SSZ-13/SSZ-39 composite structure molecular sieve as well as synthesis method thereof

A technology of SSZ-39 and composite structure, applied in molecular sieve catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve unrelated problems and achieve good stability and good technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

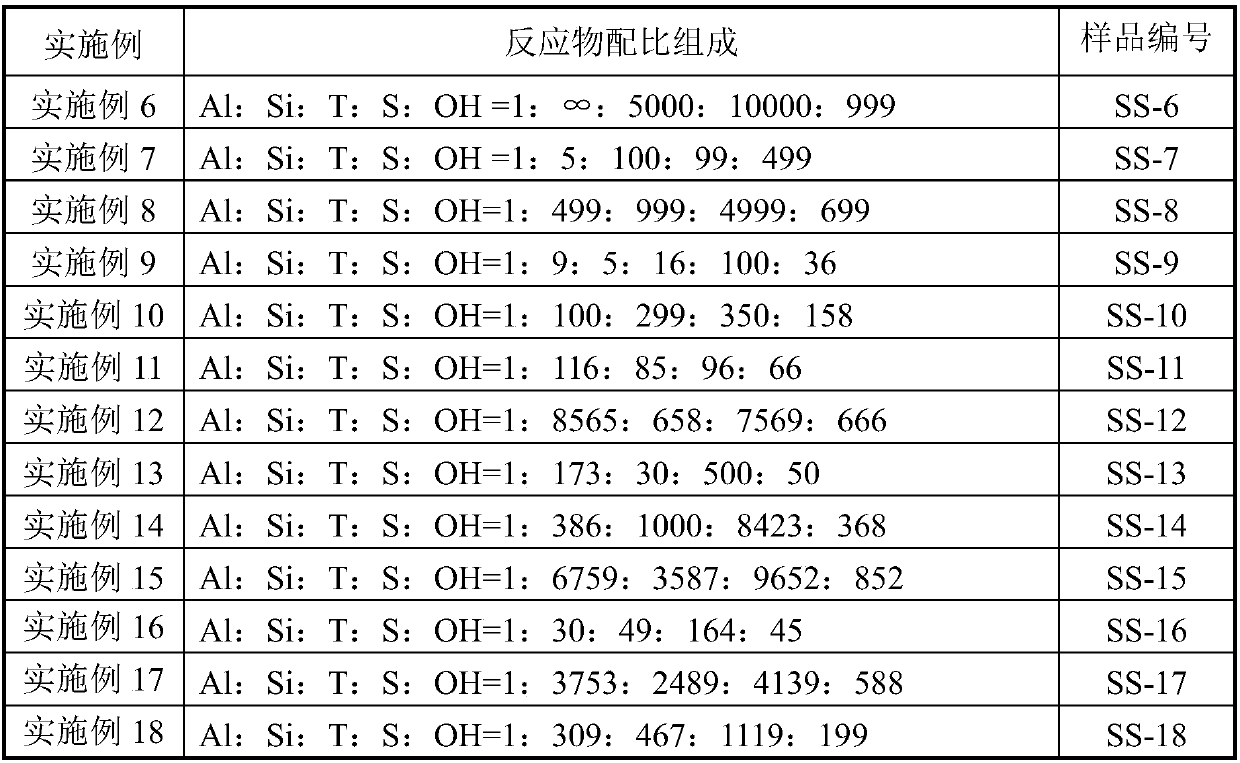

Examples

Embodiment 1

[0040] Synthesis of SSZ-13 / SSZ-39 Composite Molecular Sieves

[0041] 10.58g of silica sol [SiO 2 , 40wt.%, 0.07mol] was dissolved in 60.74mL of water, mixed to make solution S, and then the solution was divided into two parts by mass, 75% and 25%, respectively, and recorded as solution S c and solution S a , 3.27g sodium aluminate [NaAlO 2 , purity ≥98wt.%, 0.04mol], 15.78g amantadine [TMAdaOH, purity ≥98wt.%, 0.10mol] into S c solution, stirred for 0.5h to obtain solution S c '; 1.73g of sodium aluminate [NaAlO 2 , purity≥98wt.%,, 0.02mol] and 0.62g of USY molecular sieve, 0.23g of Beta molecular sieve and 8.19g of N,N-dimethyl-2-ethylpiperidinium bromide [DMEPBr, 0.06mol] and 3.13 g of 1-methyl-4-aminopiperidine [MAP, 0.04mol] was put into S a In the solution, after fully stirring for 0.2h, add 3.64g of sodium hydroxide [NaOH, 0.09mol] into the above solution to adjust the pH value of the solution between 8 and 9, and continue stirring for 0.3h to obtain solution S a...

Embodiment 2

[0043] Synthesis of SSZ-13 / SSZ-39 Composite Molecular Sieves

[0044] 4414.85g of silica sol [SiO 2 , 60wt.%, 44.15mol] was dissolved in 34651.86mL of water, mixed to make solution S, and then the solution was divided into two parts by mass, 35% and 65%, respectively, and recorded as solution S c and solution Sa , 995.99g of aluminum sulfate [Al 2 (SO 4 ) 3 18H 2 O, purity ≥98wt.%, 1.49mol], 530.64g choline [Choline, 50wt.%, 2.19mol] and 119.39g amantadine [TMAdaOH, purity ≥98wt.%, 0.37mol] were put into S c solution, stirred for 3.5h to obtain solution S c '; 1004.01g of aluminum sulfate [Al 2 (SO 4 ) 3 18H 2 O, purity ≥98wt.%, 1.51mol] and 99.68g of USY molecular sieves, 50.55g of MOR molecular sieves and 535.91g of 1-benzyl-4-hydroxypiperidine [BeOP, 3.26mol], 463.13g of N,N -Dimethyl-2-ethylpiperidinium chloride [DMEPCl, 2.21mol] into S a In the solution, 909.89g of potassium hydroxide [KOH, 16.23mol] was added to the above solution to adjust the pH value of the...

Embodiment 3

[0046] Synthesis of SSZ-13 / SSZ-39 Composite Molecular Sieves

[0047] 666.78g of white carbon black [SiO 2 , 99wt.%, 11.10mol] was dissolved in 5520.88mL of water, mixed to make solution S, and then the solution was divided into two parts by mass, 50% and 50%, respectively, and recorded as solution S c and solution S a , 82.33g of aluminum nitrate [Al(NO 3 ) 3 9H 2 O, purity ≥98wt.%, 0.22mol], 127.98g amantadine [TMAdaOH, purity ≥98wt.%, 0.85mol] into S c solution, stirred for 3.3h to obtain solution S c '; 56.21g of aluminum nitrate [Al(NO 3 ) 3 9H 2 O, purity ≥98wt.%, 0.15mol], 33.22g of USY molecular sieves, and 135.30g of 2,2,4,6,6-pentamethyl-2-azabicyclo[3.2.1]octane [PMNO , 0.66mol] and 90.65g of N,N-dimethyl-3,5-dimethylpiperidinium bromide [DMDMPBr, 0.41mol] into S a In the solution, after fully stirring for 2.9 hours, add 2656.56 g of lithium hydroxide [LiOH, 110.69 mol] to the above solution to adjust the pH value of the solution between 11 and 12, and con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com