Copper-based supported ammoxidation catalyst and preparation method thereof

A supported, ammonia oxidation technology, applied in the field of ammonia escape control and environmental protection, to achieve the effects of high selectivity, improved N2 selectivity, and high activity selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

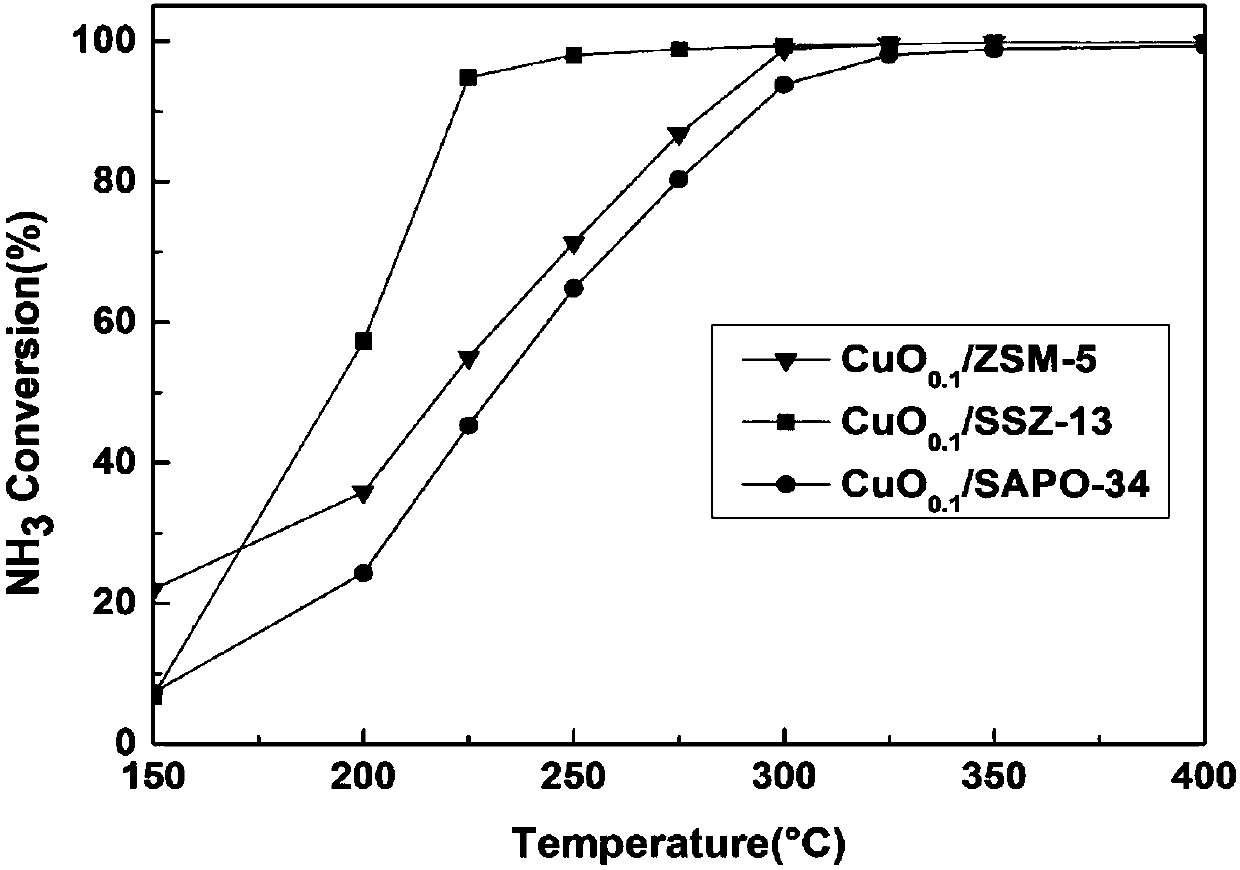

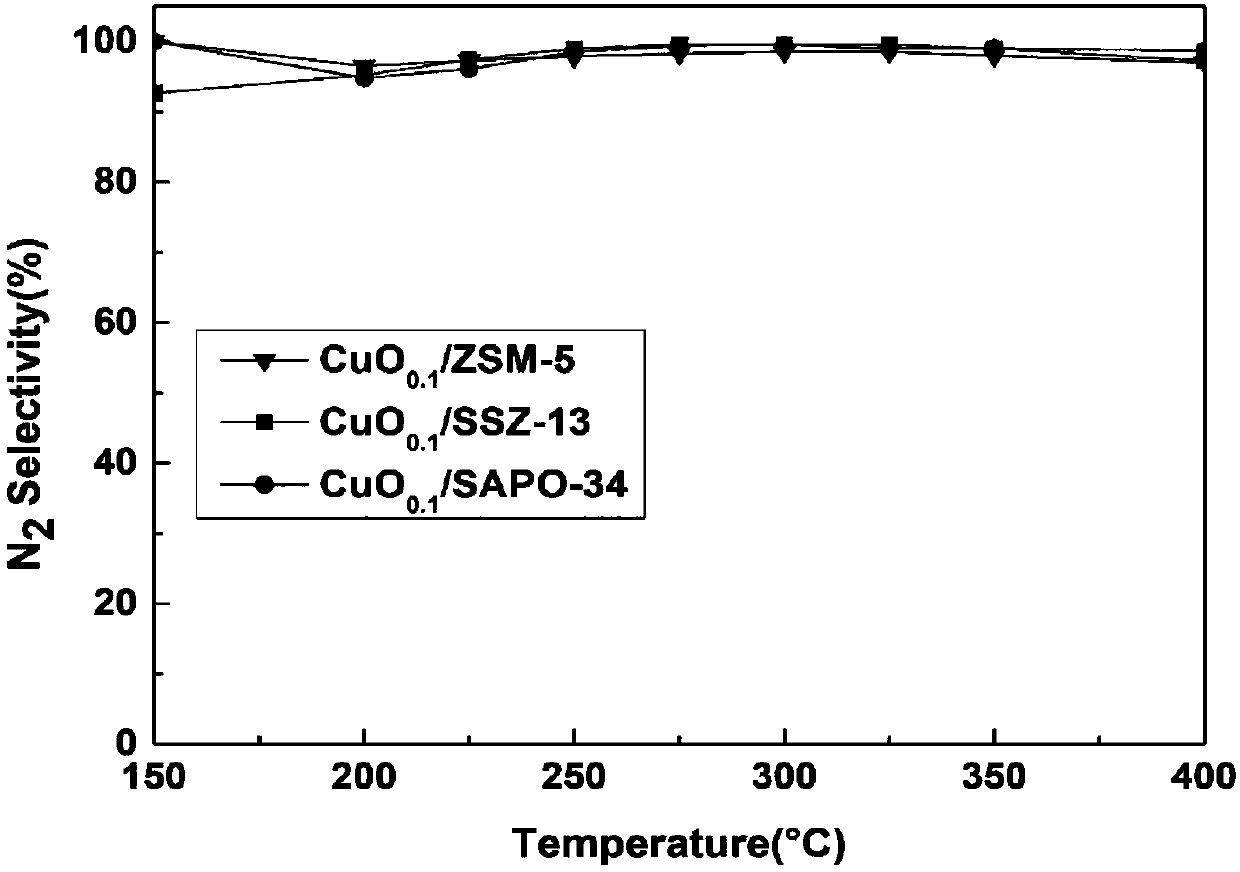

[0027] CuO 0.1 / Preparation of ZSM-5 samples

[0028] (1) take by weighing 0.9075g copper nitrate trihydrate and 3g ZSM-5 powder for subsequent use;

[0029] (2) Dissolve the weighed copper nitrate trihydrate in a small amount of deionized water;

[0030] (3) After the copper nitrate trihydrate is completely dissolved, add the weighed ZSM-5 powder therein, and stir at room temperature for 5 minutes;

[0031] (4) After stopping stirring, transfer the obtained solution to a rotary evaporator, and use a rotary evaporator to evaporate at a speed of 500r / min and a water bath temperature of 70°C for 2h to evaporate the solvent;

[0032] (5) Put the evaporated material into an oven at 100°C for 12 hours to obtain a semi-finished product;

[0033] (6) Put the obtained semi-finished product into the muffle furnace, and heat it at 10°C min -1 The temperature was raised to 400°C for 6 hours, and then cooled naturally in the furnace to prepare a copper-based supported ammoxidation ca...

Embodiment 2

[0036] CuO 0.1 / SAPO-34 sample preparation

[0037] (1) Take by weighing 0.9075g copper nitrate trihydrate and 3g H-SAPO-34 powder for subsequent use;

[0038] (2) Dissolve the weighed copper nitrate trihydrate in a small amount of deionized water;

[0039] (3) After the copper nitrate trihydrate is completely dissolved, add the weighed H-SAPO-34 powder therein, and stir at room temperature for 5 minutes;

[0040] (4) After stopping stirring, transfer the obtained solution to a rotary evaporator, and use a rotary evaporator to evaporate at a speed of 400r / min and a water bath temperature of 60°C for 2h to evaporate the solvent;

[0041] (5) Put the evaporated material into an oven at 100°C and dry for 14 hours to obtain a semi-finished product;

[0042] (6) Put the obtained semi-finished product into the muffle furnace, and heat it at 10°C min -1 The temperature was raised to 500°C for 6 hours, and then cooled naturally in the furnace to prepare a copper-based supported am...

Embodiment 3

[0045] CuO 0.1 / SSZ-13 sample preparation

[0046] (1) Take by weighing 0.7500g copper acetate trihydrate and 3g H-SSZ-13 powder for subsequent use;

[0047] (2) Dissolve the weighed copper acetate trihydrate in a small amount of deionized water;

[0048] (3) After the copper acetate trihydrate is completely dissolved, add the weighed H-SSZ-13 powder, and stir at room temperature for 5 minutes;

[0049] (4) After stopping stirring, transfer the obtained solution to a rotary evaporator, and use a rotary evaporator to evaporate at a speed of 500r / min and a water bath temperature of 60°C for 4 hours to evaporate the solvent;

[0050] (5) Put the evaporated material into an oven at 100°C for 12 hours to obtain a semi-finished product;

[0051] (6) Put the obtained semi-finished product into the muffle furnace, and heat it at 10°C min -1 The temperature was raised to 400°C for 8 hours, and then cooled naturally in the furnace to prepare a copper-based supported ammoxidation cat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com