Method for synthesizing SSZ-13 molecular sieve by double-template agent in one step and application of SSZ-13 molecular sieve

A dual-template, molecular sieve technology, used in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem that SSZ-13 molecular sieve cannot be widely used, and achieve excellent selective reduction ability and wide reaction temperature. Window, high-yield effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

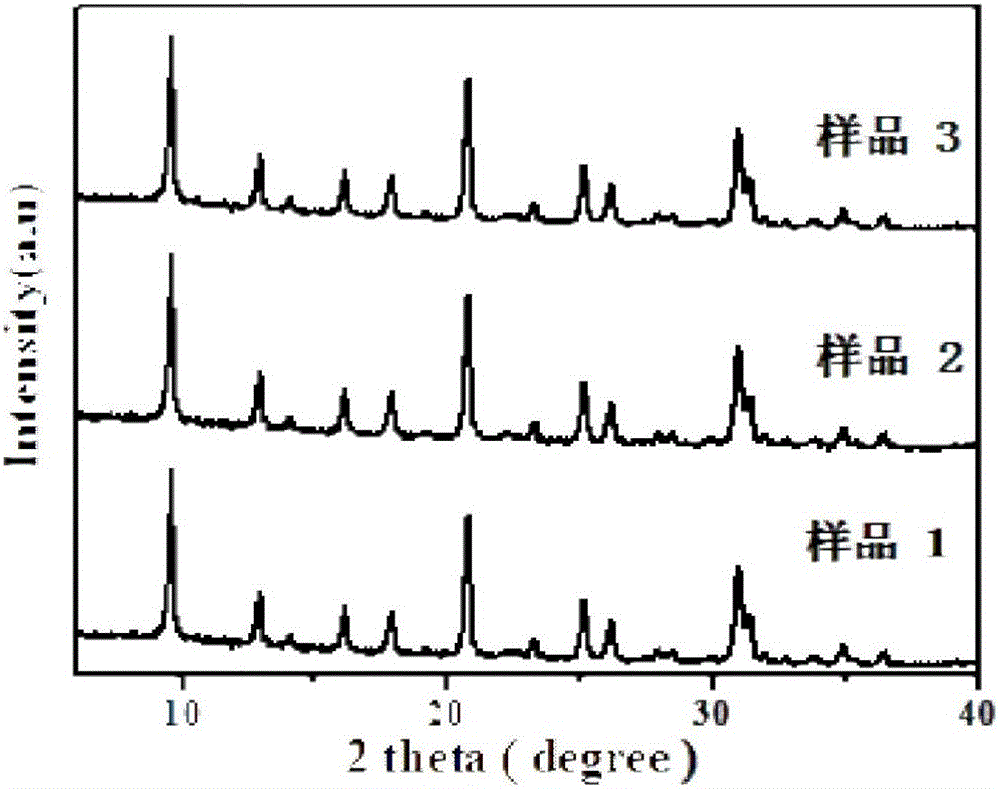

Embodiment 1

[0024] (1) Add 0.8 g of sodium hydroxide to 40 g of deionized water at room temperature, and stir for 2 hours at room temperature until the sodium hydroxide is completely dissolved;

[0025] (2) Then add 0.5g sodium metaaluminate (content is 80%), stir until uniform;

[0026] (3) Slowly add 0.2g N,N,N-trimethyl-1-adamantanamine (content: 25%) and 0.85g choline chloride respectively, and continue to stir until uniform;

[0027] (4) continue to add 15g silica sol (content is 30%), stir to form homogeneous sol;

[0028] (5) Put the sol into a hydrothermal reaction kettle with a polytetrafluoroethylene liner, and crystallize at 155° C. for 4 days;

[0029] (6) After the crystallization is completed, the sol is cooled to room temperature, after centrifugal filtration, deionized water washing, drying, and calcining at 600°C for 5 hours to obtain SSZ-13 molecular sieve, which is designated as sample 1;

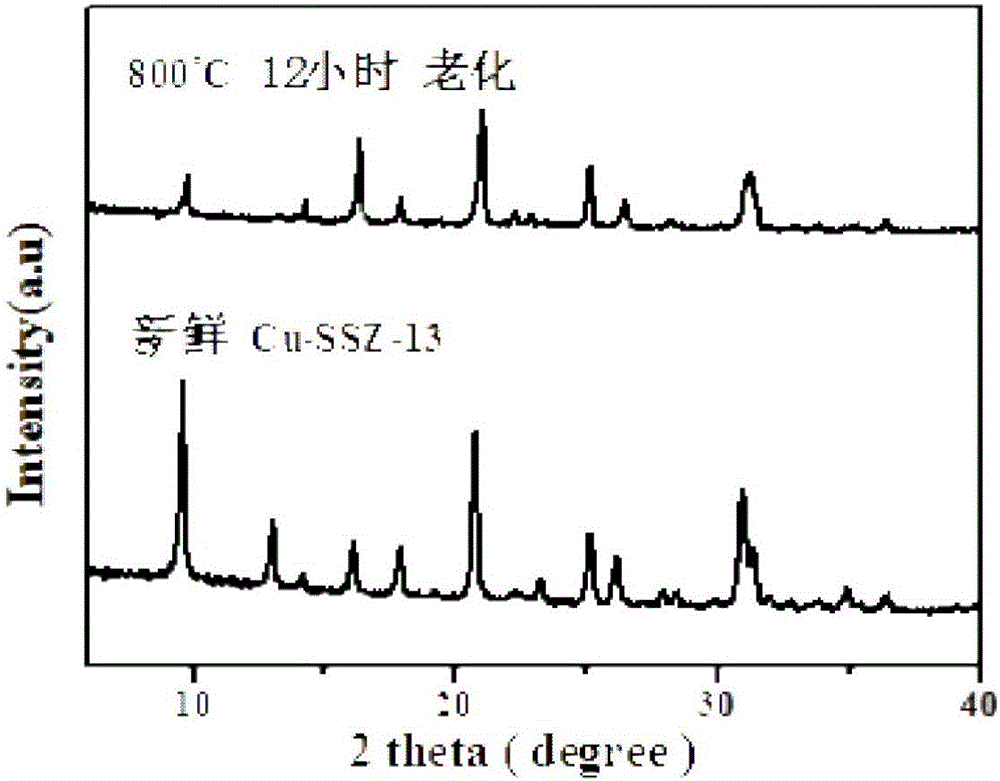

[0030] (7) The obtained SSZ-13 molecular sieve was ion-exchanged with 0.5mol / L...

Embodiment 2

[0038] (1) Add 0.7 g of sodium hydroxide to 40 g of deionized water at room temperature, and stir for 2 hours at room temperature until the sodium hydroxide is completely dissolved;

[0039] (2) Then add 0.6g sodium metaaluminate (content is 80%), stir until uniform;

[0040] (3) Slowly add 0.4g of N,N,N-trimethyl-1-adamantanamine (content: 25%) and 0.45g of choline chloride respectively, and continue stirring until uniform;

[0041] (4) continue to add 12g silica sol (content is 30%) again, stir to form homogeneous sol;

[0042] (5) Put the sol into a hydrothermal reaction kettle with a polytetrafluoroethylene liner, and crystallize at 155° C. for 4 days;

[0043] (6) After the crystallization is completed, the sol is cooled to room temperature, and after being centrifugally filtered, washed with deionized water, and dried, it is calcined at 600°C for 5 hours to obtain SSZ-13 molecular sieve, which is designated as sample 2;

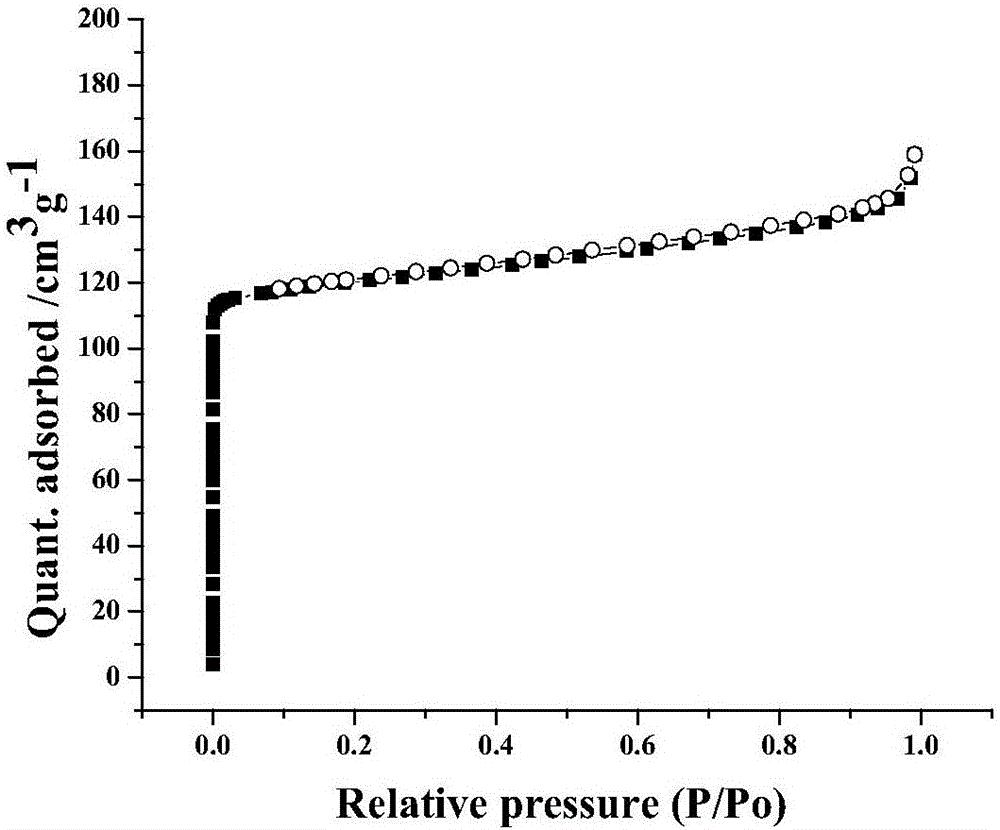

[0044] After the bet test, the bet specific sur...

Embodiment 3

[0046] (1) Add 0.7 g of sodium hydroxide to 40 g of deionized water at room temperature, and stir for 2 hours at room temperature until the sodium hydroxide is completely dissolved;

[0047] (2) Then add 0.6g sodium metaaluminate (content is 80%), stir until uniform;

[0048] (3) Slowly add 0.6g of N,N,N-trimethyl-1-adamantanamine (25% content) and 0.15g of choline chloride, and continue stirring until uniform;

[0049] (4) continue to add 15g silica sol (content is 30%) again, stir to form homogeneous sol;

[0050] (5) Put the sol into a hydrothermal reaction kettle with a polytetrafluoroethylene liner, and crystallize at 155° C. for 4 days;

[0051] (6) After the crystallization is completed, the sol is cooled to room temperature, and after being centrifugally filtered, washed with deionized water, and dried, it is calcined at 600°C for 5 hours to obtain SSZ-13 molecular sieve, which is designated as sample 3;

[0052] After the bet test, the bet specific surface area of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com