Impregnation-coating method for rapidly preparing Cu-SSZ-13 monolithic catalyst and application of monolithic catalyst

A monolithic catalyst, cu-ssz-13 technology, applied in the direction of catalyst activation/preparation, molecular sieve catalyst, physical/chemical process catalyst, etc., can solve the problems of long time consumption, large amount of waste water, high energy consumption in the production process, and achieve reduction Production energy consumption, high SCR denitrification catalytic activity, satisfying the effect of tail gas denitrification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The Cu salt precursor used in this embodiment is copper nitrate trihydrate (Cu(NO 3 ) 2 ·3H 2 O), the impregnation method adopted is the equal volume impregnation method, and the Cu content accounts for 2% of the dry mass of the mixture. The prepared Cu-SSZ-13 precursor mixture is firstly dried to obtain a precursor powder, which is then used for slurry coating and finally roasted.

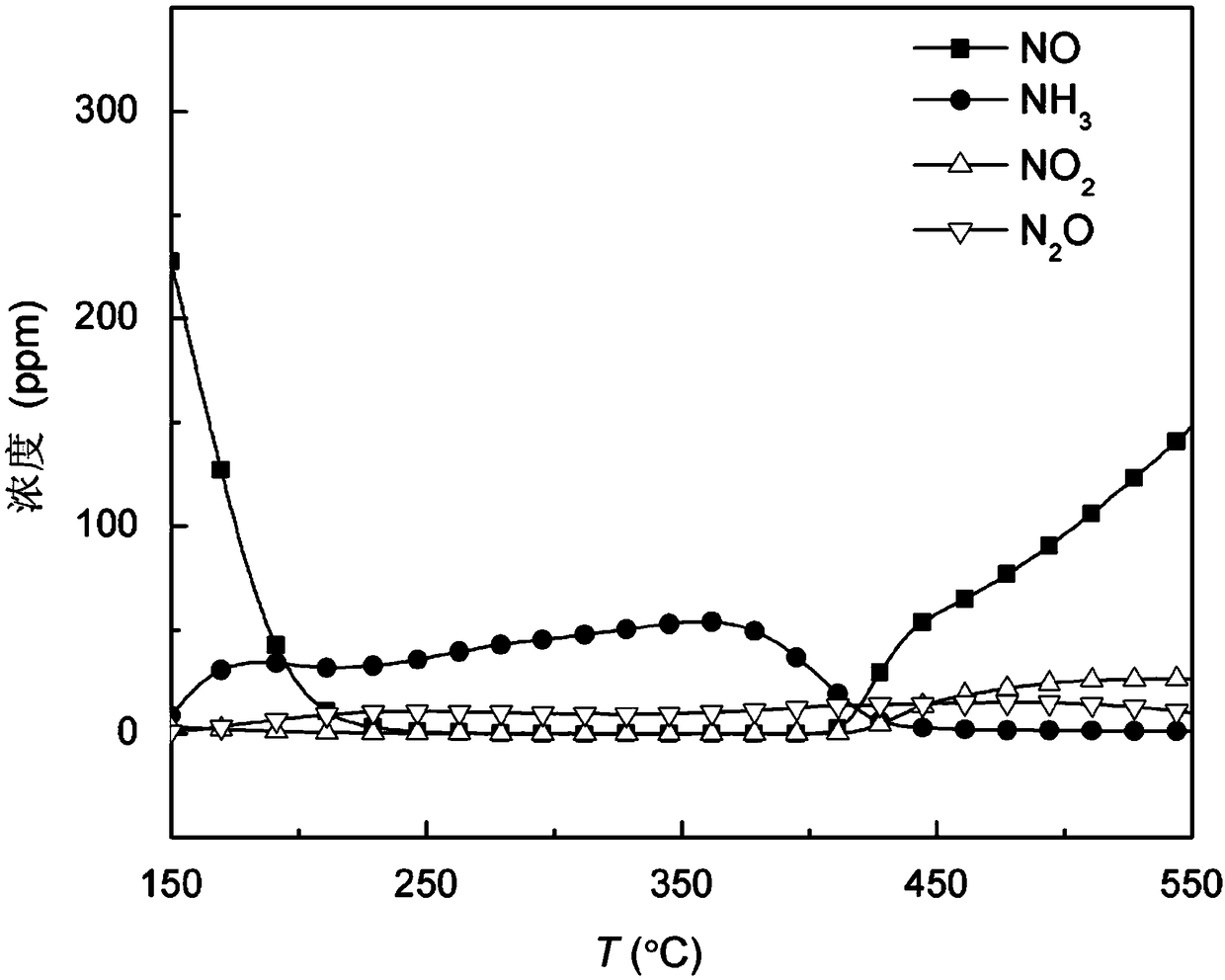

[0028] The specific process is as follows: Weigh 22.7g of copper nitrate trihydrate, dissolve it in 170mL of deionized water, mix it with 300g of H-type SSZ-13 molecular sieve powder at room temperature to obtain the catalyst precursor sludge, and obtain the catalyst precursor powder after drying. Add appropriate amount of water to the obtained powder, disperse by ball milling, then add binder and thickener to prepare a slurry with a solid content of 40g / 100g, and coat it on a 400cpsi cordierite honeycomb carrier with a coating amount of 160g / L. After drying, it was calcined at 550° C. f...

Embodiment 2

[0030] The Cu salt precursor used in this embodiment is copper nitrate trihydrate (Cu(NO 3 ) 2 ·3H 2 O), the impregnation method adopted is the equal volume impregnation method, and the Cu content accounts for 2% of the dry mass of the mixture. The prepared Cu-SSZ-13 precursor wet mud is directly used for slurry coating without drying, and finally roasted.

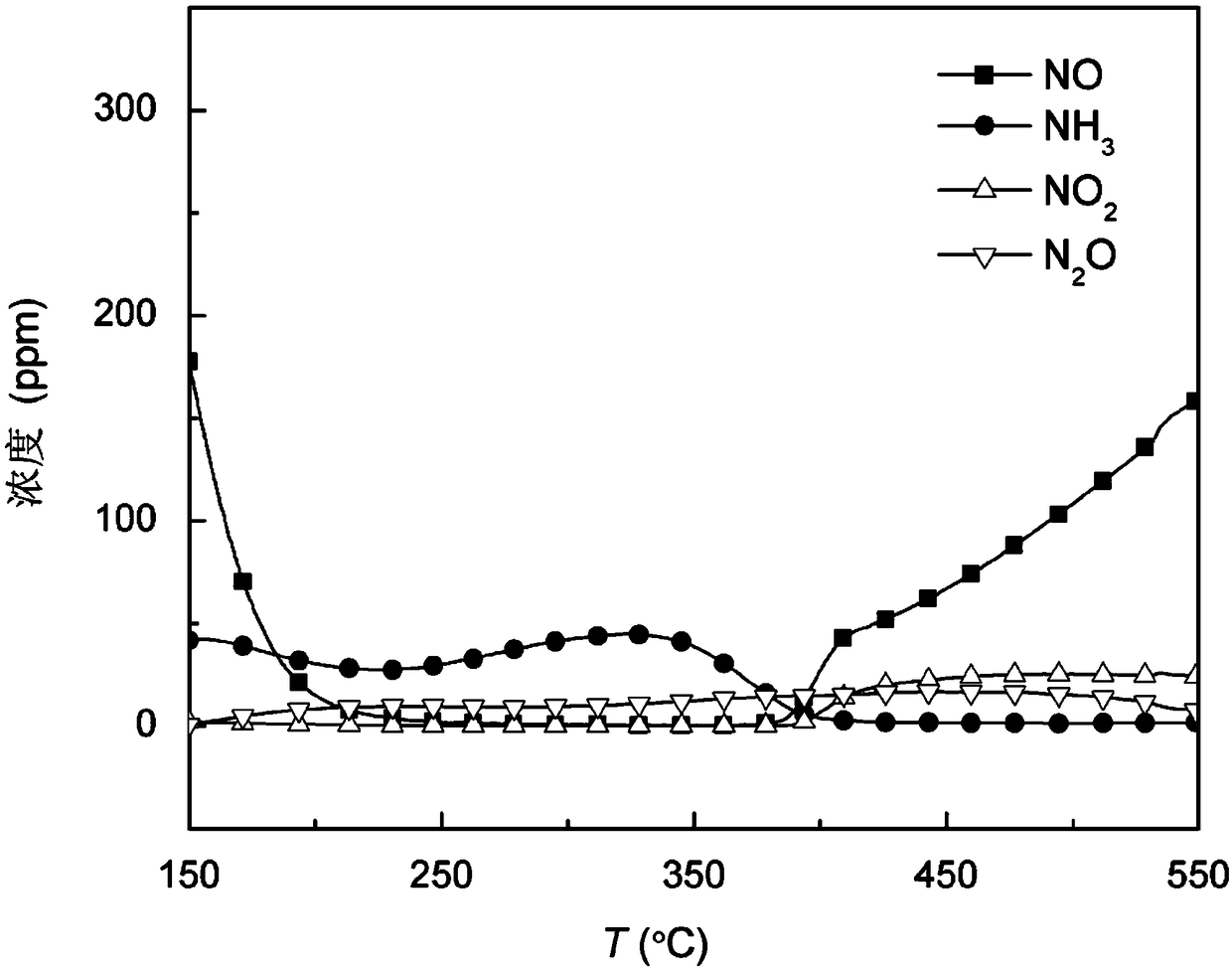

[0031] The specific process is as follows: Weigh 22.7g of copper nitrate trihydrate, dissolve it in 170mL of deionized water, and mix it with 300g of H-type SSZ-13 molecular sieve powder at room temperature to obtain catalyst precursor sludge. Add an appropriate amount of water to the mud, and then add a binder and a thickener to prepare a slurry with a solid content of 40g / 100g after dispersion by ball milling, and coat it on a 400cpsi cordierite honeycomb carrier with a coating amount of 160g / L. After drying, it was calcined at 550°C for 1 hour, and the obtained monolithic catalyst was named Monolith-2. Cut out a cro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com