A synthetic method of an SSZ-13 molecular sieve

A molecular sieve and seed crystal technology, which is applied in the direction of crystalline aluminosilicate zeolite, etc., achieves the effects of easy preparation, reduced usage, and easy popularization and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

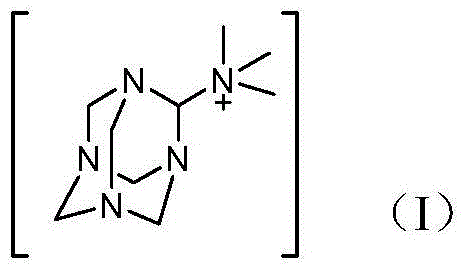

[0038] Synthesis of template N,N,N-trimethyl-1,3,5,7-tetraazatricyclo[3.3.1.1]decane-2-ammonium hydroxide.

[0039] This example introduces a synthesis of N,N,N-trimethyl-1,3,5, A method for 7-tetraazatricyclo[3.3.1.1]decane-2-ammonium hydroxide, which comprises four steps of ①nitration, ②hydrogenation, ③quaternization and ④electrolysis.

[0040] ①In a cold bath at -15°C, put 663.2 grams of 95% nitric acid in a 2-liter three-necked flask, and slowly add 140.2 grams of urotropine under stirring conditions, and react for 90 minutes after the addition. The cold bath was removed, and 900 g of water was added, stirred for 30 minutes, and white crystals were precipitated. Filter and wash with water until neutral, then place the filter cake in a vacuum oven at 50°C and dry for 5-6 hours to obtain about 138.9 grams of white powdery solid A, namely 2-nitro-1,3,5 , 7-tetraazatricyclo[3.3.1.1]decane, yield 75.1%.

[0041] ② Dissolve 120 grams of solid A in 300 milliliters of ethanol, ...

Embodiment 2

[0046] First, 4.210 grams of sodium hydroxide was dissolved in 21 grams of deionized water, and then 0.656 grams of sodium metaaluminate (aluminum source) was added to the above sodium hydroxide solution, and stirred vigorously to dissolve it. Next, add 7.230 grams of N,N,N-trimethyl-1,3,5,7-tetraazatricyclo[3.3.1.1]decane-2-hydrogen obtained in Example 1 to the above solution The ammonium oxide solution was used as the template agent R, which was dissolved by strong stirring, and 42.062 grams of 40%wt silica sol (silicon source) was slowly added under strong stirring conditions.

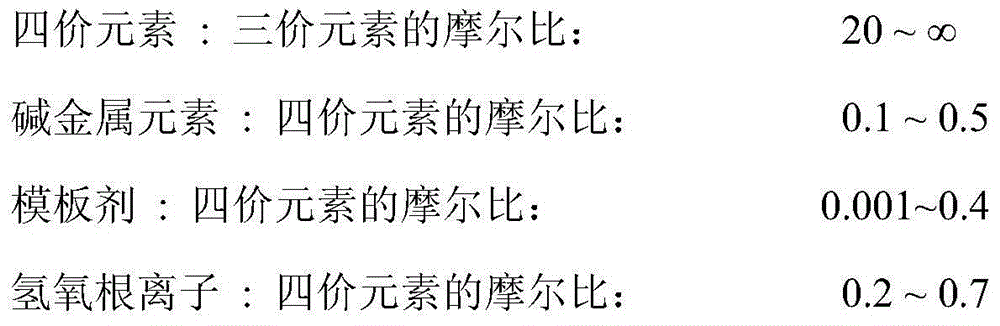

[0047] The molar ratio of each material of the synthetic mixture consists of:

[0048]

[0049] Stir the above mixture at room temperature for one hour, then divide it into two parts (Part A and Part B), and transfer Part A and Part B to a stainless steel autoclave with a Teflon liner, and place it at 150°C Oven and keep for 4 days (for Part A) and 6 days (for Part B).

[0050] The product was ...

Embodiment 3

[0053] First, 2.880 g of sodium hydroxide was dissolved in 21 g of deionized water, and then 0.656 g of sodium metaaluminate (aluminum source) was added to the above sodium hydroxide solution, and stirred vigorously to dissolve it. Next, add 3.443 grams of N,N,N-trimethyl-1,3,5,7-tetraazatricyclo[3.3.1.1]decane-2-hydrogen obtained in Example 1 to the above solution The ammonium oxide solution was used as the template agent R, which was dissolved by vigorous stirring, and 24.033 grams of 40%wt silica sol (silicon source) was slowly added under the condition of strong stirring.

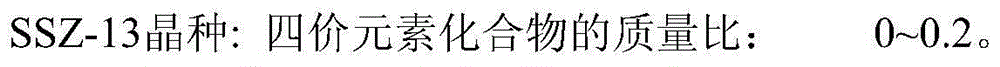

[0054] The molar ratio of each material of the synthetic mixture consists of:

[0055]

[0056] The above mixture was stirred at room temperature for one hour, and then it was divided into two parts (Part A and Part B), and Part A and Part B were respectively transferred to a stainless steel autoclave with a Teflon liner, and placed in 140°C oven and 160°C oven for 6 days.

[0057] The product was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com