Rapid synthesis method for small-crystal-grain molecular sieves and application of small-crystal-grain molecular sieves

A synthesis method and molecular sieve technology are applied in molecular sieve and alkali exchange phosphate, molecular sieve characteristic silicoaluminophosphate, crystalline aluminosilicate zeolite, etc., and can solve problems such as unfavorable industrial application, unfavorable industrial production, and increasing crystallization cycle. , to achieve the effect of shortening crystallization time, small grain size and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A quantitative amount of pseudo-boehmite was taken and dried at 150° C. for 12 hours. Then slowly add it into the n-butylamine (R-1) template solution, and stir rapidly until the aluminum source is completely dissolved to obtain a mixed solution. The mixed solution was transferred to a crystallization kettle, and crystallized at 120° C. for 3 hours to obtain a precursor mixed solution. The molar ratio of effective components in the precursor mixture is as follows: R-1: Al 2 o 3 =10:1.

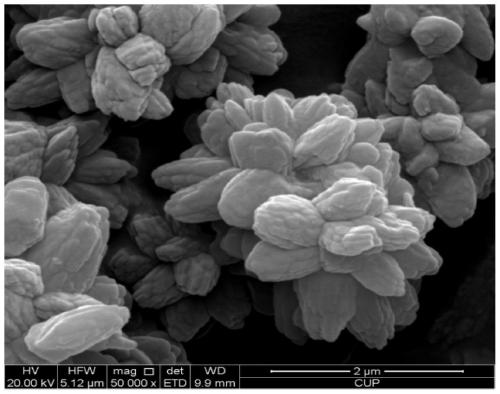

[0029] Add pseudo-boehmite, caustic soda, n-butylamine (R-1), and silica sol to deionized water in sequence, stir evenly, add precursor mixed solution, and form a gel after fully stirring. The molar ratio of each component in the gel is as follows: H 2 O: Al 2 o 3 :SiO2 2 :R-1:Na 2 O=20:0.025:1:0.25:0.12. The gel was transferred to a crystallization kettle, and crystallized at 170° C. for 12 hours to obtain a molecular sieve slurry. The slurry is separated from the mother liquo...

Embodiment 2

[0031] Take a quantitative amount of solid sodium metaaluminate and dry it at 150°C for 12 hours. Then slowly add it into the triethylamine (R-1) template solution, and stir rapidly until the aluminum source is completely dissolved to obtain a mixed solution. The mixed solution was transferred to a crystallization kettle, and crystallized at 140° C. for 8 hours to obtain a precursor mixed solution. The molar ratio of effective components in the precursor mixture is as follows: R-1: Al 2 o 3 =30:1.

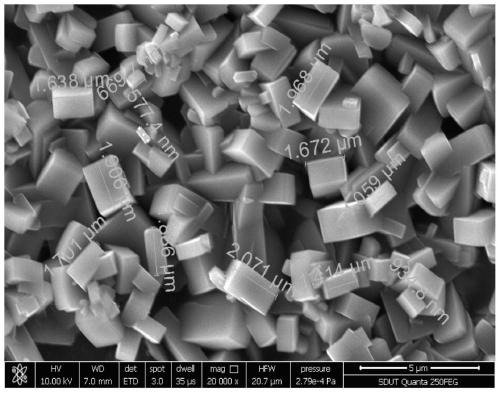

[0032] Add solid sodium metaaluminate, liquid caustic soda, triethylamine (R-1), N,N,N,-trimethyl-1-adamantyl ammonium hydroxide (R-2), and silica gel to the deionized In water, stir evenly, add the precursor mixture, and form a gel after fully stirring. The molar ratio of each component in the gel is as follows: H 2 O: Al 2 o 3 :SiO2 2 :R-1:R-2:Na 2 O=20:0.033:1:1:0.02:0.26. The gel was transferred to a crystallization kettle, and crystallized at 150° C. for 24 hours to ...

Embodiment 3

[0034] Take a certain amount of solid aluminum hydroxide and dry it at 150°C for 12 hours. Then slowly add it into the isopropylamine (R-1) template solution, and stir rapidly until the aluminum source is completely dissolved to obtain a mixed solution. The mixed solution was transferred to a crystallization kettle, and crystallized at 100° C. for 6 hours to obtain a precursor mixed solution. The molar ratio of effective components in the precursor mixture is as follows: R-1: Al 2 o 3 =40:1.

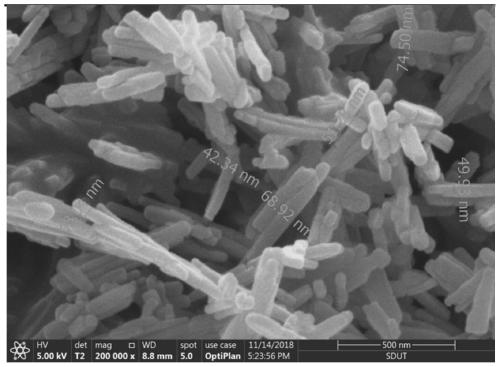

[0035] Add solid aluminum hydroxide, liquid caustic soda, isopropylamine (R-1), n-propylamine (R-2), and silica sol to deionized water in sequence, stir evenly, add precursor mixture, and form a gel after fully stirring. The molar ratio of each component in the gel is as follows: H 2 O: Al 2 o 3 :SiO2 2 :R-1:R-2:Na 2 O=30:0.01:1:0.4:0.3:0.04. The gel was transferred to a crystallization kettle, and crystallized at 160° C. for 24 hours to obtain a molecular sieve slurry. The slurr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com