained; after Cu<2+> is loaded, the SSZ-13 molecular sieve has excellent NO selective reduction capability and high hydrothermal stability. According to the method provided by the invention, the utilization of an expensive template agent, namely the N,N,N-trimethyl adamantanamine, can be greatly reduced, so that the production cost of the SSZ-13 molecular sieve is reduced; the method utilizes a cheap template agent to replace one part of the expensive template agent and a product can be applied to an NOx elimination process of a catalyzing device of a diesel vehicle post-treatment (NH3-SCR (Selective Catalytic Reduction)) system.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for synthesizing CHA by using tetraethyl ammonium hydroxide and N,N,N-trimethyl adamantane ammonium hydroxide mixture as templating agent

InactiveCN105236441ALow priceHigh solid phase yieldCrystalline aluminosilicate zeolitesFiltrationRoom temperature

The present invention provides a method for synthesizing CHA by using tetraethyl ammonium hydroxide and N,N,N-trimethyl adamantane ammonium hydroxide mixture as templating agent. The method comprises: mixing TEA and TMAdA as a mixed templating agent, mixing the templating agent and NaOH, melting into an appropriate amount of water to obtain a mixed solution, adding a USY molecular sieve as a silicon source and an aluminum source, continuously stirring until obtaining a homogeneous gel, transferring the gel to an autoclave, crystallizing for a certain time at a certain temperature, cooling at a room temperature, recovering the solid phase product through filtration, washing with deionized water, drying, and calcining at a temperature of 580 DEG C in air so as to obtain the SSZ-13 molecular sieve. According to the present invention, the synthesized CHA molecular sieve has high crystallinity and high solid phase yield, and the TEA and the TMAdA are adopted as the mixed templating agent to replace the expensive TMAdA single templating agent, such that the production cost is substantially reduced, and the large-scale promotion application of SSZ-13 is easily achieved.

Owner:TIANJIN UNIV

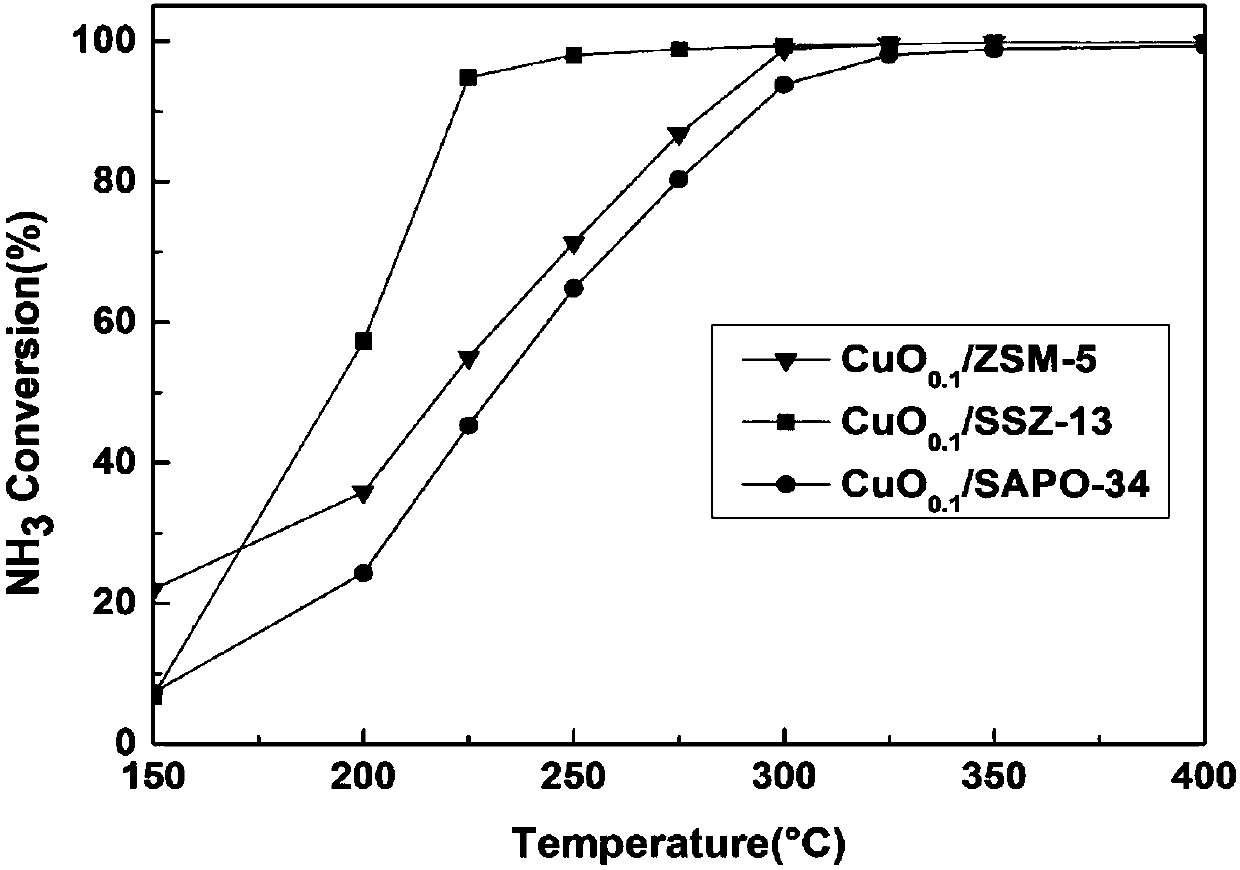

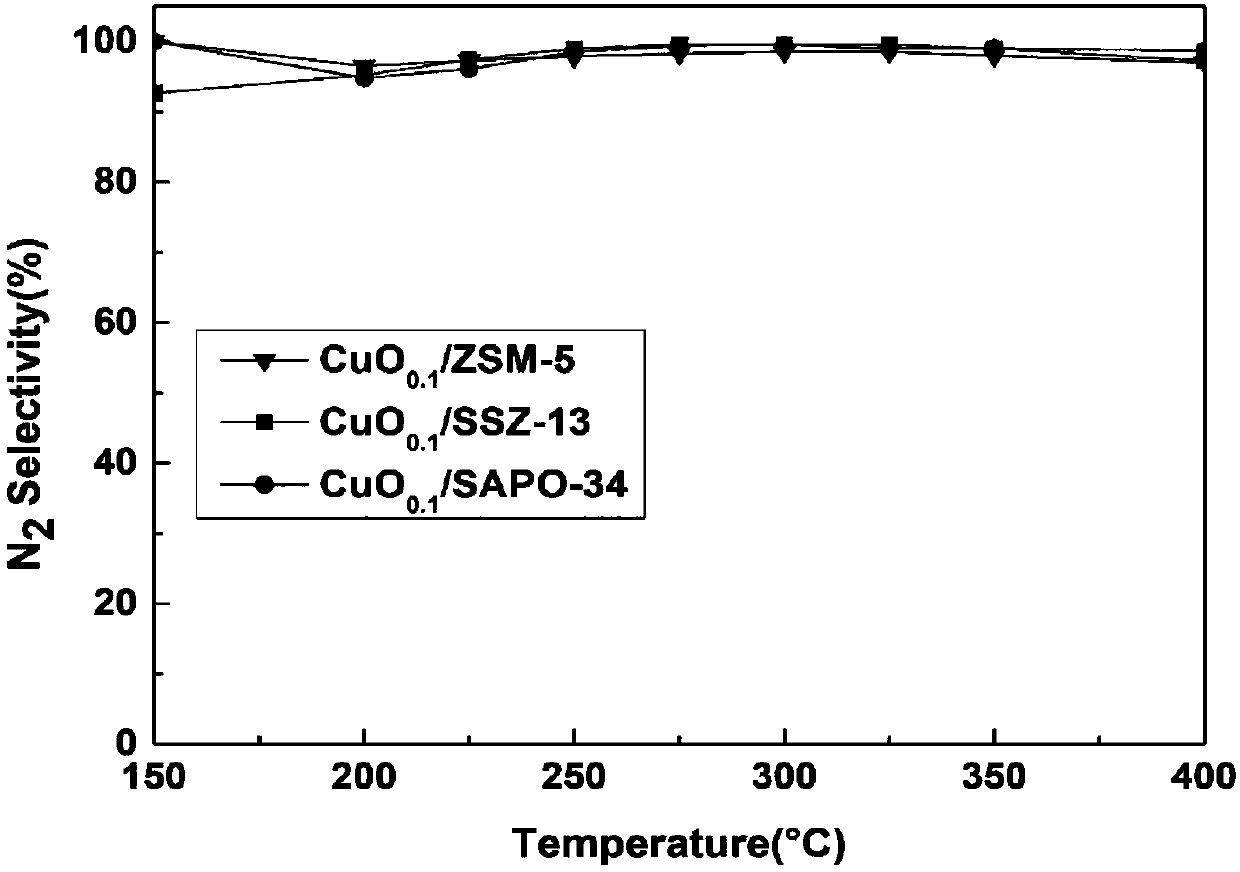

Copper-based supported ammoxidation catalyst and preparation method thereof

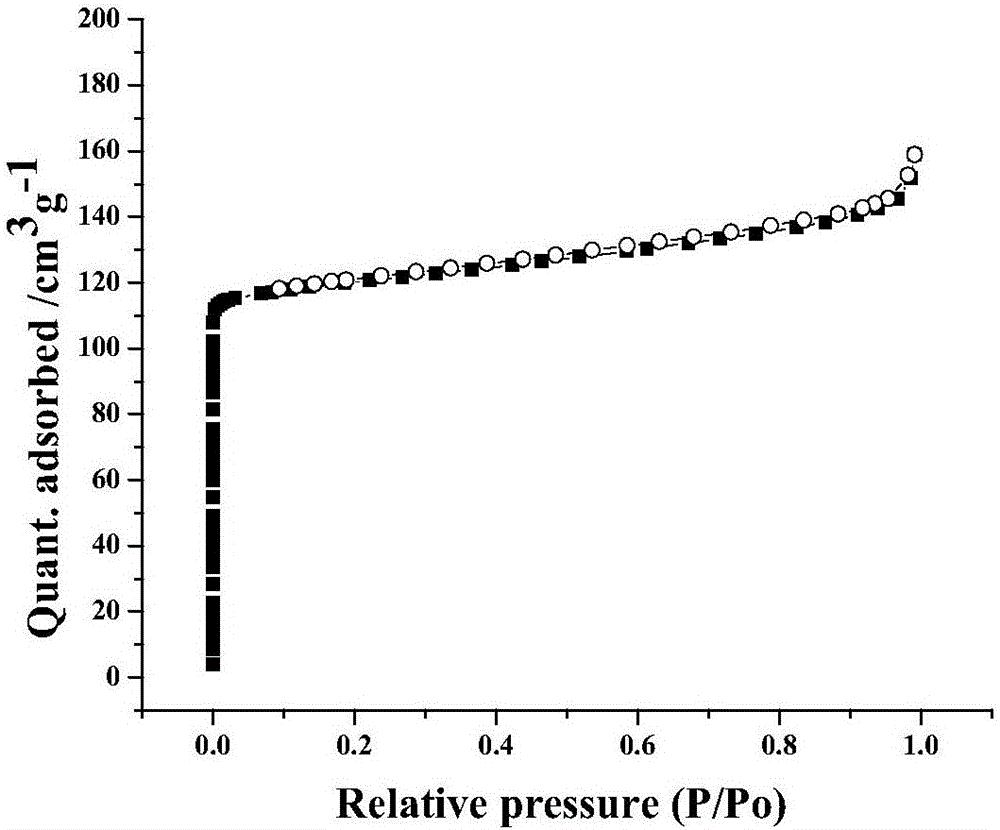

InactiveCN108043451AHigh selectivityReduce generationGas treatmentNitrogen preparationActive componentCopper

The invention discloses a copper-based supported ammoxidation catalyst and a preparation method thereof. The catalyst takes CuO as an active component and is expressed as CuO / M (M represents a supporter), wherein the supporting ratio is m(CuO) / m(M)=0.1. The invention also provides the preparation method of the copper-based supported ammoxidation catalyst. The prepared copper-based supported ammoxidation catalyst is applicable to ammonia gas purification for fixed sources and movable sources and can be applied in the downstream position of an SCR system to eliminate ammonia escape. Meanwhile, the catalyst is also applicable to treatment of ammonia gas produced and exhausted in breeding industry plants and agricultural sources. Compared with other ammoxidation catalysts, the catalyst copper-based supported ammoxidation catalyst taking SSZ-13 as a supporter has the characteristics of no toxicity, high activity, high selectivity and the like, good NH3 conversion rate is realized by the aidof the active component CuO, high Na selectivity is guaranteed by the aid of the supporter SSZ-13, and 90% or above of N2 selectivity can be kept in the whole temperature window. The copper-based supported ammoxidation catalyst has good catalytic activity and N2 selectivity in a wide temperature test interval at 200-400 DEG C.

Owner:TSINGHUA UNIV

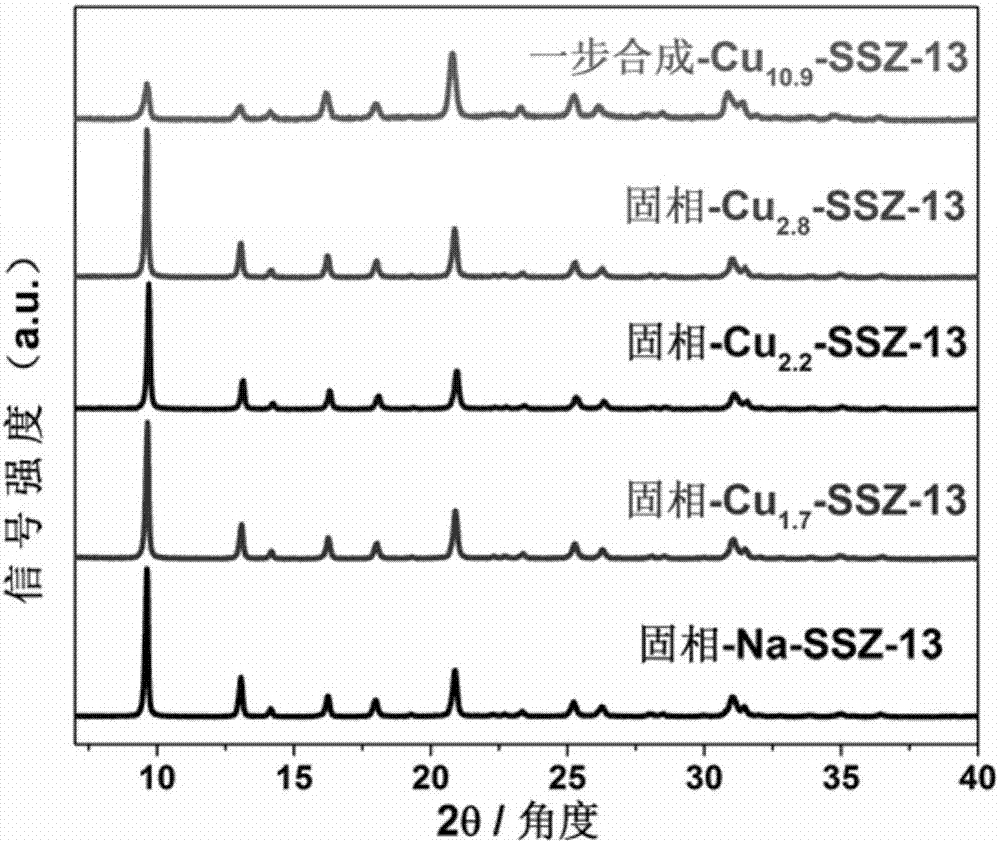

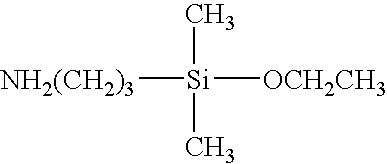

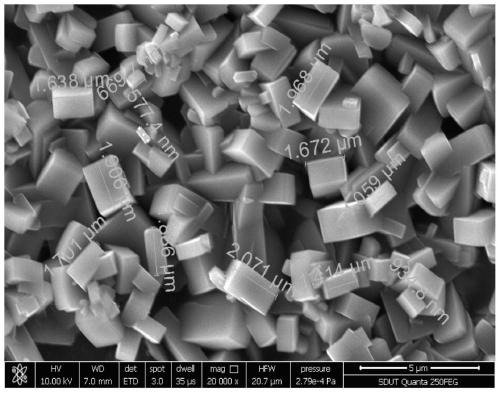

Method for synthesizing SSZ-13 molecular sieve through solid-phase grinding

ActiveCN104709917AThe synthesis steps are simpleReduce usageCrystalline aluminosilicate zeolitesSolvent freeSolvent

The invention relates to the field of molecular sieve preparation, and aims to provide a method for synthesizing an SSZ-13 molecular sieve through solid-phase grinding. The method for synthesizing the SSZ-13 molecular sieve through solid-phase grinding comprises the following steps: weighing a silicon source, an aluminum source, an alkali source and a template agent for crystallization reaction so as to obtain a crystallization reaction product after the reaction is completed, cooling and washing till being neutral, drying to obtain crude molecular sieve powder, and roasting the crude molecular sieve powder for 5 hours in air of 550 DEG C, thereby obtaining a final product SSZ-13 molecular sieve. The SSZ-13 molecular sieve with relatively good crystallinity degree is synthesized through solid-phase raw material grinding under a solvent-free condition, so that the use of solvent water is reduced to the maximum extent, the synthesis route only involves mixing synthesis steps of primary raw materials, the method is greatly simplified when being compared with a conventional method, the yield and the utilization rate of a single kettle are both relatively increased, the production cost is greatly lowered, the pollution to the environment is greatly reduced, and great industrial application prospect can be achieved.

Owner:ZHEJIANG UNIV

Impregnation-coating method for rapidly preparing Cu-SSZ-13 monolithic catalyst and application of monolithic catalyst

InactiveCN109174171AShort manufacturing cycleShorten the durationGas treatmentMolecular sieve catalystsSlurryBiological activation

The invention provides an impregnation-coating method for rapidly preparing a Cu-SSZ-13 monolithic catalyst. According to the method, mixing of a Cu salt precursor and an SSZ-13 molecular sieve is realized through impregnation; then slurry is prepared from the prepared mixture and coats the inner surface of a honeycomb carrier or in wall-flow type filter; and calcination in the air or in an oxygen-containing atmosphere is performed, and catalyst activation and adhesion of a catalyst coating are simultaneously achieved during the calcination. The method of the invention has the following advantages: (1) a preparation cycle is significantly shortened; (2) calcination frequency and calcination time are reduced; (3) wastewater discharge in the preparation process is drastically lowered; (4) the loading amount of Cu is accurately controlled; and (5) the prepared catalyst has high SCR catalytic activity. The Cu-SSZ-13 monolith catalyst prepared in the invention is applicable to the ammonia-process selective catalytic reduction denitration (NH3-SCR) of diesel exhaust gas.

Owner:TSINGHUA UNIV

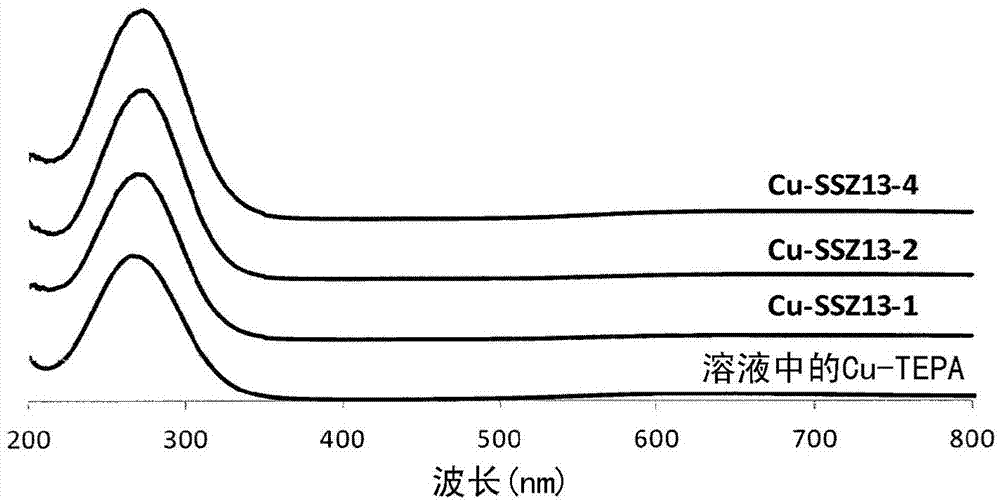

Method for synthesizing Cu-SSZ-13 molecular sieve catalyst by one step

InactiveCN106238092AOptimizing Hydrothermal Aging PropertiesHigh solid phase yieldMolecular sieve catalystsCrystalline aluminosilicate zeolitesAlkali metalChemistry

The invention relates to a method for synthesizing Cu-SSZ-13 molecular sieve catalyst by one step. The method is characterized by comprising the following steps: (1) mixing an organic amine template agent and deionized water; adding or not adding an NaOH aqueous solution; adding Cu-TEPA clathrate, and stirring evenly; adding an aluminum source and a silicon source, and stirring until all materials are mixed evenly; (2) placing a mixed solution obtained in step (1) into a stainless reaction still with a tetrafluoroethylene or para-polyphenylene lining; crystallizing the reaction still for 12 hours to 6 days at 100 to 200 DEG C.; (3) washing a crystallized product for a plurality of times until the solution is neutral; drying the obtained solid product in a drying oven for 5 to 12 hours at 60 to 150 DEG C; heating the dried solid to 500 to 600 DEG C. and roasting for 3 to 10 hours so as to obtain the Cu-SSZ-13 molecular sieve catalyst product. By adopting the method disclosed by the invention, the use amount of the N,N,N-trimethyl-1-ammonium adamantane template agent is greatly reduced, and the alkali metal ion content of the product is controlled, so that the hydrothermal aging property of the catalyst is optimized.

Owner:WUXI WEIFU ENVIRONMENT PROTECTION CATALYST

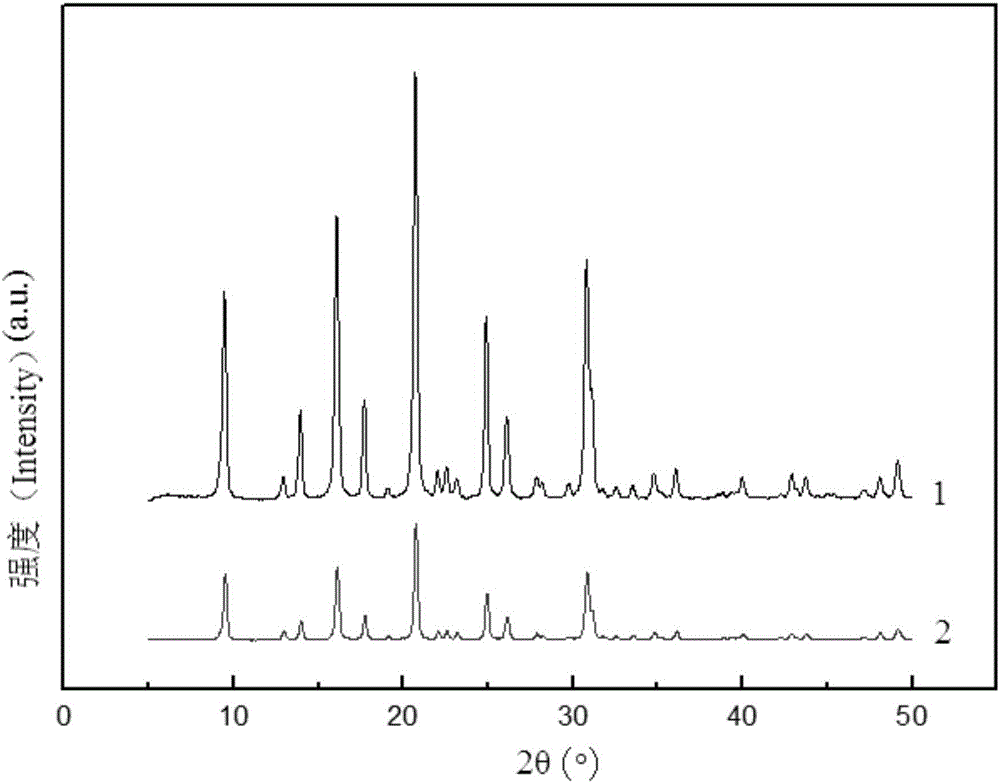

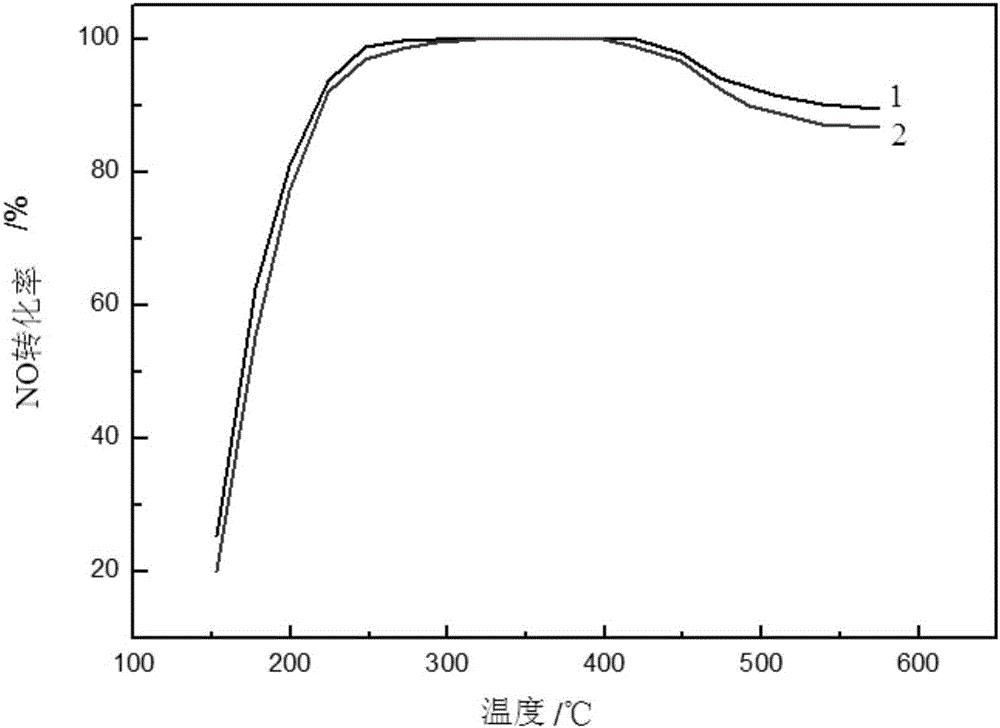

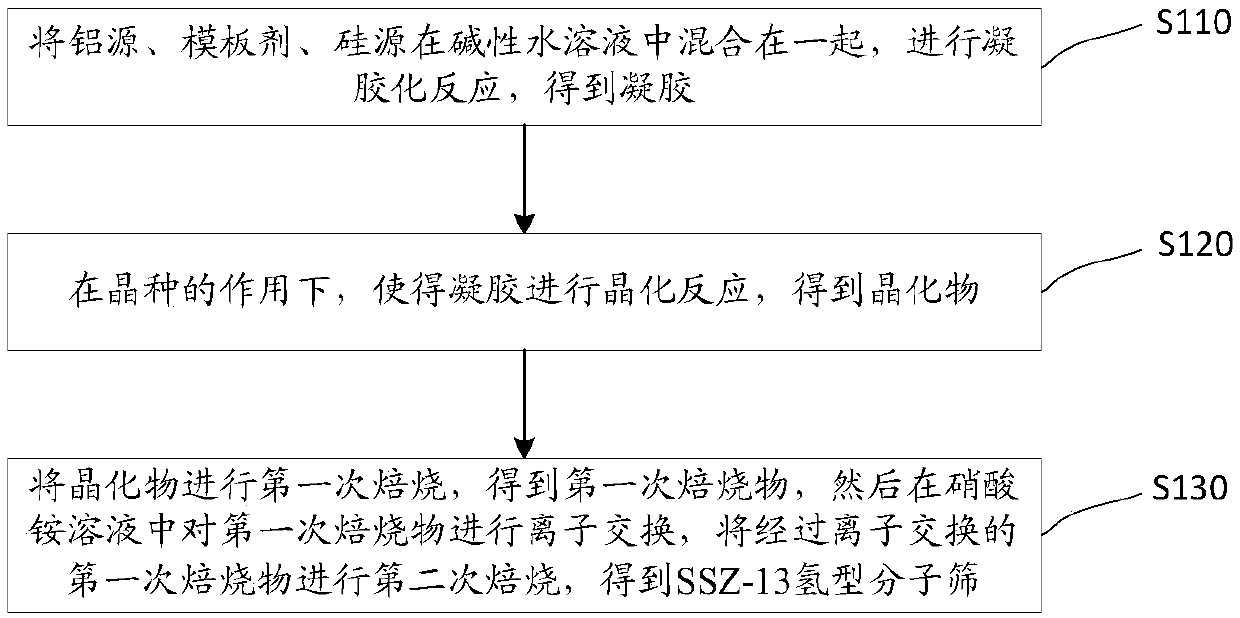

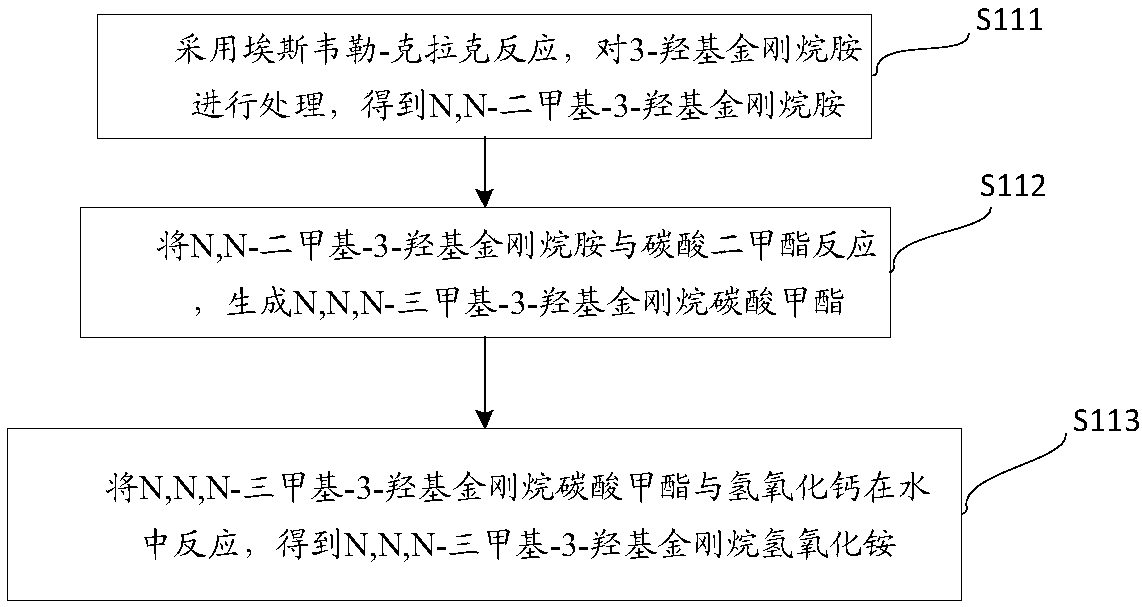

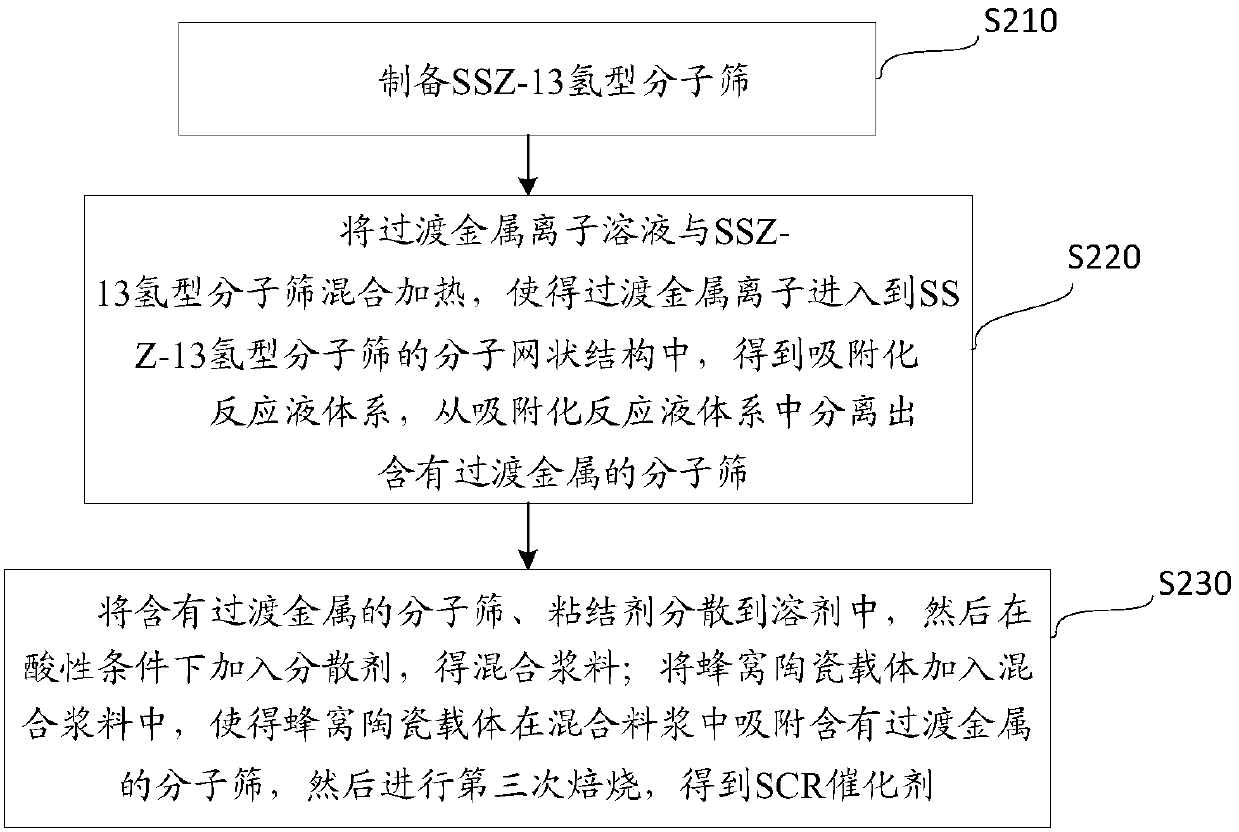

Preparation method of SSZ-13 hydrogen type molecular sieve, and preparation method of SCR catalyst

The invention discloses a preparation method of an SSZ-13 hydrogen type molecular sieve, and a preparation method of SCR catalyst, and relates to the technical field of catalyst; the preparation method of the SSZ-13 hydrogen type molecular sieve can shorten the preparation time of the SSZ-13 hydrogen type molecular sieve and reduce the preparation cost, the SCR catalyst can be produced on a largebatch. The preparation method of the SSZ-13 hydrogen type molecular sieve includes steps of mixing aluminum source, template agent and silicon source in the alkali water solution together, and performing gelatinization reaction to obtain gel; under the effect of crystal seed, performing crystallization reaction on the gel, performing the first roasting on the crystalized matter to obtain a first roasting matter; performing ion exchange on the first roasting matter by ammonium salt solution; performing the secondary roasting on the first roasting matter after the ion exchange, so as to obtain the SSZ-13 hydrogen type molecular sieve. The hydrogen type molecular sieve comprises a preparation method of the mentioned SSZ-13 hydrogen type molecular sieve. The SSZ-13 hydrogen type molecular sieve provided by the invention is applied to preparation of the nitric oxide transformation catalyst.

Owner:FUYANG XINYIHUA MATERIAL TECH

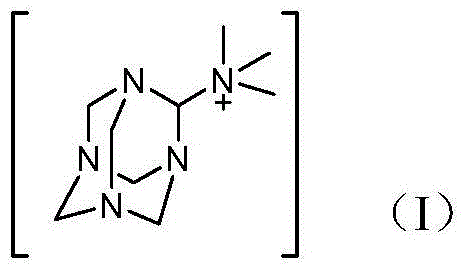

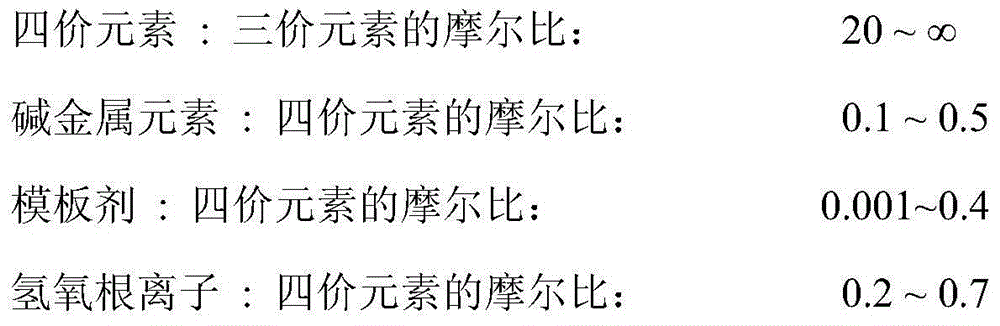

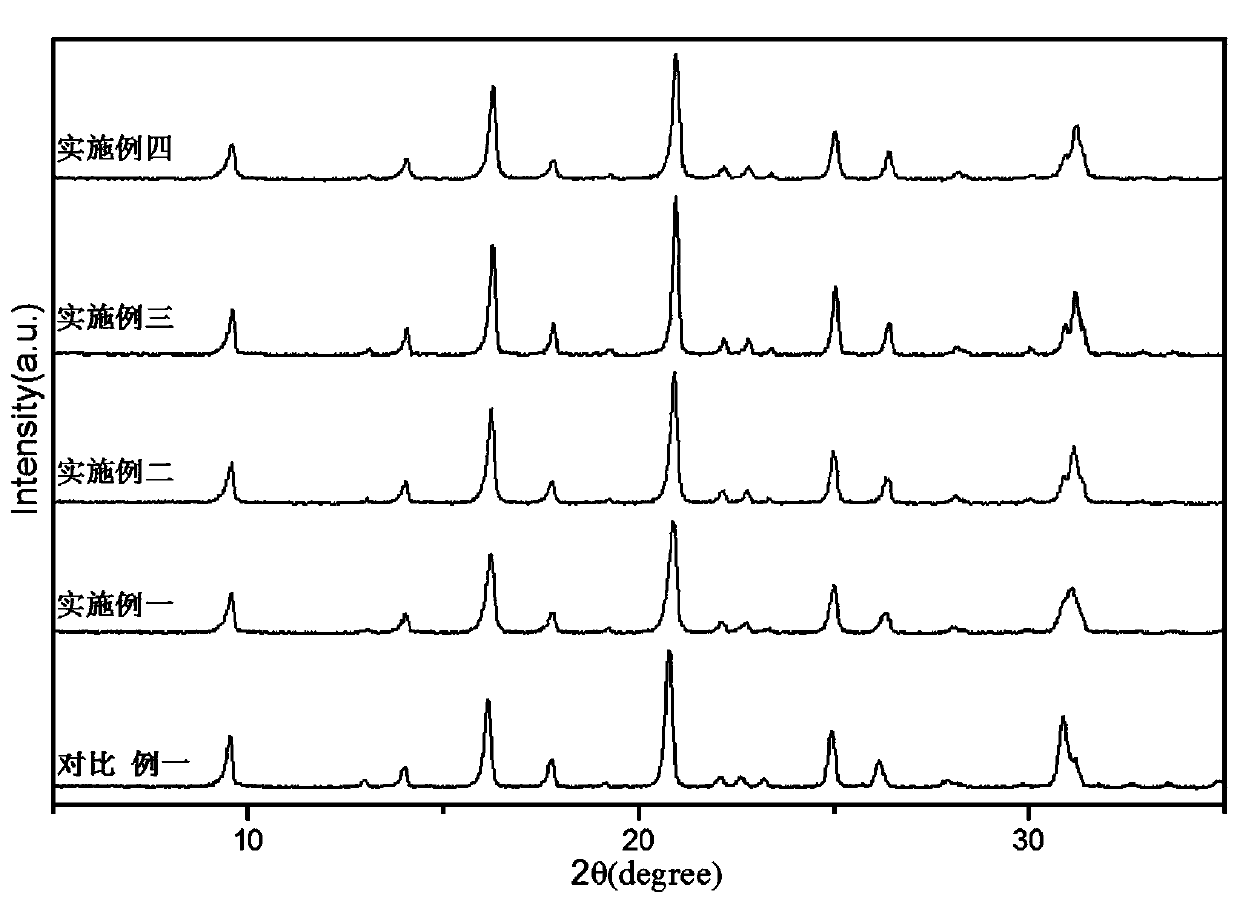

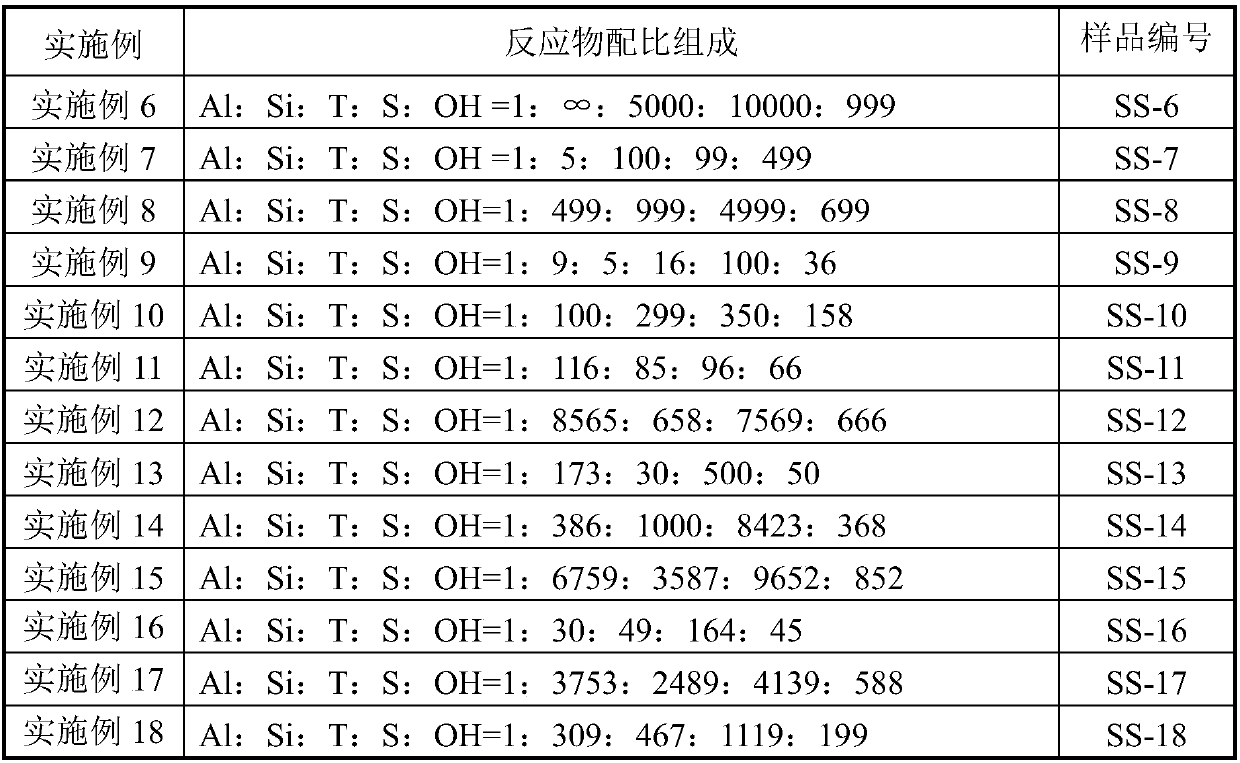

A synthetic method of an SSZ-13 molecular sieve

ActiveCN105645426AEasy to removeReduce usageCrystalline aluminosilicate zeolitesQuaternary ammonium cationHydroxyl ion

A synthetic method of an SSZ-13 zeolite molecular sieve is disclosed. The method includes preparing SSZ-13 crystals under crystallization conditions from raw materials comprising an oxide of at least one quadrivalent element or a quadrivalent element mixture, an oxide of at least one trivalent element and a trivalent element mixture, at least one alkali metal compound, N,N,N-trimethyl-1,3,5,7-tetraazatricyclo[3.3.1.1]decane-2-ammonium hydroxide or a mixture of the N,N,N-trimethyl-1,3,5,7-tetraazatricyclo[3.3.1.1]decane-2-ammonium hydroxide and the SSZ-13 molecular sieve crystal seeds, hydroxyl ions and water. The method is a method of synthesizing the SSZ-13 molecular sieve by adopting a novel and cheap template. The method avoids adoption of traditional expensive N,N,N-trimethyladamantan-1-ammonium cations or benzyl trimethyl quaternary ammonium cations as templates to synthesize the SSZ-13 molecular sieve, thus significantly reducing the cost of synthesizing the SSZ-13 zeolite molecular sieve.

Owner:CHINA CATALYST HLDG CO LTD

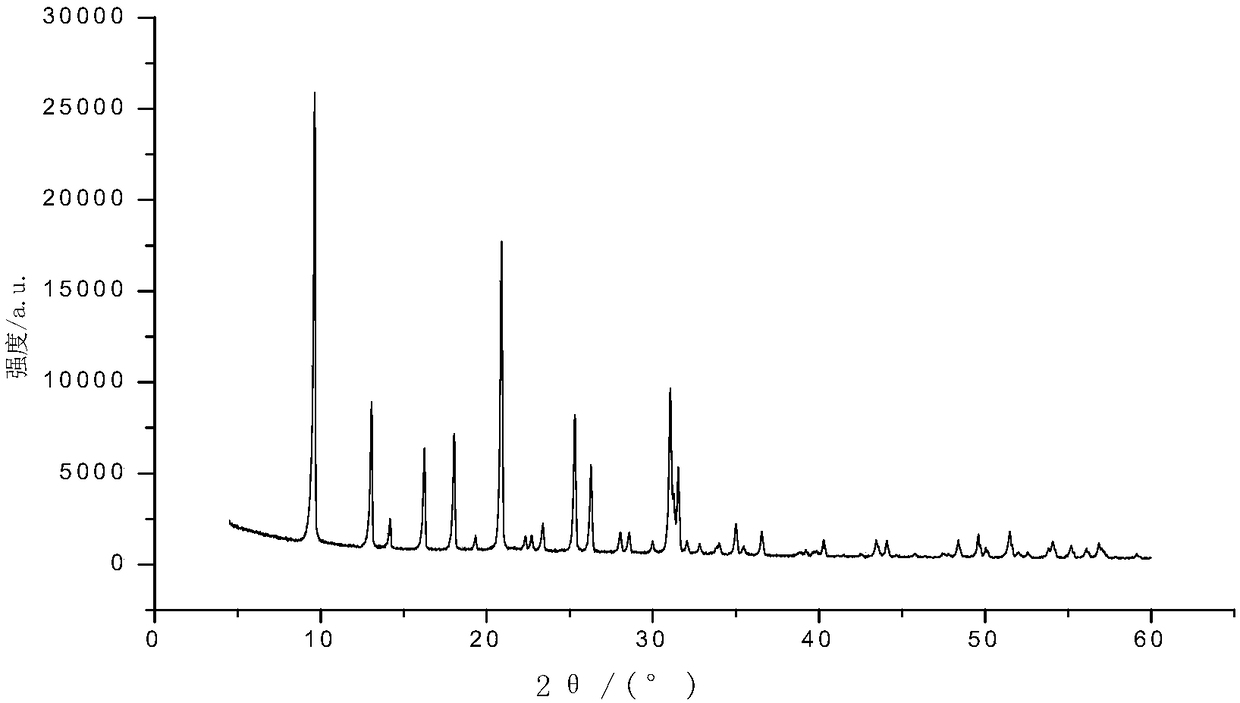

Method for preparing high-silicon CHA type SSZ-13 molecular sieve

ActiveCN107758691AImprove qualityHigh crystallinityMolecular-sieve and base-exchange compoundsSeed crystalSilicon

The invention discloses a method for synthesizing a high-silicon CHA type SSZ-13 molecular sieve by utilizing topologic reconstruction of a seed crystal and LTL type L zeolite. The method comprises the following steps: weighing water, an alkali source, a template agent, an additional solid silicon source, L zeolite and a seed crystal to carry out a crystallization reaction, completely reacting toobtain a crystallization reaction product, cooling and washing to be neutral, and drying to obtain crude molecular sieve powder; and calcining the crude molecular sieve powder in air at the temperature of 550 DEG C for a certain time, thereby obtaining the final product SSZ-13 molecular sieve. According to the method disclosed by the invention, the high-silicon CHA type SSZ-13 molecular sieve is synthesized by adopting direct topologic reconstruction of the LTL type L zeolite at a low silica-alumina ratio, and the initial L zeolite does not need to be subjected to dealuminzation pretreatment.By regulating the addition amount of the L zeolite, the silica-alumina ratio of the product SSZ-13 molecular sieve can be regulated in a wide range, the solid phase yield is increased, the productioncost can be reduced, and industrialized production is facilitated.

Owner:TAIYUAN UNIV OF TECH

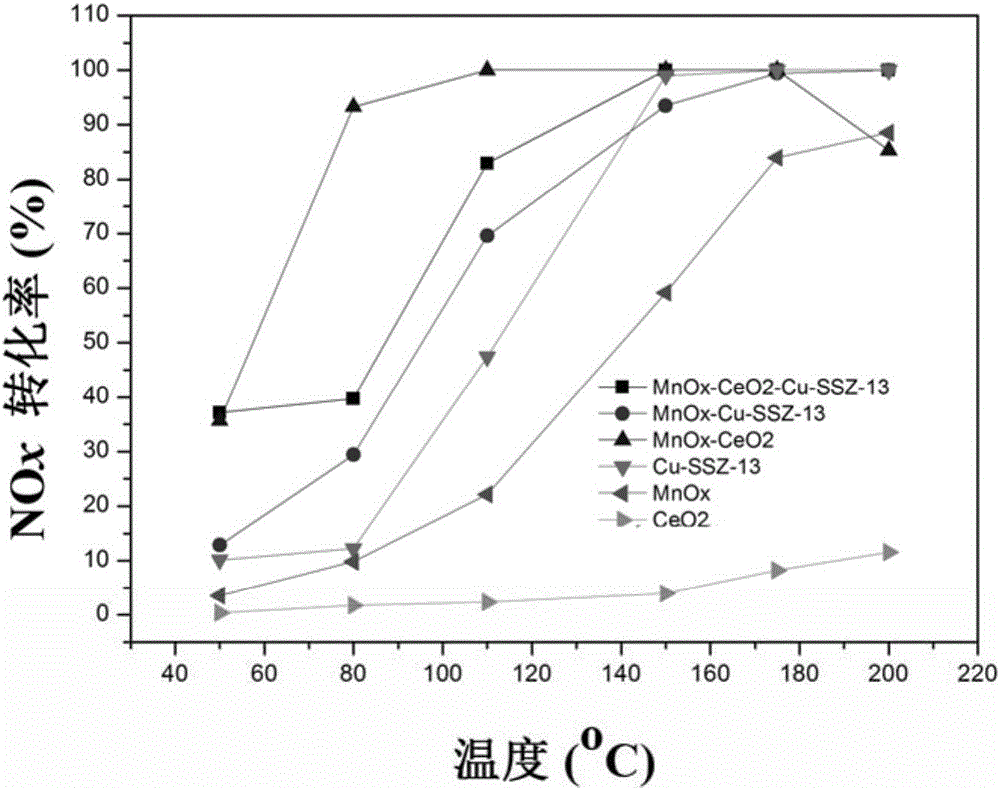

Oxide and molecular sieve compound catalyst and preparation and application thereof

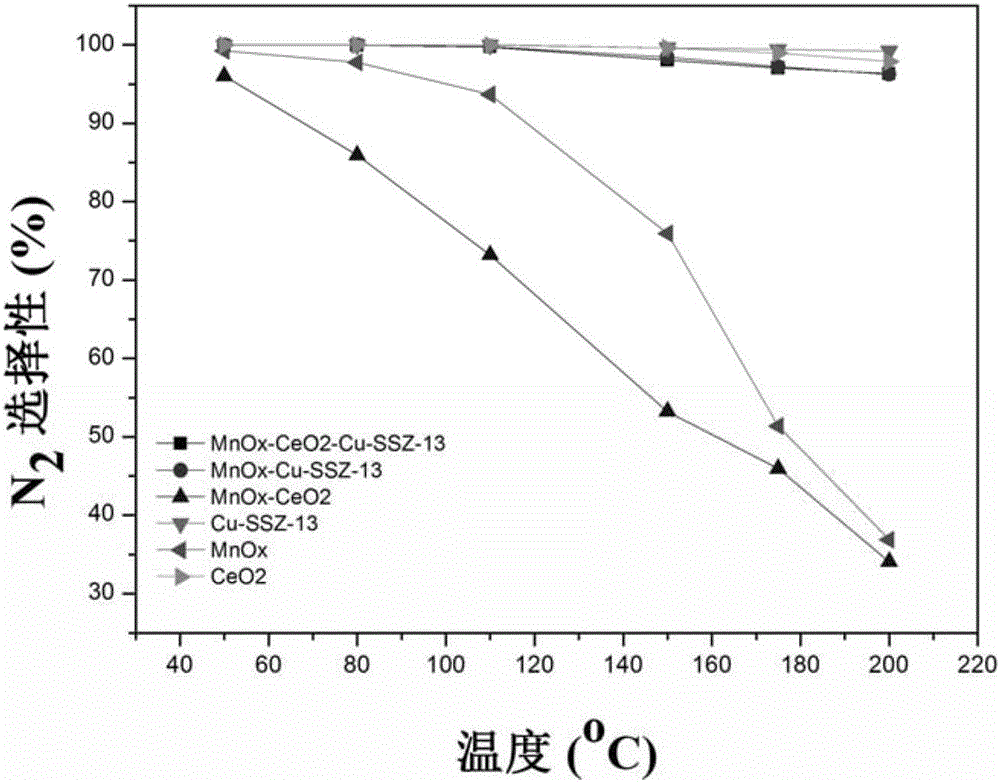

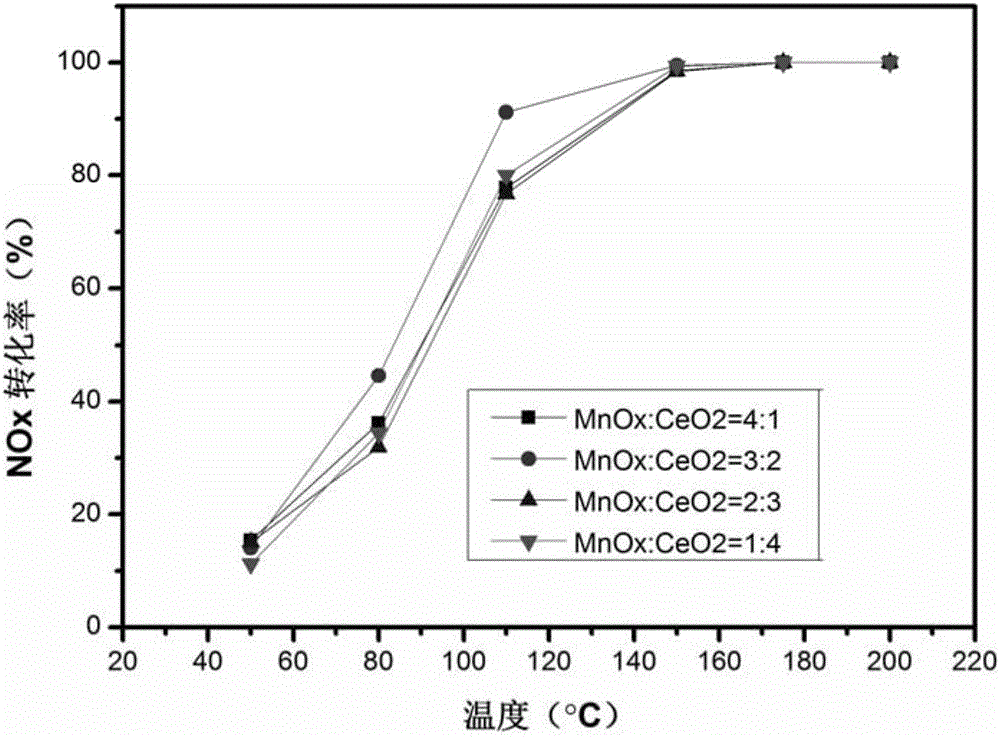

InactiveCN106311318AHigh catalytic activityHigh selectivityMolecular sieve catalystsDispersed particle separationFlue gasActive component

The invention relates to an oxide and molecular sieve compound catalyst and preparation and application thereof, and belongs to the technical fields of environmental material, environmental catalysis and environmental protection. The catalyst is prepared by taking Cu-SSZ-13 as a primary active component and manganese oxide and cerium oxide as secondary active components exerting synergistic effect, and an impregnation method is adopted. The catalyst is characterized in that low-temperature activity is greatly improved while good medium-high temperature activity of the Cu-SSZ-13 and N2 selectivity are sustained, light-off temperature is reduced to 80DEG C, and NOx conversion rate higher than 90% is achieved within the temperature range of 100-200DEG C; NH3 is taken as a reducing agent, total gas flow rate is 300ml / min, and airspeed is respectively controlled to be 15000, 50000 and 100000h<1>. The catalyst is suitable for both low-temperature NOx treatment after dust separation and desulfation in stationary-source flue gas treatment and low-temperature NOx treatment of cold-start stage in diesel exhaust treatment.

Owner:TIANJIN UNIV

Mixed matrix membrane with mesoporous particles and methods for making and using the same

InactiveUS7306647B2More productivity per unit costImprove the level ofSemi-permeable membranesIsotope separationProduct gasPorous particle

A mixed matrix membrane for separating gas components from a mixture of gas components is disclosed. The membrane comprises a continuous phase polymer with inorganic porous particles, preferably molecular sieves, interspersed in the polymer. The polymer has a CO2 / CH4 selectivity of at least 20 and the porous particles have a mesoporosity of at least 0.1 cc STP / g. The mixed matrix membrane exhibits an increase in permeability of least 30% with any decrease in selectivity being no more than 10% relative to a membrane made of the neat polymer. The porous particles may include, but are not limited to, molecular sieves such as CVX-7 and SSZ-13, and / or other molecular sieves having the required mesoporosity. A method for making the mixed matrix membrane is also described. Further, a method is disclosed for separating gas components from a mixture of gas components using the mixed matrix membrane with mesoporous particles.

Owner:CHEVROU USA INC

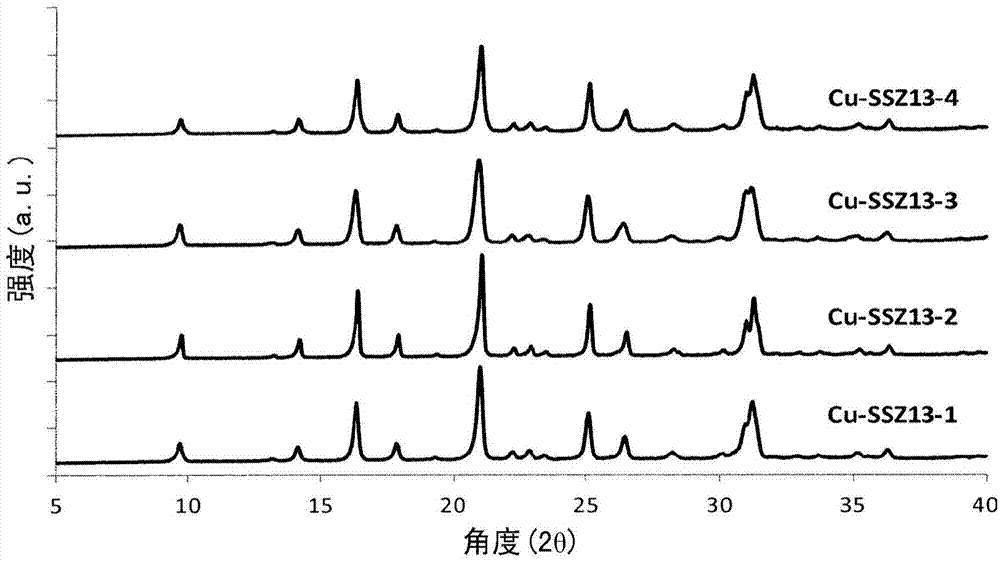

Preparation method of Cu-SSZ-13 molecular sieve

ActiveCN108529642AHigh crystallinityGood hydrothermal stabilityCrystalline aluminosilicate zeolitesPetrochemicalSilicon

The invention provides a preparation method of a Cu-SSZ-13 molecular sieve. The method comprises the following steps: (1) mixing an aluminum source, sodium hydroxide, a Cu-TEPA complex and a templateagent with deionized water, uniformly stirring, then adding a silicon source, continuously stirring till the materials are uniformly mixed to obtain a mixture; (2) crystallizing the mixture for 48-96hours at 120-170 DEG C to obtain a crystallized product; (3) drying the crystallized product for 8-12 hours at 80-120 DEG C to obtain a dried product; and (4) roasting the dried product for 6-10 hoursat 500-600 DEG C to obtain the Cu-SSZ-13 molecular sieve. The molecular sieve has broad application prospects in the fields of the petrochemical industry, MTO reaction, exhaust purification and the industry of fine chemicals, and can be used as a catalyst for removing NOx in the automobile exhaust.

Owner:山东泓泰恒瑞新材料有限公司

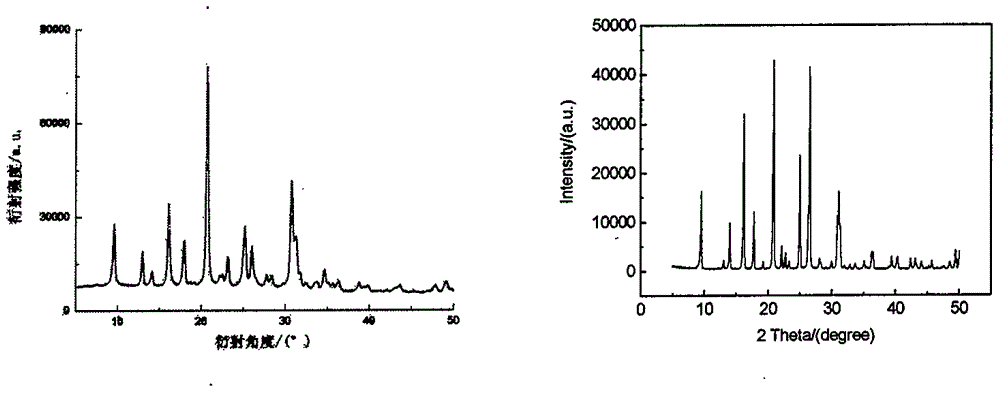

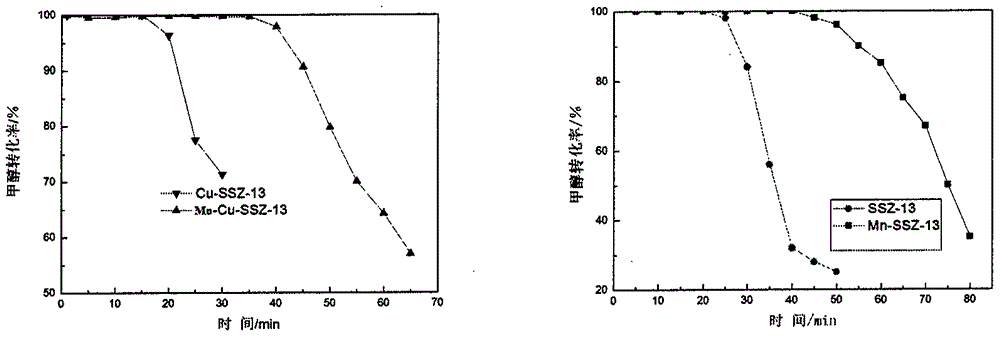

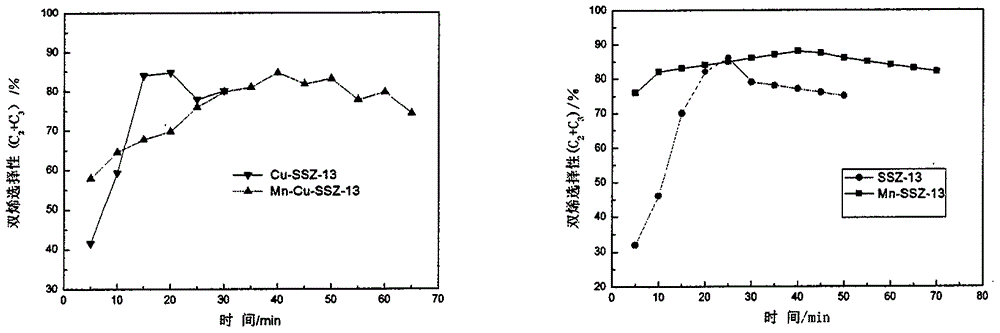

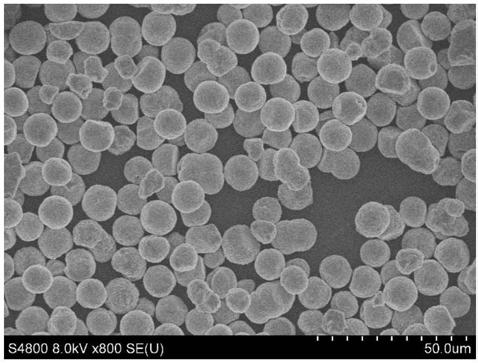

Preparation of a metal manganese modified silicon-aluminum molecular sieve material Mn-SSZ-13, and applications of the material in alkene preparation from methanol and denitration

A metal manganese modified silicon-aluminum molecular sieve material Mn-SSZ-13 is provided. The material comprises 0.1-10% of manganese, 0-15% of aluminum, 75-100% of silicon and 0-25% of copper. Two materials have CHA type topological structures, and the specific surface area measured by a BET process after calcination at 600 DEG C for 4 h is not less than 500 m<2> / g. A preparing process includes fully mixing a copper source (may be none), a template, an aluminum source, sodium hydroxide, a silicon source and water according to a certain sequence to obtain an initial gel solution, crystallizing, performing ammonium chloride ion exchange, calcinating and performing manganese ion exchange to obtain a product. The prepared molecular sieve material has advantages of high MTO diolefin selectivity and long catalytic service lifetime, and can be used for nitrogen oxide selective reduction (SCR catalysts).

Owner:TIANJIN POLYTECHNIC UNIV

SSZ-13 molecular sieve synthesis method

InactiveCN109110777AEasy to manufactureNo pollution in the processMolecular sieve catalystsCrystalline aluminosilicate zeolites1-adamantanamineSynthesis methods

The invention provides a SSZ-13 molecular sieve synthesis method, wherein the SSZ-13 molecular sieve is synthesized by using a tetravalent silicon source, a tetravalent aluminum source, hydroxide radical ions and an alkali metal compound as raw materials and using choline cations and N,N,N-trimethyl-1-ammonium adamantane as template agents. According to the present invention, the partial expensiveN,N,N-trimethyl-1-adamantanamine cation is replaced with the inexpensive choline cation as the template agent so as to significantly reduce the cost, the prepared SSZ-13 has high crystallinity, and the vanadium-free SCR catalyst capable of efficiently reducing and decomposing nitrogen oxides can be obtained through the ion exchange method.

Owner:ZHEJIANG ZHENENG TECHN RES INST

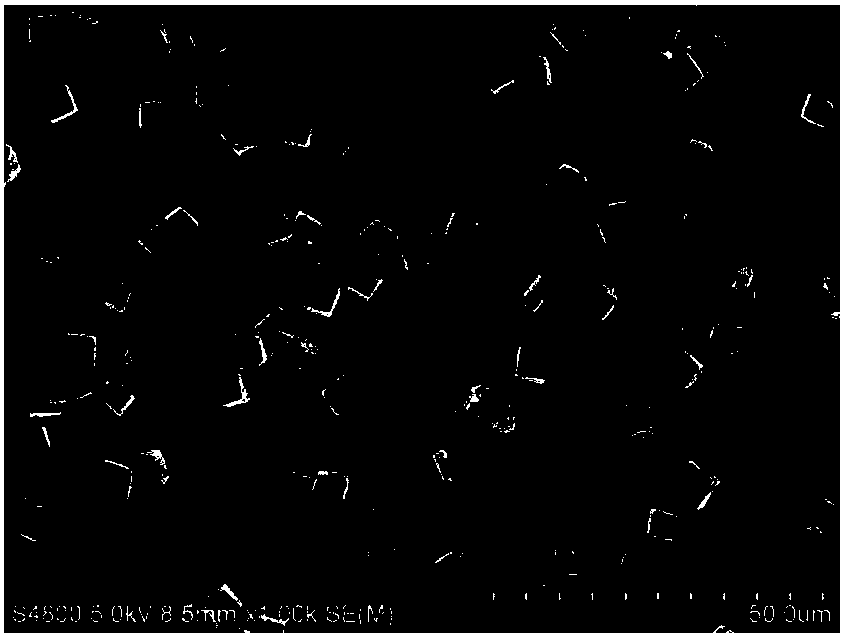

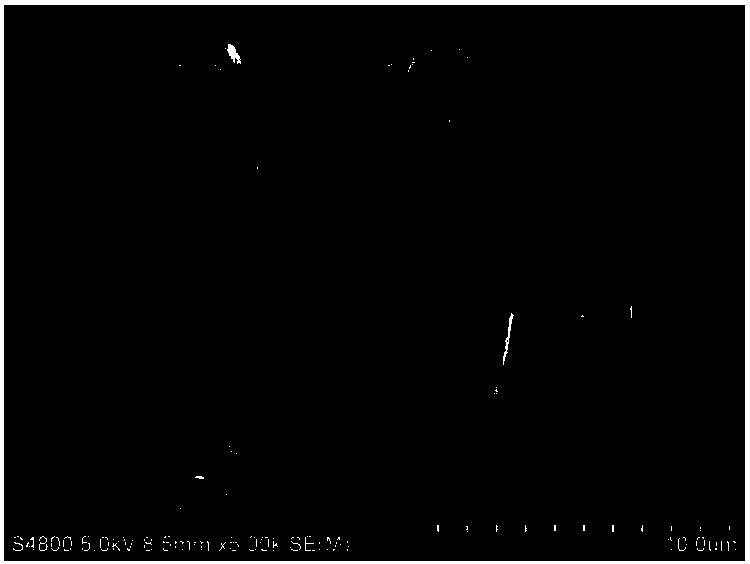

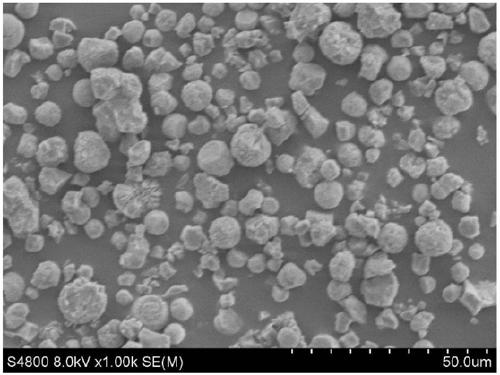

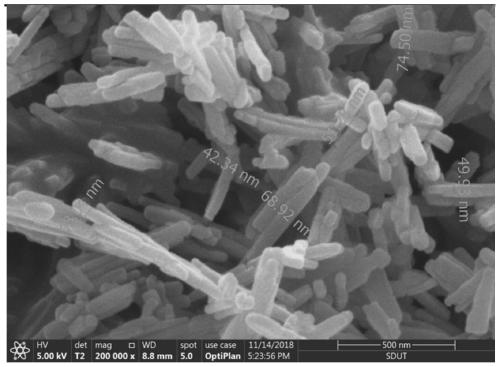

Rapid synthesis method for small-crystal-grain molecular sieves and application of small-crystal-grain molecular sieves

ActiveCN109704365ASmall grainReduce manufacturing costFerrierite aluminosilicate zeoliteMolecular-sieve and base-exchange phosphatesSynthesis methodsCombinatorial chemistry

The invention belongs to the field of preparation of molecular sieves and particularly relates to a rapid synthesis method for small-crystal-grain molecular sieves and an application of the small-crystal-grain molecular sieves. The rapid synthesis of the small-crystal-grain molecular sieves is achieved through the procedures of firstly, preparing a precursor mixture, then, preparing gel and finally carrying out direct crystallization. The method is applied to the synthesis of the following molecular sieves, but not limited to: ZSM-5, ZSM-11, ZSM-22, ZSM-23, ZSM-35, SAPO-34, SAPO-11, SAPO-18, SSZ-13 and EU-1. Molecular sieve products synthesized by the method have the characteristics of small crystal grain, large specific surface area, high crystallinity and high yield. According to the method, the crystallization time can be shortened greatly, the production efficiency is increased, and the manufacturing cost of the molecular sieves is reduced.

Owner:SHANDONG QILU HUAXIN HIGH TECH

Synthesis method of SSZ-13 zeolite

ActiveCN106986354ALow toxicityOvercome expensiveCrystalline aluminosilicate zeolitesAlkaline earth metalSynthesis methods

The present invention belongs to the technical field of zeolite molecular sieves, and in particular relates to a synthesis method of SSZ-13 zeolite. The method comprises the steps: performing hydrothermal reaction on a mixture of alkali metal or an alkaline earth metal source, an oxide source of a trivalent element, an oxide source of a tetravalent element, water and a structural guiding agent, to obtain an SSZ-13 zeolite crystal, cooling, filtering, and washing with water to obtain SSZ-13 zeolite. The structural guiding agent used in the invention has the advantages of low toxicity, low cost, wide range of Si / Al ratio of a synthetic product, low activation temperature, and easiness in industrialization compared with other known structural guiding agents. The SSZ-13 zeolite prepared in the invention shows a high catalytic conversion rate in catalytic removal reaction of nitrogen oxides when being used as a catalyst.

Owner:FUYU ZHANGJIAGANG NEW MATERIALS TECH CO LTD

SSZ-13/SSZ-39 composite structure molecular sieve as well as synthesis method thereof

ActiveCN109701619AGood channel structureSuitable for acidityHydrocarbon from carbon oxidesMolecular sieve catalystsSynthesis methodsHydrocarbon

The invention relates to an SSZ-13 / SSZ-39 composite structure molecular sieve as well as a synthesis method thereof, and mainly solves the problems of single structures, less strong and weak acid centers and low catalytic activity of molecular sieve porous materials in the prior art. The SSZ-13 / SSZ-39 composite structure molecular sieve is characterized by comprising the SSZ-13 and SSZ-39 two phases, the problems are well solved, and the SSZ-13 / SSZ-39 composite structure molecular sieve can be applied to industrial production of hydrocarbon downstream products from a synthesis gas.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method for SCR catalyst for purifying oxynitride in motor vehicle exhaust

InactiveCN105833899ASmooth coating processImprove stabilityGas treatmentInternal combustion piston enginesCrystallizationSSZ-13

The invention discloses a preparation method for an SCR catalyst for purifying oxynitride in motor vehicle exhaust .The preparation method includes the steps of preparation of an SSZ-13 molecular sieve, preparation of a Cu-SSZ-13 catalyst and preparation of an integrated SCR catalyst .The preparation method is simple, production cost is lowered, SSZ-13 crystallization time is short, crystallization is relatively pure, HN3-SCR catalytic activity is high, and the purification rate of oxynitride in motor vehicle exhaust is high.

Owner:ZHEJIANG FORSOL ENERGY

SSZ-13 molecular sieve catalyst as well as preparation method and application thereof

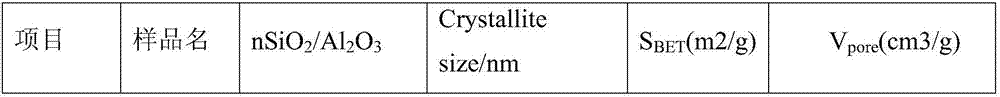

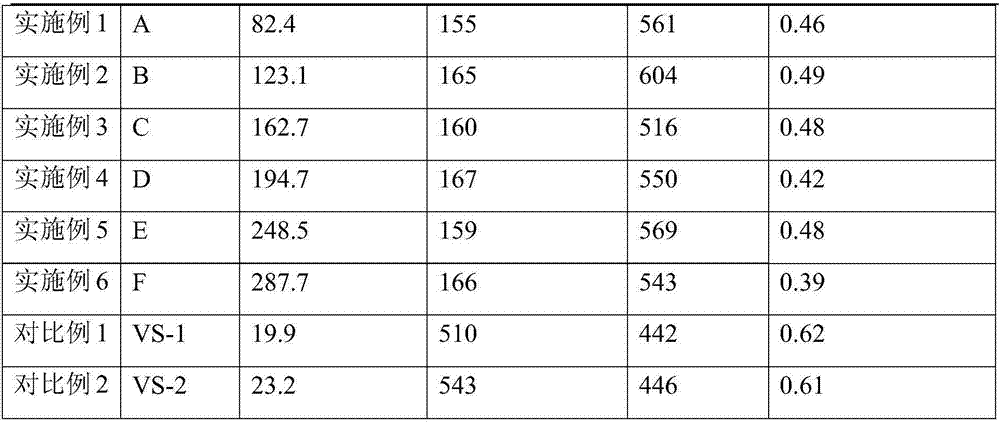

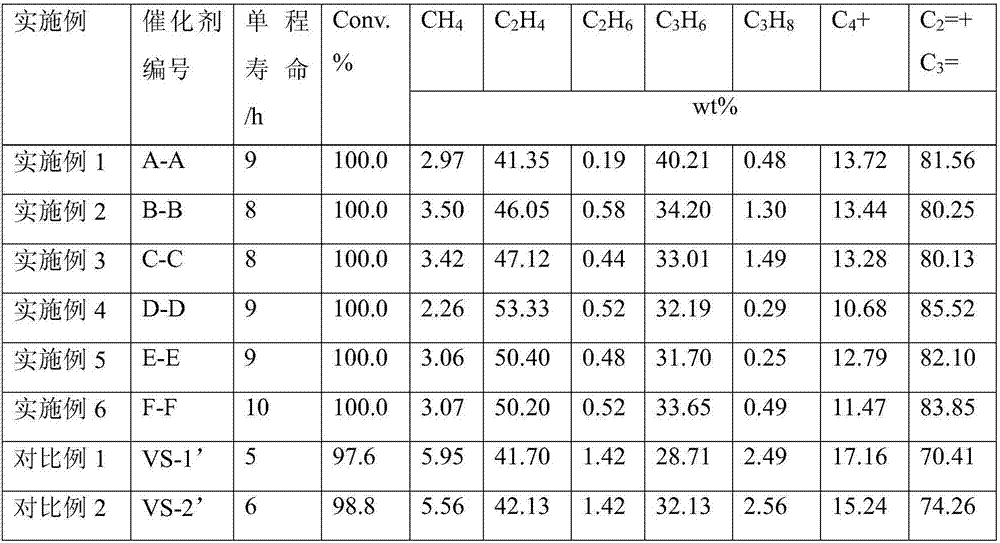

ActiveCN107282096ASmall grainReduce scaling resistanceMolecular sieve catalystsMolecular sieve catalystAir atmosphereHydrogen

The invention provides an SSZ-13 molecular sieve catalyst as well as a preparation method and application thereof. The preparation method comprises the following steps: adding a sodium source, a silicon source, an aluminum source, a boron source, a template agent and deionized water into a synthesis kettle according to a ratio, then dynamically or statically crystallizing in temperature stages, filtering, washing and drying the product to obtain molecular sieve raw powder; roasting the molecular sieve raw powder at high temperature in the air atmosphere for removing the template agent, exchanging the molecular sieve raw powder with ammonium ions, then roasting the molecular sieve raw powder at the high temperature to obtain a hydrogen type SSZ-13 molecular sieve with a high silicon-aluminum ratio (the ratio of nSiO2 to nAl2O3 is greater than 80), wherein the hydrogen type SSZ-13 molecular sieve has appropriate acidic sites, thermal stability and aperture size. According to the SSZ-13 molecular sieve with controllable and high silicon-aluminum ratio, high crystallinity, small crystal grains, the range of the silicon-aluminum ratio of SSZ-13 prepared by the conventional method is broken through; the problem that the crystallinity of the molecular sieve catalyst during regeneration is reduced can be solved; when the SSZ-13 molecular sieve is used as a catalyst and is applied to MTO reaction, the SSZ-13 molecular sieve has extremely high reaction activity and selectivity.

Owner:CHINA CATALYST HLDG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com