High silicon CHA type SSZ-13 zeolite membrane preparation method

A molecular sieve and high-silicon technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of limited carbon dioxide and gas permeation flux decline, and achieve the promotion of cross-linking growth and high separation selectivity , the effect of reducing the synthesis cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

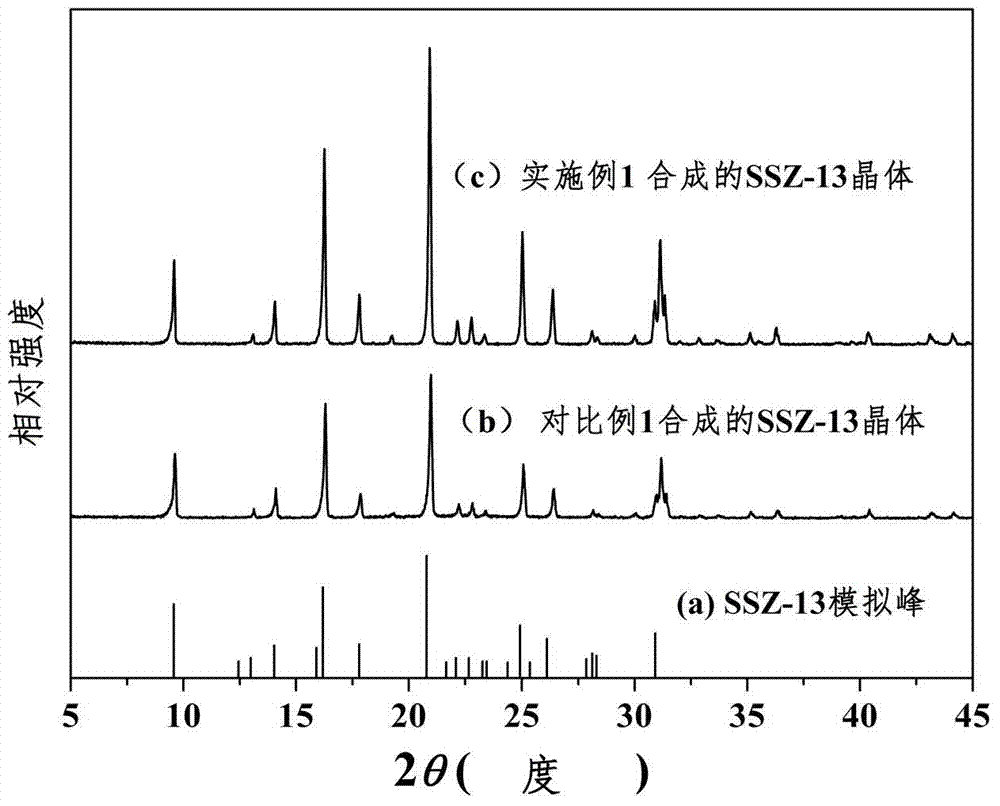

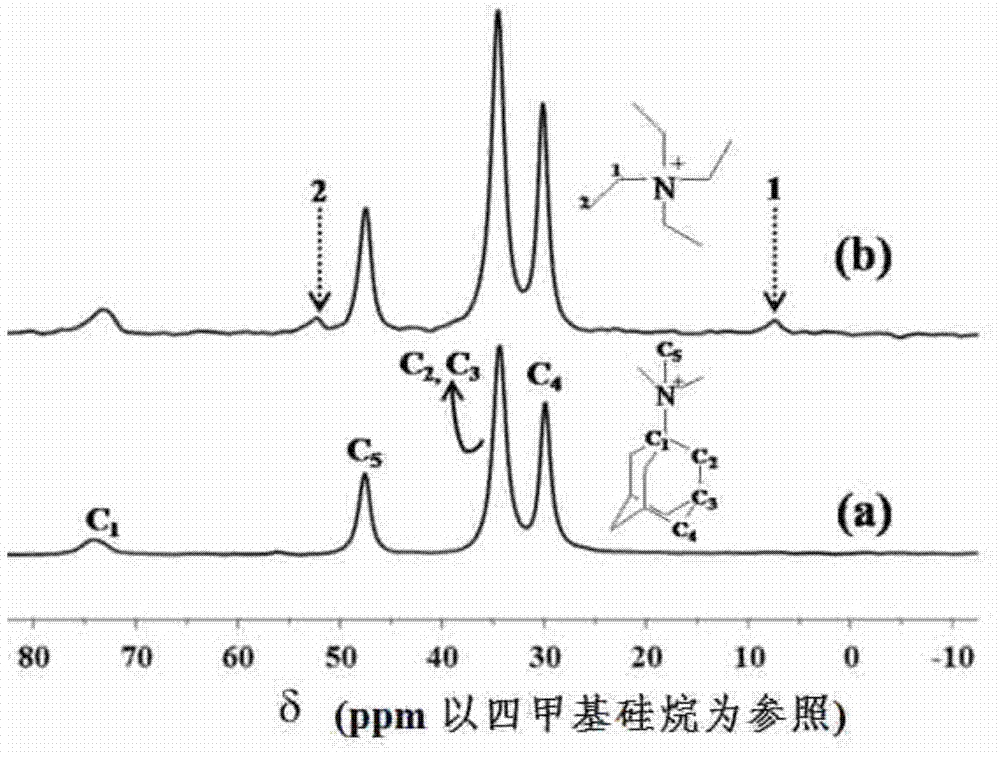

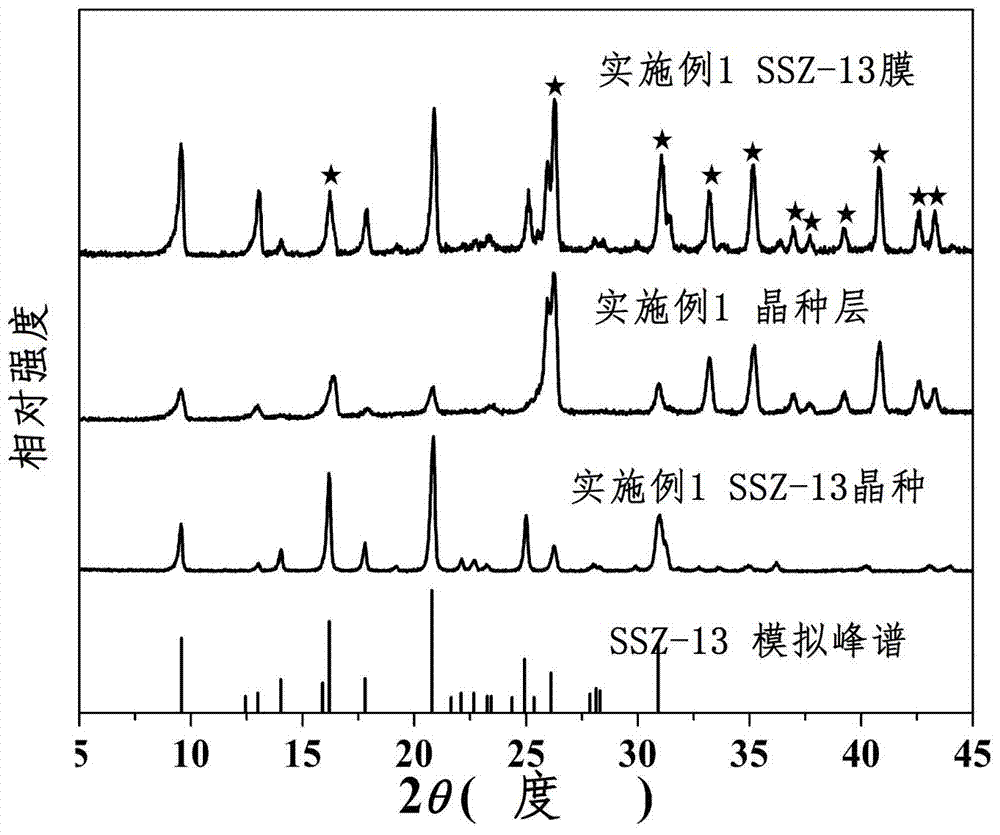

[0031] (1) SSZ-13 molecular sieve seed crystal preparation: trimethylammonium hydroxide, tetraethylammonium hydroxide, aluminum hydroxide, silica sol and water were mixed, stirred and aged for 12 hours, and the components of the formed sol The molar ratio is: SiO 2 / Al 2 o 3 =60, TMAdaOH / SiO 2 = 0.4, TEAOH / SiO 2 =0.4,H 2 O / SiO 2 =30. The sol was placed in a polytetrafluoroethylene-lined stainless steel reactor, hydrothermally synthesized at a synthesis temperature of 190°C for 30 hours, and centrifuged to obtain SSZ-13 molecular sieve crystals.

[0032] (2) Support body pretreatment: Nanjing Jiusi porous mullite tube is used as the support body for membrane synthesis, and the molar ratio is 66% Al 2 o 3 and 34% SiO 2 . The inner and outer diameters are 9mm and 12mm respectively, the length is 100mm, the average pore diameter is about 1.0μm, and the porosity is about 30%. After the support is pretreated with 800-mesh sandpaper and ultrasonic cleaning, after drying, i...

Embodiment 2

[0042] (1) Preparation of SSZ-13 molecular sieve seed crystals: the preparation process is the same as step (1) of Example 1, except that the sol aging time is 1 hour, the reaction temperature is 140° C., and the reaction time is 72 hours.

[0043] (2) support body pretreatment: same as embodiment 1 step (2), the difference is that the macroporous alumina tube produced by Nanjing Jiusi Company is used as the support body, and the inner diameter and outer diameter of the support body are 9mm and 12mm respectively, The length is 100 mm, the average pore diameter is about 1.3 μm, and the porosity is about 35%.

[0044] (3) Preparation of SSZ-13 molecular sieve membrane: the same as step (3) in Example 1, except that the sol molar ratio is SiO 2 / Al 2 o 3 = 10, TMAdaOH / SiO 2 = 0.8, TEAOH / SiO 2 =0.2,H 2 O / SiO 2 =180, the reaction temperature is 230° C., and the reaction time is 12 hours.

[0045] The synthesized molecular sieve membrane M2 was used at 25°C, CO 2 / CH 4 The ...

Embodiment 3

[0047] (1) SSZ-13 molecular sieve seed crystal preparation: the preparation process is the same as step (1) of Example 1, the difference is that the silicon source is silicon powder, and the sol ratio is that the molar ratio of each component of the sol is: SiO 2 / Al 2 o 3 =240, TMAdaOH / SiO 2 = 0.8, TEAOH / SiO 2 =0.2,H 2 O / SiO 2 =100, the reaction temperature is 230° C., and the reaction time is 12 hours.

[0048] (2) Support body pretreatment: After the porous alumina tube (the specifications are the same as in Example 5) is pretreated with 800-mesh sandpaper and ultrasonic cleaning and dried, SSZ-13 seed crystals are wiped on the surface of the support body, and repeated Wipe for 1 minute, blow the support surface with 0.15Mpa (absolute pressure) compressed air for 10 seconds, and the seed crystal loading density on the support surface is about 0.5mg / cm 2 .

[0049] (3) Preparation of SSZ-13 molecular sieve membrane: same as step (3) of Example 1, the difference is tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com